High-precision radiotherapy collimator

A collimator and high-precision technology, which is applied in the field of collimator, can solve the problems of enlarged rotating arm, machining and motion control difficulties of the treatment head, and achieve weight reduction of the head, simplification of electromechanical control complexity, and saving The effect of treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

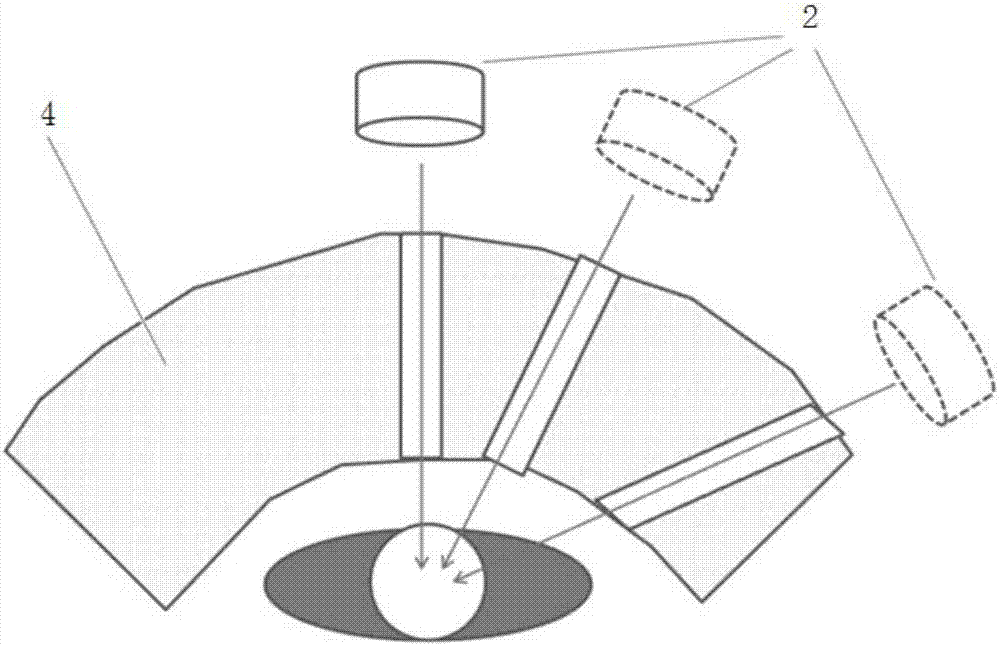

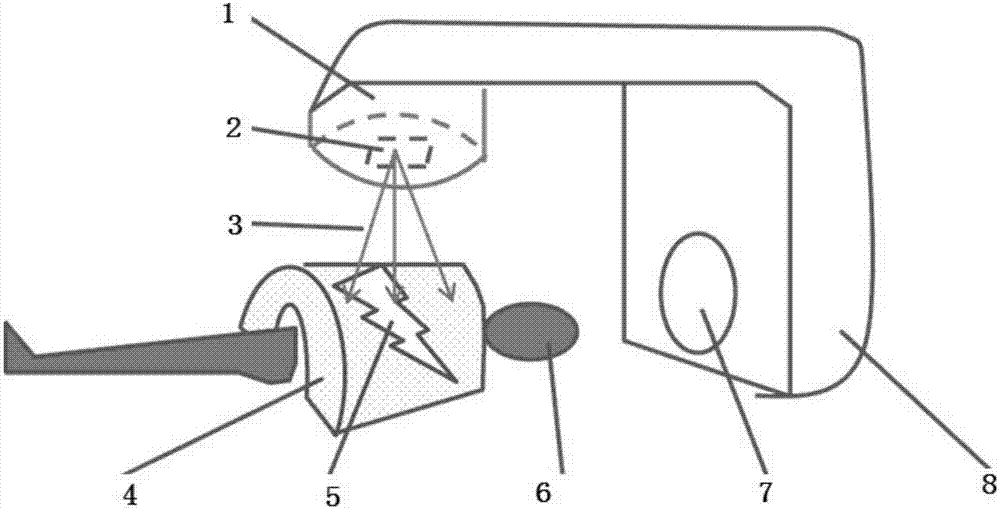

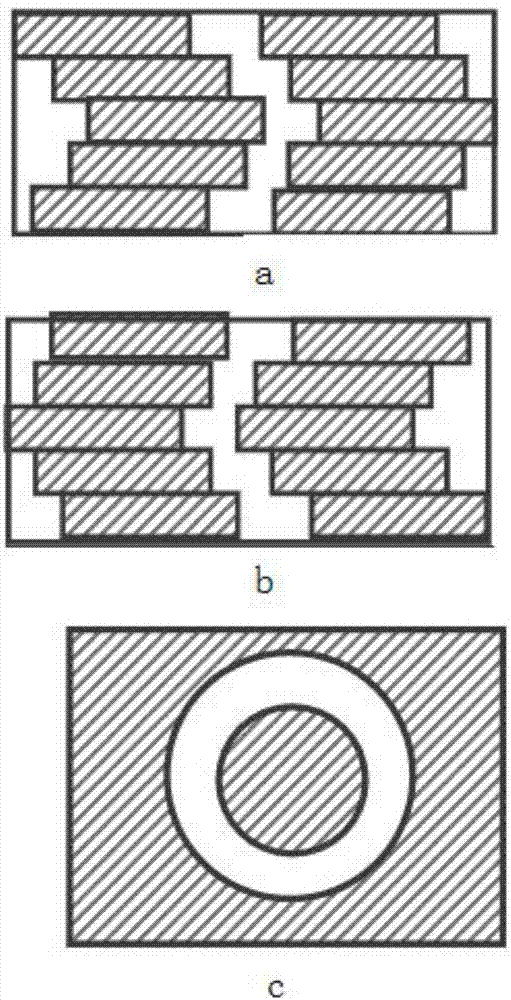

[0020] Such as figure 1 and figure 2 As shown, this embodiment includes a conformal phantom 4 arranged under the X light source. The conformal phantom 4 in this embodiment is an arched structure, and the conformal phantom 4 is an integrally formed hollow body, and the hollow body is filled with Heavy metal powder, the conformal mold body 4 is provided with a plurality of hollow parts 5 .

[0021] The heavy metal powder is tungsten powder or lead powder. The conformal mold body 4 is made by 3D printing of artificial resin.

[0022] The conformal phantom 4 prepared in this embodiment is placed under the treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com