A dust filter substrate, its preparation method and application

A technology of dust filtration and substrate, applied in the field of electrospinning, can solve the problems of accumulation and aggregation of catalysts and poor denitration effect, and achieve the effects of less damage, increased contact area, and improved catalytic denitration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

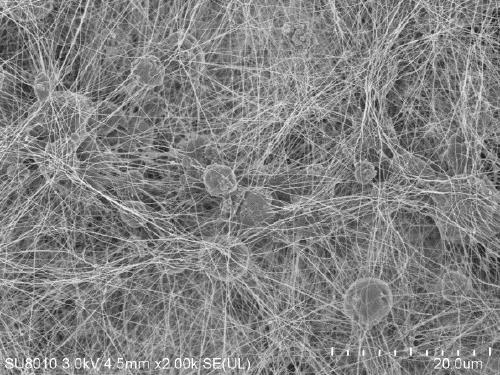

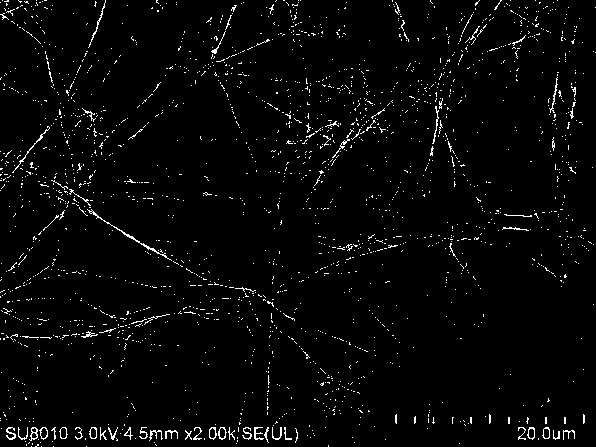

Embodiment 1

[0015] Weigh 0.15g manganese cerium titanium denitrification catalyst and 1.35g aramid fiber and dissolve in 10ml N-N dimethylacetamide solution to obtain a denitration catalyst-aramid fiber mixed solution with a mass volume ratio concentration of 15% (m / V). The mass ratio of the denitrification catalyst to the aramid fiber is 10:90. The solution is stirred at 105°C until it is completely dissolved, and then statically spun for 10 minutes. Electrospinning parameters: electric field voltage 25KV, receiving distance 15cm, spinning speed 0.6ml / h, received by polyphenylene sulfide filament plain weave fabric, and finally obtained composite fiber membrane material, that is, dust filter substrate with catalytic denitrification function, catalytic The denitrification efficiency can reach more than 35%.

Embodiment 2

[0017] Weigh 0.3g of vanadium-titanium denitration catalyst and 1.2g of aramid fibers and dissolve them in 10ml of N-N dimethylacetamide solution to obtain a nitrogen oxide removal catalyst with a mass volume ratio concentration of 15% (m / V) - aromatic Aramid mixed solution, the mass ratio of denitrification catalyst and aramid fiber is 20:80, the solution is stirred at 103°C until it is completely dissolved, and it is left to stand for 20 minutes before electrospinning. Electrospinning parameters: electric field voltage 22KV, receiving distance 16cm, spinning speed 0.5ml / h, received with aramid filament plain weave fabric, and finally obtained a composite fiber membrane material, that is, a dust filter substrate with catalytic denitrification function, catalytic denitrification efficiency Can reach more than 35%.

Embodiment 3

[0019] Weigh 0.48g manganese cerium titanium denitrification catalyst and 1.12g aramid fiber and dissolve in 10ml N-N dimethylacetamide solution to obtain a denitrification catalyst-aramid fiber mixed solution with a mass volume ratio concentration of 15% (m / V). The mass ratio of the denitrification catalyst to the aramid fiber is 30:70, the solution is stirred at 100°C until it is completely dissolved, and the electrospinning is performed after standing for 15 minutes. Electrospinning parameters: electric field voltage 20KV, receiving distance 12cm, spinning speed 0.7ml / h, received by glass fiber filament plain weave fabric, and finally obtained composite fiber membrane material, that is, dust filter substrate with catalytic denitrification function, catalytic denitrification efficiency can be achieved up to 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com