Sawing device for full-automatic pipe sawing machine

The technology of a sawing device and a pipe sawing machine is applied in the direction of sawing machine device, metal sawing equipment, metal processing equipment, etc., which can solve the problems of low processing efficiency, slow processing speed and high defective rate, and achieve high processing efficiency and processing. Fast, fast resizing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

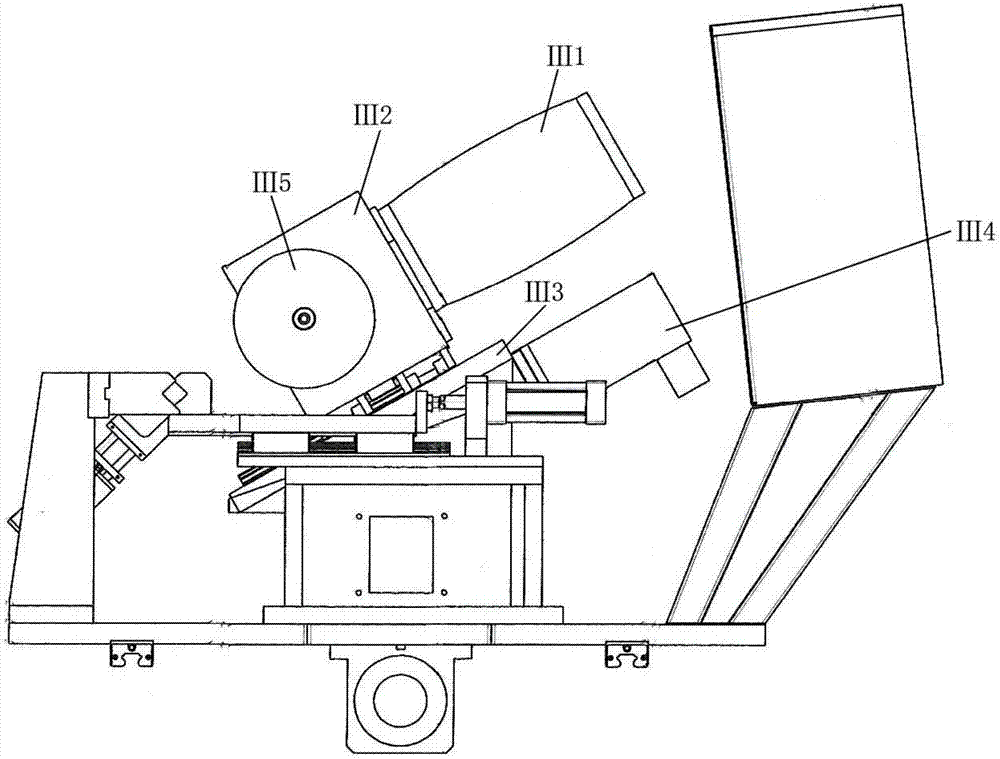

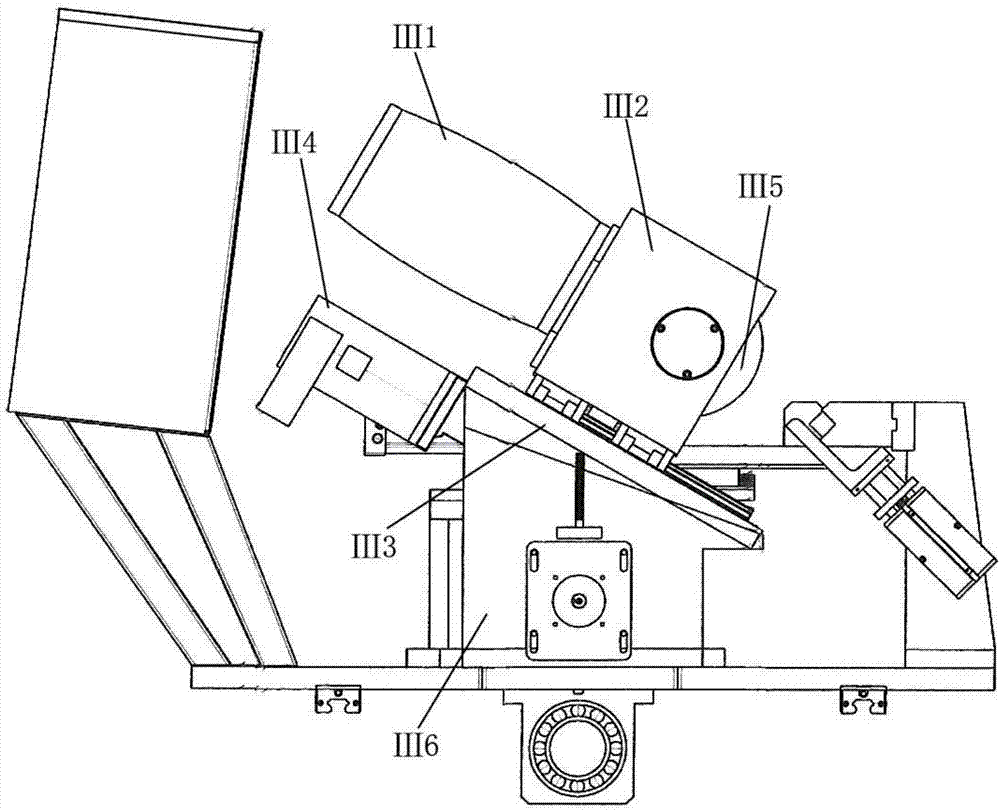

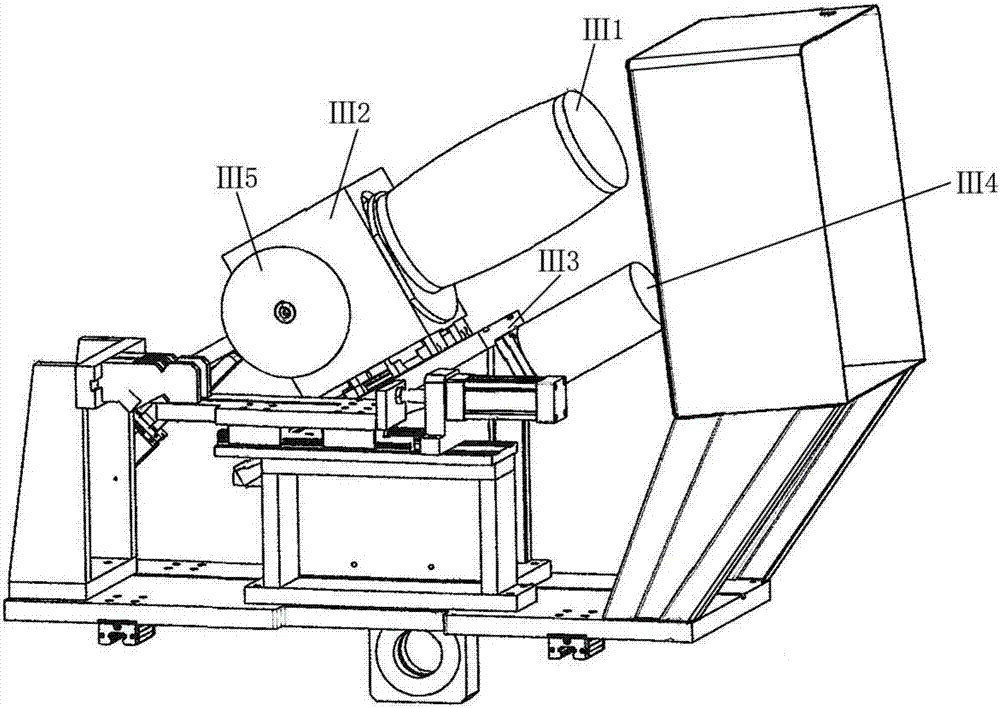

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a sawing device used in a fully automatic pipe sawing machine is composed of a main seat III6, an oblique support table III3, a servo motor III4, a knife seat III2, a main motor III1, a flange, and a saw blade III5 Composition, characterized in that,

[0020] The top surface of the main seat III6 is cut with a bevel, which is inclined from front to back and downward, and the inclination angle of the bevel is 25 º ~45 º , the bottom surface of the oblique support platform III3 is welded to the top surface of the main base III6, and the oblique support platform III3 is also 25 º ~45 º Angle inclination, the inclination direction of the oblique support platform III3 is from front to rear and downward, two steel rail bars are welded on the top surface of the oblique support platform III3, and a rectangular through hole is cut in the middle part The rails are distributed on the left and right sides of the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com