Special-shaped outline structure of TBR (all-steel radial truck) tire and tire with outline

A profile structure, tire technology, applied in the direction of tire tread/tread pattern, special tires, tire parts, etc., to achieve the effect of easy disassembly, comfortable driving experience, and low rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

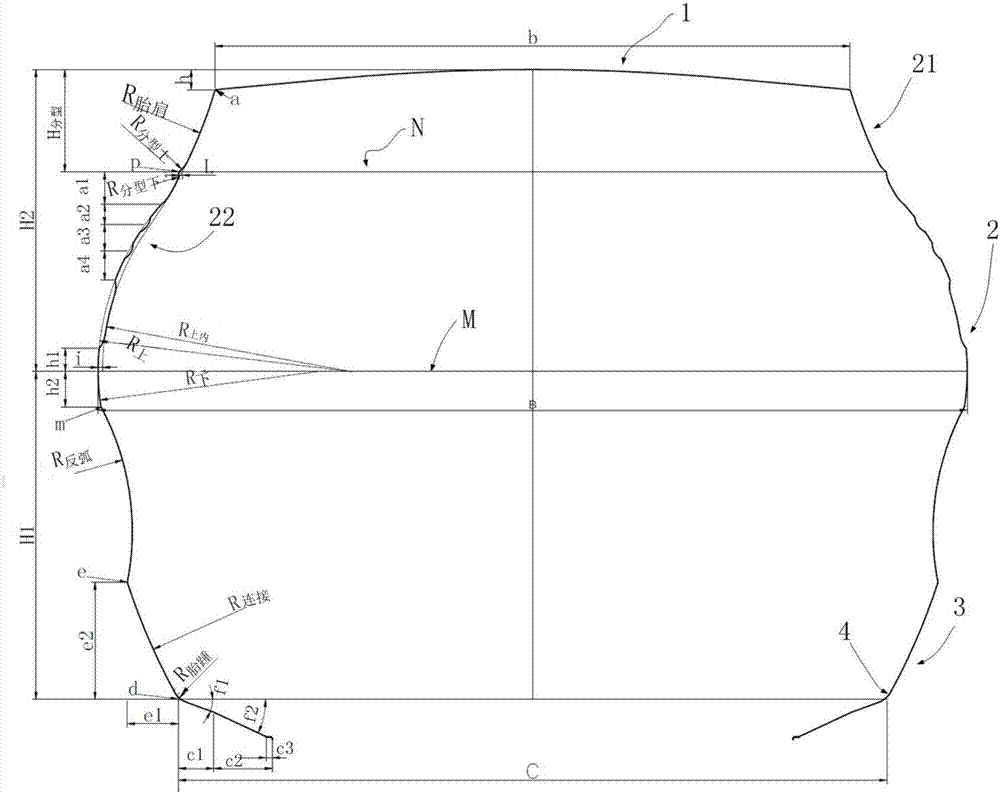

[0020] Embodiment 1. This embodiment proposes a TBR tire profile structure, including a crown portion 1, a sidewall portion 2, a bead portion 3, and a heel portion 4. The overall design of the tire profile is different from the existing conventional design, reflecting the In terms of the number and direction of the design arcs of the sidewall part 2 of the tire, specifically, refer to figure 2 :

[0021] The sidewall portion 2 includes a shoulder section 21 and an upper sidewall arc located above the horizontal axis of the tire, and a lower sidewall arc located below the horizontal axis M of the tire; The two sides of the lower part are tangent to the upper sidewall arc; the upper sidewall arc includes the upper arc and the upper inner arc (the radii of which are respectively R 上 and R 上内 ), and the upper arc and the upper inner arc are concentric arcs whose center is located on the horizontal axis of the tire, and the radius of the upper inner arc is R 上内 and upper arc ra...

Embodiment 2

[0029] Embodiment 2. On the basis of Embodiment 1, this embodiment proposes a tire with the profile structure described in Embodiment 1. Due to the special design of its side profile, the thickness of its upper sidewall is due to the combination of different arc segments and The groove design of the anti-friction part is 0.5mm-1.0mm thinner than the sidewall thickness of conventional tires of the same model. mm, the bead part is designed with a large radius arc (connecting arc), and in order to improve the rigidity and support effect of the bead, the thickness of the bead is 2mm thicker than the normal thickness.

[0030] Table 1: The monitoring data (rolling resistance and weight) comparison table between the special-shaped profile tire of this embodiment and the existing conventional tire of the same type under the condition that the tread pattern is consistent:

[0031]

[0032] The tire described in this proposal is light in weight, low in rolling resistance, eas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com