Cylindrical latticed mesh mounting method for erecting keels via symmetric method

An installation method, a cylindrical technology, applied to the structure of the dome, the processing of building materials, and building components, etc., can solve the problems of large internal force during the structural installation stage, large installation and quality risks, and a large number of splicing high-altitude partitions. To achieve the effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] The installation method of the cylindrical reticulated shell of the symmetrical method of the dragon bar according to the present invention comprises the following steps:

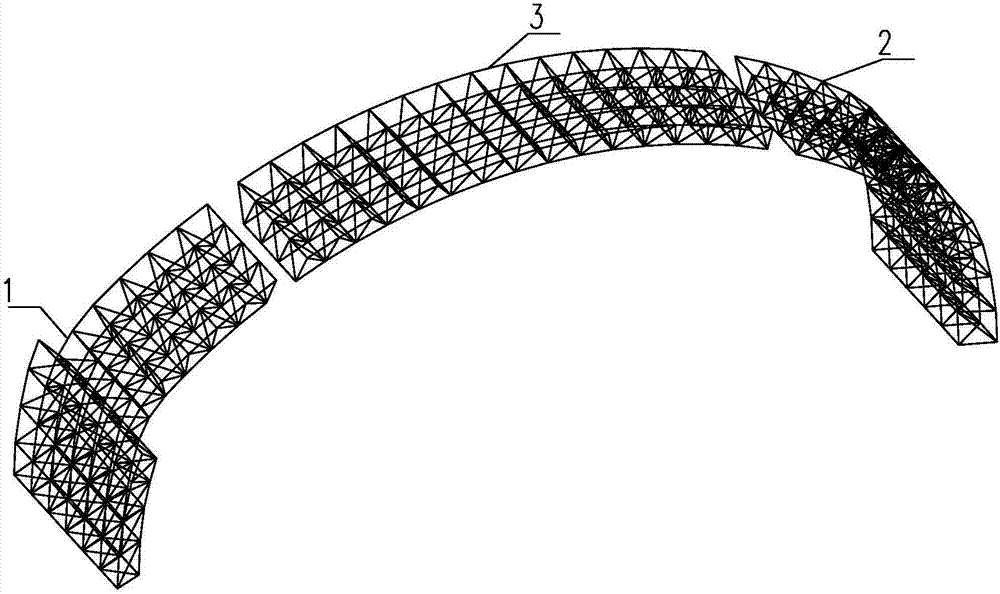

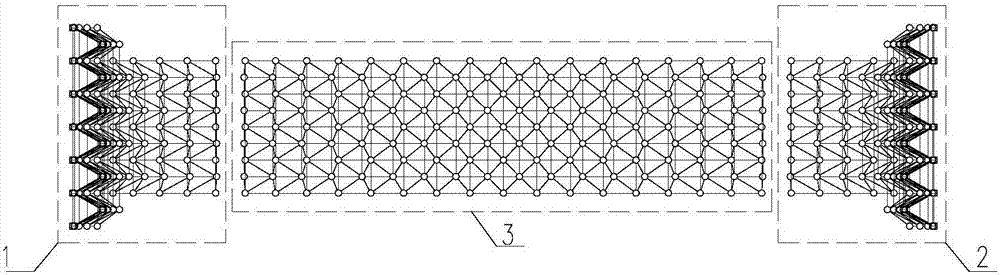

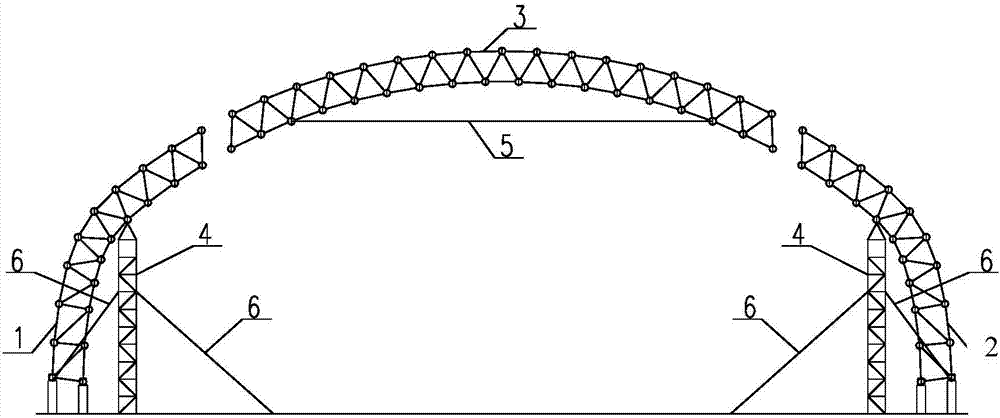

[0026] (1) Divide the arc-shaped ribs of the cylindrical reticulated shell along its axial direction into the mid-span rib block 3 located in the middle, the support rib block 1 and the support rib area symmetrically arranged on both sides Block 2, support dragon tendon block 1 and support dragon tendon block 2 respectively correspond to reticulated shells with 3-5 grid numbers;

[0027] (2) After assembling the support dragon tendon block 1 on one side on the ground, arrange the vertical support frame 4; lift the support dragon tendon block 1 with lifting equipment, and fix its bottom on the preset In the installation position, the inner side of the arc is fixed on the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com