An easy-to-clean dishwasher

A dishwasher and cleaning cavity technology, which is applied to the washing machine/washing machine for tableware, the parts of the washing machine/rinsing machine for tableware, cleaning equipment, etc., can solve the problems of poor cleaning effect and inconvenient disassembly and assembly of the filter device , to achieve the effect of easy operation of cleaning work, simplifying the complexity of the structure, and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

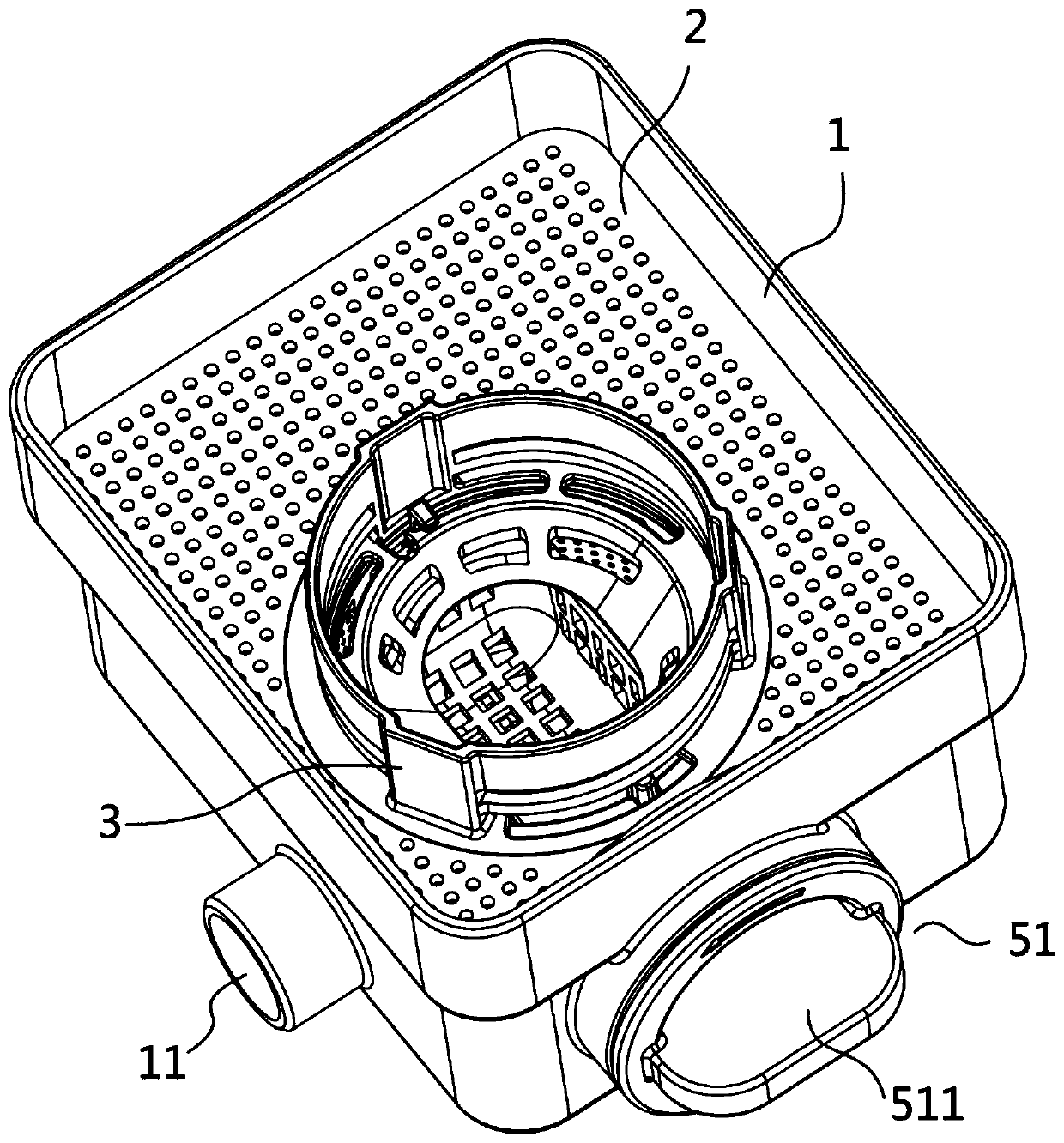

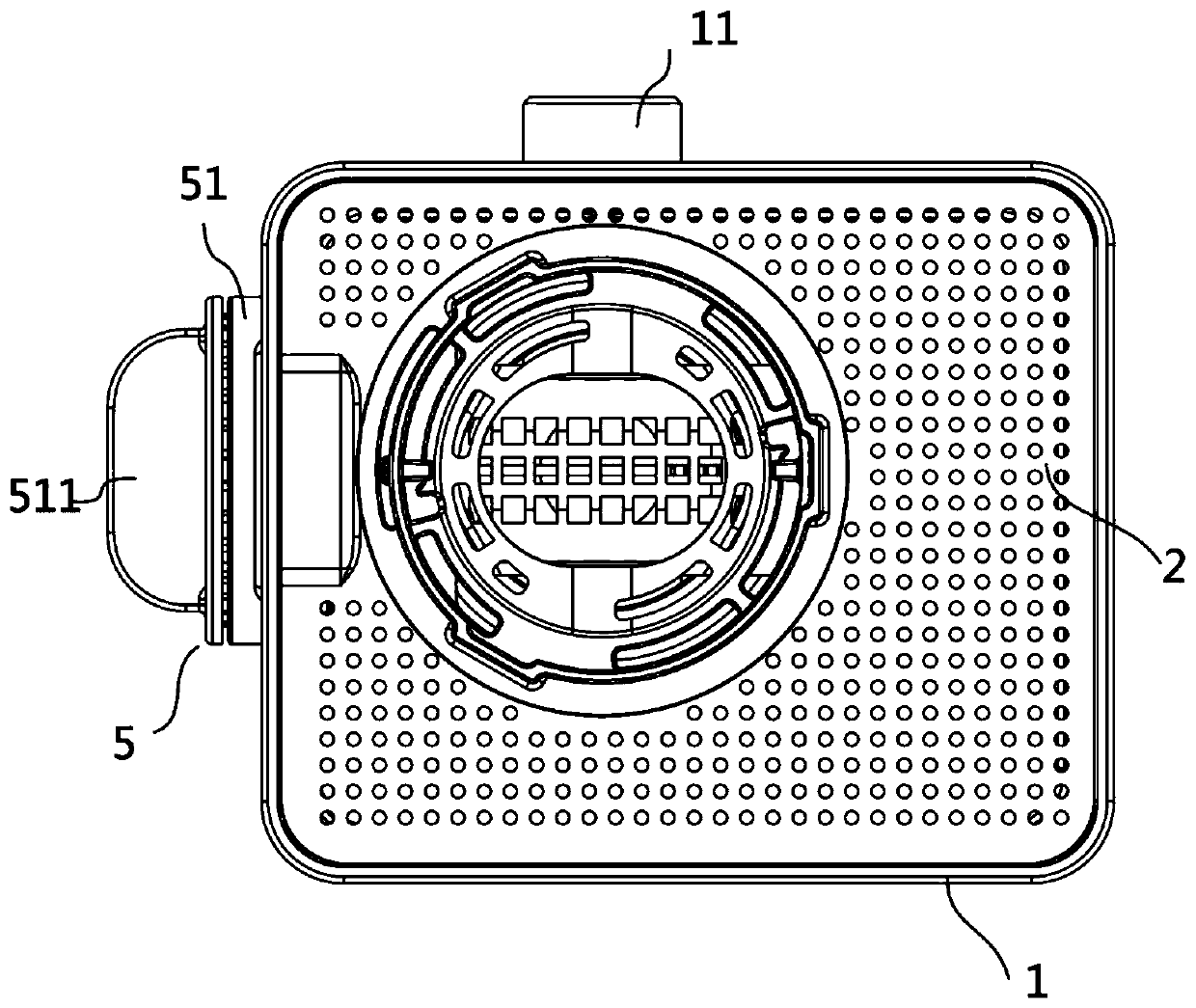

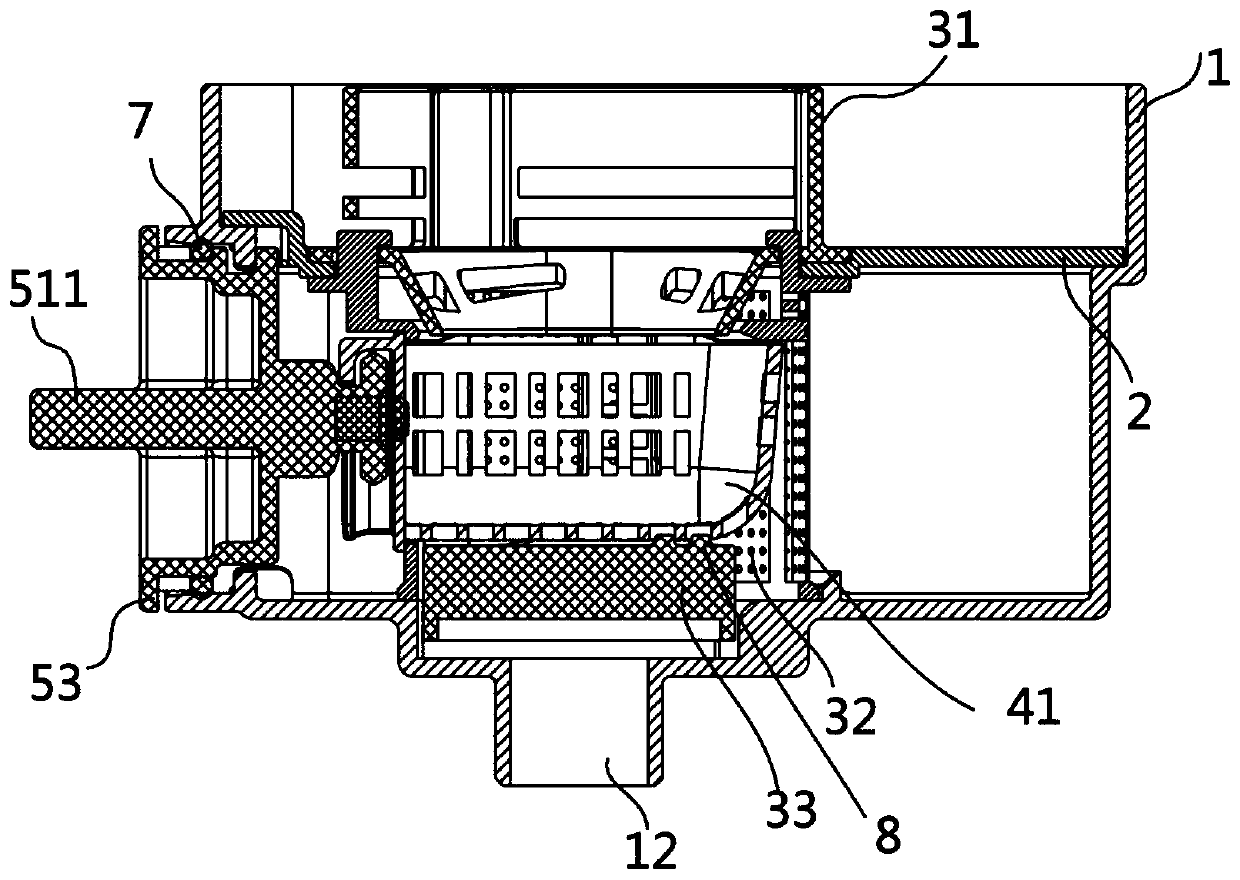

[0043] The present embodiment 1 provides a kind of dishwasher that is easy to clean, including a cleaning cavity (not shown in the figure), and a circulating water cup 1 is provided in the cleaning cavity, such as Figure 1-5 As shown, a filter assembly is provided on the circulating water cup 1, and the filter assembly includes a plane filter screen 2, a handle cup 3, a fine filter screen and a residue collector 4 located below the plane filter screen 2, and the handle cup 3 passes through the plane The filter screen 2 is fixed, and the side of the handle cup 3 is provided with a through hole 30 for installing the residue collector 4. The residue collector 4 is detachably extended into the handle cup 3 and fixed, and the fine filter is located in the residue collector 4 the periphery. By opening the through hole 30 for installing the residue collector at the side of the handle cup 3, and making the residue collector 4 detachably extend into the handle cup 3 for fixation, on the...

Embodiment 2

[0064] The difference between this embodiment 2 and embodiment 1 is that one of the combination plate and the external disassembly handle is provided with a lifting head for pulling out the residue collector, and the other is provided with a lifting rib. The head and the pulley are detachably fixed. The lifting head is, for example, a cylindrical cavity protruding outward from the joint plate, and the lifting rib is, for example, a protrusion formed on the inside of the outer handle. The outer end surface of the cylindrical cavity is provided with a The hole where the card protrusion is snapped in or out.

[0065] Through the cooperation of the lifting head and the lifting rib, the external removal handle can be separated and matched with the residue collector, so that when the two are integrated, the residue collector can be removed from the through hole on the side wall of the water cup together with the external removal handle And installation, and when the two are separat...

Embodiment 3

[0067] The difference between the embodiment 3 and the embodiment 1 is that the carrying cup further includes a fine filter mesh, and the fine filter mesh is arranged on the side wall of the carrying cup and is located below the plane filter mesh. The cleaning water enters the cup, the residue collector and the fine filter in turn, and the fine filter can filter the cleaning water entering the cup to prevent more food residue from entering the circulation pump and the spray system, so that the recycled Cleaner washing water prevents clogging of the spray nozzle, thereby further improving the washing effect of the dishwasher. And compared to the technical solution of Embodiment 1, the structure is simple, and no handle and fine filter need to be installed, which makes the whole system more reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com