Machining mold and method for overlapping ''Z''-shaped bend on lightning protection belt

A technology for processing molds and lightning protection belts, which is applied in the field of processing molds for overlapping "B" bends of lightning protection belts. It can solve the problems that lightning protection belts cannot be quickly processed and formed, the supporting mold structure is not tight, and the processing ability is weak, etc., and it is easy to promote. Convenient use, processing and forming inspection, stable processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

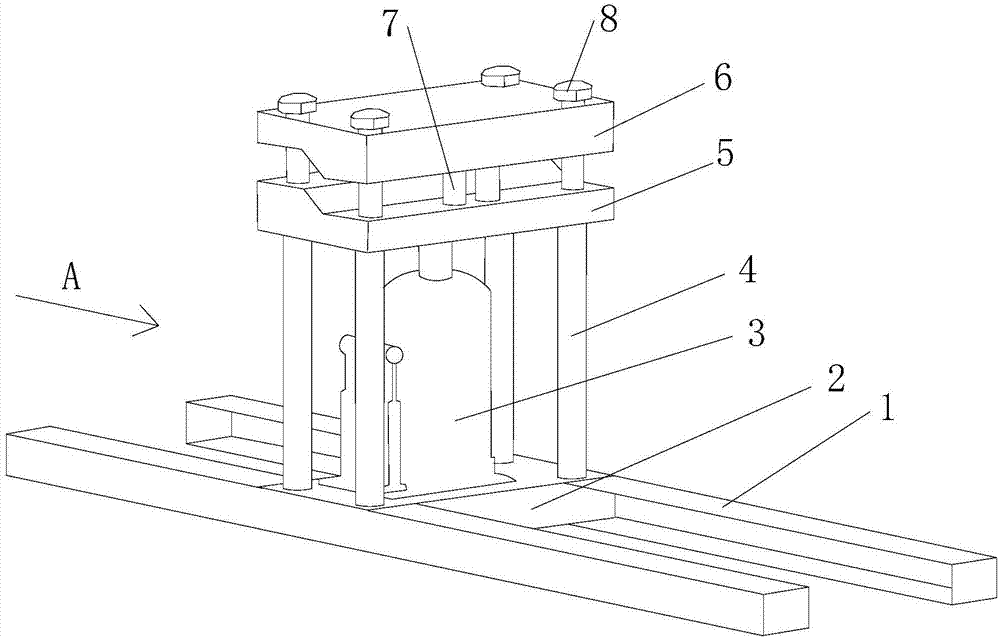

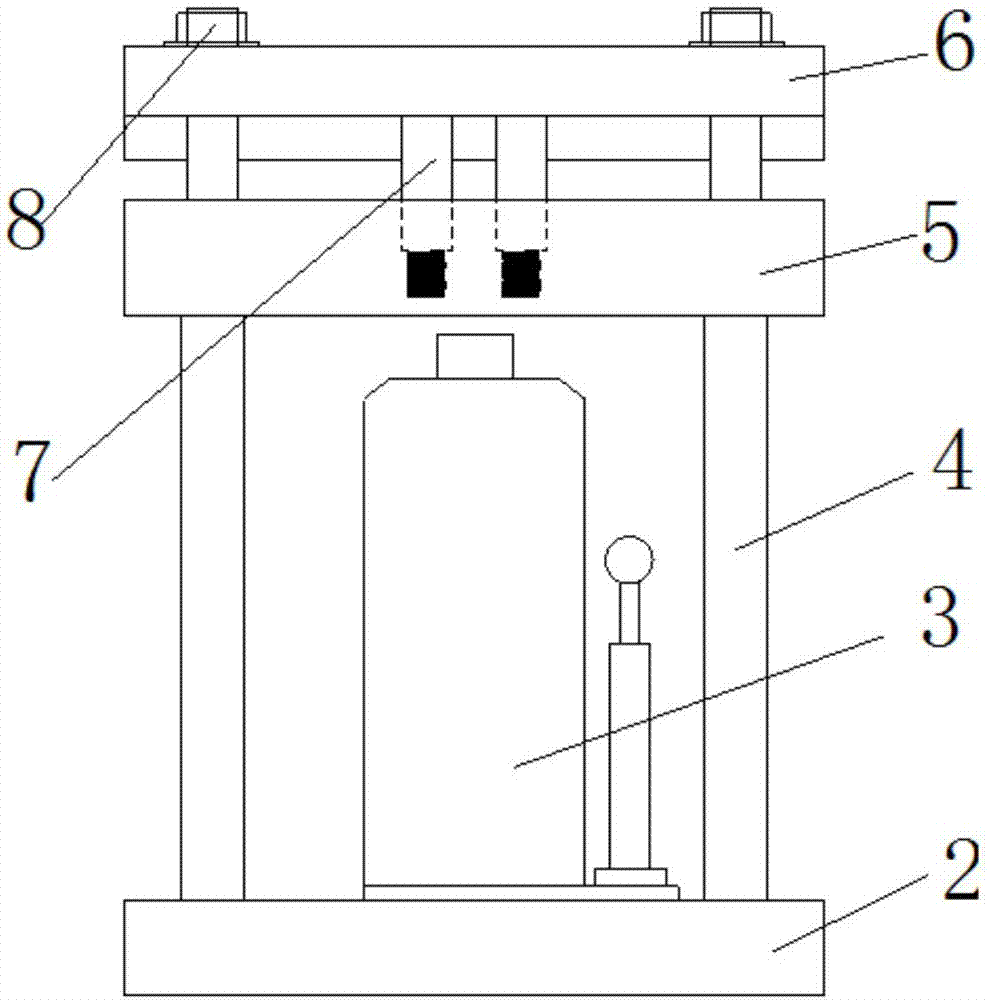

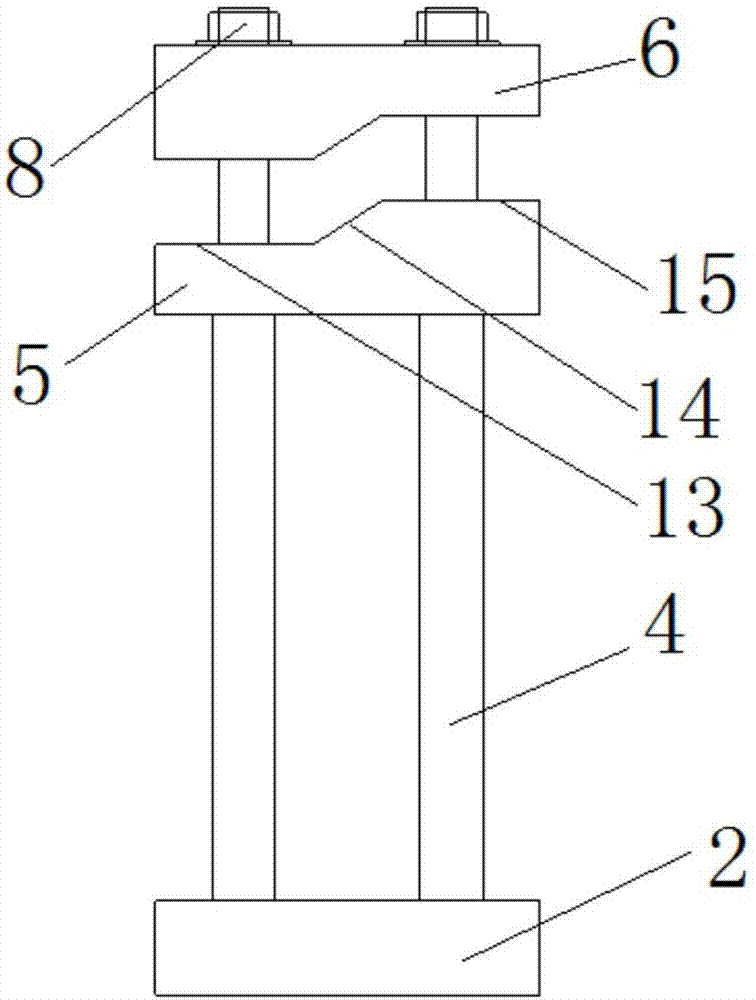

[0042] Such as Figure 1 to Figure 5As shown, a kind of lightning protection belt overlapping "B" bending processing mold according to the present invention includes a base plate 2, a support column 4 installed on the base plate 2, and a forming template horizontally installed on the support column 4. The forming The formwork includes an upper mold 6 and a lower mold 5 that are anti-parallel and interlocking. The structural dimensions of the upper mold 6 and the lower mold 5 are all the same. The upper surface of 6 and the lower surface of lower mold 5 are both horizontal planes, and the stepped surface is composed of first horizontal plane 13 and second horizontal plane 15, and an inclined plane 14 connecting first horizontal plane 13 and second horizontal plane 15. Upper mold 6 passes through The bolt 8 is fixedly installed on the top of the support column 4, the lower mold 5 is slidably installed on the support column 4, the upper mold 6 and the lower mold 5 are provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com