Polishing method

A polishing liquid and polishing surface technology, applied in the polishing field, can solve the problems of large consumption of consumables, low production efficiency, long polishing time, etc., and achieve the effects of reducing the use of consumables, improving production efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

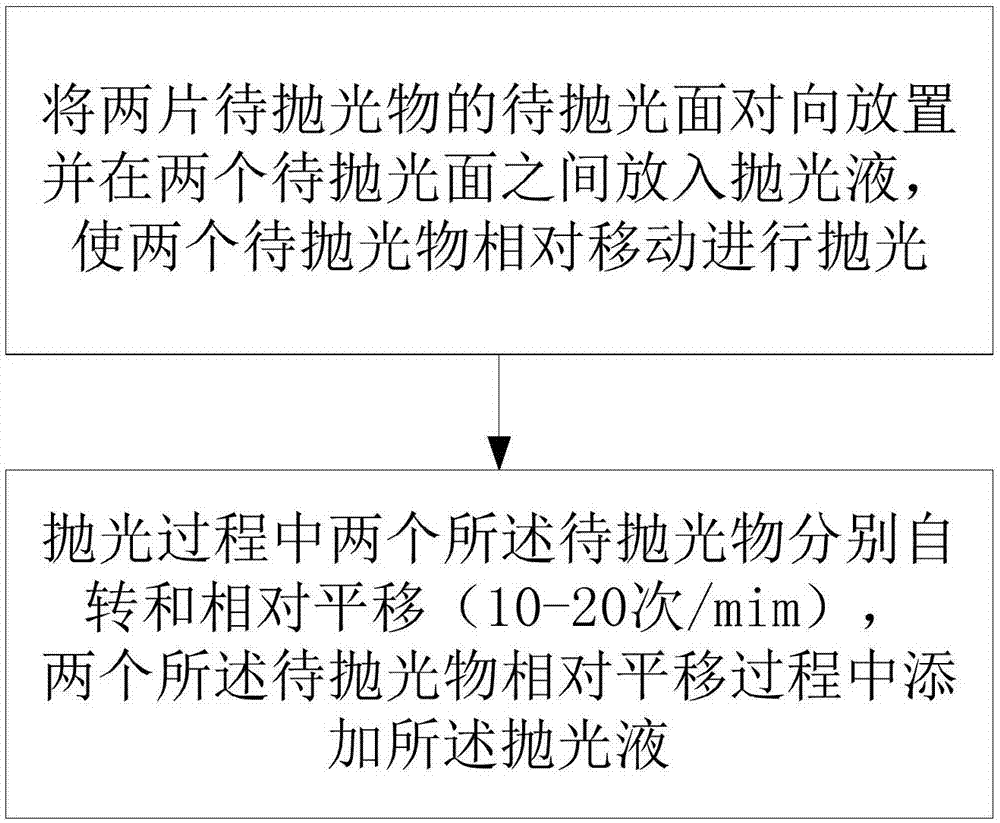

Method used

Image

Examples

Embodiment 1

[0043] According to one embodiment of the present invention, the upper polishing head clamps a 2inc wafer (wafer diameter is 2 inches), rotates at a speed of 50rpm, and the lower polishing head clamps a slice of 2inc wafer, rotates with a speed of 120rpm, while the upper The polishing head reciprocates relative to the lower polishing head at 15 times / min, and the swing range of the upper polishing head is 100 mm. The abrasive of the polishing liquid used for polishing is diamond, and the proportion of the abrasive in the polishing liquid is 5%.

Embodiment 2

[0045] According to one embodiment of the present invention, the upper polishing head holds a slice of 2inc wafer and rotates at a speed of 100rpm, and the lower polishing head holds a slice of 2inc wafer and rotates at a speed of 50rpm. The upper polishing swing range is 100mm and moves back and forth relative to the lower polishing head. The abrasive of the polishing liquid used for polishing is diamond, and the proportion of the abrasive in the polishing liquid is 8%.

Embodiment 3

[0047] According to one embodiment of the present invention, the upper polishing head holds a slice of 4inc wafer and rotates at a speed of 50rpm, and the lower polishing head holds a slice of 4inc wafer and rotates at a speed of 120rpm. The upper polishing swing range is 200mm and moves back and forth relative to the lower polishing head. The abrasive of the polishing liquid used for polishing is silicon carbide, and the proportion of the abrasive in the polishing liquid is 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com