Oblique blade grinding wheel type grinding machining equipment

A technology of grinding processing and grinding wheel, which is applied in the field of grinding processing, can solve the problems of prone to breakage, easy breakage and tearing of residual materials and workpieces, so as to ensure the processing quality and efficiency, and avoid re-entering the grinding process. The effect of cutting processing position and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

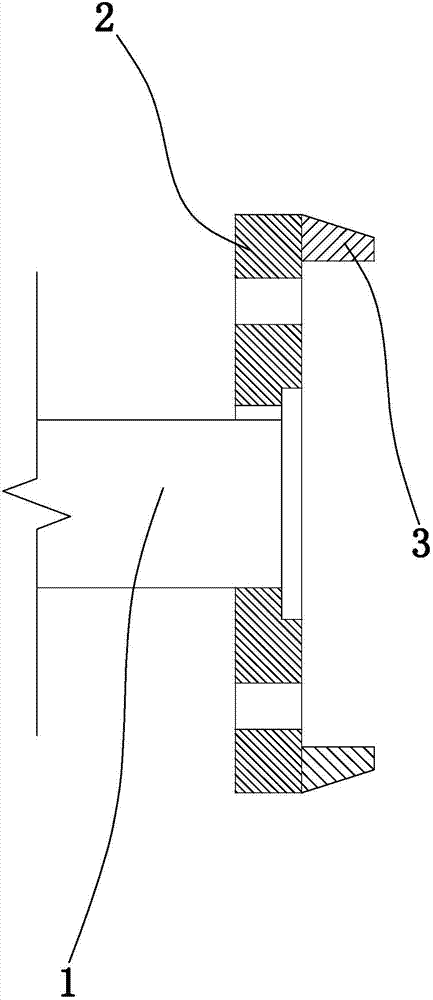

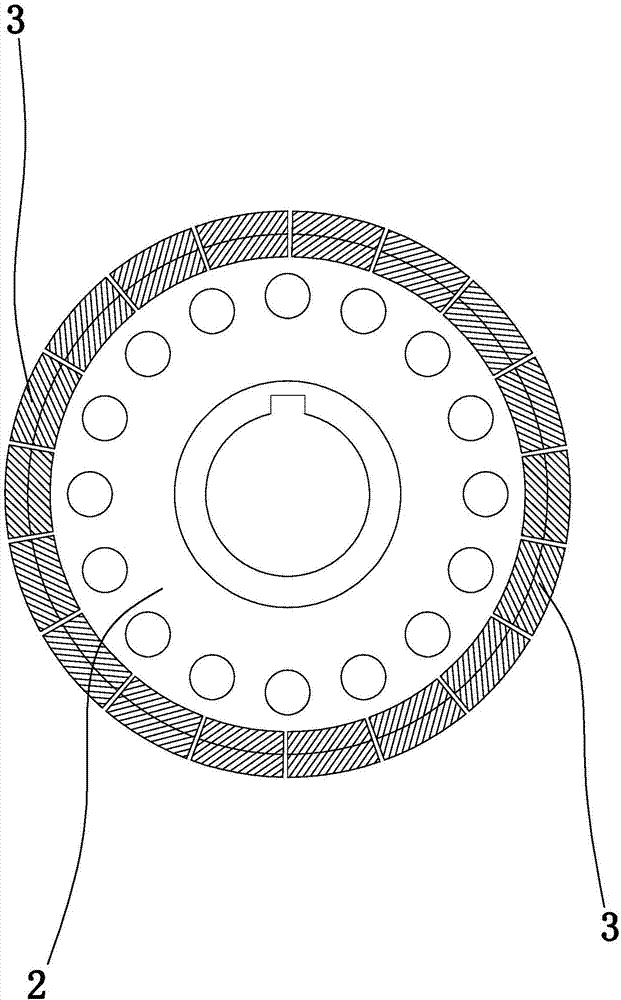

[0027] Embodiment 1: as Figure 1 to Figure 2 In the shown embodiment, a kind of oblique knife grinding wheel type grinding processing equipment comprises

[0028] The main frame, the main wheel shaft 1 arranged on the main frame, the main wheel body 2 coaxially connected with the main wheel shaft and the main motor for driving the main wheel shaft to rotate, the main motor is fixed to the main frame, and the main wheel shaft is connected to the main frame in rotation;

[0029] The main wheel body is provided with a plurality of grinding knives 3, and each grinding knives are evenly distributed along the circumference of the main wheel body. One side is a sliding contact plane 3b for contacting the workpiece;

[0030] It also includes a fixture for clamping the workpiece and a propulsion mechanism for driving the movement of the fixture. The moving direction of the fixture is perpendicular to the axis of the main wheel body;

[0031] One end face of the main wheel body is a ...

Embodiment 2

[0036] Embodiment 2: The basic structure and implementation of this embodiment are the same as those in Embodiment 1, the difference is that the propulsion mechanism is replaced by the following form: the propulsion mechanism is an oil cylinder / air cylinder / electric cylinder.

Embodiment 3

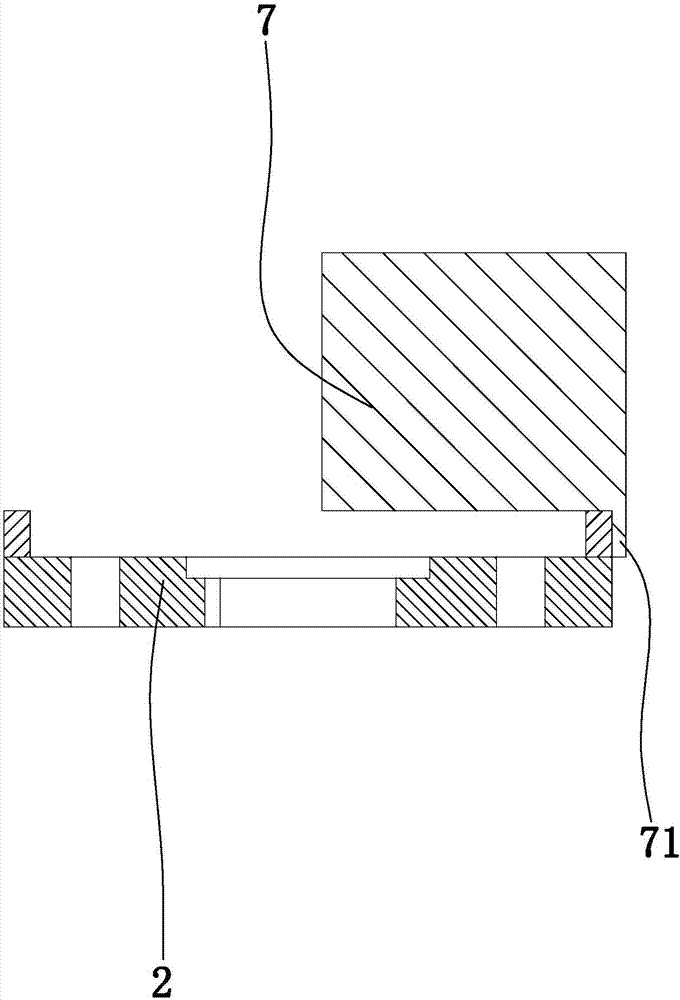

[0037] Embodiment 3: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 4 to Figure 6As shown in , the main frame is provided with a nozzle frame 4, an air supply cylinder block 51, a fixed slide seat 52 and a gear shaft 53 connected in rotation with the main frame, a driven gear is provided on the gear shaft, and the output shaft of the main motor There is a driving gear on the top, the driving gear meshes with the driven gear, the gear shaft is provided with a starting plate 54 coaxially connected with the gear shaft, the starting plate is provided with an eccentric rod 55, and the air supply cylinder body is provided with a The air supply piston 511 that is sliding and sealingly matched with the body, the air supply piston divides the interior of the air supply cylinder body into a first air chamber 51a and a second air chamber 51b, and the air supply piston is provided with a piston rod 512 that is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com