Barstock clamping robot arm

A technology for robotic arms and bars, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of easily damaged bar surfaces, difficulty in adjusting the critical value of clamping force, and changes in clamping force, so as to ensure quality and avoid The surface of the bar is damaged and the effect of preventing the bar from loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

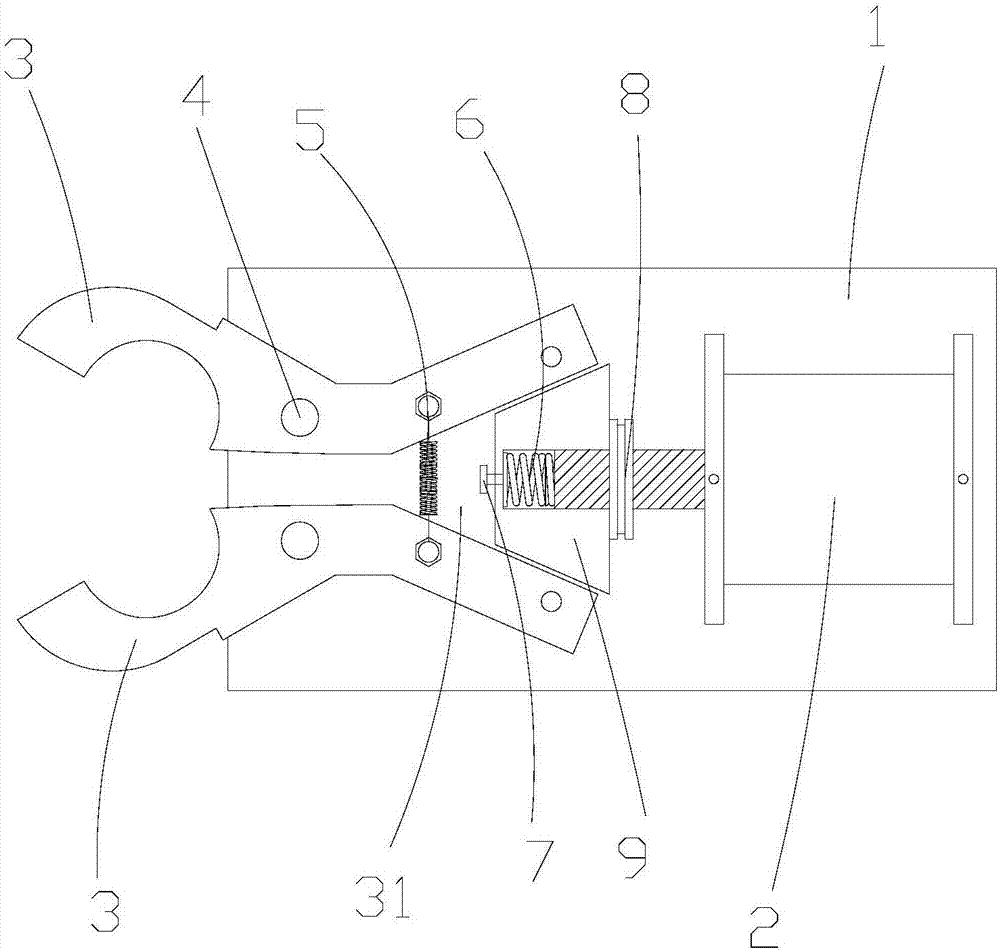

[0012] Such as figure 1 A bar clamping robot arm is shown, including a bearing seat 1, a driving cylinder 2, a clamping claw 3, a rotating shaft 4, a tension spring 5, a spring 6, a limit lock sleeve 8 and a trapezoidal block 9, and two clamping claws 3 The front end of the bearing seat 1 is installed by rotating the rotating shaft 4 correspondingly, and the two ends of the tension spring 5 are respectively connected to the rear ends of the two clamping claws 3, and the rear ends of the two clamping claws 3 form a fan-shaped area 31 with a small inside and a large outside. The cylinder body of the driving cylinder 2 is fixedly installed on the rear end of the bearing seat 1, the shape of the trapezoidal block 9 is set corresponding to the shape of the fan-shaped area 31, the outer end of the trapezoidal block 9 is provided with a mounting hole, the spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com