Kneading machine

A kneading machine and body technology, applied in the field of kneading machines, can solve the problems of affecting the life of the motor, damage to the coil insulation layer, waste of electric energy, etc., and achieve the effects of improving the kneading quality, reducing the labor burden, and being convenient to use and operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

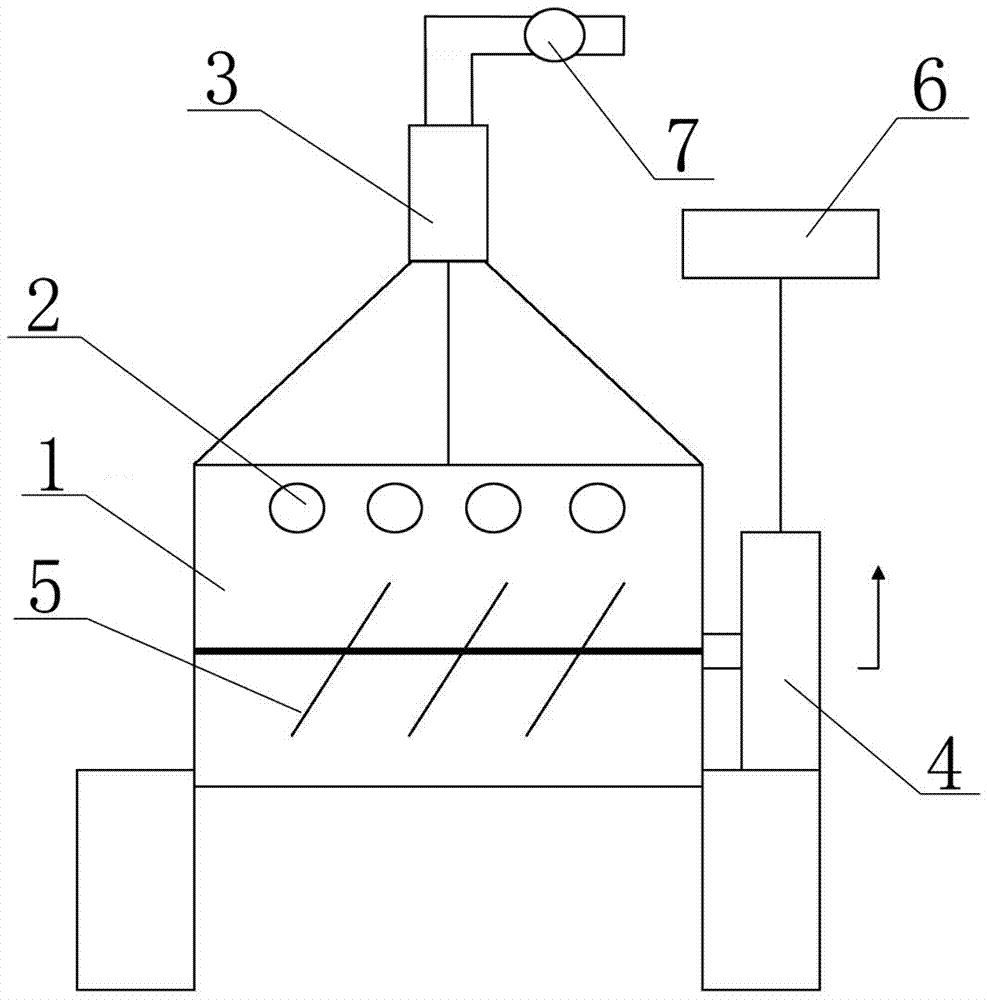

[0009] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, a kneader according to the present invention includes a kneading chamber 1 formed in the axial direction, an air inlet 2 connected to the kneading chamber 1 and an air outlet 3, an axially arranged paddle in the kneading chamber 1, Power supply and drive motor 4, the paddle is a Z-shaped paddle 5, one end of the paddle shaft of the Z-shaped paddle 5 is connected to a servo motor 4 installed on the outside of the kneader body, the servo motor 4 is connected to an external PC Or PLC control cabinet 6 connection.

[0010] As shown in the figure, the air outlet 3 connected to the kneading chamber 1 is connected to the induced draft fan 7 arranged outside the kneader body through an induced draft pipe 8; the input end of the induced draft fan 7 is connected to the external PC Machine or PLC control cabinet 6 are connected; the upper part of the kneading chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com