Electronic product fixture carrying device

A technology for carrying devices and electronic products, applied in transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of low processing efficiency, high production costs, cumbersome operations, etc., and achieve simple operation, high degree of automation, and movement good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

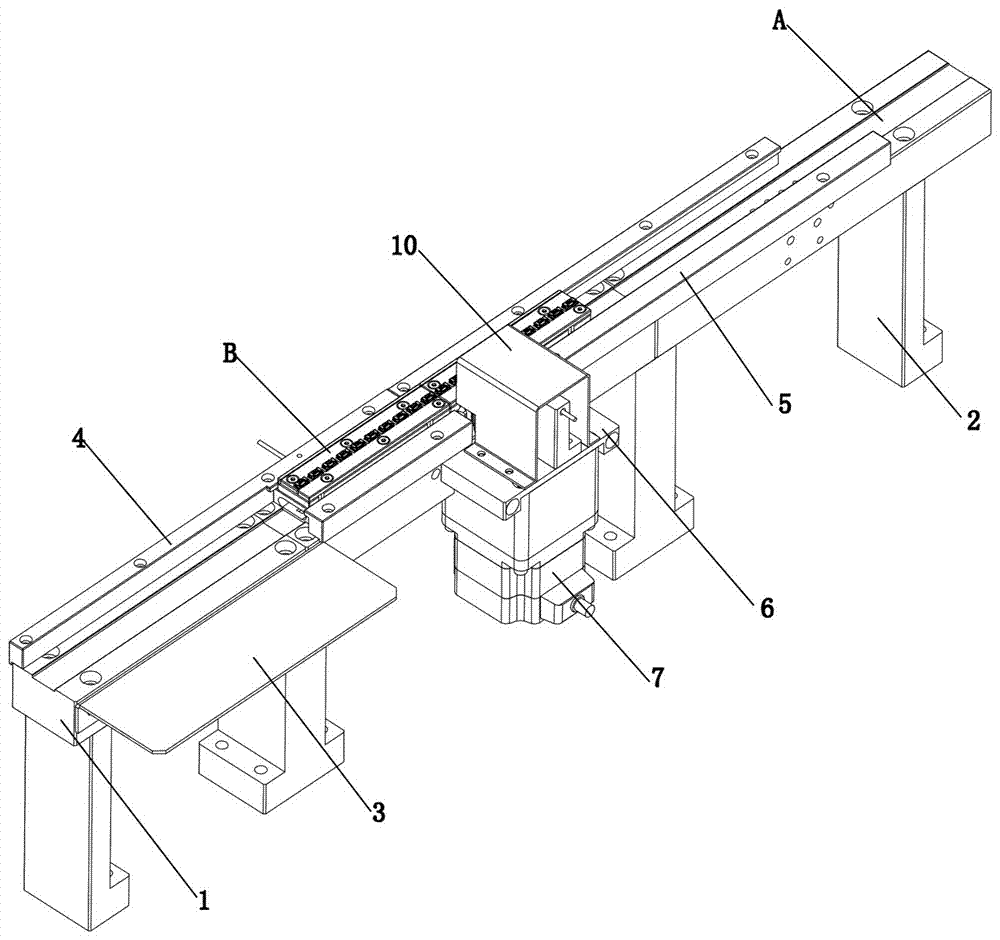

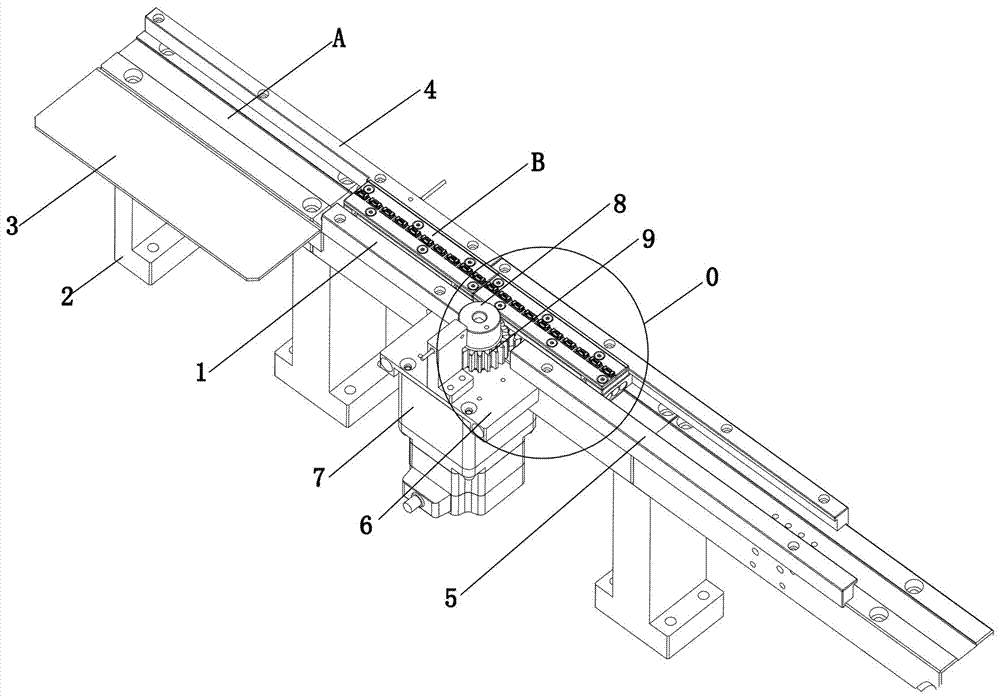

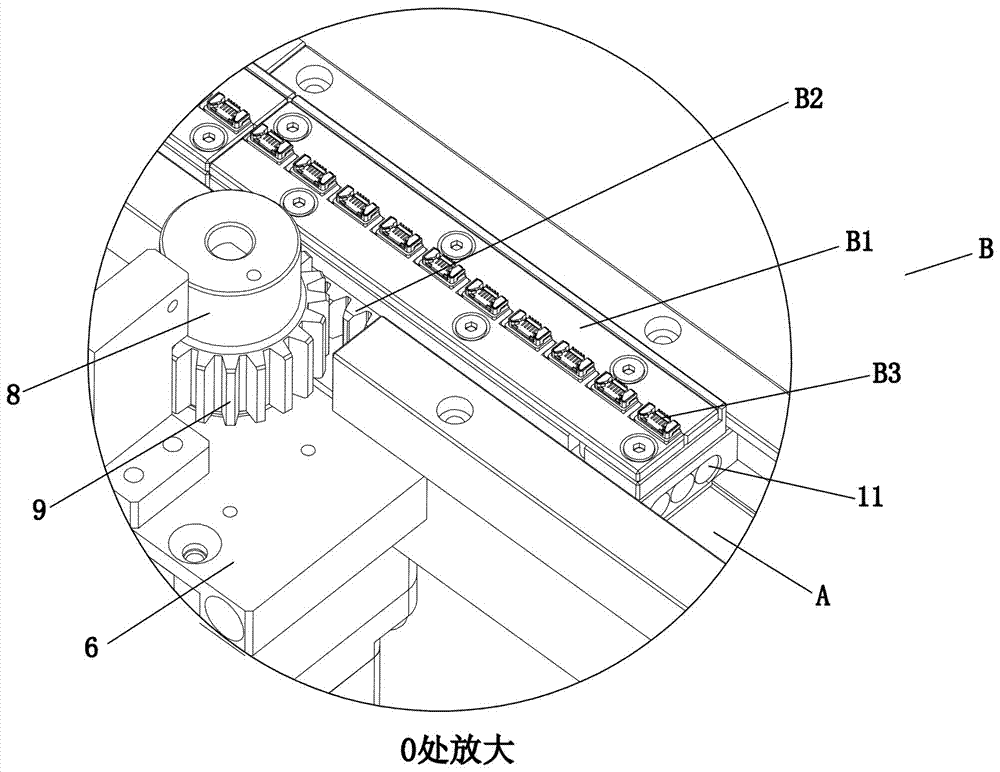

[0018] like Figure 1 to Figure 3 As shown, the technical solution adopted by the present invention is as follows: a jig carrying device for electronic products, including a transport seat 1, a support 2, a loading plate 3, a rear bar 4, a front bar 5 and a drive assembly, wherein the above-mentioned The transport seat 1 is a strip-shaped seat structure; the above-mentioned support 2 includes at least two, and the support 2 is arranged at the lower part of the transport seat 1 at intervals to support the transport seat 1; the above-mentioned feeding plate 3 is arranged in front of the left end of the transport seat 1 side, the jig B to be carried is pushed into the transport seat 1 through the loading plate 3; Extending in a straight line in the side direction, the jig B slides into the gap space between the rear bar 4 and the front bar 5, and is guided and limited by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com