Preparation method of porous graphene

A technology of porous graphene and reduction method, applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems of many equipments, unfavorable direct use, unsatisfactory electrical conductivity of products, etc., and achieve a simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The concrete steps of preparation are:

[0023] Step 1, according to the weight ratio of ammonium salt, glucose and deionized water is 0.6:0.8:5, the ammonium salt and glucose are dissolved in deionized water; wherein the ammonium salt is ammonium chloride to obtain a mixed solution. Then according to the weight ratio of the 1.8g / L graphene oxide aqueous solution and the ammonium salt in the mixed solution as a ratio of 10:1.2, the graphene oxide aqueous solution is added to the mixed solution and stirred, and dried into a paste at 30° C. to obtain Pasty mixture.

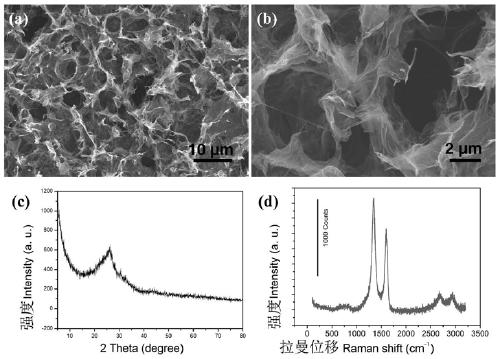

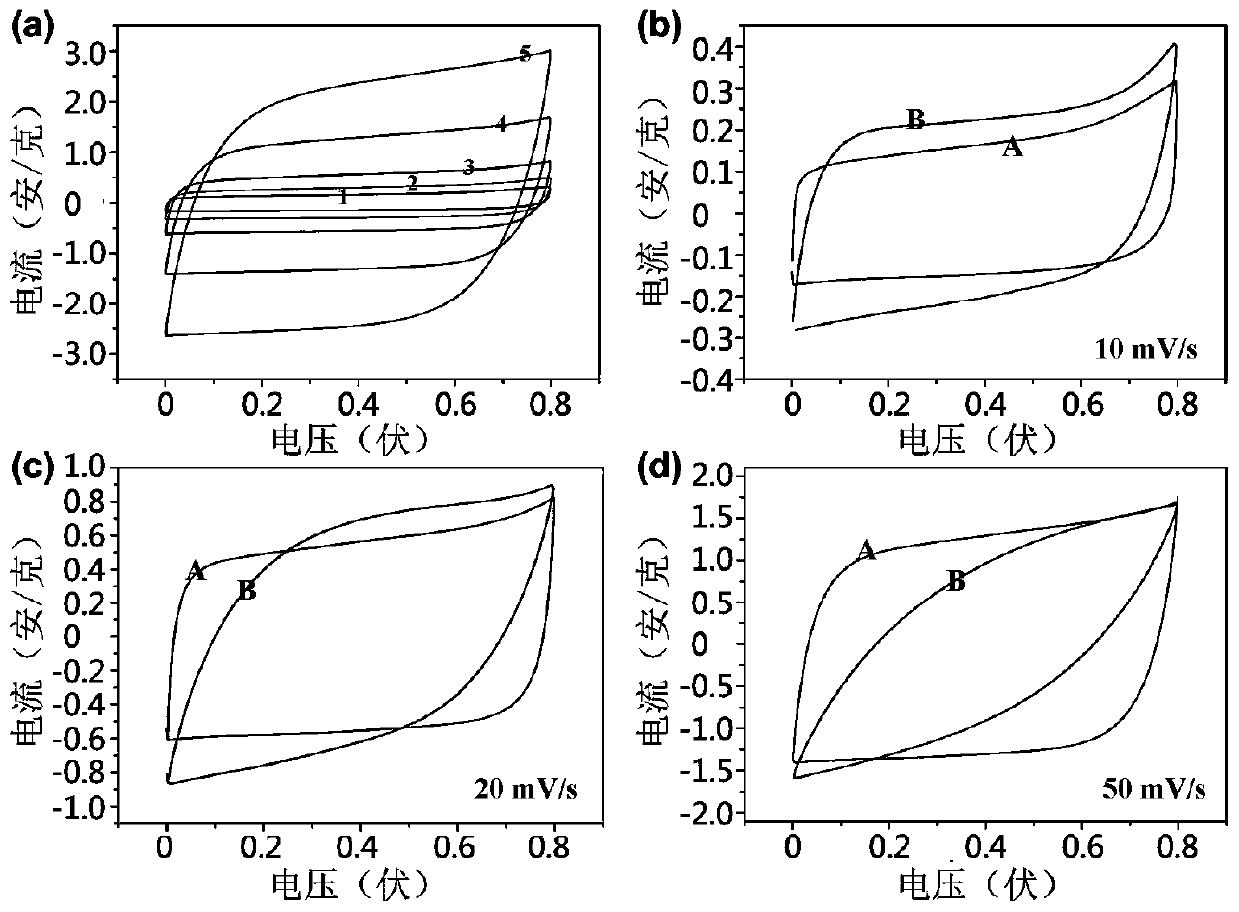

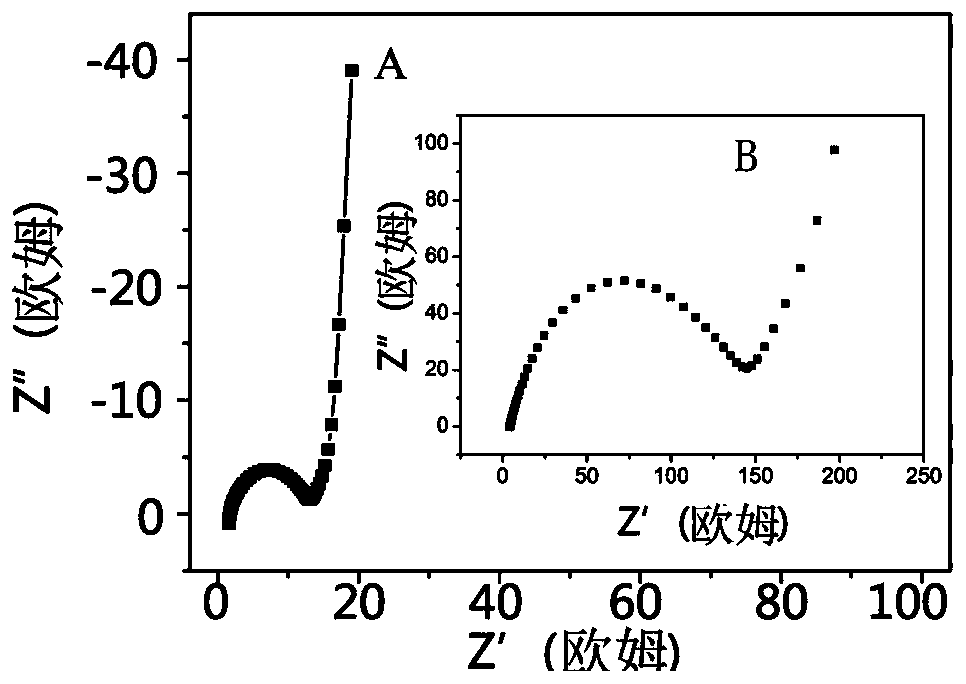

[0024] Step 2, first place the pasty mixture in a protective atmosphere; wherein, the protective atmosphere is an argon atmosphere. Then it was raised from room temperature to 1000°C over 2 hours, and kept for 1 hour to obtain a product similar to figure 1 As shown in Figure a and Figure b, and as figure 1 Figures c and d in the figure 2 and image 3 The porous graphene shown in the curve.

Embodiment 2

[0026] The concrete steps of preparation are:

[0027] Step 1, according to the weight ratio of ammonium salt, glucose and deionized water is 0.75:0.7:5, ammonium salt and glucose are dissolved in deionized water; wherein the ammonium salt is ammonium chloride to obtain a mixed solution. Then according to the weight ratio of the 1.9g / L graphene oxide aqueous solution and the ammonium salt in the mixed solution as a ratio of 10:1.05, the graphene oxide aqueous solution is added to the mixed solution and stirred, and dried into a paste at 35° C. to obtain Pasty mixture.

[0028] Step 2, first place the pasty mixture in a protective atmosphere; wherein, the protective atmosphere is an argon atmosphere. Then it was raised from room temperature to 975°C over 2.5h, and kept for 1.3h to obtain a product similar to figure 1 As shown in Figure a and Figure b, and as figure 1 Figures c and d in the figure 2 and image 3 The porous graphene shown in the curve.

Embodiment 3

[0030] The concrete steps of preparation are:

[0031] Step 1, according to the weight ratio of ammonium salt, glucose and deionized water is 0.9:0.6:5, ammonium salt and glucose are dissolved in deionized water; wherein the ammonium salt is ammonium chloride to obtain a mixed solution. Then according to the weight ratio of the 2g / L graphene oxide aqueous solution and the ammonium salt in the mixed solution being 10:0.9, the graphene oxide aqueous solution was added to the mixed solution and stirred, and dried at 40°C to form a paste to obtain a paste shape mixture.

[0032] Step 2, first place the pasty mixture in a protective atmosphere; wherein, the protective atmosphere is an argon atmosphere. Then it was raised from room temperature to 950°C over 3 hours, and kept for 1.5 hours to obtain the following figure 1 As shown in Figure a and Figure b, and as figure 1 Figures c and d in the figure 2 and image 3 The porous graphene shown in the curve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com