Patents

Literature

37results about How to "Extensive commercial application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel large-scale power energy storage device

InactiveCN102185328ALarge capacityExtend your lifeFinal product manufactureEnergy storageAutomotive engineeringElectrochemical energy storage

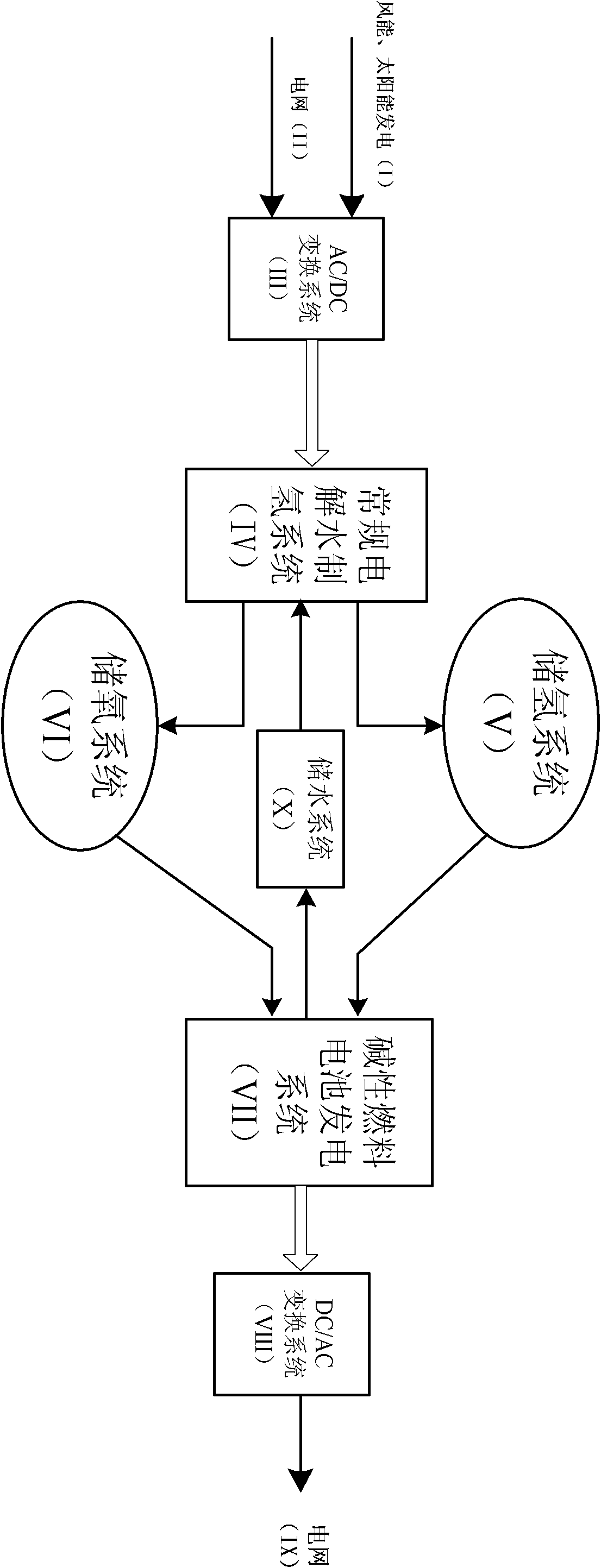

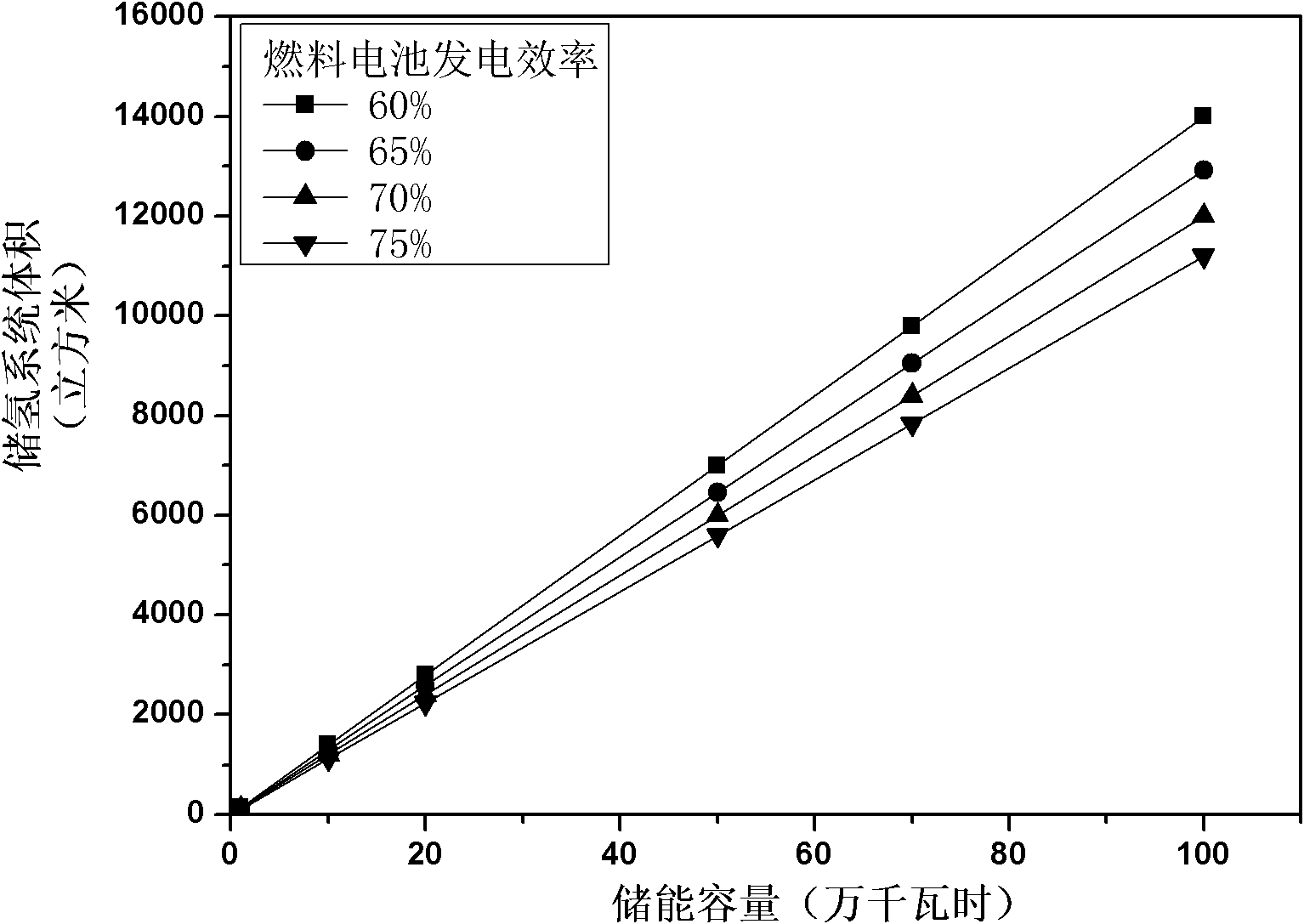

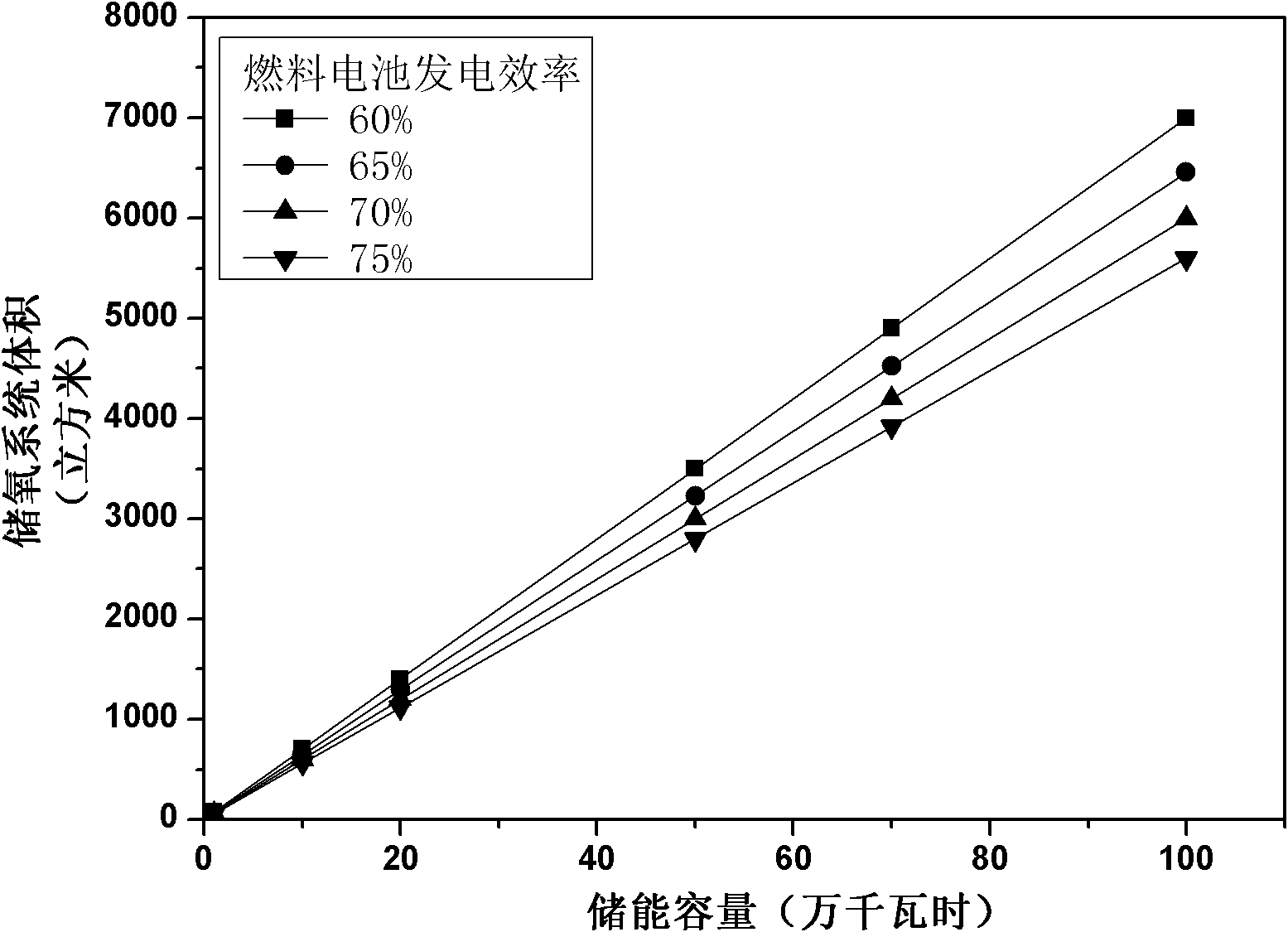

The invention discloses a novel large-scale power energy storage device, which belongs to the technology of electrochemical energy storage. The device mainly comprises an electrolytic hydrogen making system, a hydrogen storage system, an oxygen storage system, a water system, an alkaline fuel cell power generation system, an alternative current (AC) / direct current (DC) conversion system, a direct current (DC) / alternative current (AC) conversion system and corresponding control systems, wherein the electric energy is directly converted to be chemical energy which is stored in the hydrogen and oxygen storage systems respectively; at the peak of power grid load, the stored hydrogen and oxygen convert the chemical energy into electric energy directly by the alkaline fuel cell power generation system for supplying electricity; and the water consumed by the whole device in the electrolytic process can be recycled through the water generated in the power generation process of the fuel battery. The large-scale power energy storage device provided by the invention has the advantages of large capacity, long service life, low cost, environmental friendliness and the like; and the technologies of the main component parts are more mature, so that the device has an extremely broad application prospect in the electrical field.

Owner:HUANENG CLEAN ENERGY RES INST

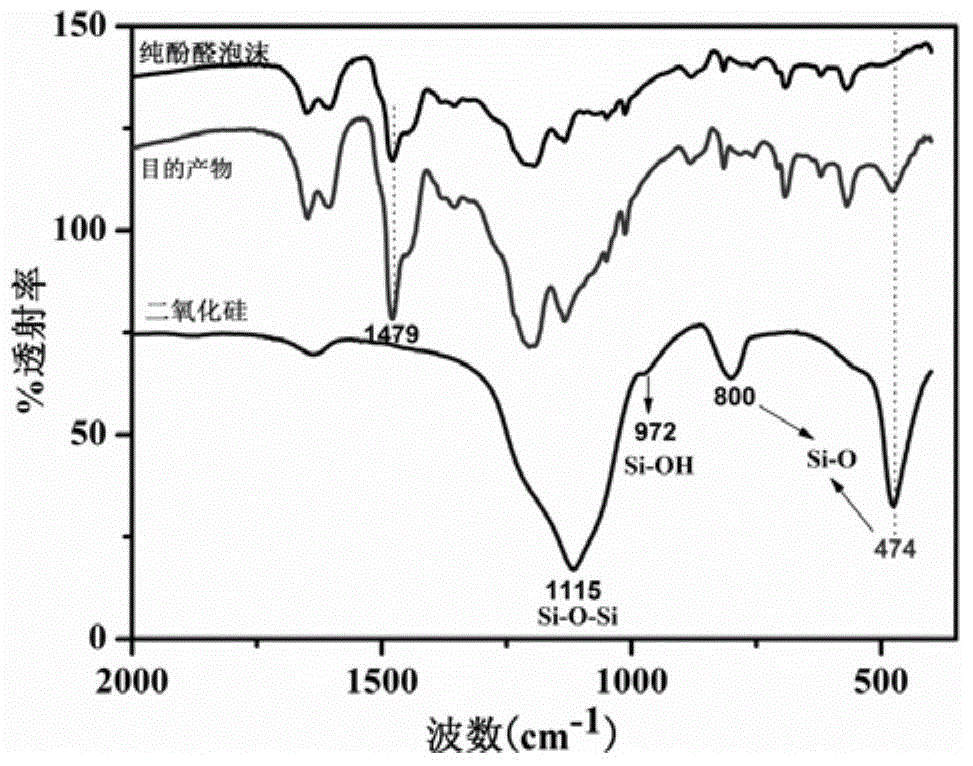

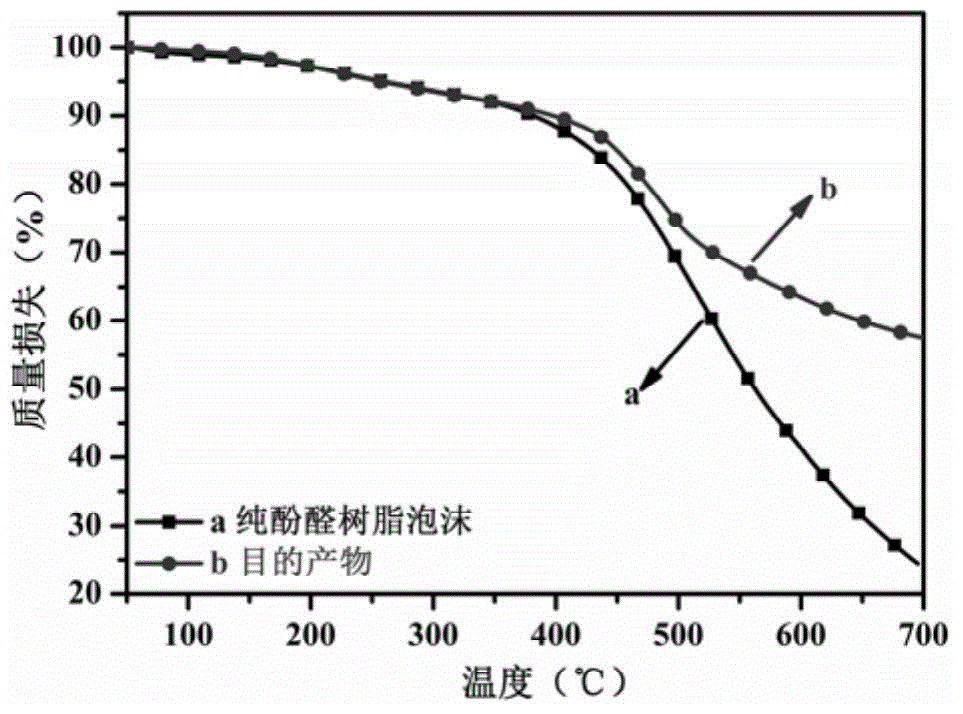

Nano carbon dioxide-phenolic resin composite foam material and preparation method thereof

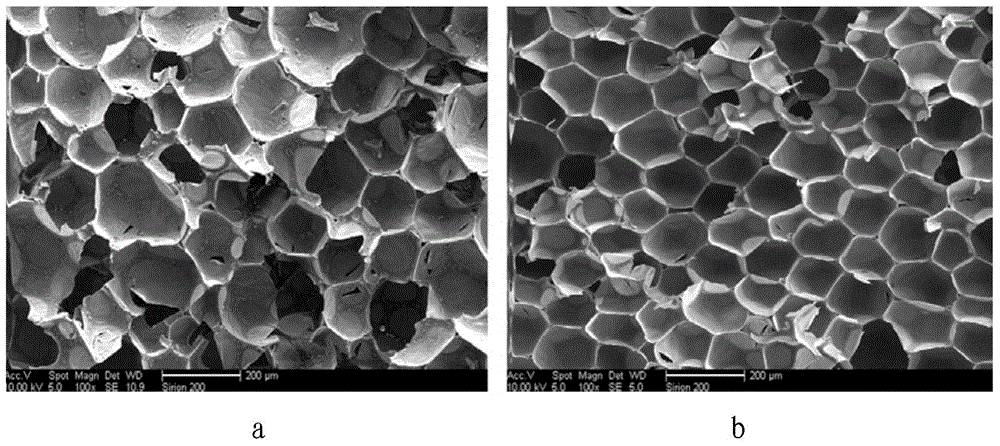

The invention discloses a nano silicon dioxide-phenolic resin composite foam material and a preparation method thereof. The composite foam material is prepared from silicon dioxide nanoparticles, free phenol, free formaldehyde, a surfactant, a curing agent and sodium chloride as well as phenolic resin, wherein the silicon dioxide nanoparticles are bonded with phenolic resin by virtue of Si-O-C chemical bonds. The method comprises the following steps: firstly, ultrasonically dispersing a SiO2 sol in a formaldehyde solution or a mixed liquid of formaldehyde solution and paraformaldehyde to obtain a mixed solution; then, after mixing the mixed solution, phenol and an alkaline solution, and carrying out polymerization reaction to obtain resol in which the silicon dioxide nanoparticles are uniformly dispersed; then, firstly, carrying out acid neutralization and reduced pressure distillation on the resol; then, mixing and stirring the resol with a foaming agent and the surfactant to obtain mixed resin; and finally, adding the curing agent into the mixed resin and putting into a die to cure and foam to prepare a targeted product. The nano silicon dioxide-phenolic resin composite foam material disclosed by the invention can be widely applied to the fields such as building, aviation, refrigeration and the like commercially.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

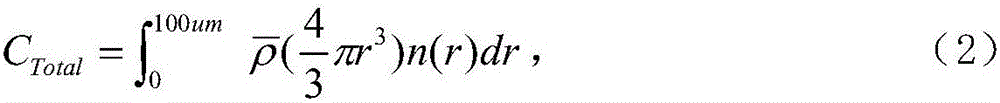

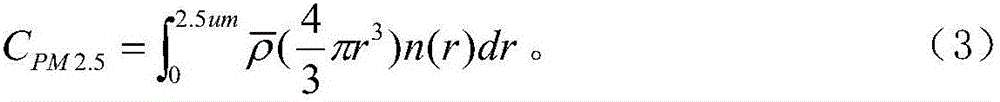

Method for inverting function relationship between aerosol extinction coefficient moisture absorption increasing factor and relative humidity by adopting PM2.5 mass concentration as constraint condition

InactiveCN106092841AEasy detectionLow costParticle suspension analysisAerosol extinction coefficientMoisture absorption

The present invention discloses a method for inverting the function relationship between the aerosol extinction coefficient moisture absorption increasing factor and the relative humidity by adopting the PM2.5 mass concentration as the constraint condition. According to the method, the determined aerosol extinction coefficient alpha dry at the relative humidity of no more than 40% and the PM2.5 mass concentration CPM2.5 are substituted into the formula defined in the specification to calculate the proportional coefficient K, the aerosol extinction coefficient alpha wet and the PM2.5 mass concentration CPM2.5 at the arbitrary relative humidity are determined at the same position, the proportional coefficient K and the PM2.5 mass concentration CPM2.5 at the arbitrary relative humidity are substituted into the formula alpha=K.CPM2.5 to calculate the dry aerosol extinction coefficient alpha dry at the arbitrary relative humidity, the determined alpha wet and the calculated alpha dry are substituted into the formula defined in the specification to calculate the aerosol extinction coefficient moisture absorption increasing factor f, the calculation process of the f is repeatedly performed at least 5 times, and the two groups of the data such as the relative humidity RH of atmosphere determined at the same position and the calculated aerosol extinction coefficient moisture absorption increasing factor f are subjected to fitting to obtain the function relationship. According to the present invention, with the method, the PM2.5 mass concentration in the height range of 0-30 km on the ground can be conveniently detected at any time in a low cost manner.

Owner:中国人民解放军陆军军官学院

Vertical graphene and growth method thereof

The invention provides vertical graphene and a growth method thereof. The growth method of the vertical graphene comprises the steps of providing a substrate and placing the substrate in a reaction cavity; and introducing a carbon source and additionally introducing a vertical electric field into the reaction chamber so as to carry out vapor deposition reaction on a surface of the substrate to grow the vertical graphene. By introducing the vertical electric field into a vapor deposition reaction system, the graphene can grow strictly in the vertical direction, and the vertical graphene completely perpendicular to the substrate is obtained. The method is simple and efficient, and the rapid growth of the vertical graphene can be realized.

Owner:BEIJING GRAPHENE INST +1

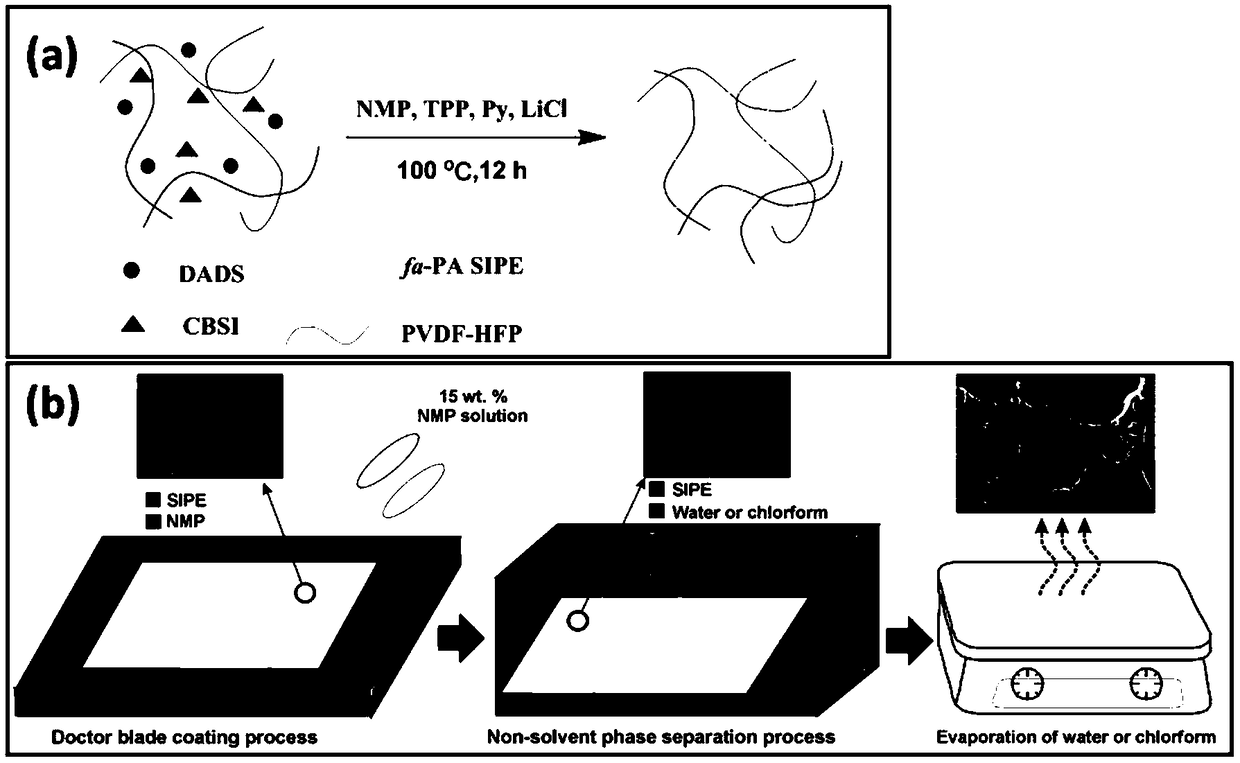

A porous monoionic conductive polymer electrolyte membrane and a preparation method and application thereof

ActiveCN109273647AImprove interface compatibilityEasy to prepareSecondary cellsCell component detailsPorosityNon solvent

The invention discloses a porous single-ion conductive polymer electrolyte membrane, wherein the film-forming raw materials of the electrolyte membrane are single-ion conductive polymer electrolyte and polymer binder. Also included is a preparation method and application of a porous monoionic conductive polymer electrolyte membrane. The invention improves a series of problems such as ionic conductivity and interface compatibility between the membrane and the electrode by preparing a high-porosity electrolyte membrane through a rapid non-solvent induced phase separation method, and provides a simple preparation method for a high-performance microporous SIPE used in a lithium ion battery, which can be widely commercialized.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for purifying quartz sands

PendingCN111203328AImprove use valueExtensive Fractional PurificationFlotationPhysical chemistryPellets

The invention discloses a method for purifying quartz sands. The method comprises the following steps: pretreating to obtain quartz sand concentrate particles; stirring and mixing 70-300-mesh quartz sand concentrate particles with single quartz minerals and pure water to obtain a mixed solution with a determined volume, adding a cationic collecting agent into the mixed solution with the determinedvolume, stirring and mixing to obtain a flotation solution, carrying out flotation on the flotation solution to obtain flotation quartz sands and a residual solution, supplementing pure water into the residual solution to a determined volume to obtain a mixed solution with the determined volume, and repeating the process of adding the cationic collecting agent into the mixed solution, stirring and mixing, and floating for at least one time to sort out quartz sands with different purity grades. The method not only can sort the same batch of quartz sands into quartz sands with different puritygrades to enable the quartz sands to be suitable for different fields and greatly improve the use value of the quartz sands, but also has the characteristics of simplicity, convenience, practicabilityand low cost, and is extremely easy to widely commercialize and apply to grading and purifying of the quartz sands.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

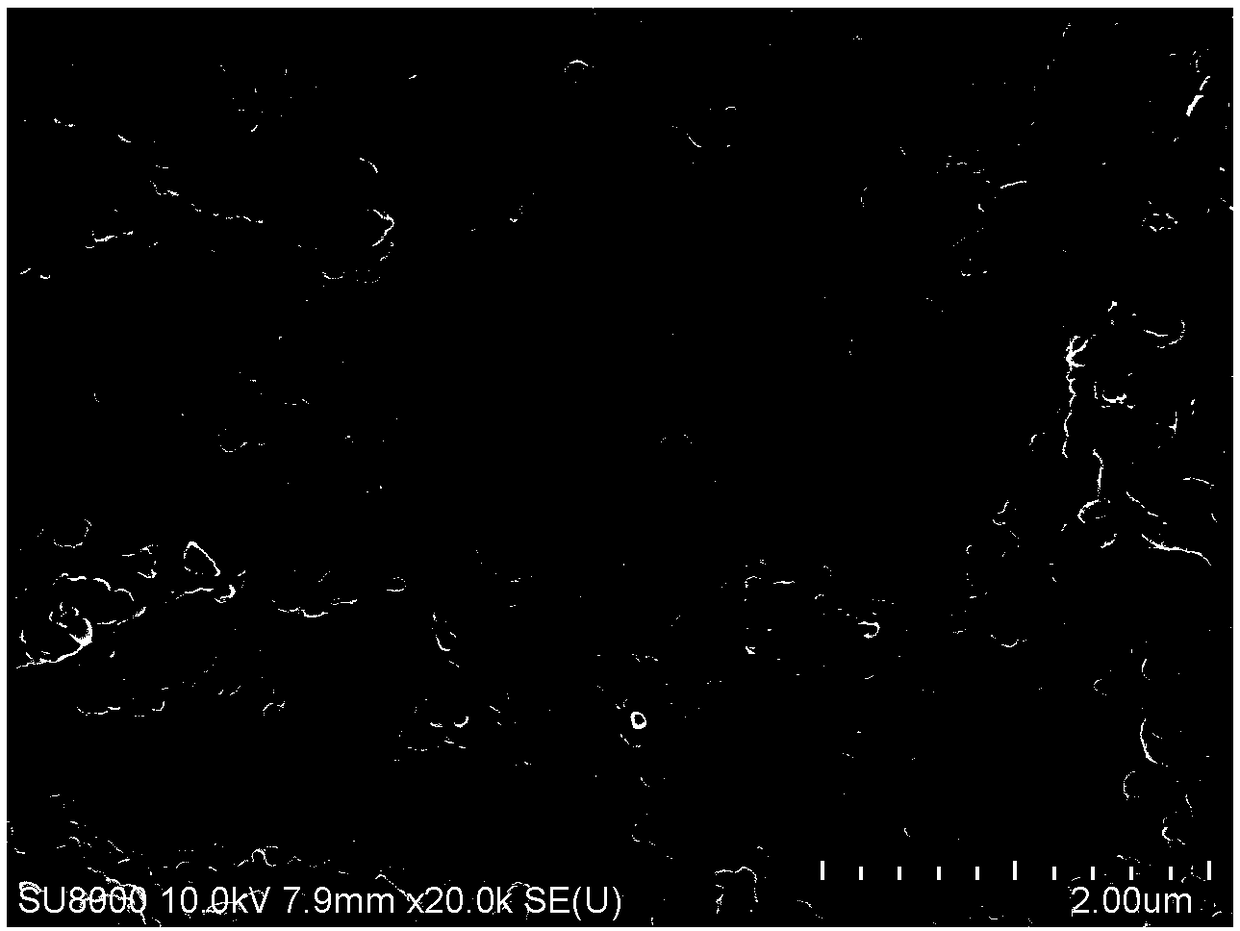

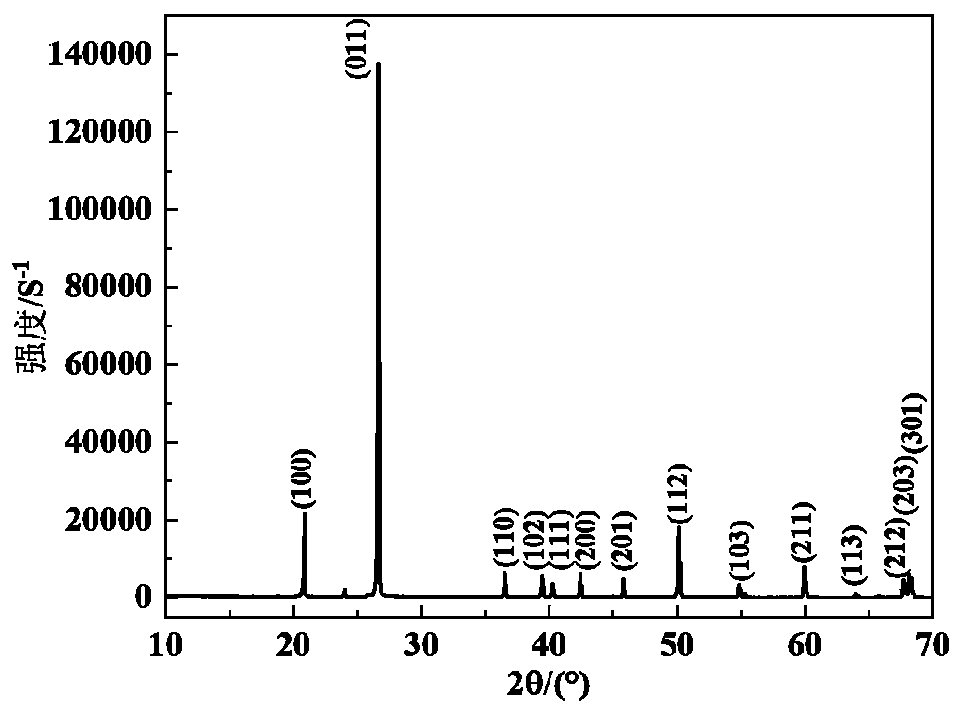

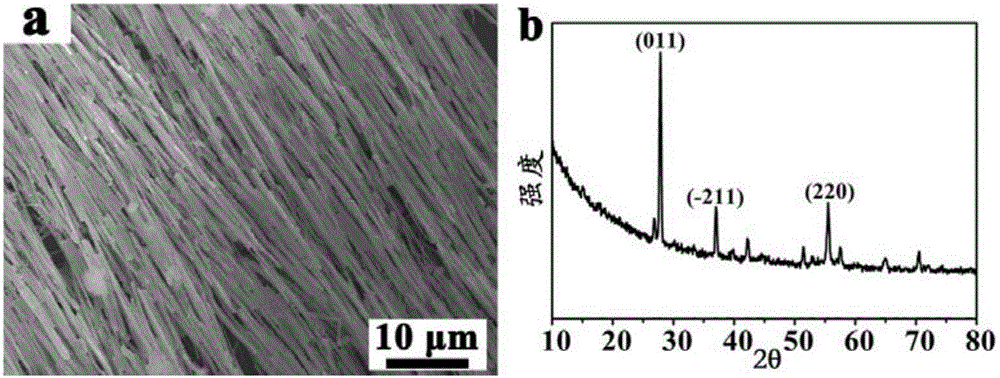

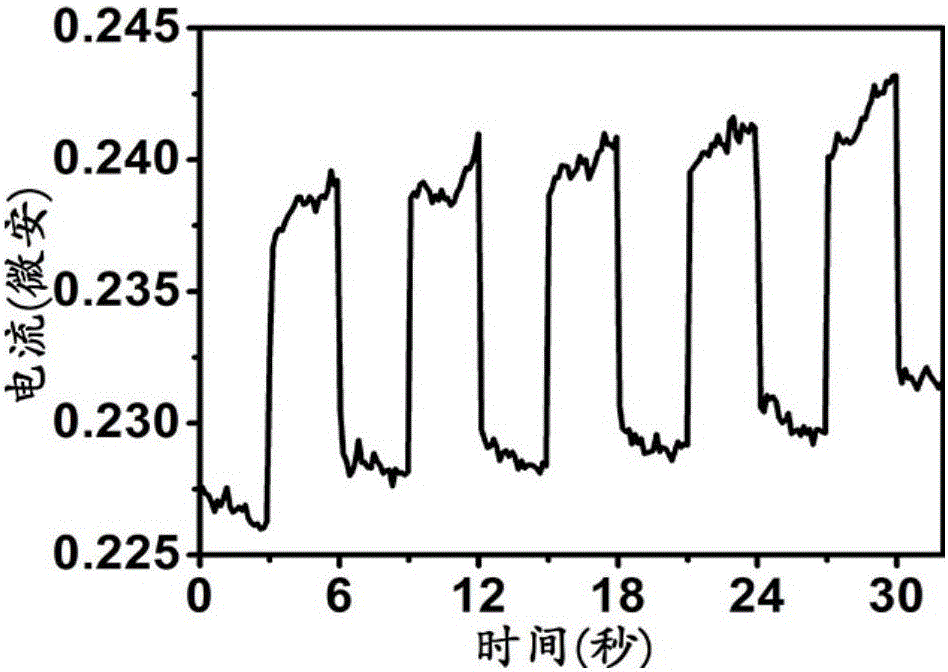

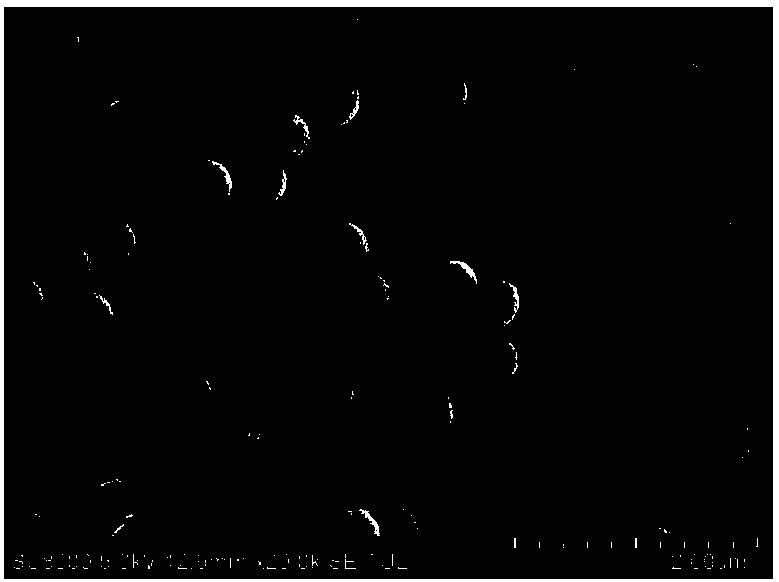

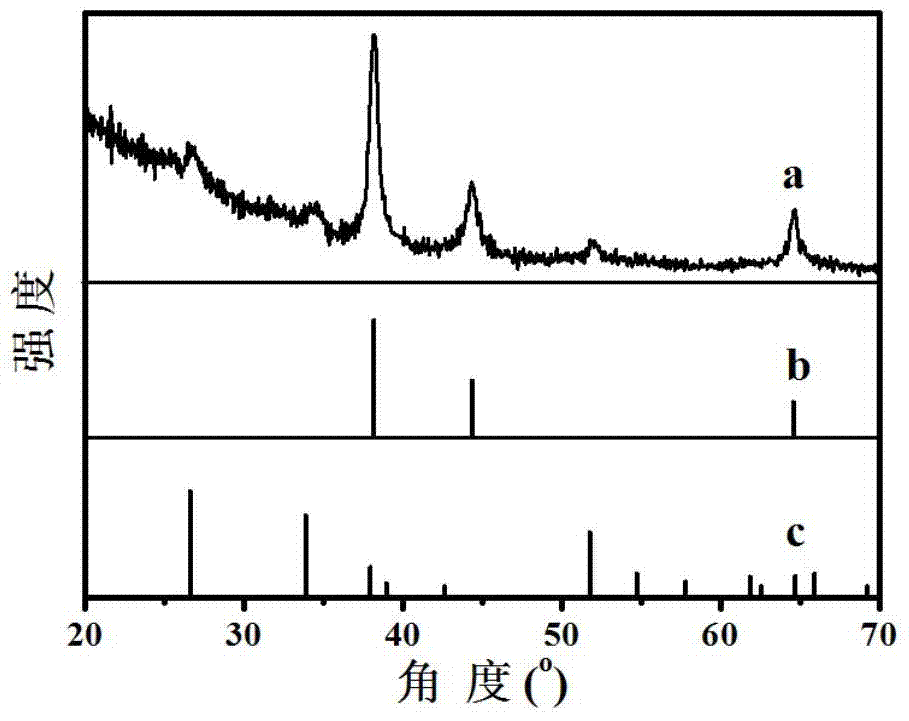

VO2(M) nanowire ordered array and preparation method thereof

InactiveCN106082337AEase of widespread commercial applicationExtensive commercial applicationVanadium oxidesMicrometerChloroform

The invention discloses a VO2(M) nanowire ordered array and a preparation method thereof. According to the ordered array, a VO2(M) nanowire is arranged orderly in the wire length direction to form an array, the diameter of the VO2(M) nano wire forming the VO2(M) nanowire ordered array ranges from 200 nm to 600 nm, and the wire length ranges from 10 micrometers to 50 micrometers. The method comprises the steps that firstly, a hydrothermal method is used for obtaining the VO2(M) nanowire, then the VO2(M) nanowire is mixed with water, then ultrasonic treatment is carried out, and a VO2(M) nanowire dispersion liquid is obtained; then, the VO2(M) nanowire dispersion liquid is firstly dropwise added into chloroform, after the VO2(M) nanowire is assembled into the ordered sequence by itself on the surface of chloroform, the VO2(M) nanowire is fished out through a substrate, and the substrate coated with the VO2(M) nanowire ordered array is obtained; then after the substrate coated with the VO2(M) nanowire ordered array is placed in a vacuum or protective atmosphere for annealing, the substrate is separated, and the target product is obtained. The VO2(M) nanowire ordered array can be widely and commercially applied to the fields of photoelectric detection, intelligent responses, electro-catalysis, sensors, magnetic devices and the like easily.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

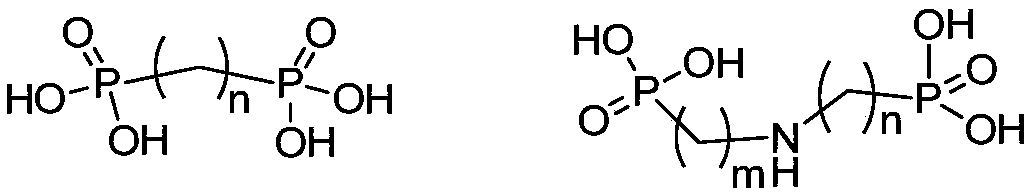

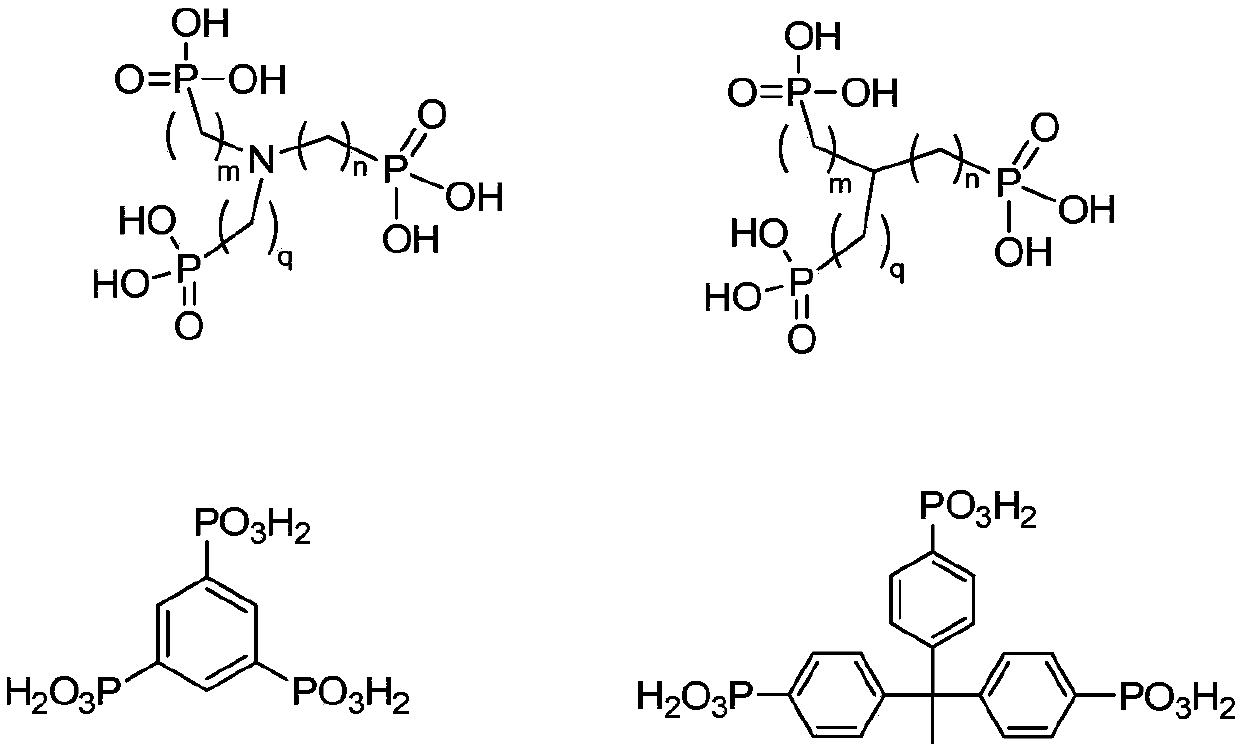

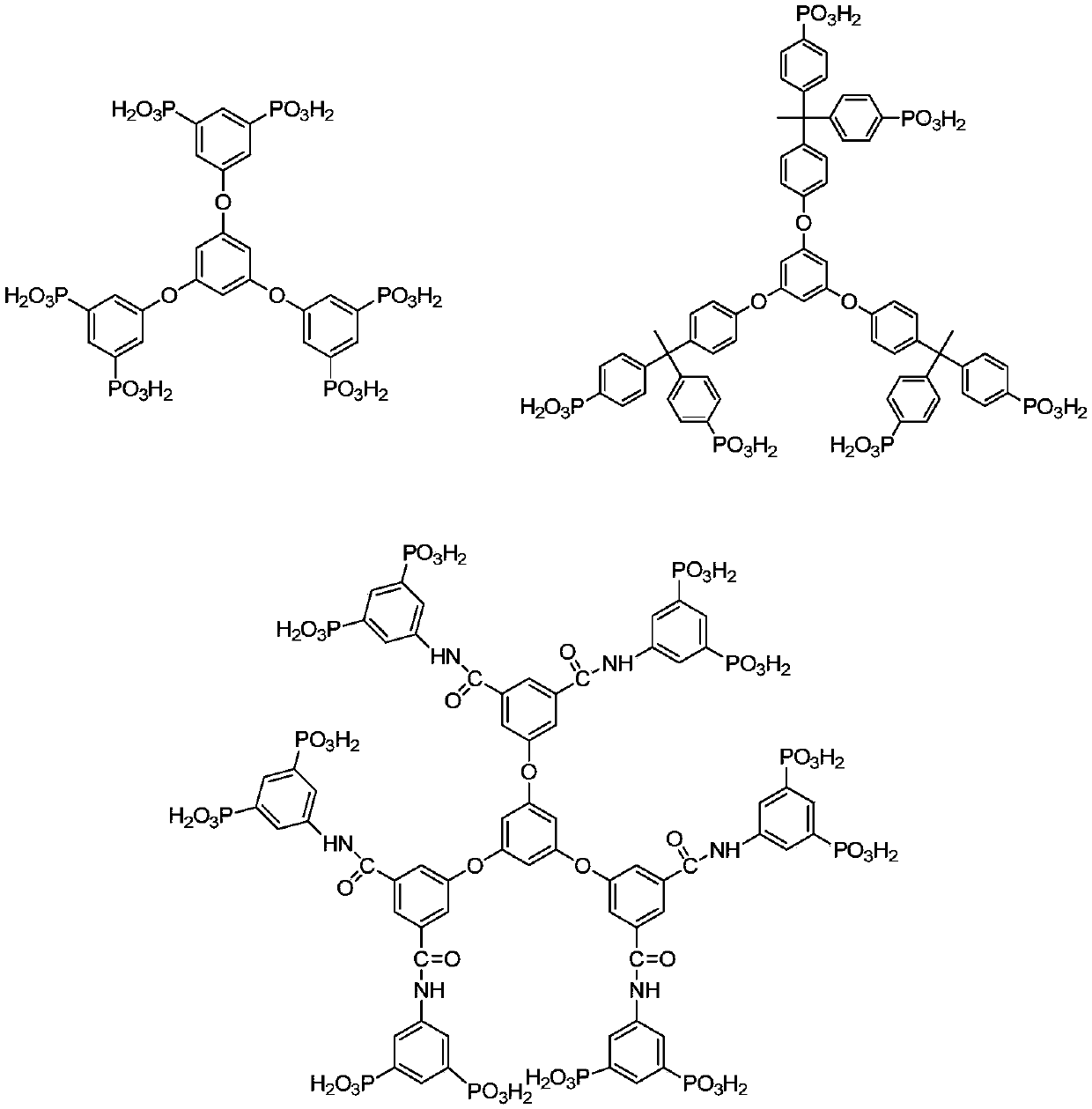

Organic phosphoric acid-based high-temperature proton exchange membrane and preparation method and application thereof

ActiveCN107799794APromote circulationImprove performanceSolid electrolytesFuel cellsBiopolymerPhosphoric acid

The invention discloses an organic phosphoric acid-based high-temperature proton exchange membrane, and provides preparation and application of the proton exchange membrane. The proton exchange membrane is prepared by doping an organic phosphoric acid into a macromolecular polymer. The organic phosphoric acid is used for substituting a phosphoric acid and is used for the high-temperature proton exchange membrane, an organic molecular chain segment in the organic phosphoric acid can be suspended on a macromolecular chain so as to limit the moving of the organic phosphoric acid in the proton exchange membrane, the problem of serious phosphoric acid runaway is solved, and the high-temperature proton exchange membrane with favorable cycle property is obtained. The types of the organic phosphoric acid, the doping quantity and the types of macromolecule have great selection ranges so as to obtain the high-temperature proton exchange membrane with excellent performance; moreover, the organicphosphoric acid is various in types and high in selectivity; and by low-cost engineering plastic and biopolymer, the high-temperature proton exchange membrane can be widely commercialized.

Owner:WUHAN HYNERTECH CO LTD

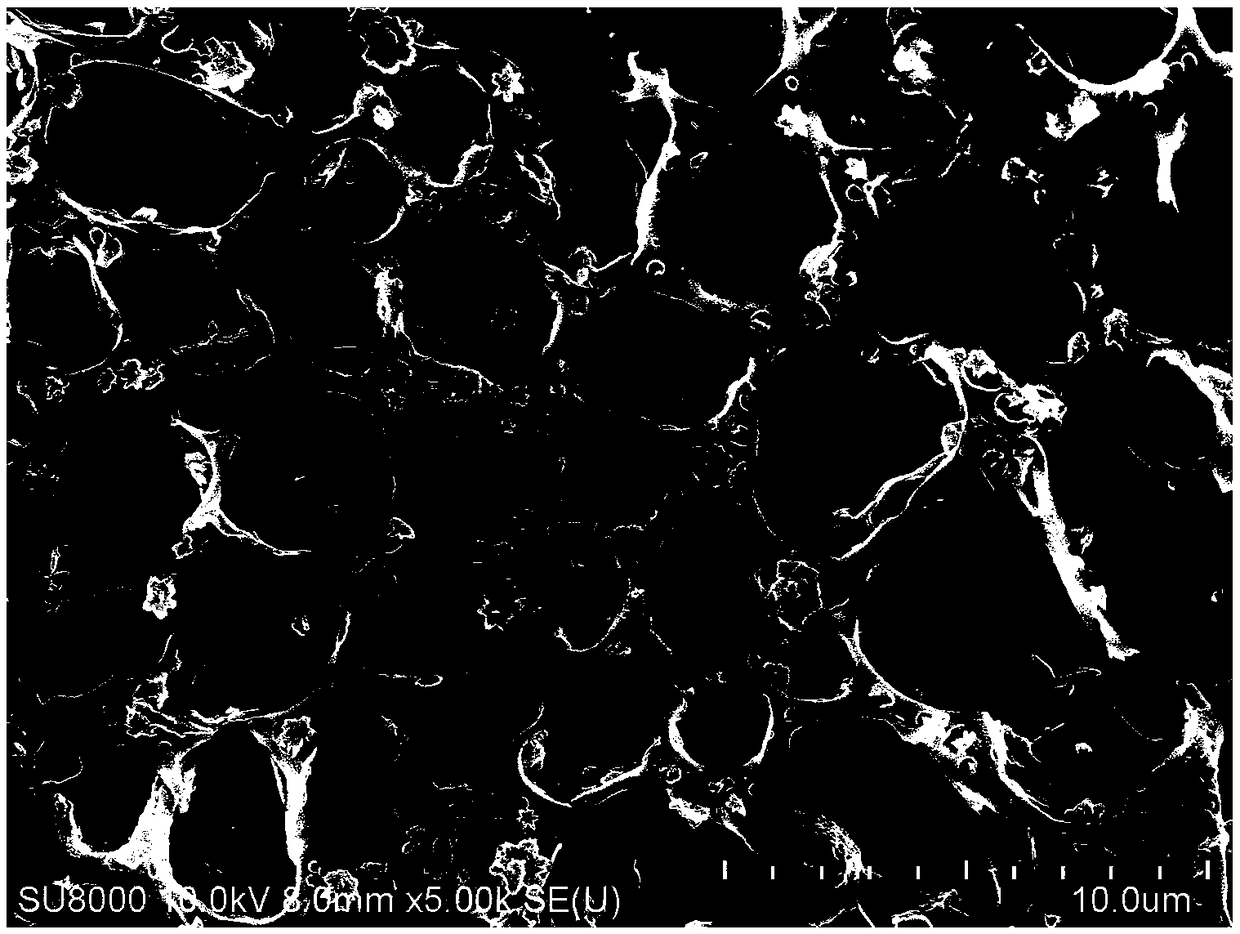

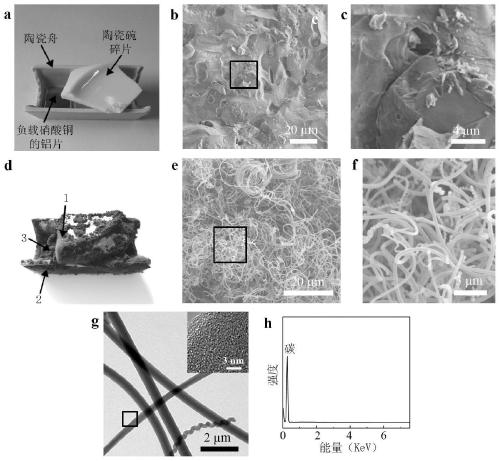

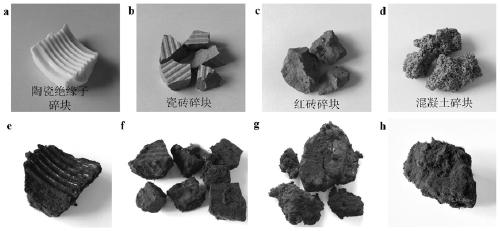

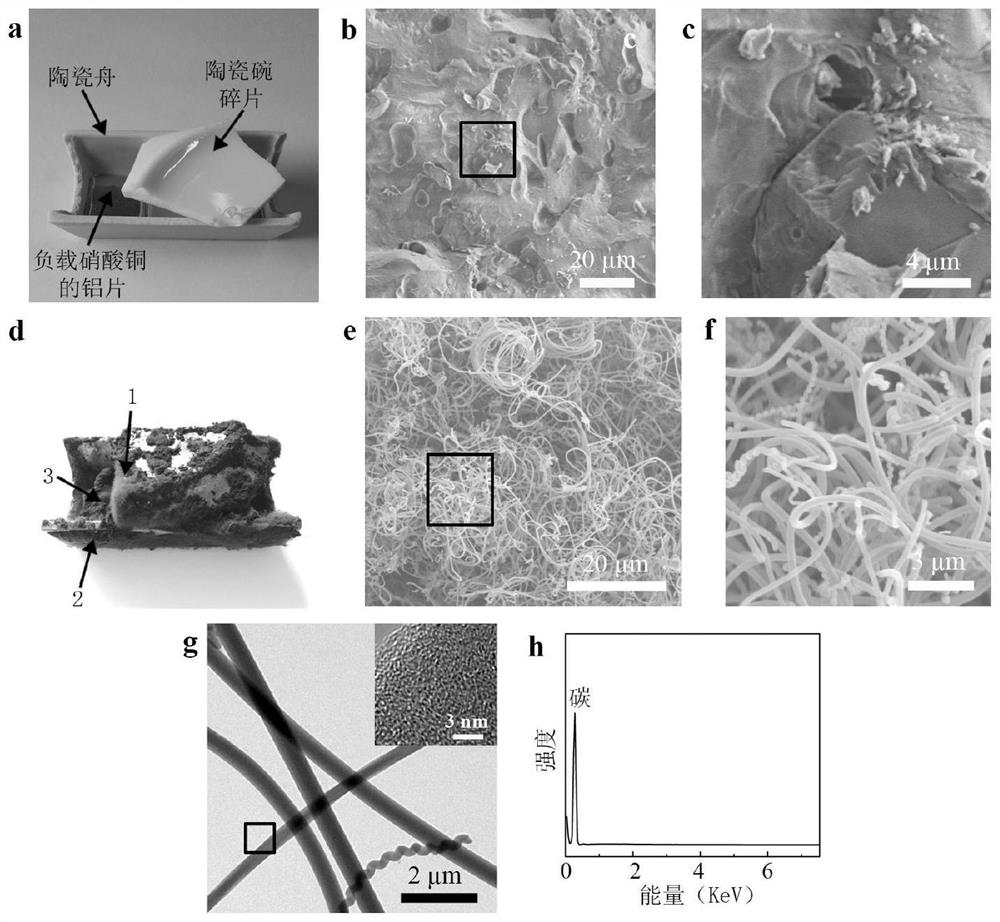

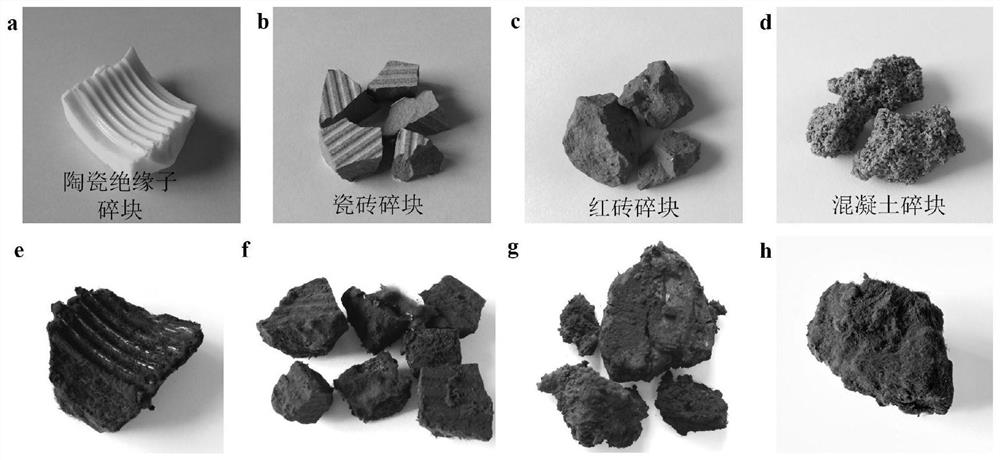

Preparation method of carbon nanofiber film without metal catalyst

The invention discloses a preparation method of a carbon nanofiber film without a metal catalyst. The method comprises the following steps of immersing an aluminum sheet into a copper nitrate aqueoussolution; taking out the aluminum sheet and drying, putting the obtained aluminum sheet loaded with the copper nitrate on the surface into a ceramic container; enabling the aluminum sheet to be covered with the ceramic product fragment, then placing a ceramic container of which the bottom is covered with the aluminum sheet loaded with the copper nitrate on the surface and the ceramic product fragment orderly in the mixed atmosphere of acetylene and argon at 420-460 DEG C below for 20-40 hours, and preparing a product on the surfaces of the ceramic container and the ceramic product fragment. The method not only prepares the carbon nanofiber film without the metal catalyst, but also has the characteristics of low cost, high yield and easiness in industrial large-scale production, and can realize the recycling of various ceramics and construction wastes, so that the environmental pollution is reduced. The prepared product has the characteristics of light weight, hydrophobicity and good mechanical properties, and can be easily, widely and commercially applied to various oil leakage cleaning fields.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

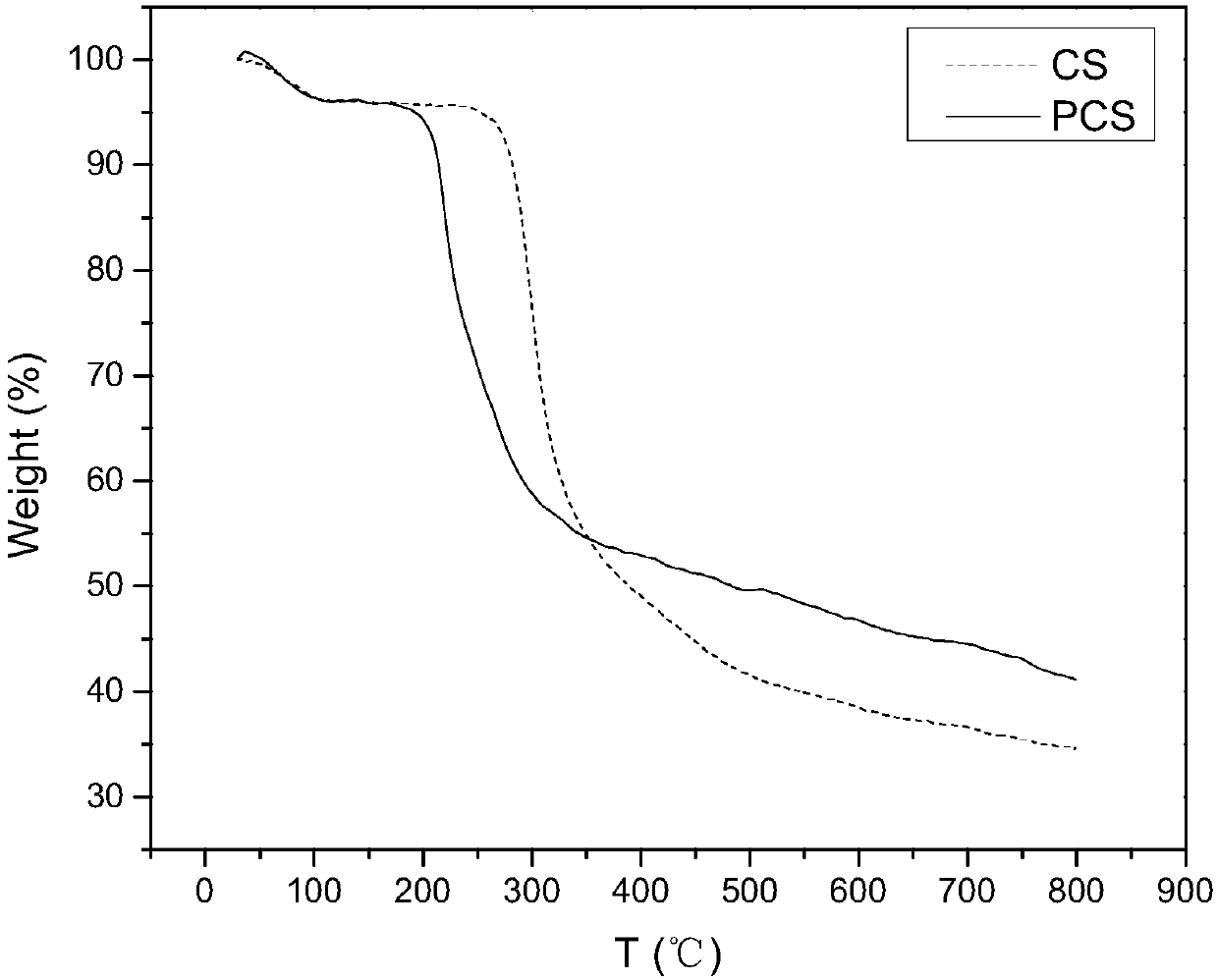

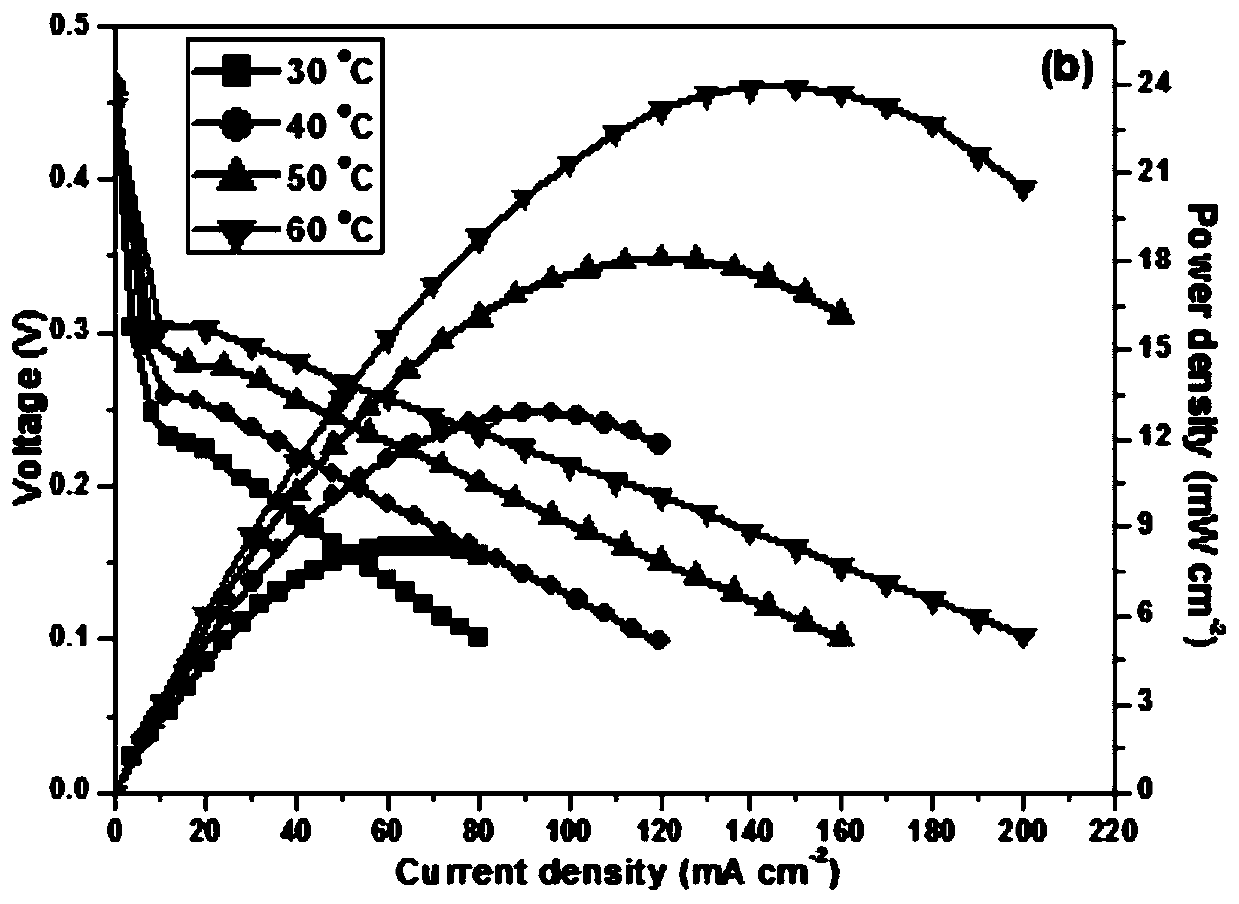

High-temperature proton exchange membrane used for membrane fuel cells, and production method and application thereof

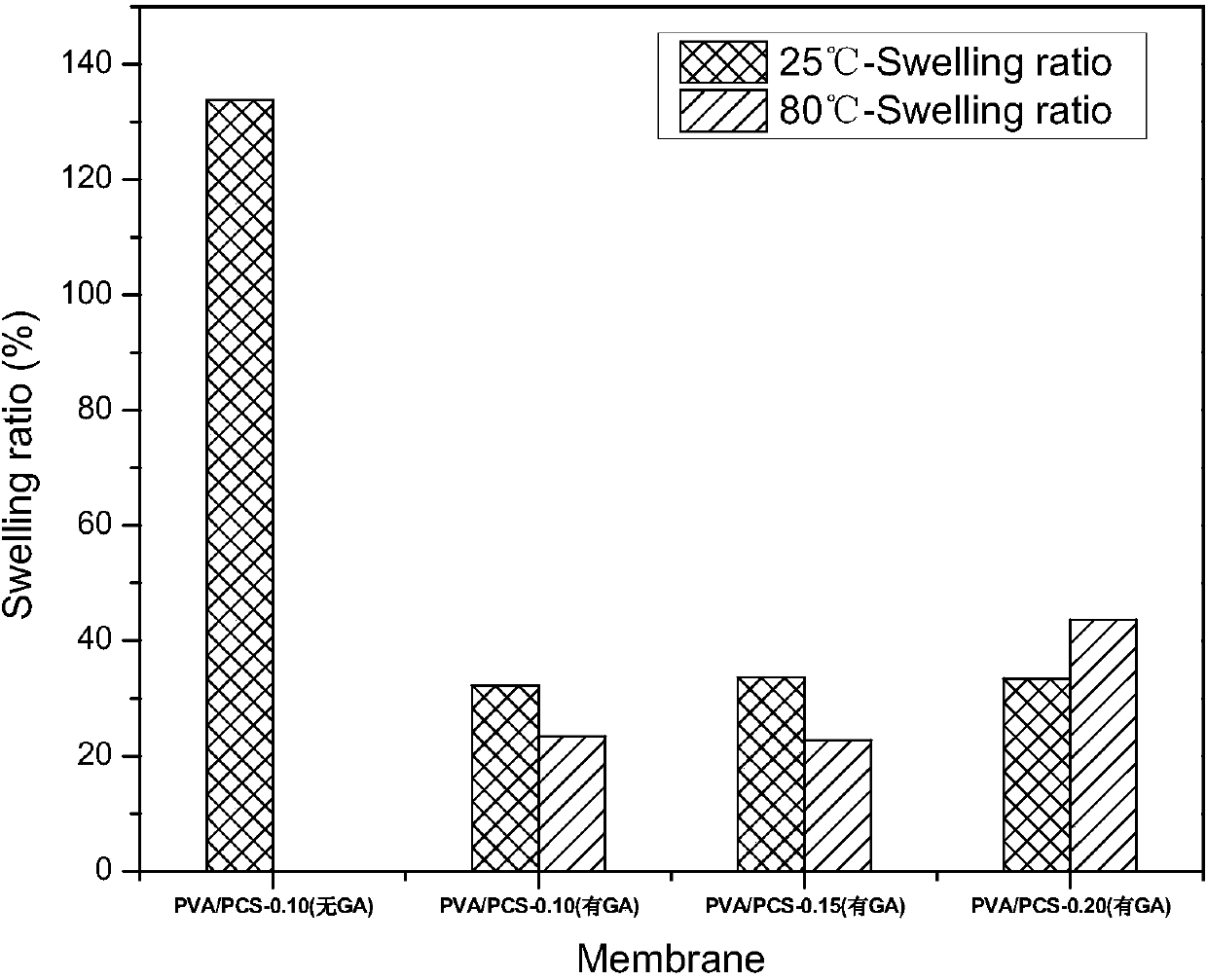

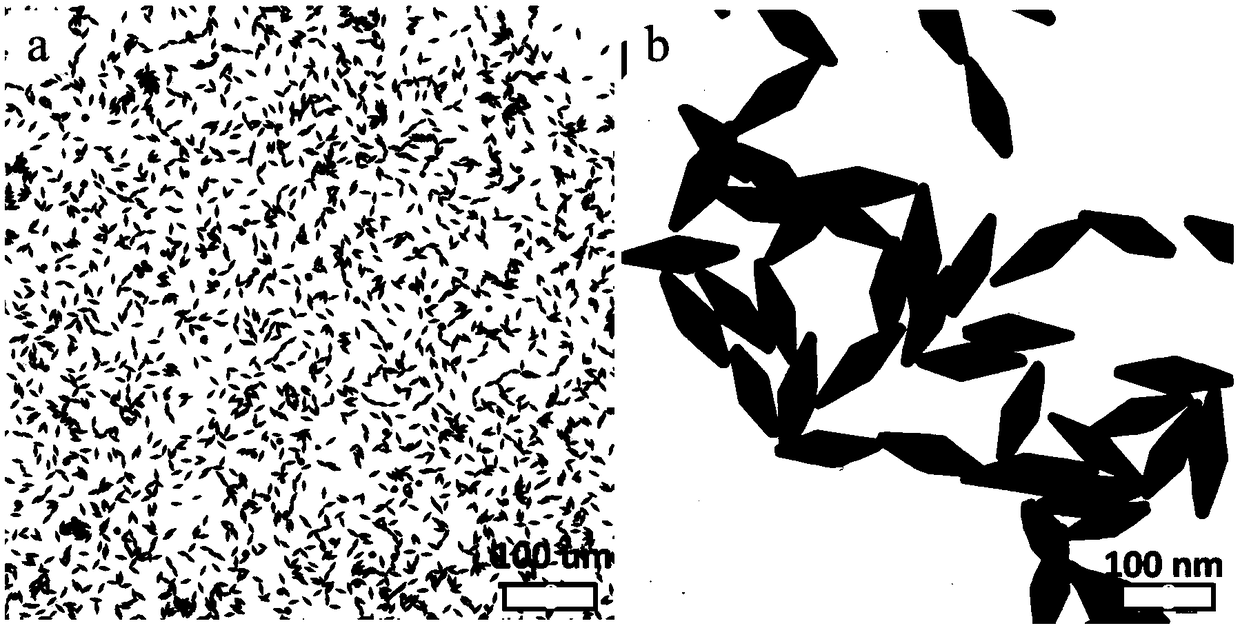

ActiveCN107834089AImprove hydrophilicityImprove permeabilityFinal product manufactureFuel cellsCross-linkAlcohol

The invention discloses a polyvinyl alcohol-phosphorylated chitosan composite membrane used for high-temperature proton exchange membrane fuel cells, and also provides a production method and an application of the composite membrane. Raw materials for forming the proton exchange membrane comprise polyvinyl alcohol and phosphorylated chitosan. The PCS and the PVA are chemically cross-linked to produce the high-performance composite membrane, and the PVA has high hydrophilicity, strong water permeability and low alcohol exchangeability as a potential blend polymer, and can be used for improvingthe mechanical, chemical and electrochemical properties of the PCS proton exchange membrane, and the PCS and the PVA are chemically cross-linked through a cross-linking agent glutaraldehyde to make the hydroxyl and amino groups of the PVA and the hydroxyl group of the PCS form strong chemical bonds, so the electric conductivity and the mechanical performances of the composite membrane are furtherimproved.

Owner:WUHAN HYNERTECH CO LTD

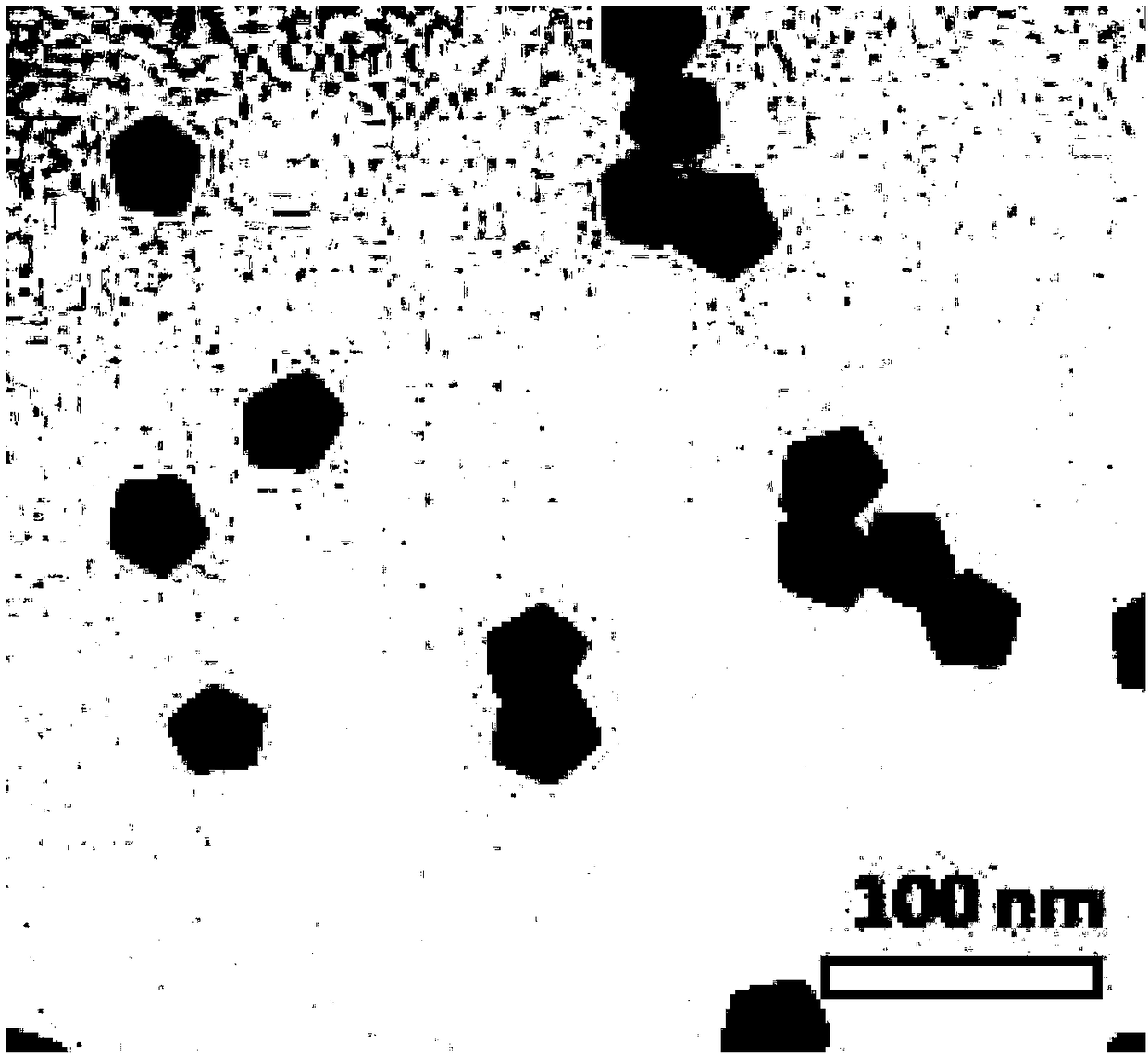

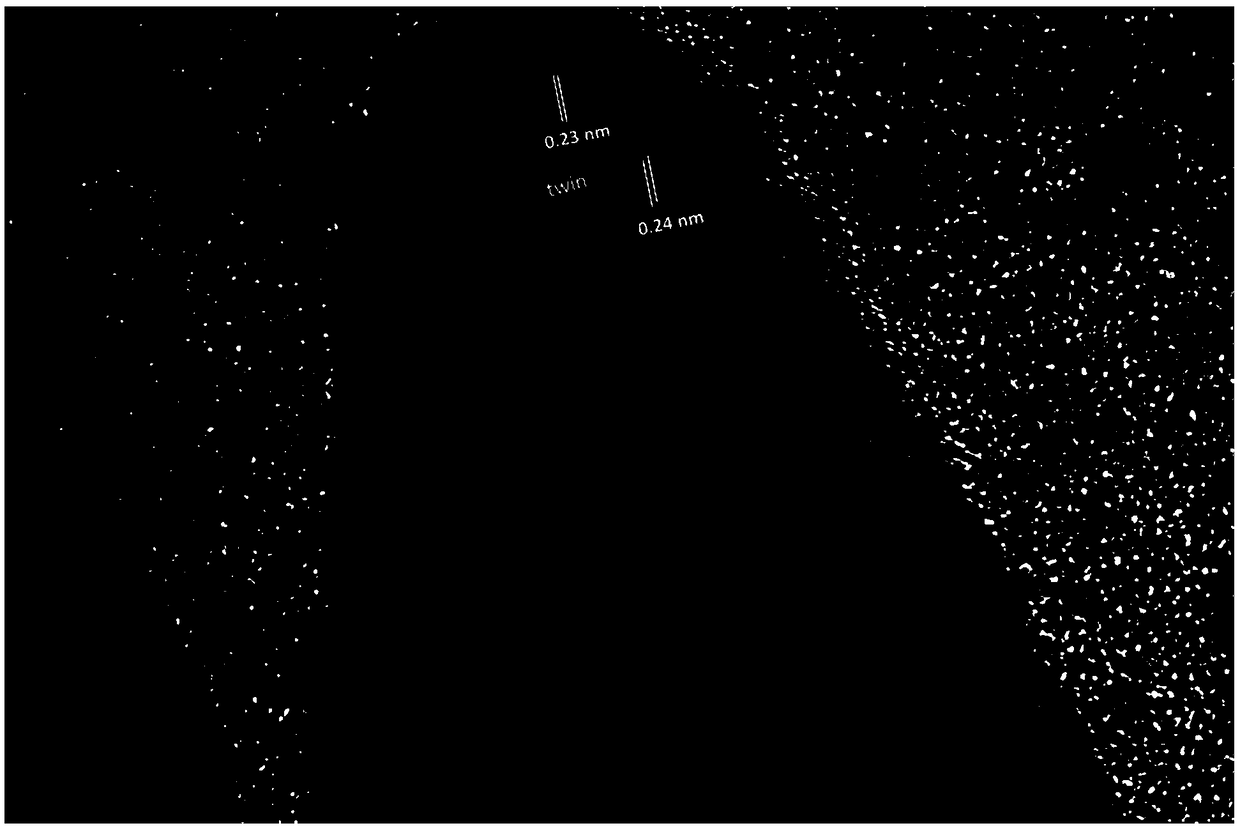

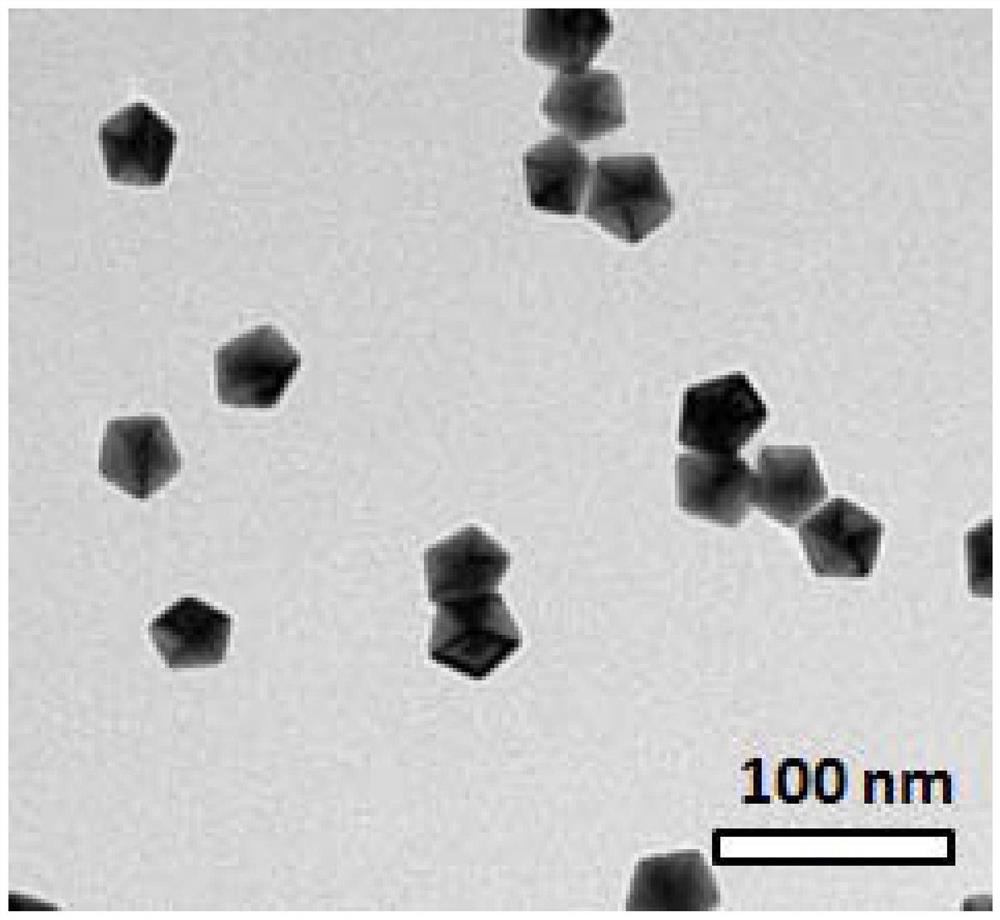

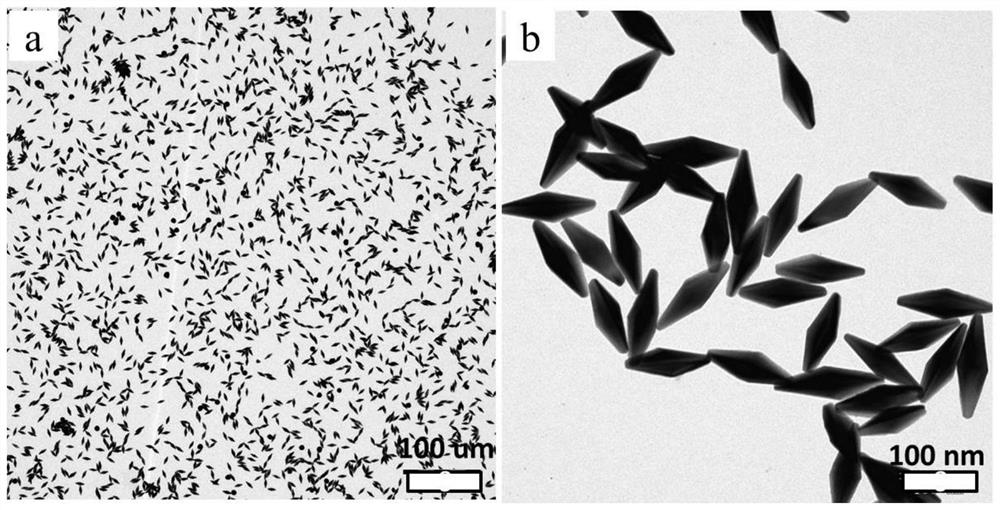

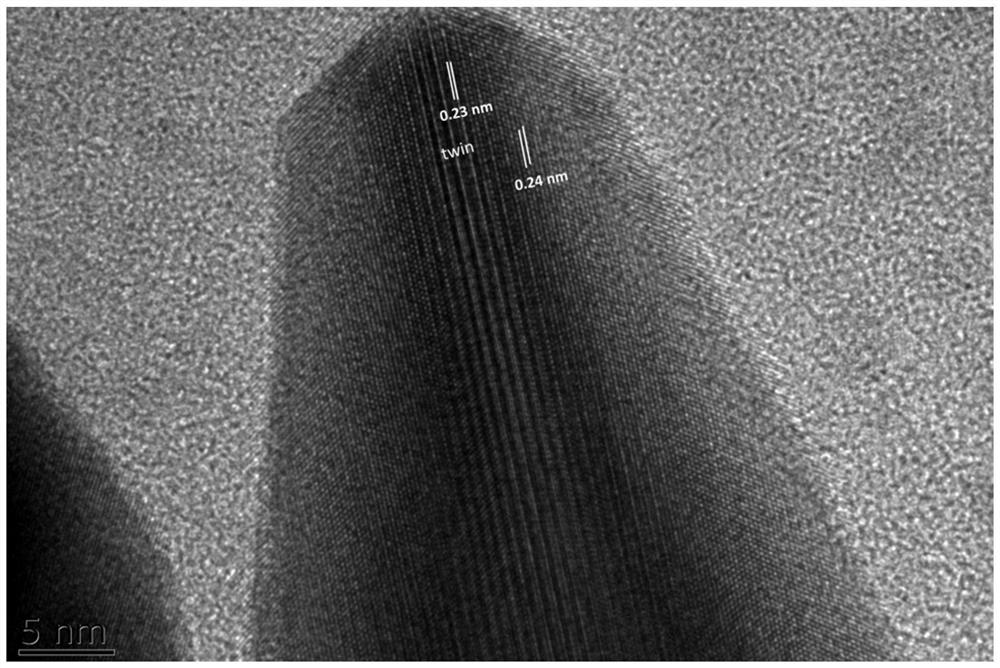

Gold nano bipyramid with five-fold twin structure and preparation method thereof

ActiveCN108637269AHigh catalytic activityExcellent near-infrared light absorption performanceMaterial nanotechnologyTransportation and packagingHydroquinone CompoundBipyramid

The invention discloses a gold nano bipyramid with a five-fold twin structure and a preparation method thereof. A gold nano decahedron is prepared in ethylene glycol by adopting a polyol reduction method; hydroquinone, chloroauric acid and the gold nano decahedron are mixed together so that the concentration of hydroquinone in the mixed solution is 0.001-0.004 mol / L, the concentration of chloroauric acid is 0.0005-0.002 mol / L, and the concentration of the gold nano decahedron is 0.0001-0.005 mol / L; and reacting is then carried out at 30-70 DEG C for 10 hours, and then solid-liquid separation is carried out to obtain the gold nano bipyramid with the five-fold twin structure. The gold nano bipyramid has good near-infrared light absorption performance and high catalytic activity of the twin structure, and has simple preparation process, low cost and environmental friendliness; and the gold nano bipyramid has important application value and wide application prospect in the fields of infrared imaging, photothermal therapy, catalysis and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

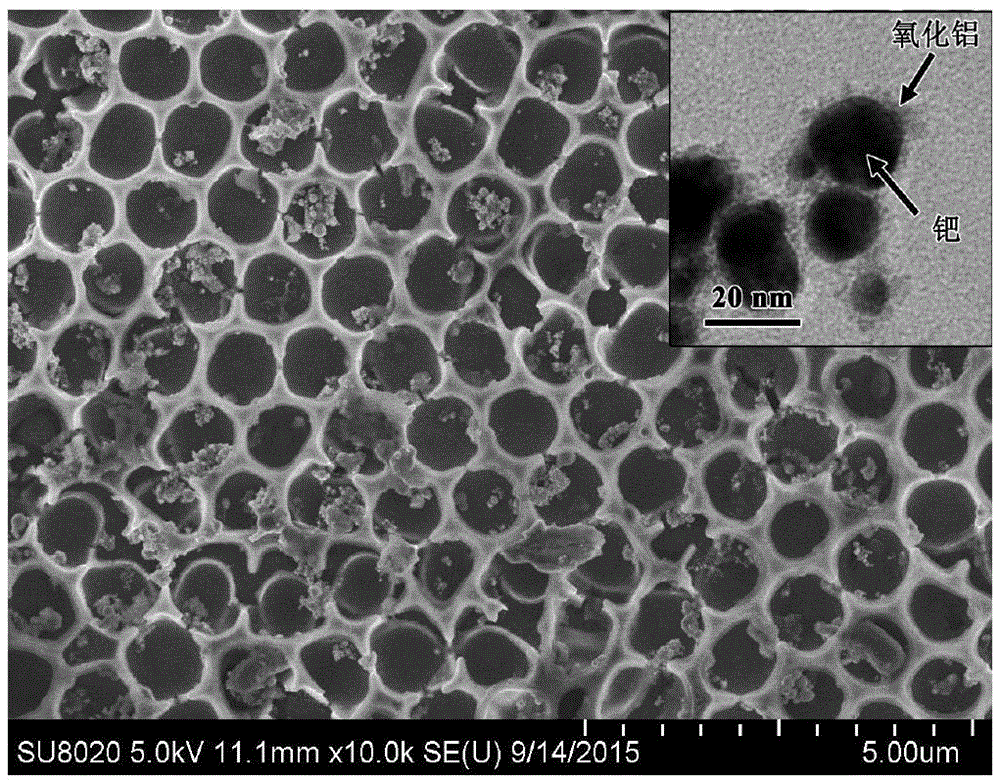

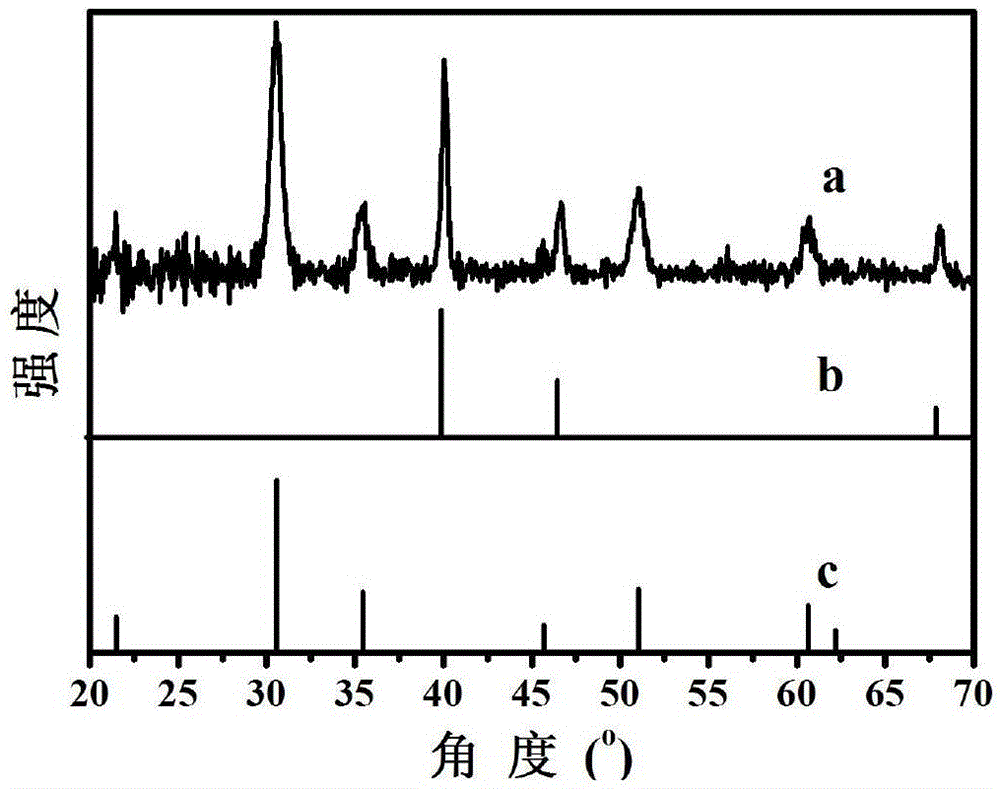

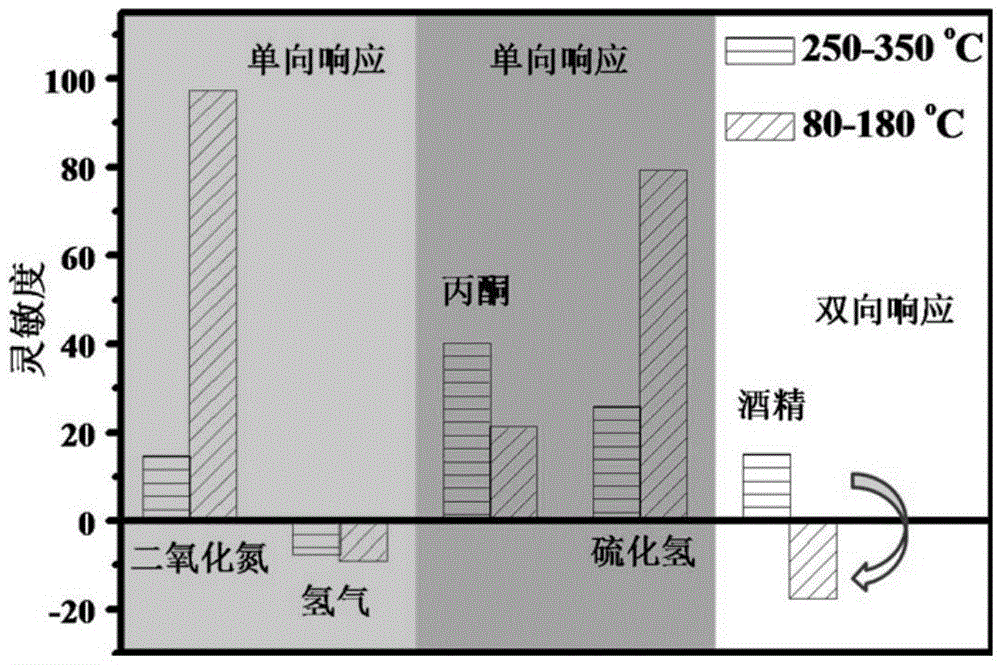

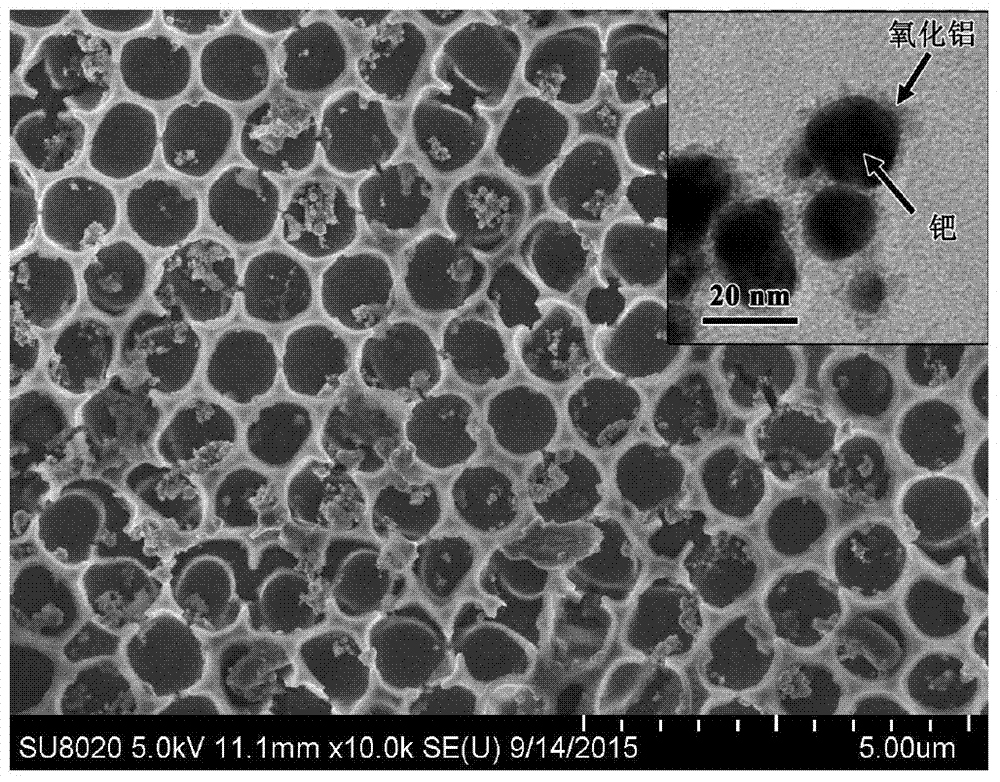

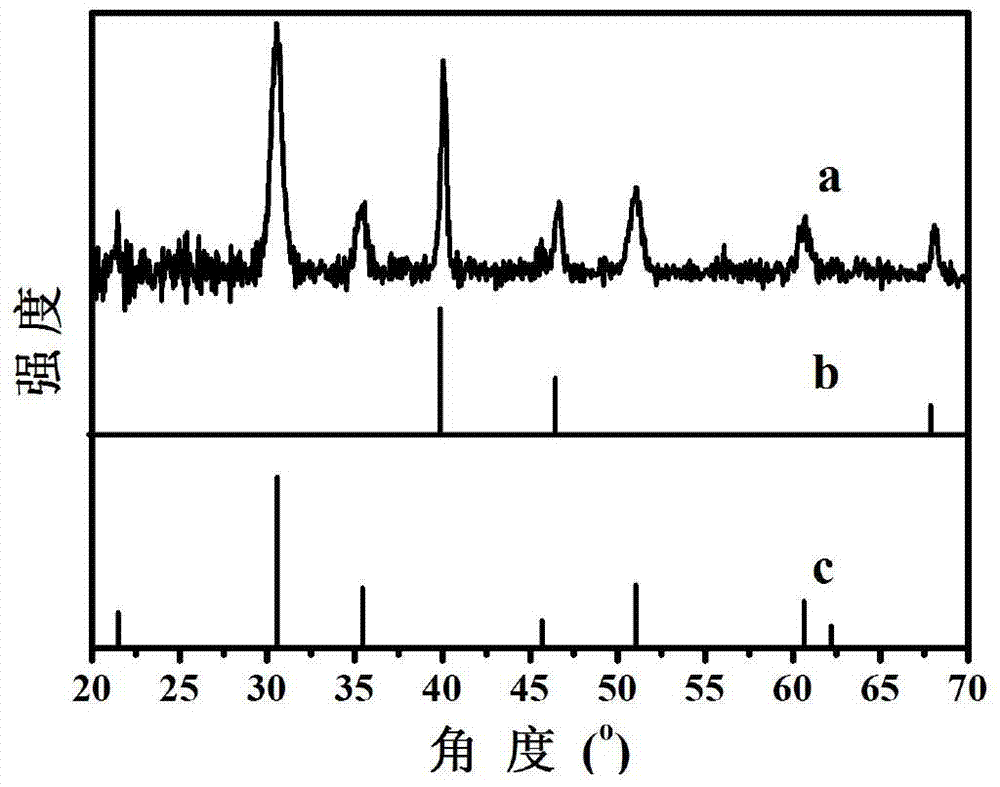

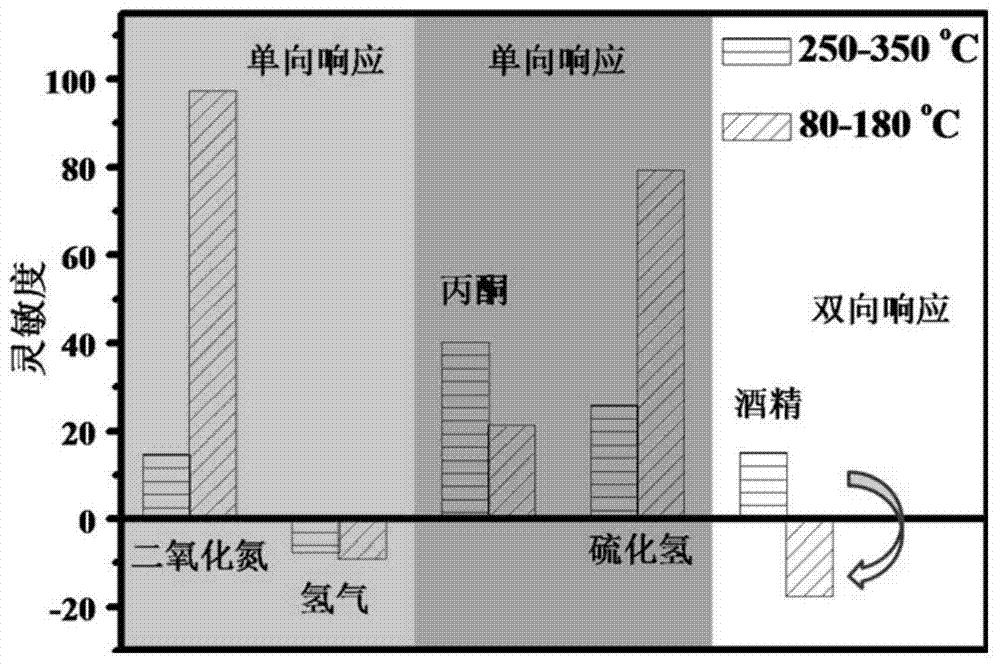

Indium oxide thin-film material modified with aluminium oxide-coated palladium nanoparticles and preparation method and application thereof

InactiveCN105523781AImprove universalityHigh sensitivityMaterial resistanceLayer thicknessMaterials science

The invention discloses an indium oxide thin-film material modified with aluminium oxide-coated palladium nanoparticles and a preparation method and an application thereof. according to the material, an indium oxide monolayer porous thin-film is modified with 1-100 micrograms / cm<2> of aluminium oxide-coated palladium nanoparticles, wherein pore diameter of the porous thin-film is 50-5000 nm; film thickness is 10-5000 nm; particle size of the aluminium oxide-coated palladium nanoparticles is 12-160 nm; layer thickness of aluminium oxide is 1-30 nm; and particle size of palladium particles is 10-100 nm. according to the method, the indium oxide monolayer porous thin-film is firstly obtained by an in-situ growth method; then, a palladium target is placed into an aluminium nitrate solution, and the palladium target is irradiated by the use of laser at wavelength of 532 nm or 1064 nm so as to obtain a mixed colloidal solution; afterwards, the mixed colloidal solution undergoes solid-liquid separation and washing; the obtained aluminium oxide-coated palladium nanoparticles are dispersed in ethanol, and the indium oxide monolayer porous thin-film is coated with the above solution obtained so as to prepare a target product. The product can be widely used in fields of selective detection of ethanol gas and gas sensing.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

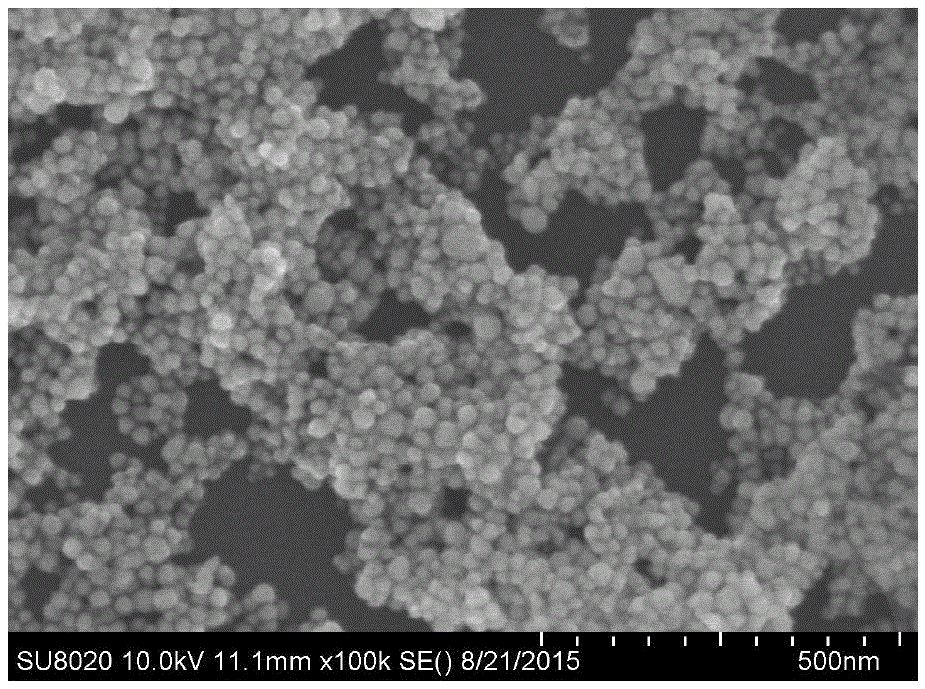

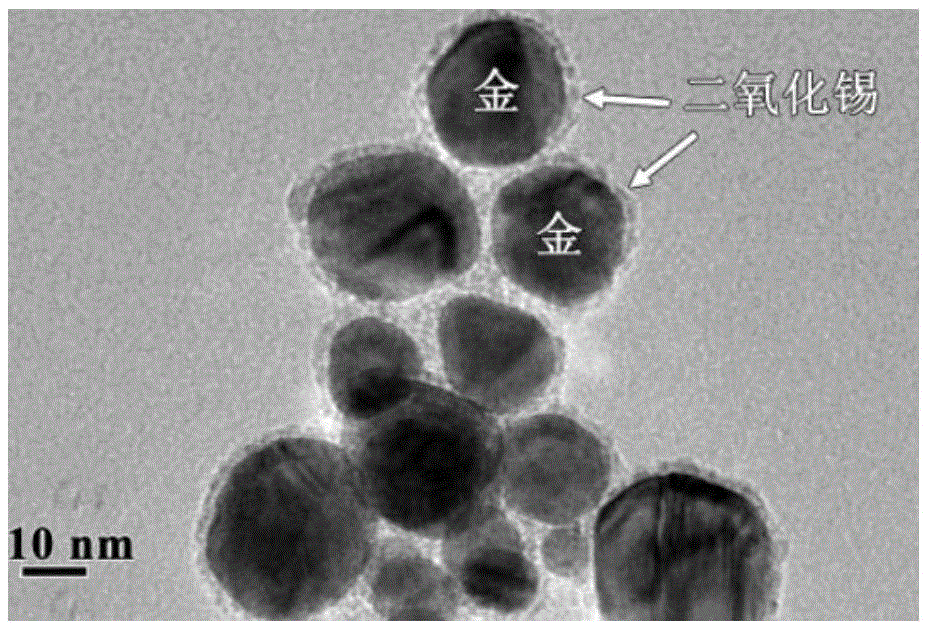

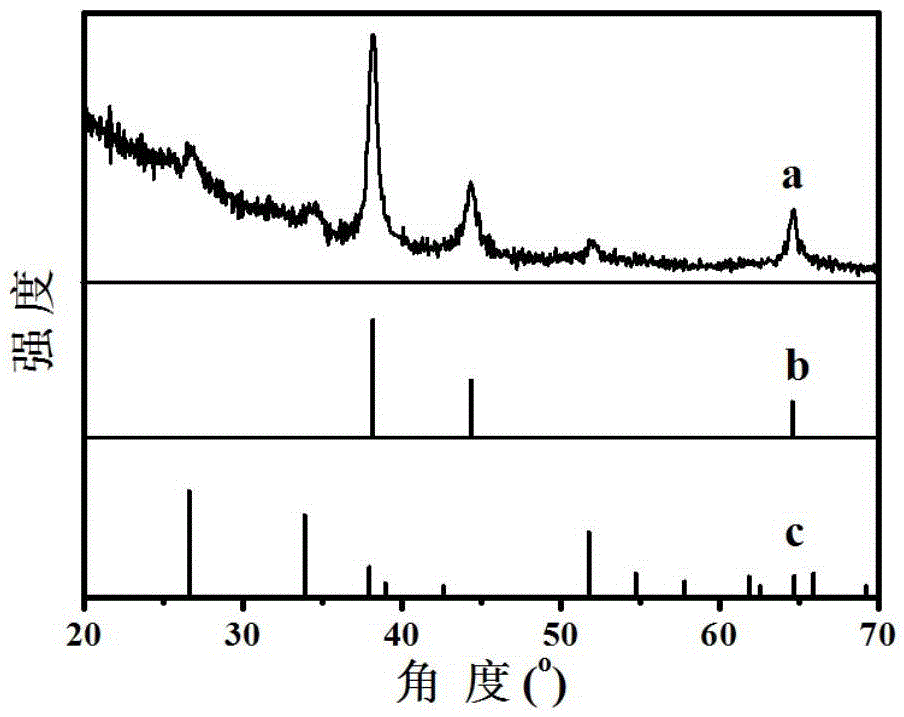

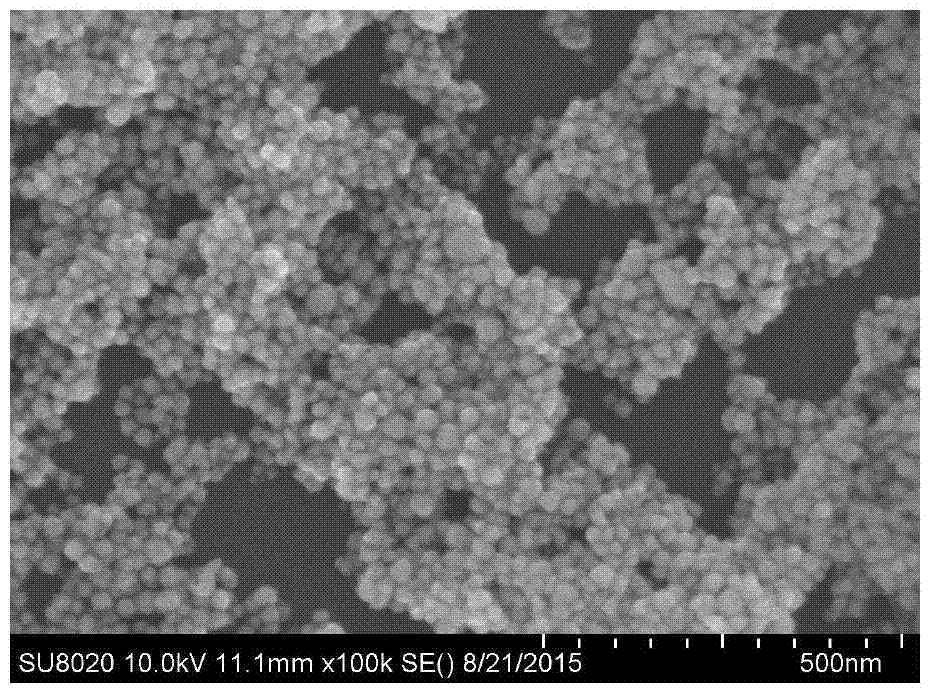

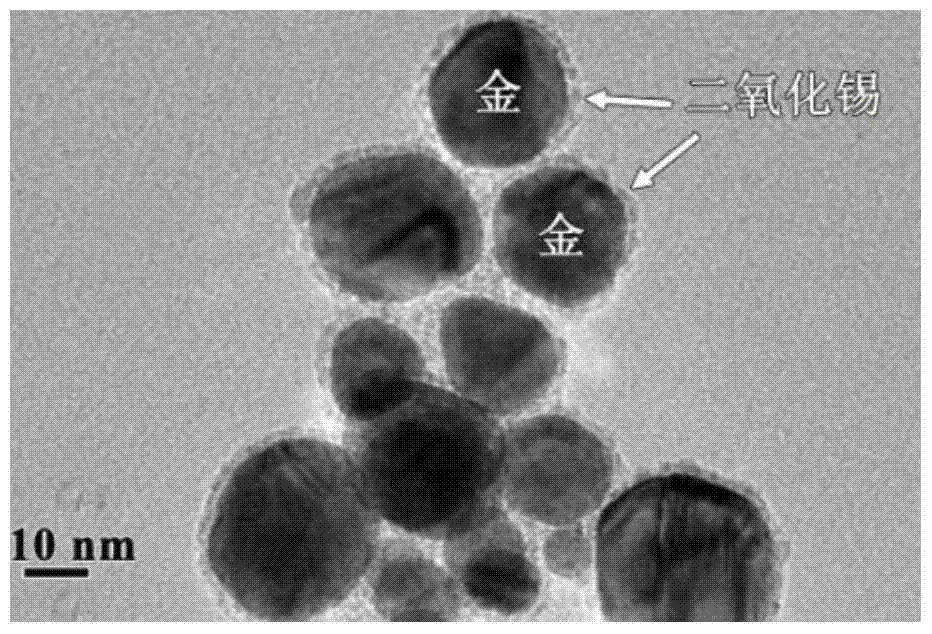

Gold-tin oxide core shell structure composite nano material and preparing method thereof

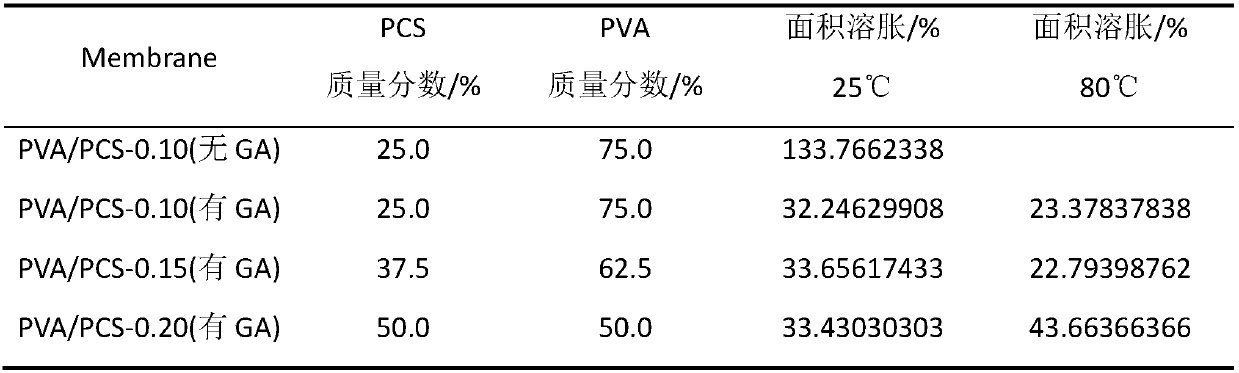

InactiveCN105458247AImprove gas sensitivityReasonable structureTransportation and packagingMetal-working apparatusNanoparticleCombustible gas

The invention discloses a gold-tin oxide core shell structure composite nano material and a preparing method thereof. The material is formed in the manner that gold nano particles are coated with tin oxide. The particle size of the material is 12-26 nm, the particle size of the gold nano particles is 10-20 nm, the thickness of a tin oxide layer is 1-3 nm, and the tin oxide layer is composed of oxide tin particles with the particle size of 1-3 nm. The method includes the steps that a gold target is put in a stirred stannic chloride aqueous solution, lasers with the wavelength of 532 nm or 1064 nm, the repetition frequency of 1-20 Hz, the pulse width of 5-15 ns and the power of 40-120 mJ / pulse are used for irradiating the gold target for at least one minute, and a mixed colloidal solution is obtained; and then, the mixed colloidal solution is subjected to solid-liquid separation, washing and drying in sequence, and the target product is obtained. The gold-tin oxide core shell structure composite nano material has higher gas sensitivity and is extremely easily and widely applied to the field of detection of poisonous and harmful gas and flammable and combustible gas in a commercialized manner.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

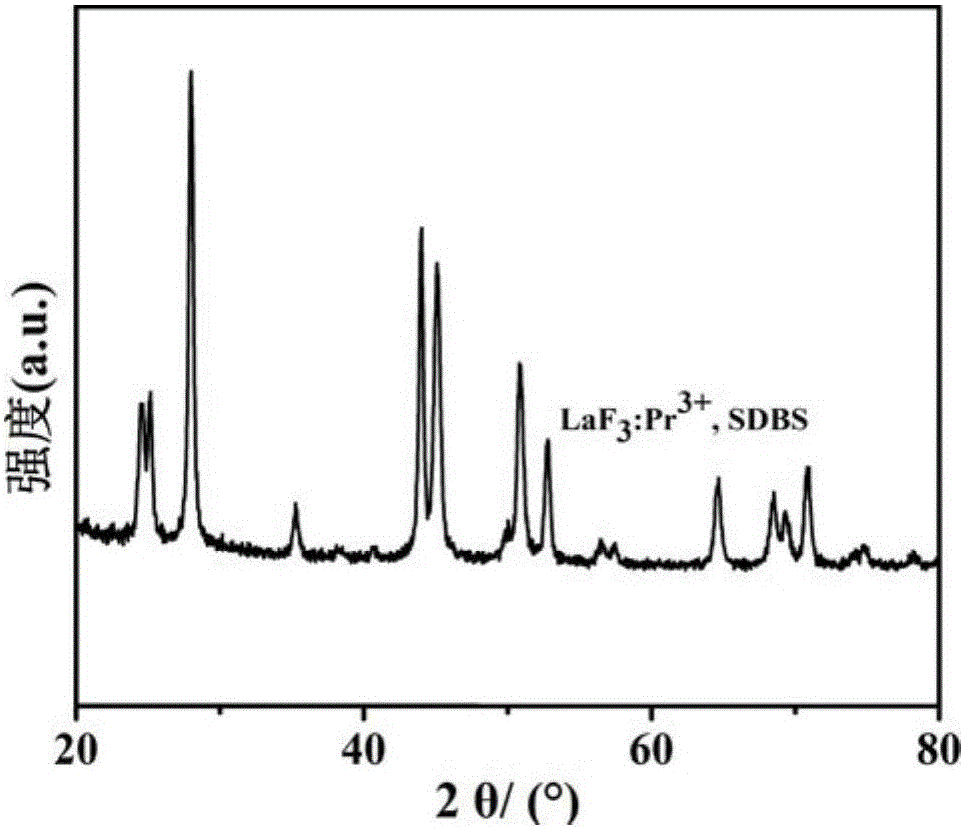

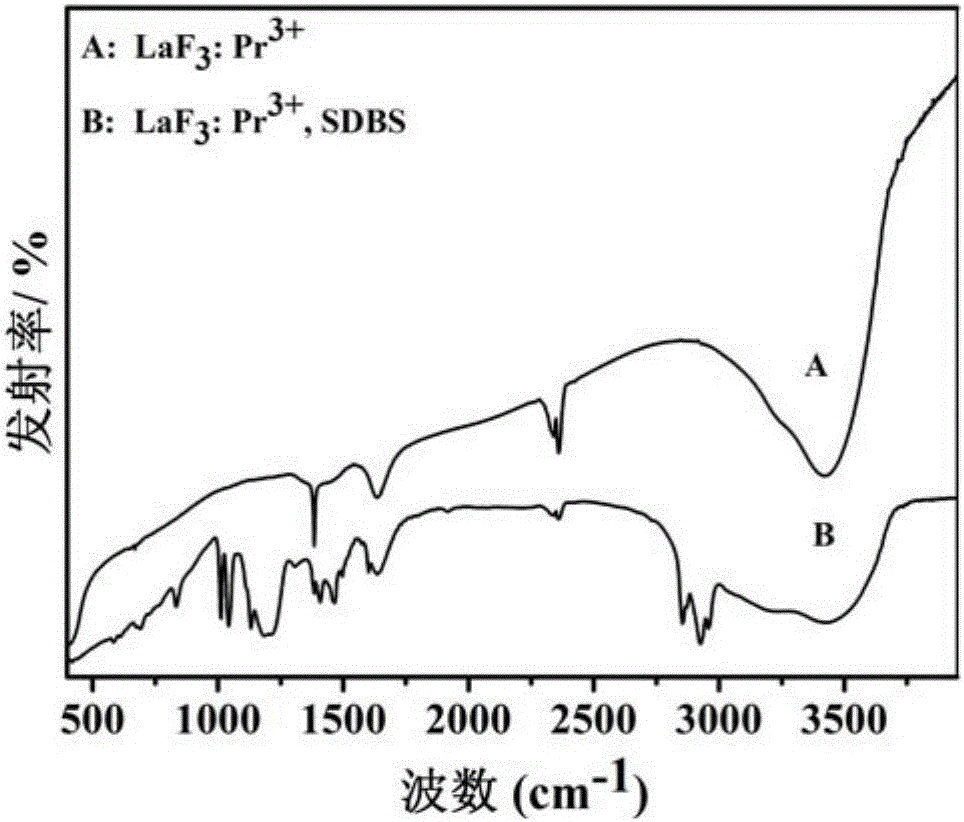

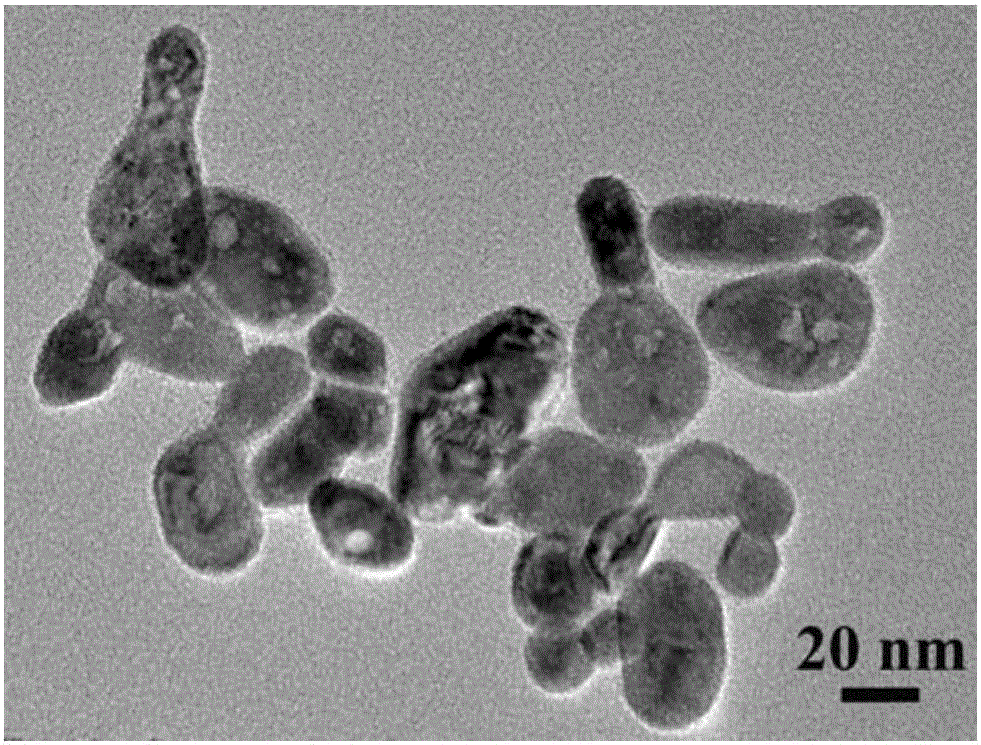

Praseodymium-doped lanthanum fluoride organic-inorganic hybrid nanometer powder and its preparation method and use

ActiveCN106085432ASimple processExtensive commercial applicationEnergy efficient lightingLuminescent compositionsLanthanum fluorideOrganic inorganic

The invention discloses praseodymium-doped lanthanum fluoride organic-inorganic hybrid nanometer powder and its preparation method and use. The nanometer powder has a chemical formula of La1-xPrxF3 and x is greater than or equal to 10<-3> and less than or equal to 10<-1>. Fluorine in La1-xPrxF3 and carbon in a surfactant are connected through a C-F chemical bond to form an organic-inorganic hybrid material and the organic-inorganic hybrid is powder with particle sizes of 20-70nm. The preparation method comprises stirring corresponding amounts of lanthana, praseodymia and a nitric acid aqueous solution according to the chemical formula of La1-xPrxF3 to obtain a rare earth nitrate aqueous solution with the total rare earth ion concentration of 0.1-0.5mol / L, orderly adding a surfactant aqueous solution and ammonium fluoride into the rare earth nitrate aqueous solution, carrying out stirring to obtain a precursor solution, carrying out a reaction process on the precursor solution in an enclosed state to obtain a reaction solution, carrying out solid-liquid separation on the cooled reaction solution, then carrying out washing and then carrying out drying on to obtain a desired product. The praseodymium-doped lanthanum fluoride organic-inorganic hybrid nanometer powder directly emits white light under UV excitation and is conducive to wide commercial application in indoor LED illumination.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

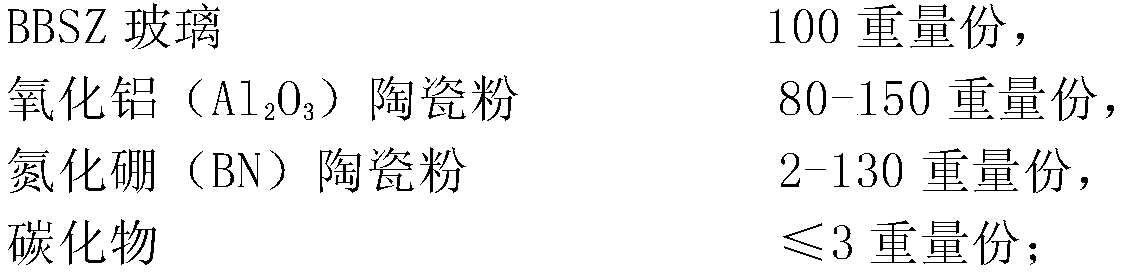

Low-temperature co-fired ceramic material of double-phase ceramic filler, and preparation method thereof

The invention discloses a low-temperature co-fired ceramic material of a double-phase ceramic filler, and a preparation method thereof. The material comprises, by weight, 100 parts of BBSZ glass, 80-150 parts of aluminum oxide ceramic powder, 2-130 parts of boron nitride ceramic powder and 3 parts or below of carbide, wherein the particle size of the aluminum oxide ceramic powder is 1-2 [mu]m, andthe particle size of the boron nitride ceramic powder is less than or equal to 400 nm. The method comprises the following steps: mixing bismuth trioxide, boron oxide, silicon oxide and zinc oxide, melting the obtained mixture, carrying out water-cooling quenching, ball-milling the obtained BBSZ glass slag into powder, and mixing the powder with the aluminum oxide ceramic powder and the boron nitride ceramic powder, and then sequentially carrying out joint ball milling on the obtained mixed powder, a solvent, a dispersing agent, a binding agent, a plasticizer and a homogenizing agent, carryingout tape casting on the obtained slurry in a mold, drying the cast slurry, sequentially placing obtained raw ceramic chips at different temperatures to remove organic additives, and carrying out sinter molding to obtain the target product. The material has excellent heat conduction and dielectric properties, and can be easily and widely commercially applied to the field of electronic packaging.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

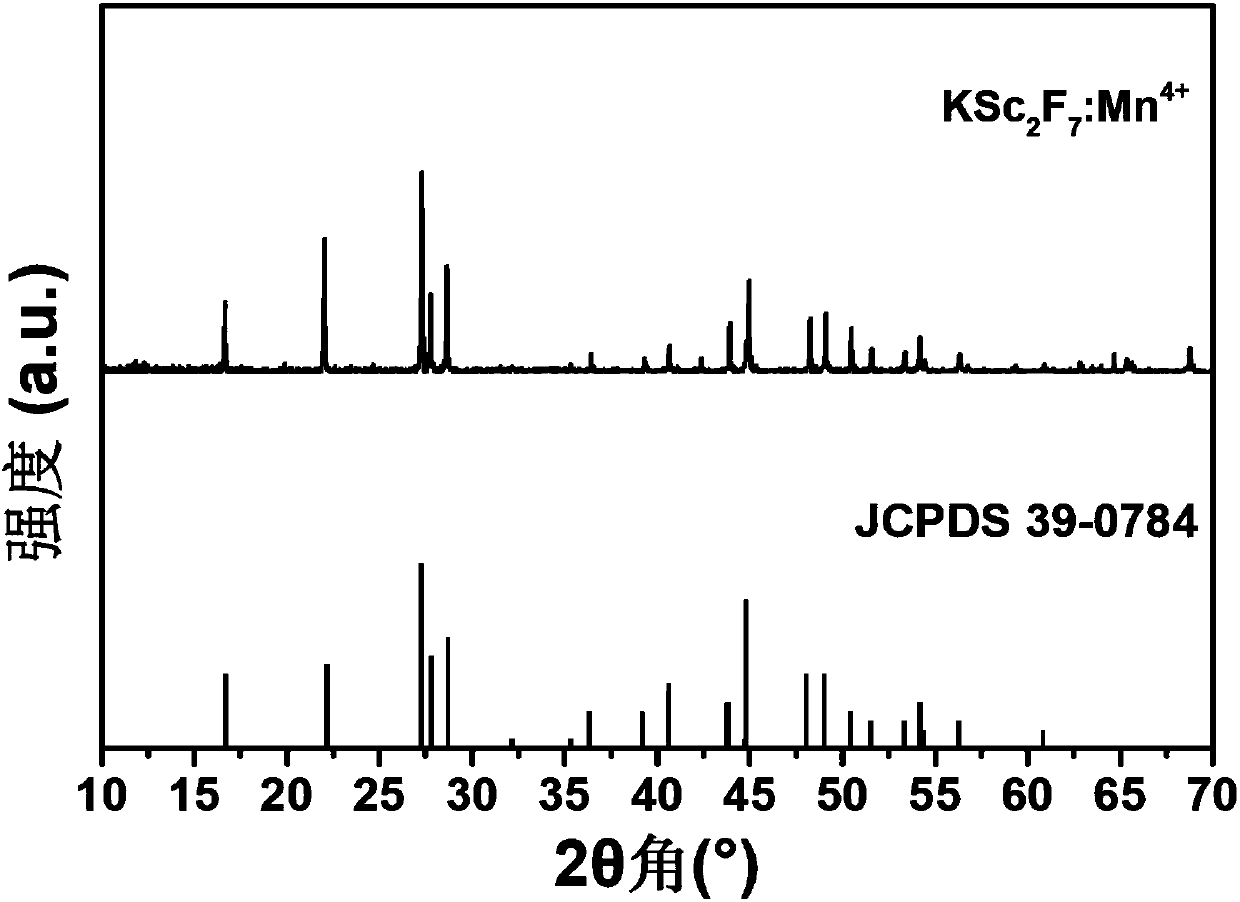

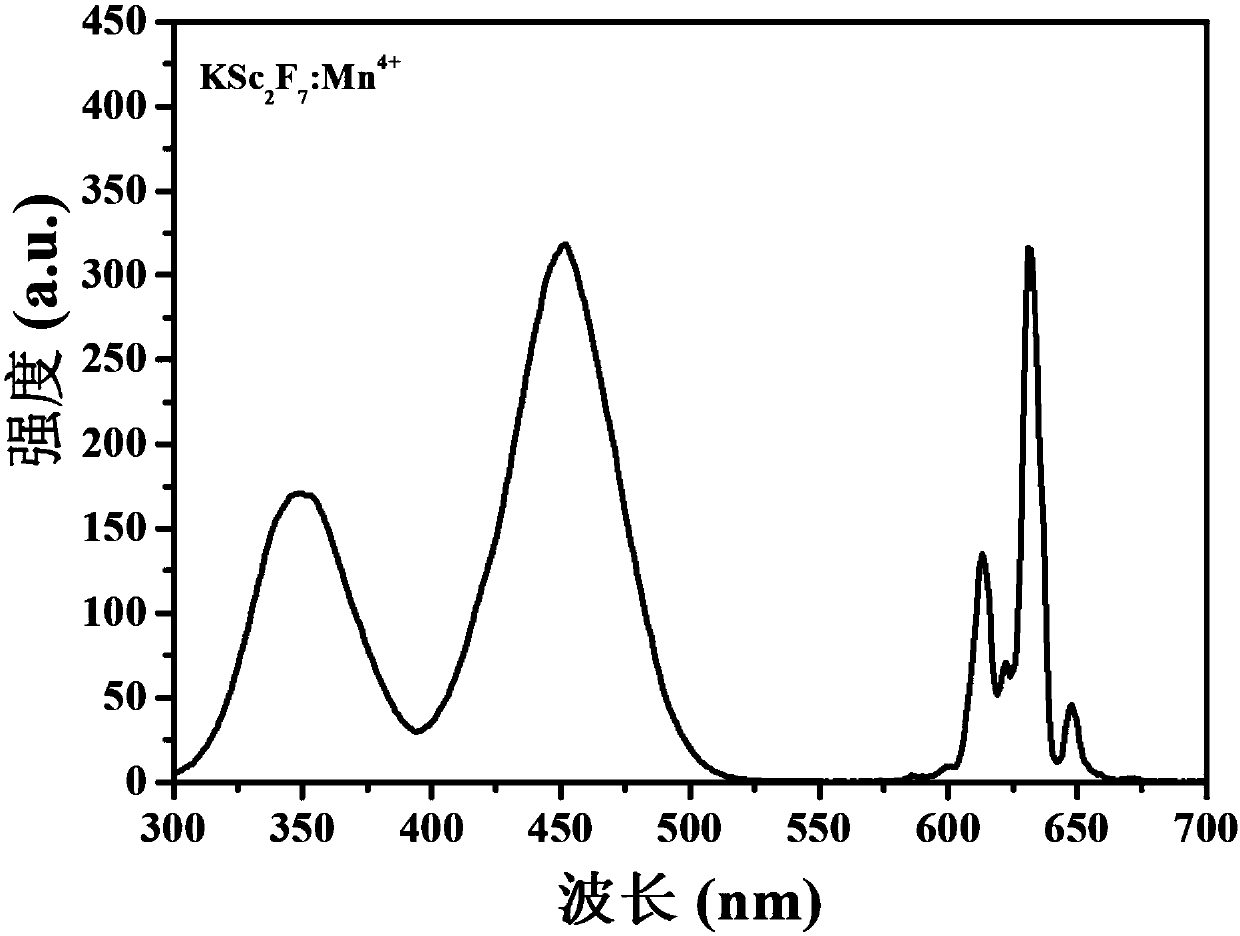

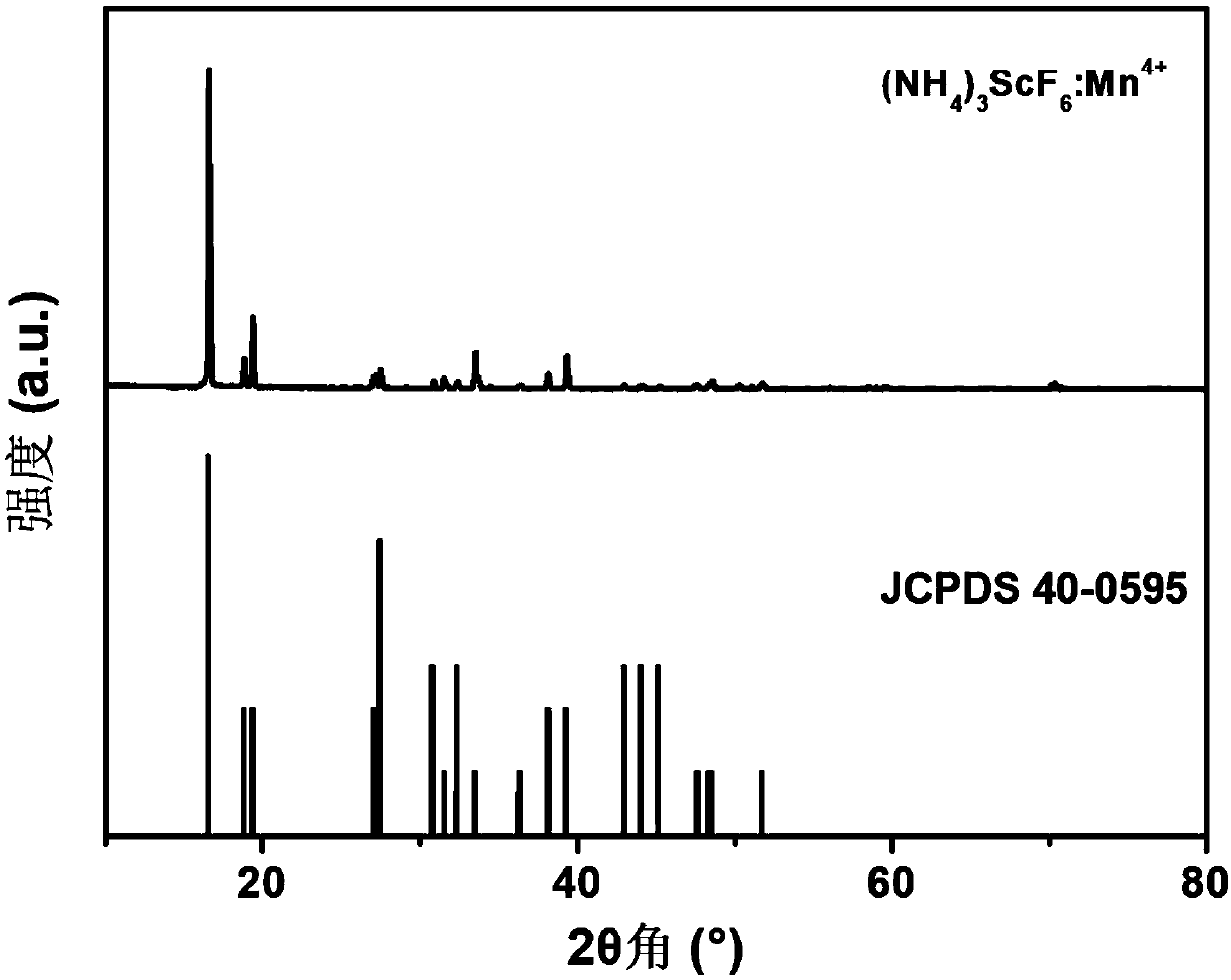

Blue-light-excited Mn<4+>-doped fluoscandate red-light-emitting material and preparation method thereof

InactiveCN107722986ARich varietyExtensive commercial applicationLuminescent compositionsSemiconductor devicesUltraviolet lightsEffect light

The invention discloses a blue-light-excited Mn<4+>-doped fluoscandate red-light-emitting material and a preparation method thereof. The blue-light-excited Mn<4+>-doped fluoscandate red-light-emittingmaterial has a chemical formula of A<x>Sc<y>F<z>: Mn<4+>, wherein A is more than one selected from a group consisting of Li, Na, K, Rb, Cs, NH<4>, Be, Mg, Ca, Sr, Ba and Zn; x is no less than 1 and no more than 3; y is no less than 1 and no more than 3; and z is no less than 5 and no more than 7. The Mn<4+>-doped fluoscandate red-light-emitting material can be effectively excited by ultraviolet light with a wavelength of 300 to 400 nm and blue light with a wavelength of 400 to 500 nm and generate narrowband red light emission in a wavelength band of 575 to 675 nm, has high luminous efficiencyand is applicable to the fields of white-light LED lighting and backlight displays. According to the invention, a co-precipitation method is adopted to prepare the Mn<4+>-doped fluoscandate red-light-emitting material; and the preparation method has the advantages of simple preparation process, short preparation time, low usage amount of hydrofluoric acid, etc.

Owner:SOUTH CHINA UNIV OF TECH

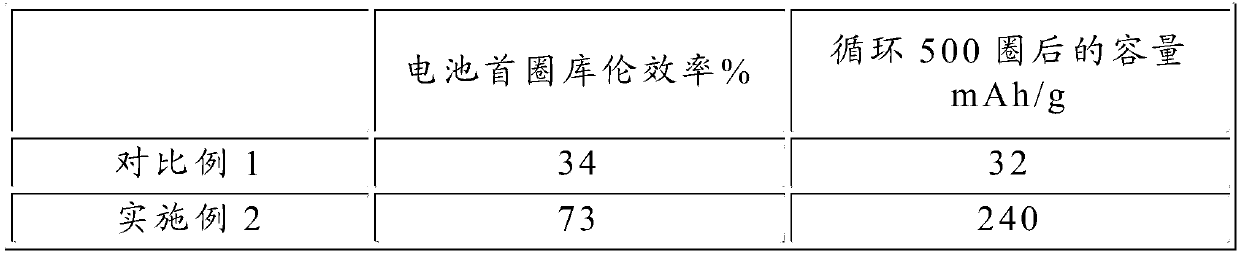

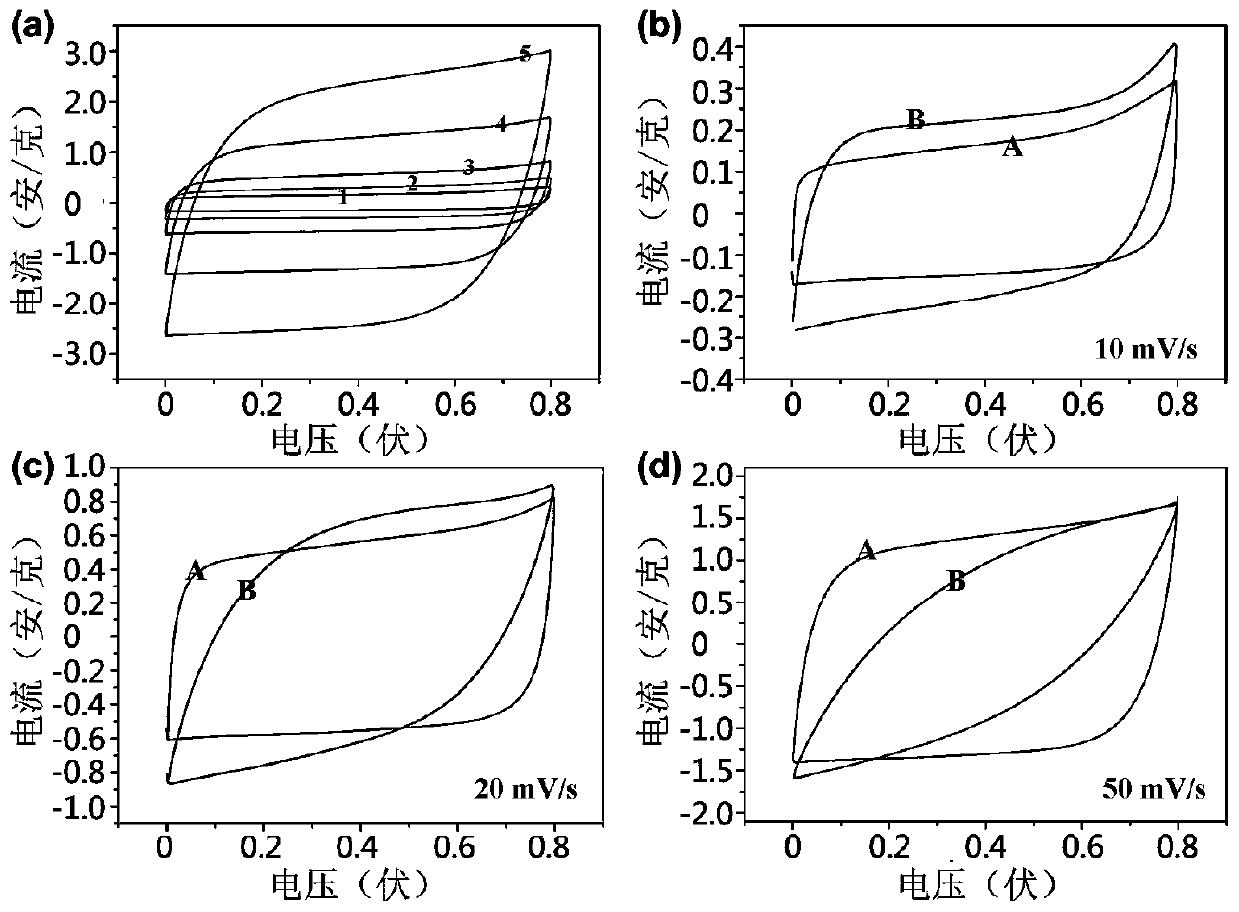

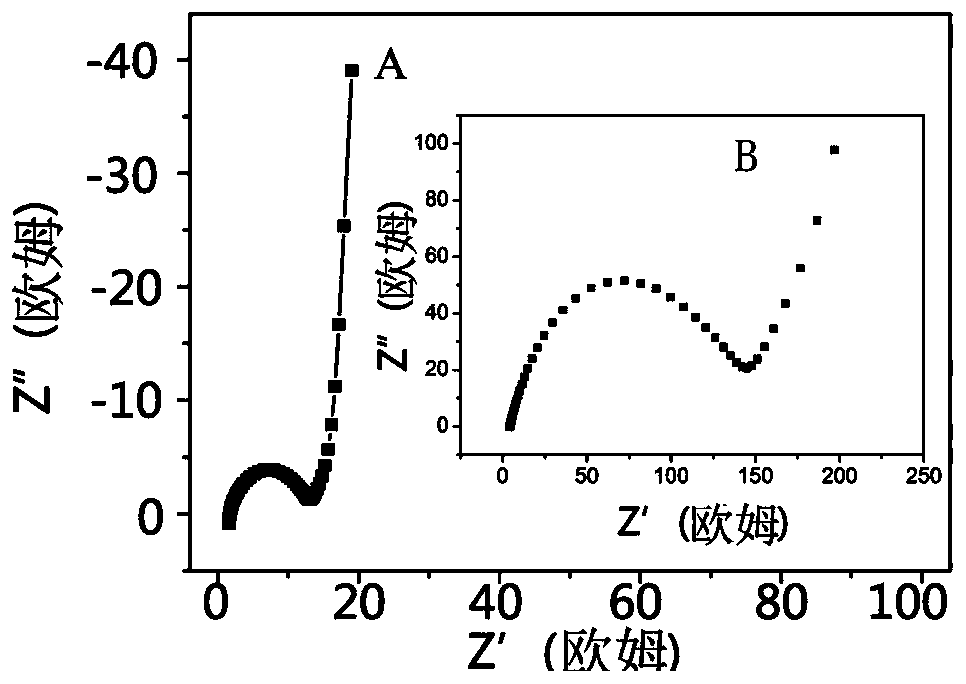

Sodium ion battery electrode material, electrode and battery

ActiveCN105514438BHigh reversible capacityLow costNon-aqueous electrolyte accumulatorsCell electrodesElectrical batterySodium-ion battery

The invention provides a sodium-ion battery electrode material. The sodium-ion battery electrode material is a conductive porous material, containing holes are formed in the conductive porous material, the effective aperture of the containing holes ranges from 0.2 nm to 50 nm, the specific surface area of the containing holes ranges from 0.5 m<2> / g to 2,500 m<2> / g, the hole volume of the containing holes ranges from 0.0102 cm<3> / g to 1.8 cm<3> / g, and the hole depth of the containing holes ranges from 0.2 nm to 5 nm. The invention further provides an electrode and battery prepared from the electrode material. The electrode material is provided with a good sodium ion disembedding channel, groups of sodium ions and a solvent cannot enter the holes, and the battery achieves high reversible capacity and good rate capability.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

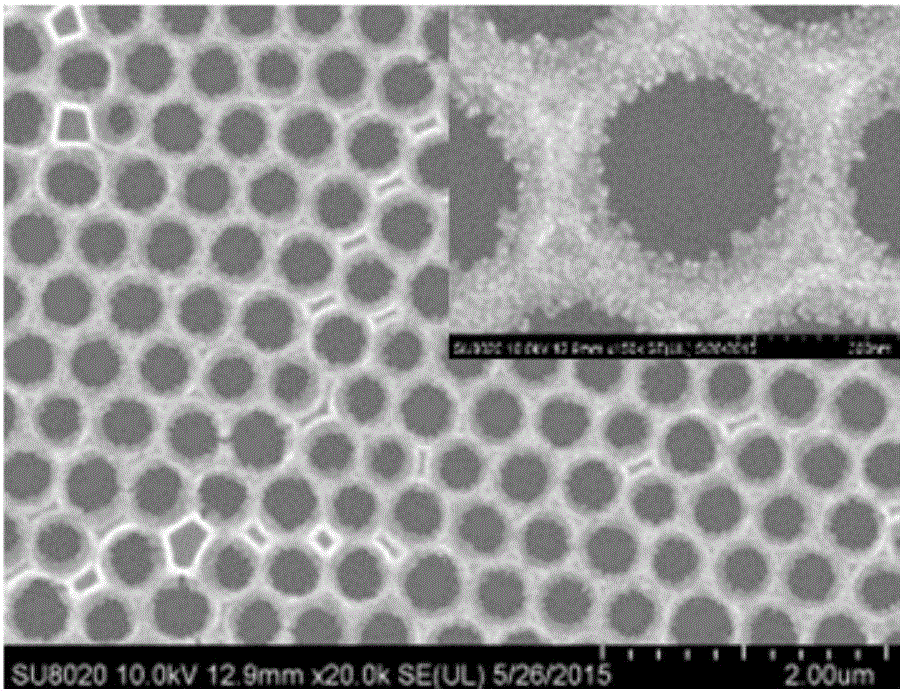

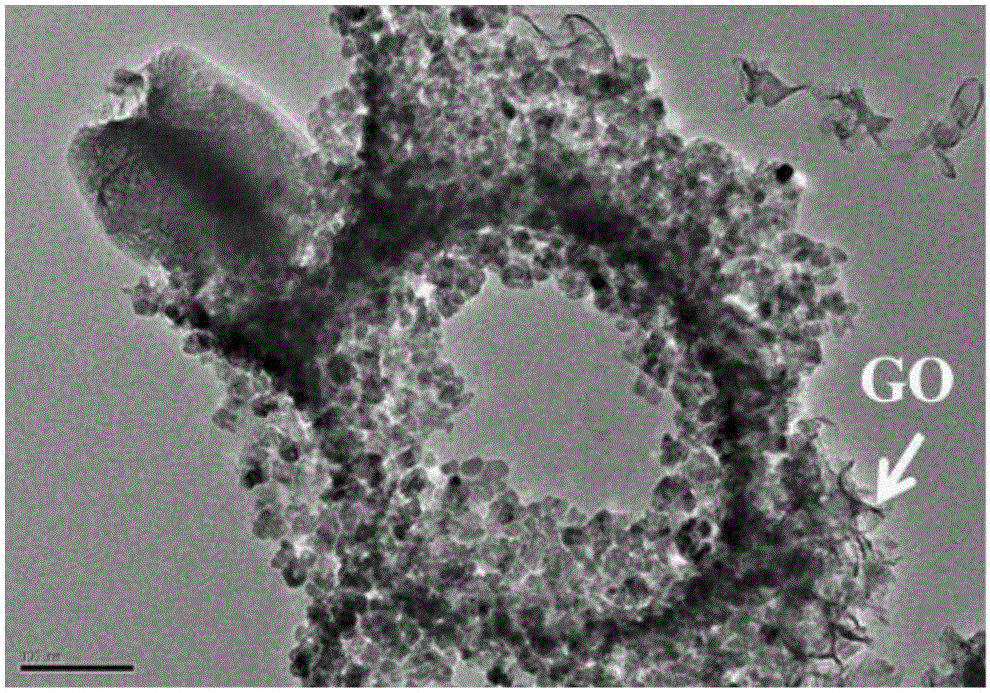

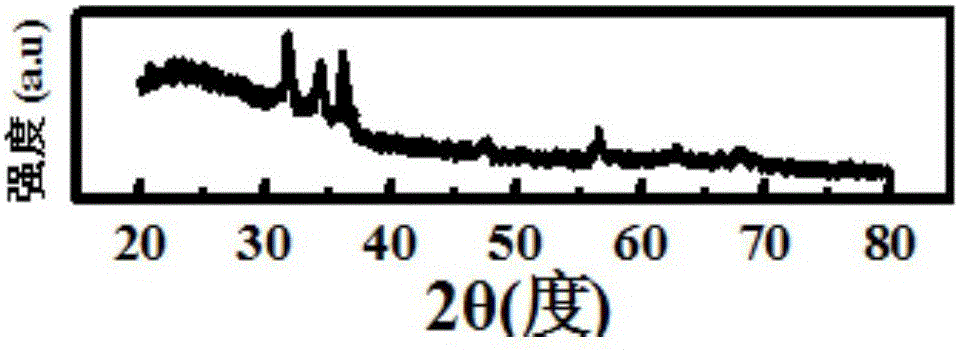

Graphene oxide modified orderly porous zinc oxide composite film and preparation method thereof

InactiveCN106044845AEasy to prepareGood gas sensing or catalytic performanceMaterial nanotechnologyZinc oxides/hydroxidesPhotocatalysisAqueous solution

The invention discloses an ordered porous zinc oxide composite film modified by graphene oxide and a preparation method thereof. The composite film is ordered porous zinc oxide decorated with graphene oxide nanosheets, wherein the ordered porous zinc oxide has a pore diameter of 50-4900nm and a pore wall thickness of 10-100nm, which is composed of zinc oxide particles with a particle size of 5-50nm Composition; the method is to firstly mix the graphene oxide aqueous solution and the zinc salt aqueous solution to obtain the precursor solution, then place the single-layer colloidal crystal template in the precursor solution, use the substrate to pick it up, and obtain the surface covered with it. Attach the substrate of the single-layer colloidal crystal template of the precursor solution, and then dry the substrate covered with the single-layer colloidal crystal template of the precursor solution on the surface, and then place it in a protective atmosphere for annealing , to obtain the target product. It can be easily and widely commercialized in the fields of photocatalysis, sensors, and electronic devices.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

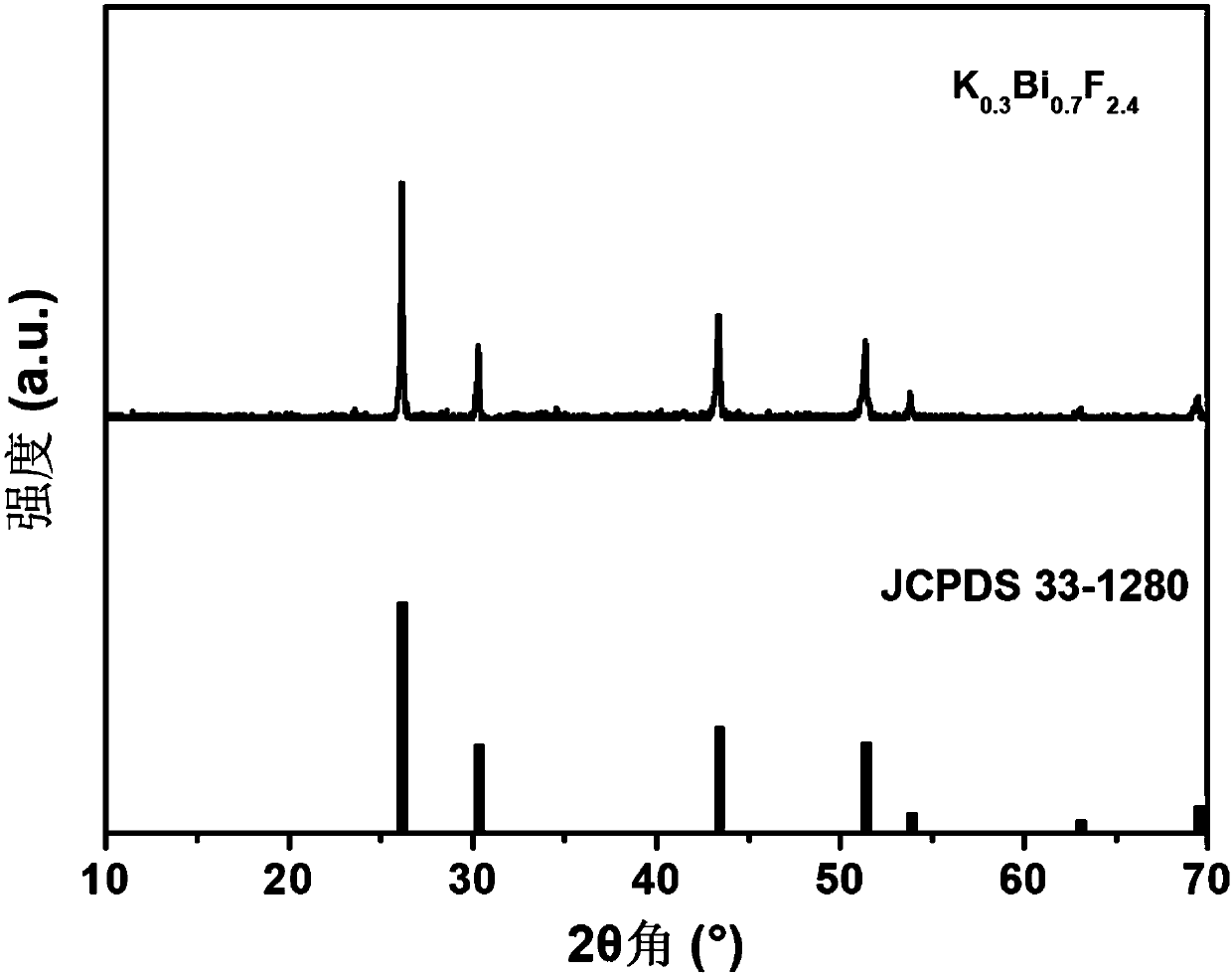

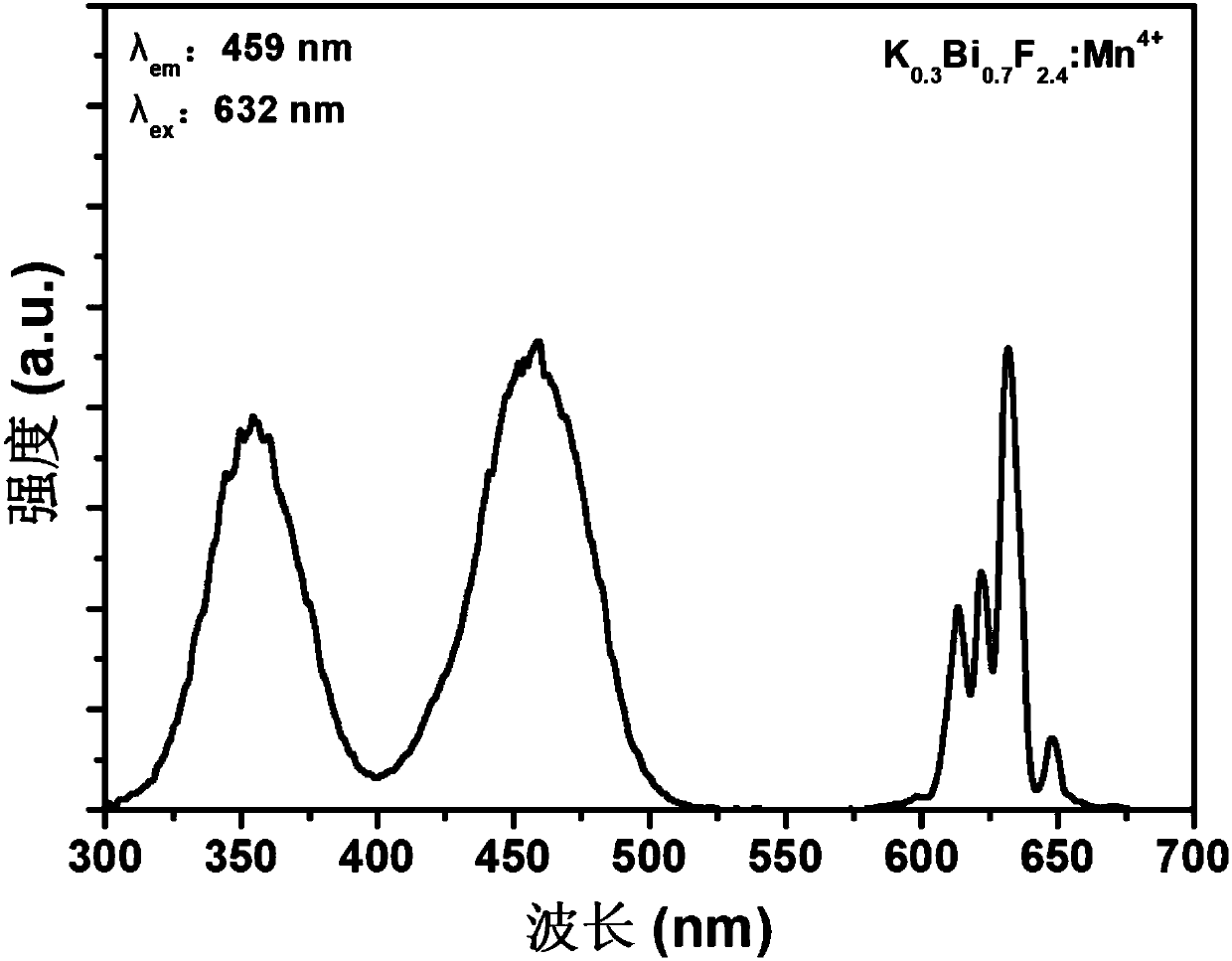

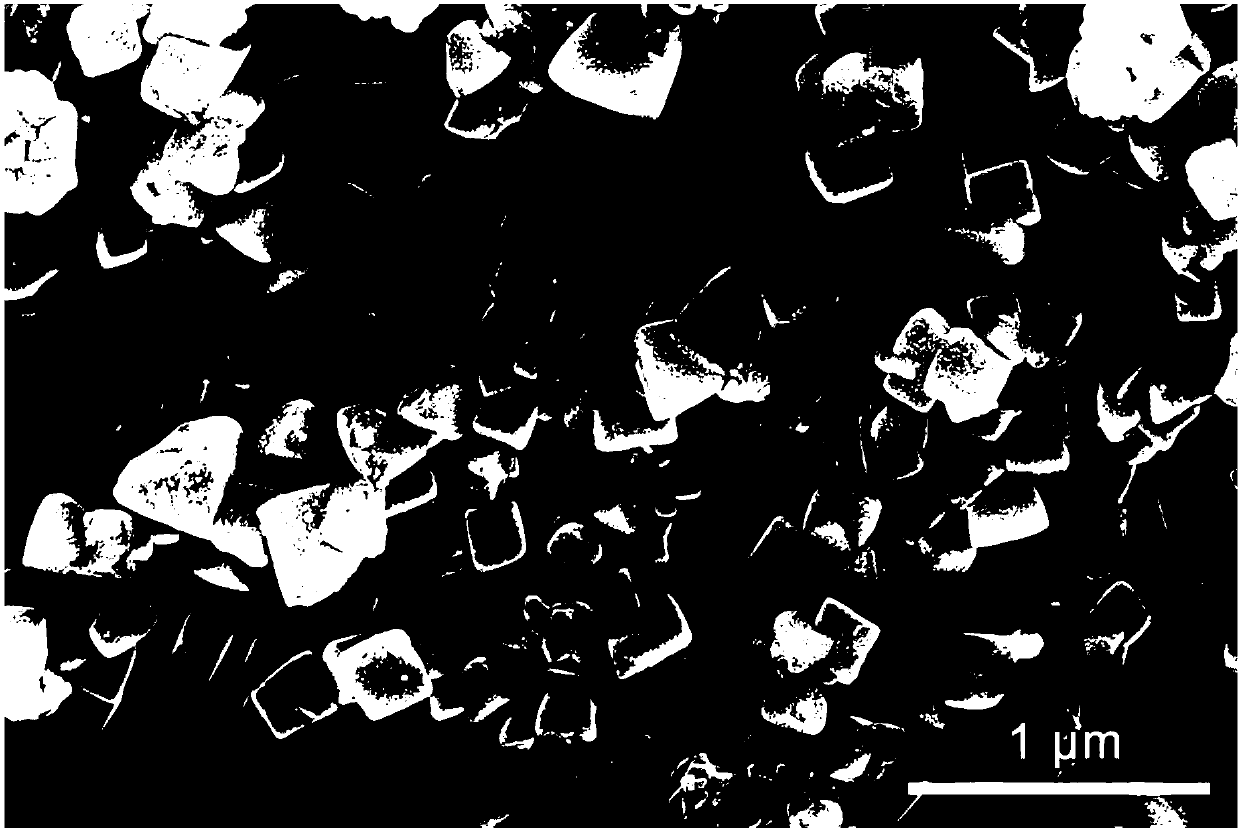

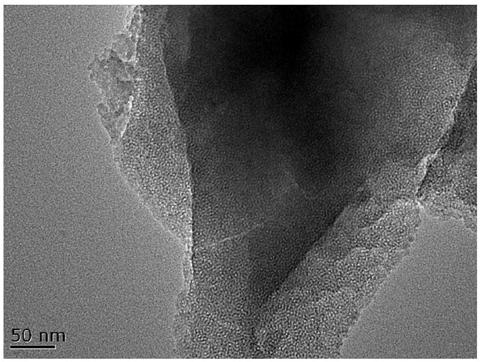

Blue-light-excited Mn4<+>-doped fluorine bismuthate red emitting material and preparation method thereof

InactiveCN107779192AUniform particle size distributionSimple preparation processEnergy efficient lightingLuminescent compositionsIon exchangeCoprecipitation

The invention discloses a blue-light-excited Mn4<+>-doped fluorine bismuthate red emitting material and a preparation method thereof. The chemical formula of the Mn4<+>-doped fluoride red emitting material is A(i)x( / i)Bi(i)y( / i)F(i)z( / i):Mn4<+>, wherein A is more than one of Li, Na, K, Rb, Cs, NH4, Be, Mg, Ca, Sr, Ba and Zn, (i)x( / i) is greater than 0 and less than or equal to 0.5, (i)y( / i) is greater than 0.5 and less than or equal to 1, and (i)z( / i) is greater than 2 and less than or equal to 3. The Mn4<+>-doped fluorine bismuthate red emitting material has the good luminous efficiency, andcan be excited by the blue light to emit the red light, and extensively applied to the fields of white light LED illumination and backlight display, and is capable of effectively improving the coloration performance of the current white light LED. The Mn4<+>-doped fluorine bismuthate red emitting material is prepared by using a coprecipitation method or an ion exchange method. The preparation technology is simple and easy, the condition is moderate, the cost is low, the usage amount of a hydrofluoric acid is small, and the material is suitable for the large-scale industrial production.

Owner:SOUTH CHINA UNIV OF TECH

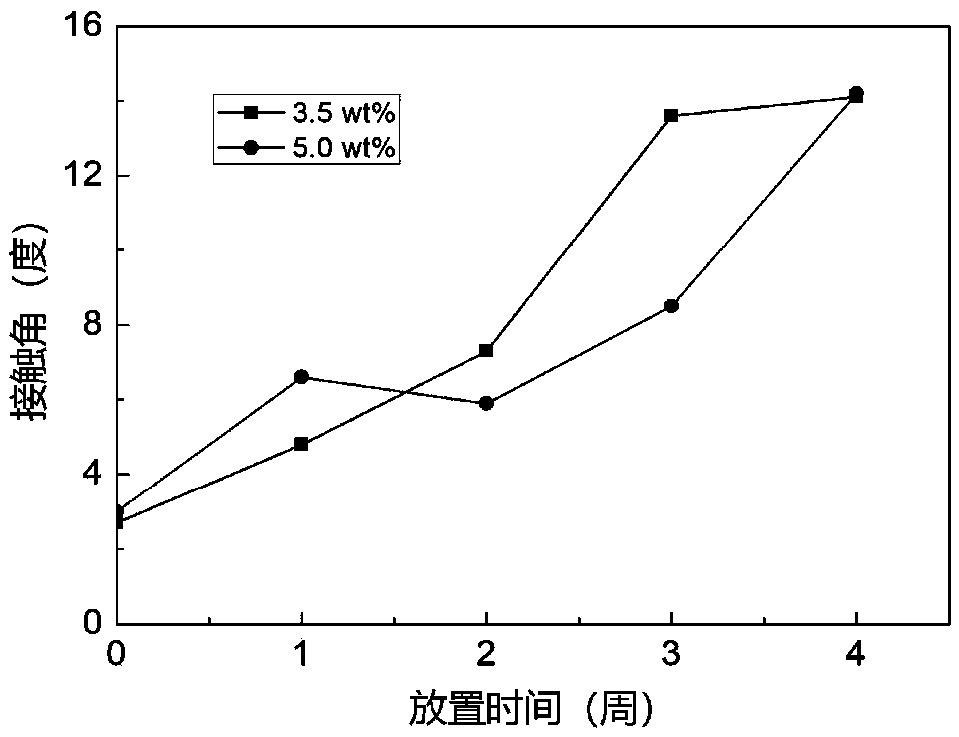

Durably-hydrophilic SiO2 nano mesoporous coating preparation method

The invention discloses durably-hydrophilic SiO2 nano mesoporous coating preparation method. The method includes: respectively preparing tetraethyl orthosilicate ethanol solution and nitric acid aqueous solution, and dropwise adding the nitric acid aqueous solution into the tetraethyl orthosilicate ethanol solution to obtain reaction precursor solution; then, stirring the reaction precursor solution, adding a pore forming agent into obtained SiO2 sol, stirring and aging to obtain sol for coating; finally, subjecting a glass substrate to dip coating in the sol for coating, airing, annealing thecoated glass substrate, cooling, and soaking in water to obtain a durably-hydrophilic SiO2 nano mesoporous coating on the glass substrate, wherein the durably-hydrophilic SiO2 nano mesoporous coatingin thickness of 100-200nm is formed by mesopores in diameter of 1-2nm. The durably-hydrophilic SiO2 nano mesoporous coating preparation method has advantages of energy saving, time saving and low manufacturing cost and can be easily, extensively and commercially applied to preparation of durably-hydrophilic SiO2 nano mesoporous coatings.

Owner:上海西源新能源技术有限公司

Indium oxide film material modified with aluminum oxide-coated palladium nanoparticles and its preparation method and application

The invention discloses an indium oxide thin-film material modified with aluminium oxide-coated palladium nanoparticles and a preparation method and an application thereof. according to the material, an indium oxide monolayer porous thin-film is modified with 1-100 micrograms / cm<2> of aluminium oxide-coated palladium nanoparticles, wherein pore diameter of the porous thin-film is 50-5000 nm; film thickness is 10-5000 nm; particle size of the aluminium oxide-coated palladium nanoparticles is 12-160 nm; layer thickness of aluminium oxide is 1-30 nm; and particle size of palladium particles is 10-100 nm. according to the method, the indium oxide monolayer porous thin-film is firstly obtained by an in-situ growth method; then, a palladium target is placed into an aluminium nitrate solution, and the palladium target is irradiated by the use of laser at wavelength of 532 nm or 1064 nm so as to obtain a mixed colloidal solution; afterwards, the mixed colloidal solution undergoes solid-liquid separation and washing; the obtained aluminium oxide-coated palladium nanoparticles are dispersed in ethanol, and the indium oxide monolayer porous thin-film is coated with the above solution obtained so as to prepare a target product. The product can be widely used in fields of selective detection of ethanol gas and gas sensing.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

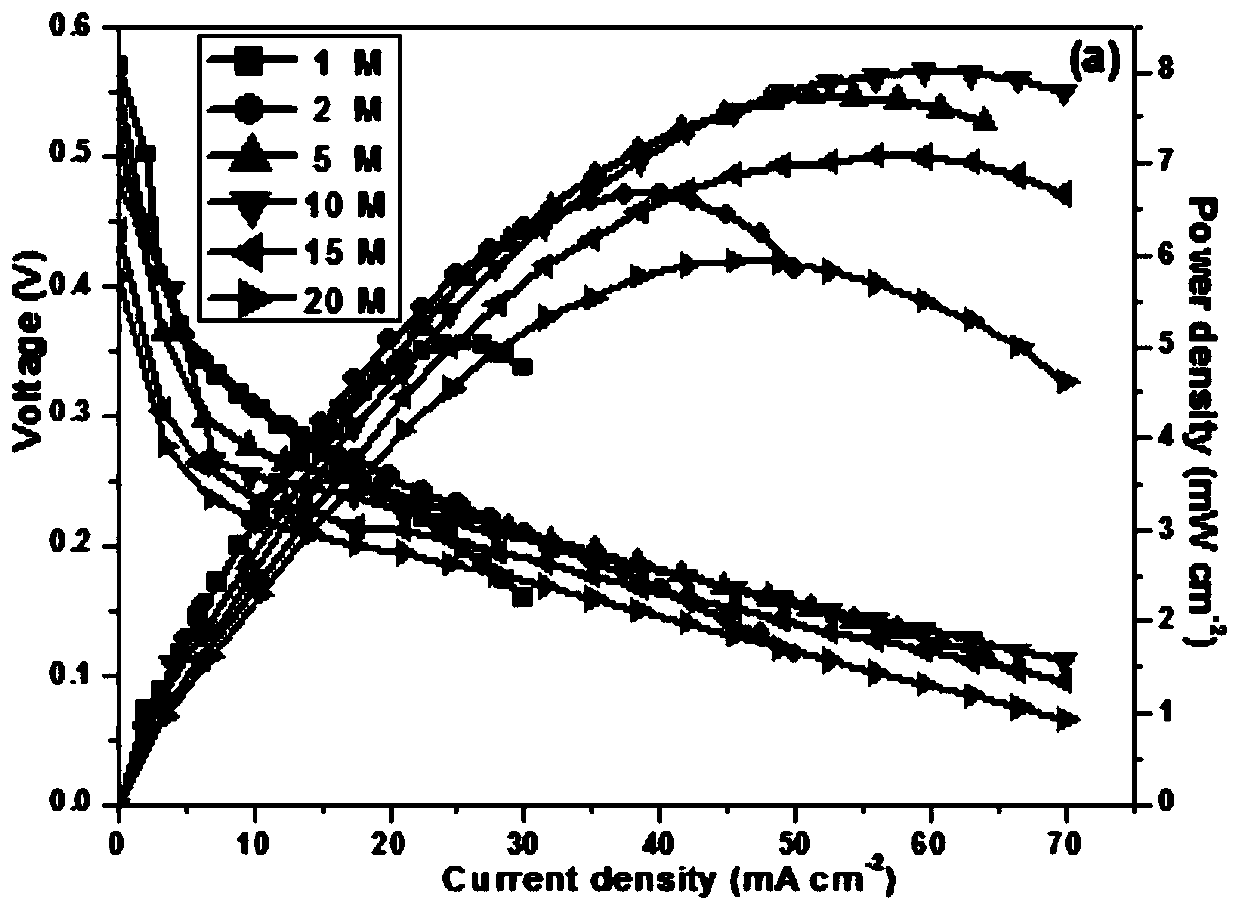

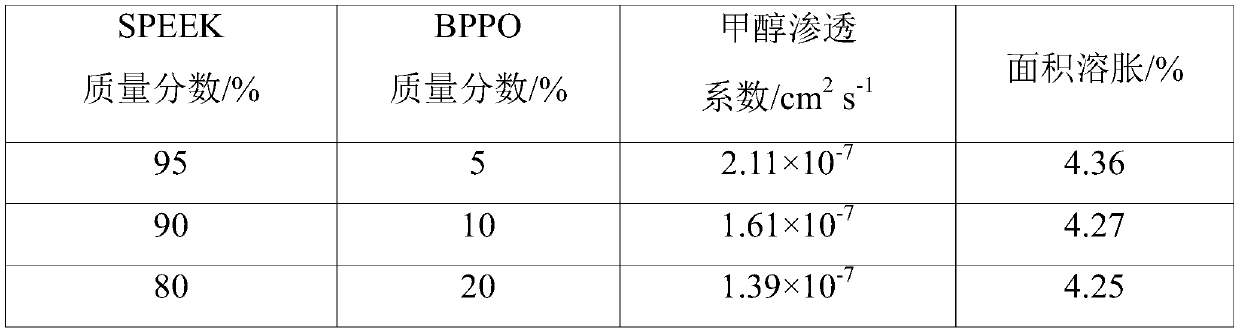

A kind of proton exchange membrane with high resistance alcohol performance and preparation method thereof

ActiveCN107482239BImprove severe swelling problemsImprove alcohol resistanceFinal product manufactureFuel cellsPoly ether ether ketoneFuel cells

The invention discloses a proton exchange membrane having high methanol resistance. The proton exchange membrane is produced from brominated polyphenylene ether and sulfonated polyetheretherketone. The invention also provides a production method and an application of the proton exchange membrane having high methanol resistance. The proton exchange membrane having high methanol resistance improves the problem of severe swelling of the sulfonated polyetheretherketone, can be applied to direct methanol fuel cells with a high methanol concentration, has a low methanol permeability, has high energy output under a high methanol concentration condition, greatly improves the energy density of the cells, and makes the cells have excellent performances. Additionally, the proton exchange membrane having high methanol resistance can be widely commercialized.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Preparation method of carbon nanofiber film without metal catalyst

The invention discloses a method for preparing a carbon nanofiber film without a metal catalyst. It first immerses the aluminum flakes in the copper nitrate aqueous solution, takes them out and dries them, then puts the obtained aluminum flakes loaded with copper nitrate on the surface in a ceramic container, and covers them with fragments of ceramic products. After that, the obtained bottoms are successively The ceramic container covered with copper nitrate-loaded aluminum flakes and ceramic product fragments is placed in a mixed atmosphere of acetylene and argon at 420-460°C for 20-40h, and the product is obtained on the surface of the ceramic container and ceramic product fragments . It not only produces carbon nanofiber films without metal catalysts, but also has the characteristics of low cost, large output, and easy industrial scale production. It can also realize the recycling of various ceramics and construction waste, thereby reducing environmental pollution; The prepared product has the characteristics of light weight, hydrophobicity and good mechanical properties, and is extremely easy to be widely commercialized and applied in the field of cleaning up various oil spills.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

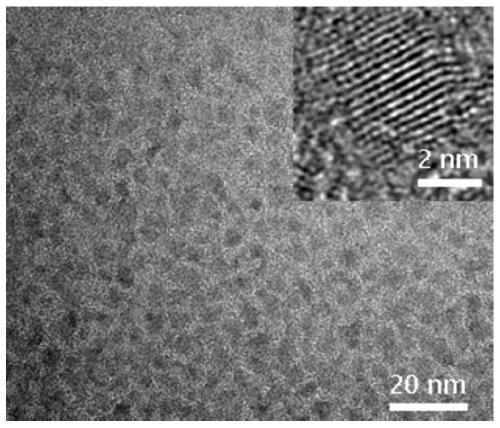

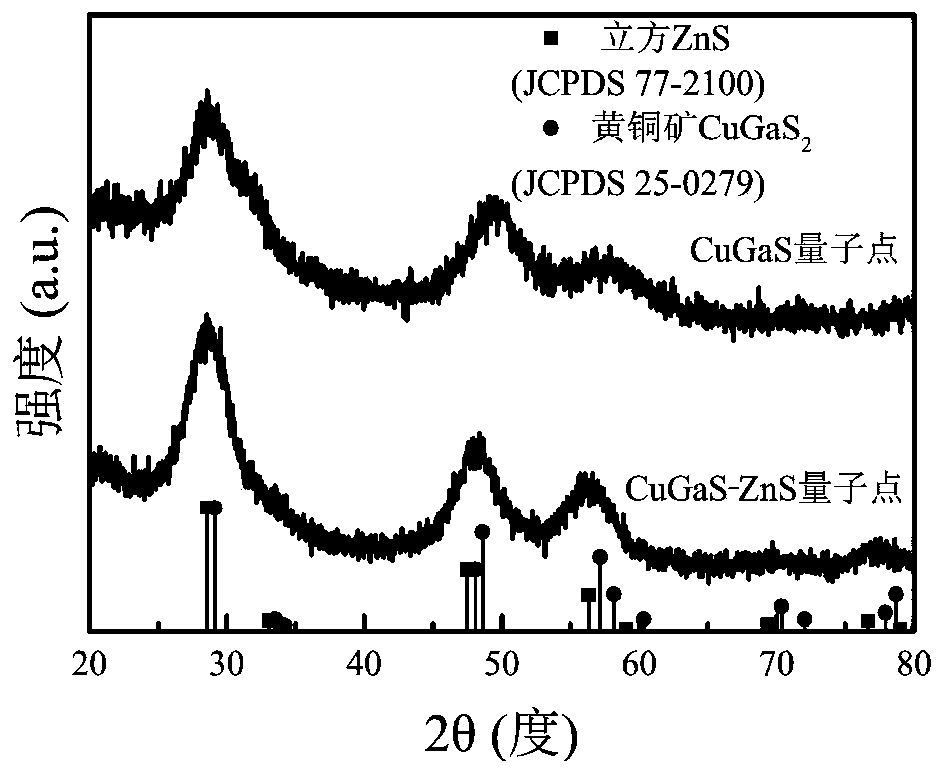

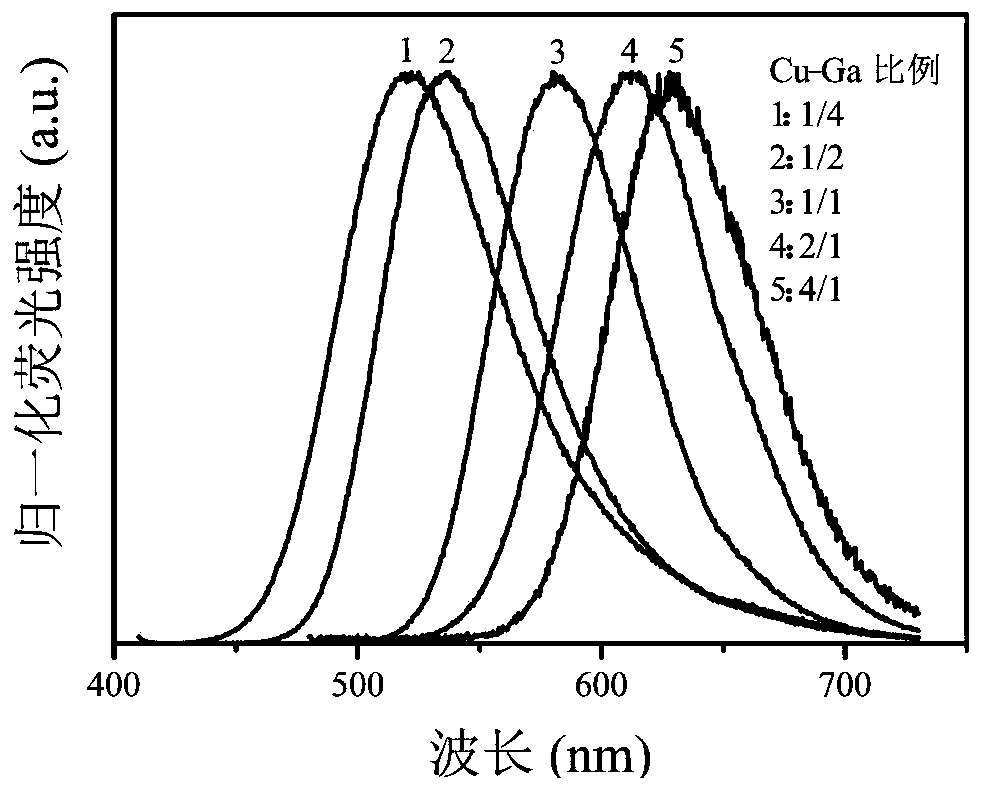

cugas-zns core-shell quantum dot material and preparation method thereof

ActiveCN107384371BBand Range ExpansionExtensive commercial applicationLuminescent compositionsPhotoluminescenceStimulated emission

The invention discloses a CuGaS-ZnS core-shell structure quantum-dot material and a preparation method thereof. The material is prepared from a copper-gallium-sulfur quantum-dot core and a zinc sulfide shell, wherein the zinc sulfide shell externally wraps the copper-gallium-sulfur quantum-dot core; a chemical molecular formula of the core is CuxGa1.33-0.33xS2; the diameter of the core is 2nm to 10nm; the shell thickness of the zinc sulfide shell is 0.3nm to 3nm. The method comprises the following steps of firstly mixing a copper source, a gallium source and a sulfur source, then putting in an inert atmosphere, heating, carrying out heat preservation, raising a temperature, reacting to obtain a CuGaS quantum-dot reaction solution, afterwards, injecting a zinc precursor solution into the CuGaS quantum-dot reaction solution, carrying out the heat preservation, then adding n-hexane and ethanol into an obtained mixture, agitating to obtain a turbid solution, and carrying out solid-liquid separation treatment on the turbid solution, so that a target product is prepared. A stimulated emission spectrum of the CuGaS-ZnS quantum-dot material reaches the wide wavelength range of 520nm to 620nm; further, the position of a light emission peak of an output spectrum is adjustable; the quantum efficiency of a quantum dot of yellow-green light at a position, which is 550nm of the light emission peak, is up to 75 percent; the CuGaS-ZnS quantum-dot material is enabled to be extremely easily, widely and commercially applied to the fields of photoluminescent devices and electroluminescent devices.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

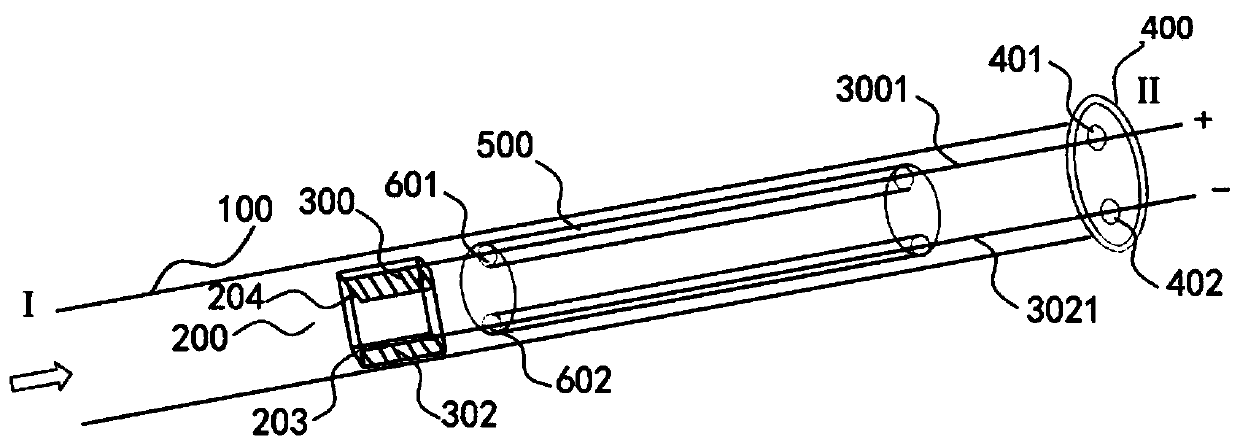

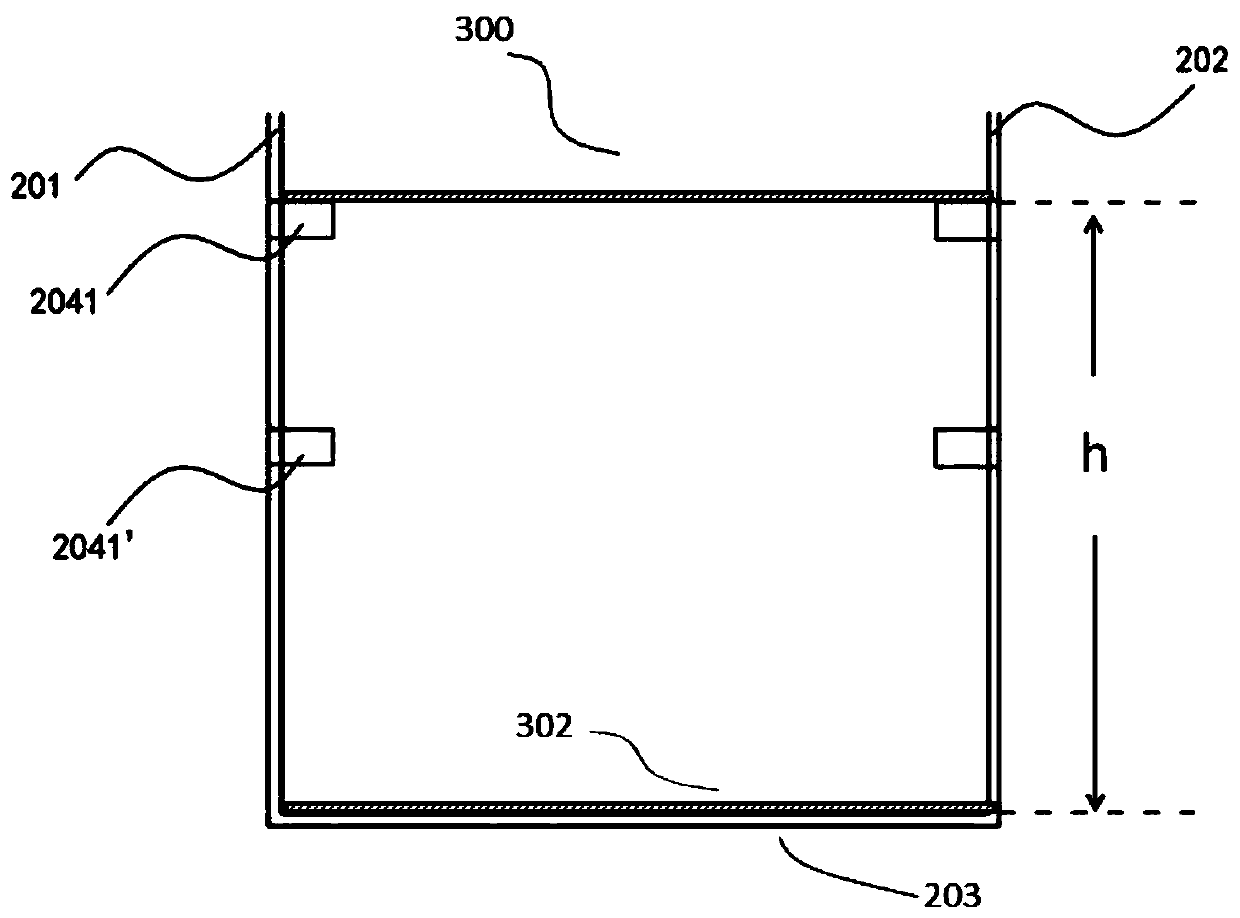

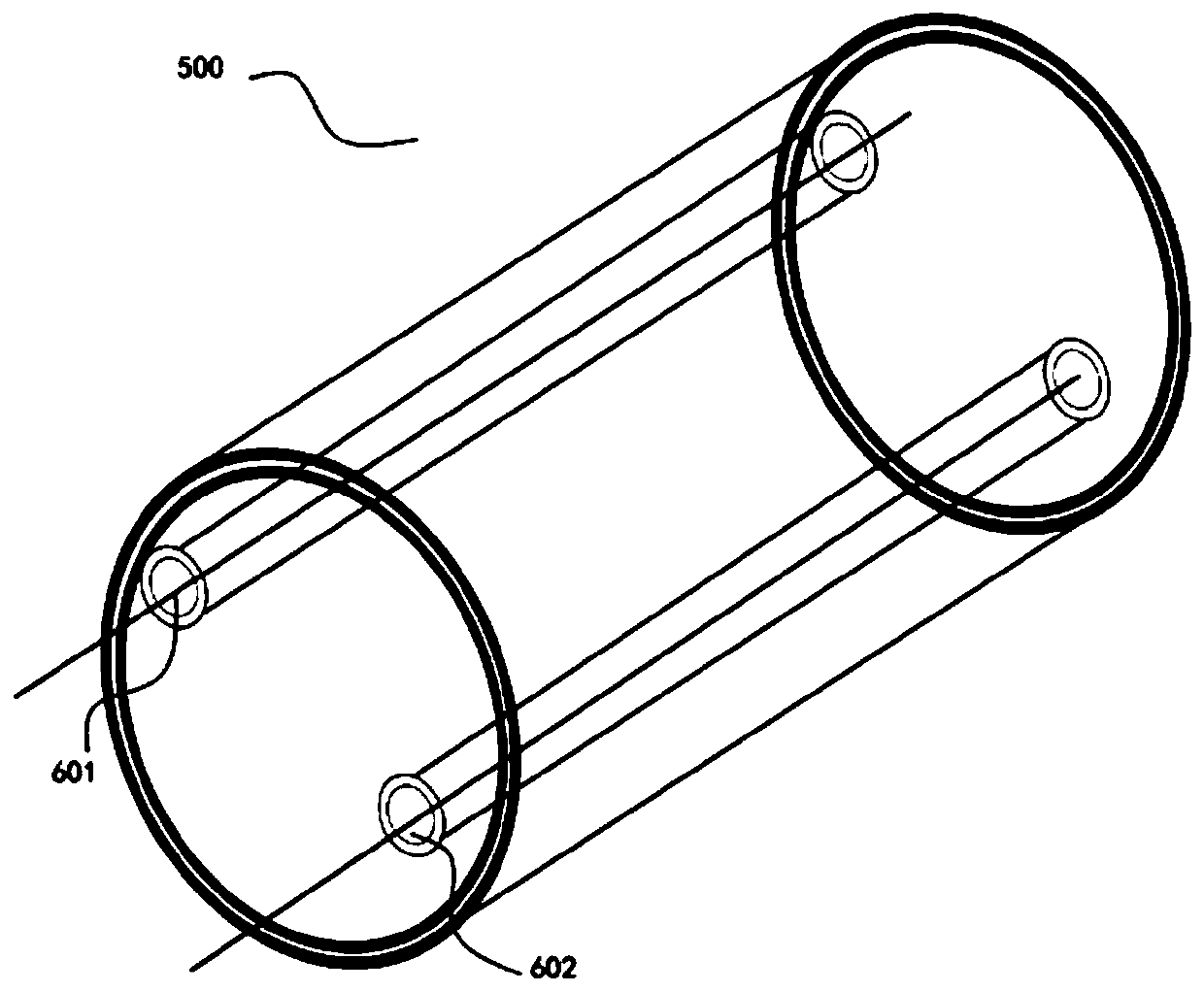

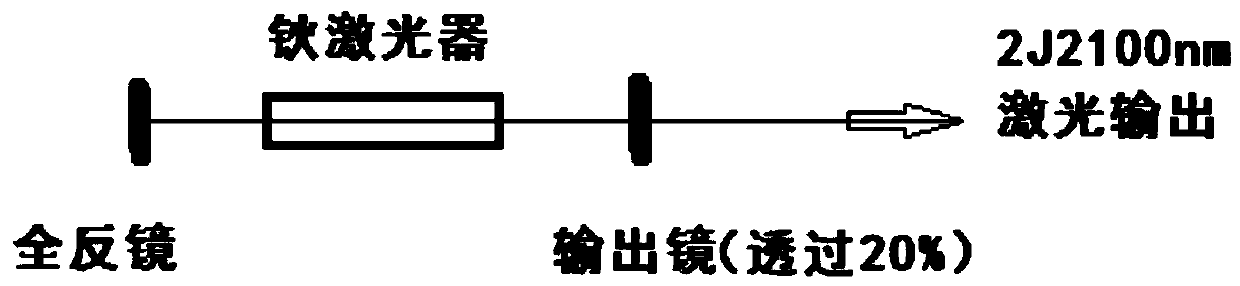

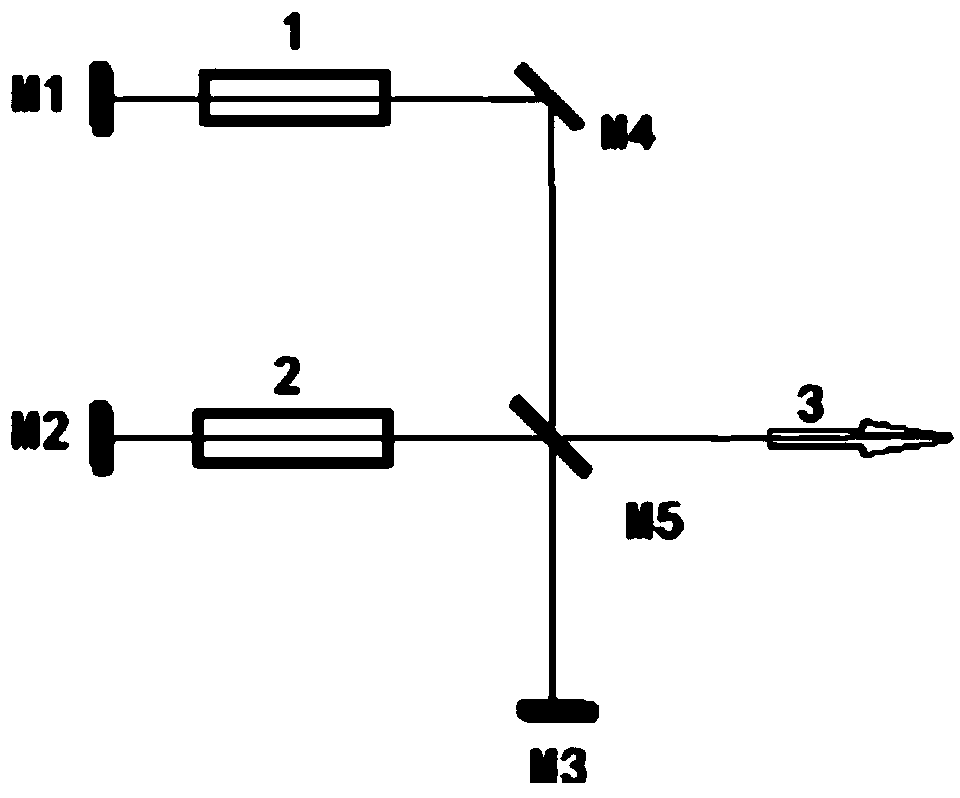

Narrow pulse holmium laser

The invention discloses a narrow pulse holmium laser. A pumping assembly composed of chromium-thulium-holmium-yttrium-aluminum-doped garnet crystals with the rod length thereof to be 15 mm and the roddiameter thereof to be 5 mm, a ceramic diffuse reflection light condensation cavity and an excitation source is arranged between the resonant cavity reflecting mirror of the laser. The resonant cavity reflecting mirror is composed of a first total reflective mirror (M1), a second total reflective mirror (M2), a third total reflective mirror (M3), a 45-degree total reflective mirror (M4), and a 45-degree semi-reflecting mirror (M5), wherein the surfaces of the first total reflective mirror (M1), the second total reflective mirror (M2), the third total reflective mirror (M3) and the 45-degree total reflective mirror (M4) are plated with a 2100nm total reflecting film; one side of the 45-degree semi-reflecting mirror (M5) is plated with a 2100nm antireflection film, and the other side of the45-degree semi-reflecting mirror (M5) is plated with a 2100nm 50% permeable film. The two ends of a first pumping assembly (1) in the pumping assembly are provided with the first total reflective mirror (M1), the 45-degree total reflective mirror (M4), the 45-degree semi-reflecting mirror (M5) and the third total reflective mirror (M3). The two ends of a second pumping assembly (2) are provided with the second total reflective mirror (M2), the 45-degree semi-reflecting mirror (M5), the third total reflective mirror (M3) and the 45-degree total reflective mirror (M4). The output of the laser is up to 4J, and the laser can be easily and widely commercially applied to the urinary system lithotripsy field.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

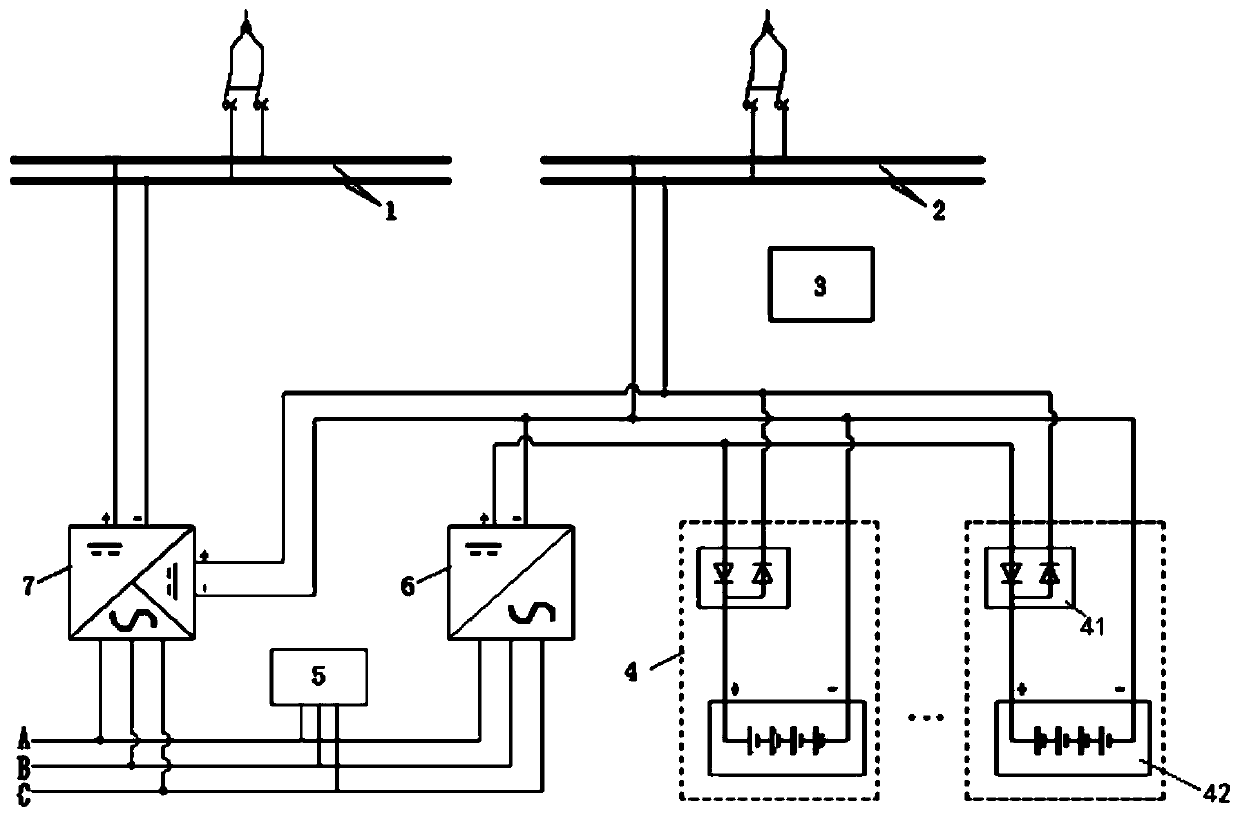

Hybrid direct-current power supply device for transformer substation

PendingCN110380507AEasy maintenanceEasy to replaceAc-dc conversion without reversalDc-dc conversionElectricityPower station

The invention discloses a hybrid direct-current power supply device for a transformer substation, which is characterized in that a storage battery pack of the hybrid direct-current power supply is a common battery pack (4) formed by connecting a counter current assembly (41) and a power storage assembly (42), the input end of the common battery pack (4) is electrically connected with the output end of a charging component (6), the output end of the common battery pack (4) is electrically connected with a communication power supply (2), the input end of the charging component (6) is electrically connected with an alternating-current power supply (ABC), the output end of the charging component (6) is electrically connected with the input end of the common battery pack (4), the output end ofa current transforming component (7) formed by a rectifying assembly and a direct current boosting assembly is electrically connected with an electric power operation power supply (1), the input end of the rectifying assembly is electrically connected with the alternating-current power supply (ABC), and the input end of the direct current boosting assembly is electrically connected with the outputend of the common battery pack (4). The hybrid direct-current power supply device is simple in structure, convenient to operate and maintain and extremely easy to be widely and commercially applied to various power plants and transformer substations in China to serve as a control power supply for popularization and application.

Owner:ANHUI XINLI ELECTRICAL EQUIP

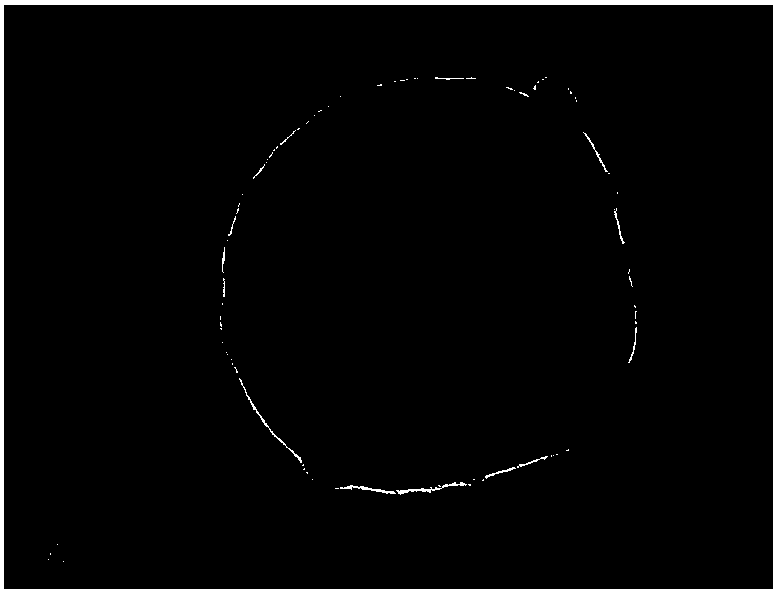

Nano colloidal motor and preparation method thereof

InactiveCN108483393AGood dispersionSuitable for targeted exerciseSpecific nanostructure formationIndividual molecule manipulationPlatinumSewage treatment

The invention discloses a nano colloidal motor and a preparation method thereof. The motor comprises an open spherical platinum shell, wherein the diameter of the shell is smaller than or equal to 500nm, the thickness of the shell is 5-30 nm, and the shell is coated with a silver shell or gold shell with thickness of 5-20 nm. The method comprises the following steps: firstly, placing a colloidalsphere on a substrate to form a single-layer close-packed colloidal crystal template, and heating the colloidal crystal template so as to obtain the single-layer close-packed colloidal crystal template, wherein the colloidal sphere is fixedly connected with the substrate; and then carrying out plasma etching on the single-layer close-packed colloidal crystal template so as to obtain a single-layernon-close-packed colloidal crystal template, wherein the colloidal sphere is fixedly connected with the substrate, then sequentially evaporating a platinum layer and a silver layer (or a gold layer)on the single-layer non-close-packed colloidal crystal template, then separating the colloidal sphere sequentially coated with the platinum layer and the silver layer (or the gold layer) on the surface on the single-layer non-close-packed colloidal crystal template from the substrate by using a physical method, putting the mixture into a solvent or subjecting the mixture to calcining to remove thecolloid ball to prepare a target product. The product is small in size, single in movement direction and hollow, and can be easily, widely and commercially applied to the technical fields of drug targeting motion, material transportation, ion detection, sewage treatment and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

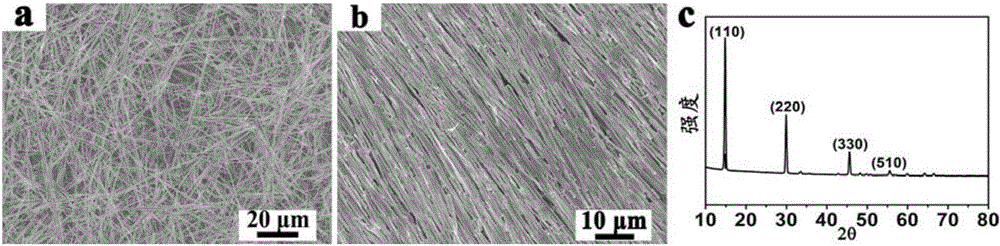

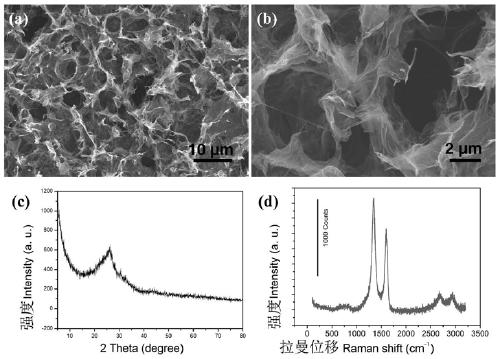

Preparation method of porous graphene

ActiveCN107311155BGood electrical conductivityEase of widespread commercial applicationGraphenePorous grapheneArgon atmosphere

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

A kind of gold nano bipyramid with quintuple twin structure and preparation method thereof

ActiveCN108637269BUniform sizeGood monodispersityMaterial nanotechnologyTransportation and packagingChlorogenic acidGlycol synthesis

The invention discloses a gold nano-pyramid with a five-fold twin structure and a preparation method thereof. A gold nano-decahedron is prepared in ethylene glycol by a polyalcohol reduction method; hydroquinone, chloroauric acid and the obtained The gold nano decahedron is mixed together so that the concentration of hydroquinone in the solution after mixing is 0.001~0.004 mole / liter, the concentration of chloroauric acid is 0.0005~0.002 mole / liter, and the concentration of the described gold nano decahedron is 0.0001-0.005 mol / liter, then react at 30-70° C. for 10 hours, and then carry out solid-liquid separation, so as to prepare gold nano-pyramids with quintuple twin structure. The invention not only has good near-infrared light absorption performance and high catalytic activity of twin crystal structure, but also has simple preparation process, low cost and environmental friendliness, and has important application value and wide application in infrared imaging, photothermal therapy, catalysis and other fields prospect.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Gold-tin oxide core-shell structure composite nanomaterial and preparation method thereof

InactiveCN105458247BHigh selectivityHigh sensitivityTransportation and packagingMetal-working apparatusCore shell nanocompositesLength wave

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com