High-temperature proton exchange membrane used for membrane fuel cells, and production method and application thereof

A proton exchange membrane and fuel cell technology, applied in fuel cells, sustainable manufacturing/processing, circuits, etc., can solve the problems of phosphoric acid with water, loss, etc., achieve strong water permeability, improve electrical conductivity, and high hydrophilicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

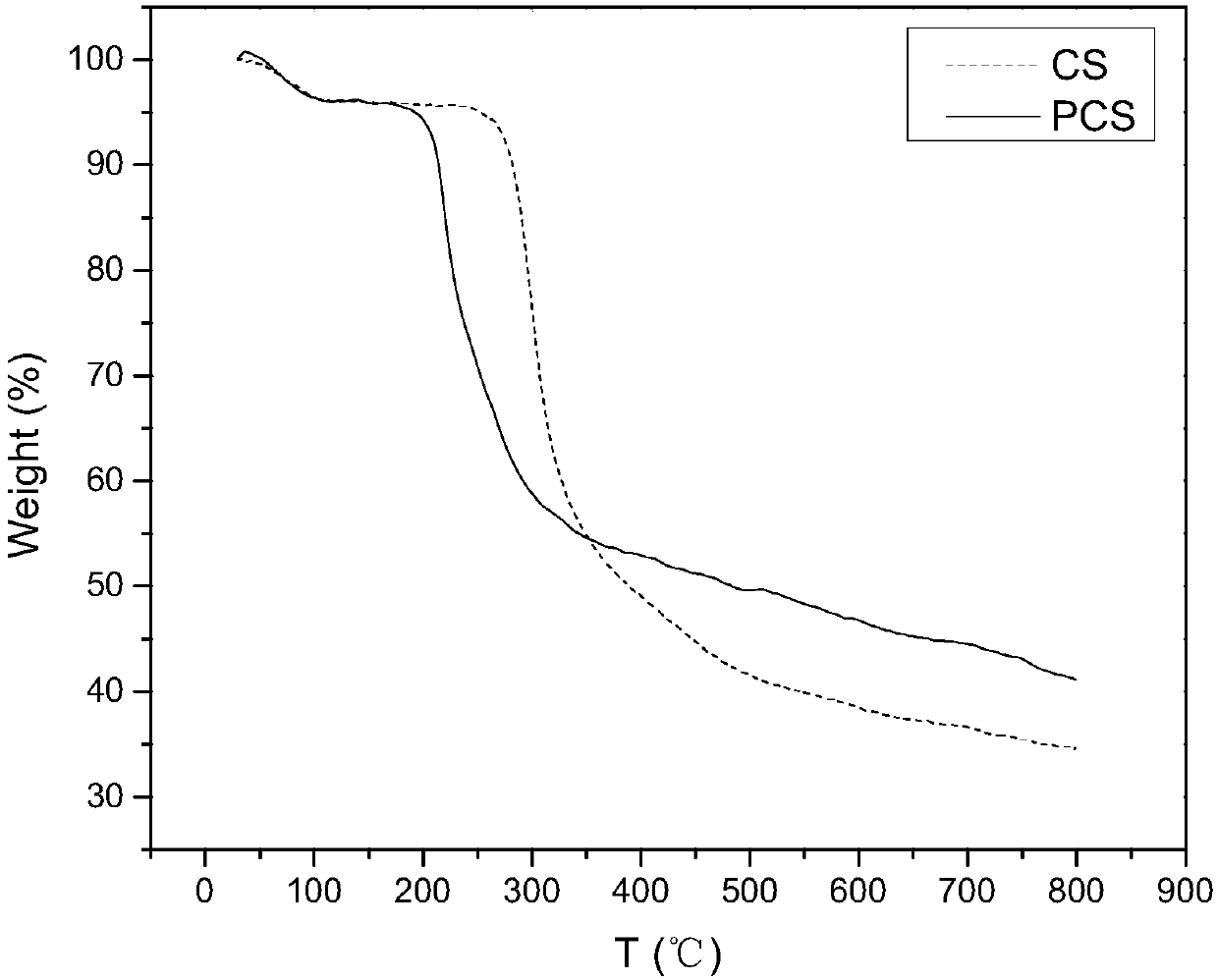

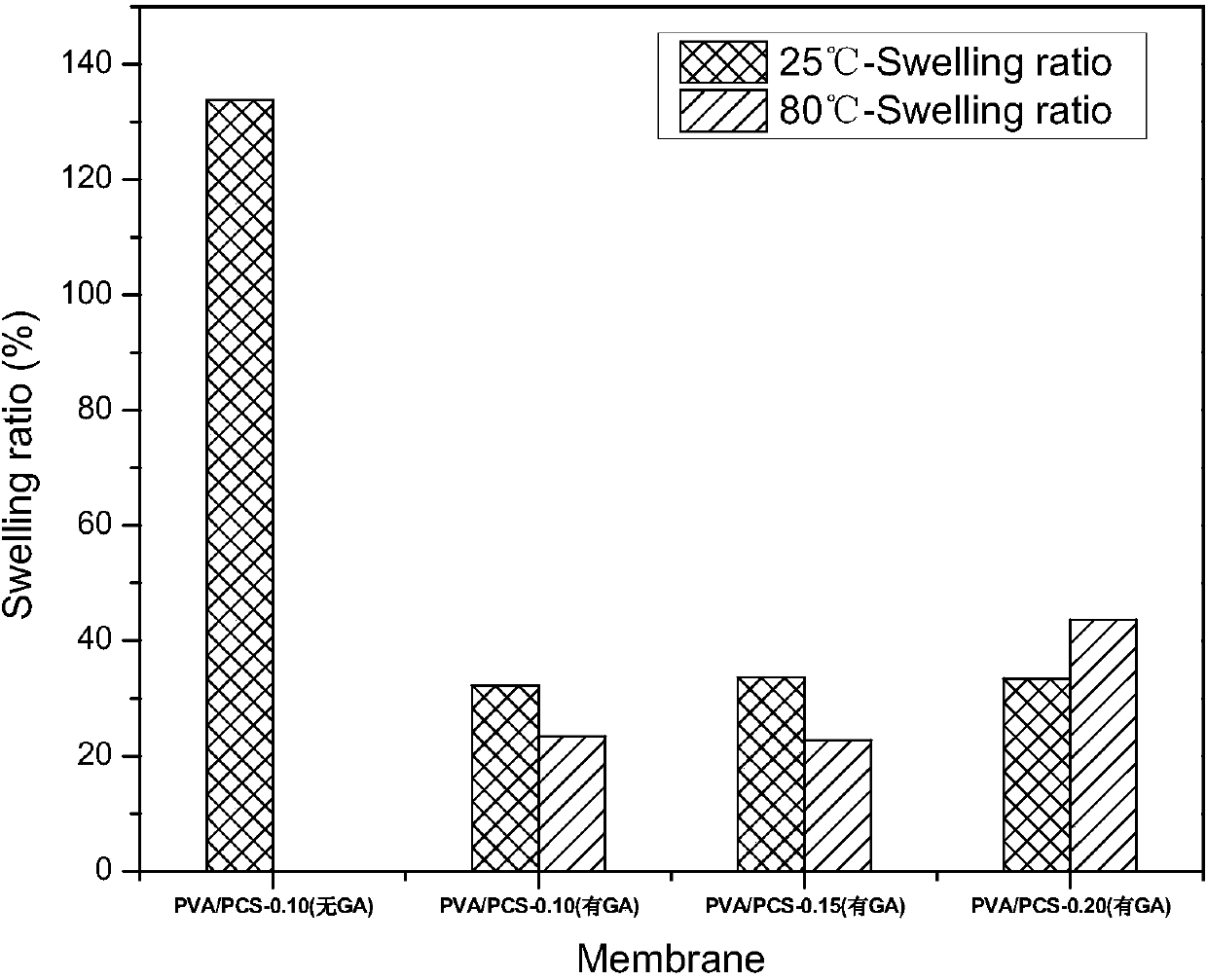

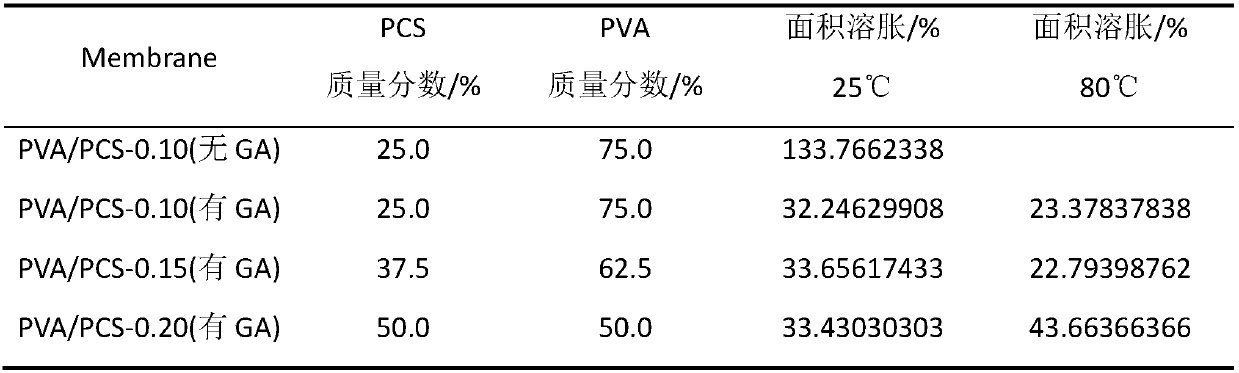

[0023] A proton exchange membrane with high resistance alcohol performance, the film-forming raw materials are polyvinyl alcohol and phosphorylated chitosan, the mass ratio of polyvinyl alcohol and phosphorylated chitosan in the film-forming raw materials can ensure the conductivity of protons, and ensure the proton Under the condition of conductivity, the mass ratio of polyvinyl alcohol and phosphorylated chitosan can be adjusted.

[0024] The preparation method of polyvinyl alcohol / phosphorylated chitosan composite proton exchange membrane comprises the following steps:

[0025] (1) Preparation of phosphorylated chitosan;

[0026] In one embodiment, the preparation method of phosphonated chitosan is: take 2g of chitosan and dissolve it in a 250mL thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com