Nano colloidal motor and preparation method thereof

A nano-colloid and motor technology, which is applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of uneven force on the motor, single motion direction, and complex motion, and achieve small size, scientific preparation method, and motion direction. single effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

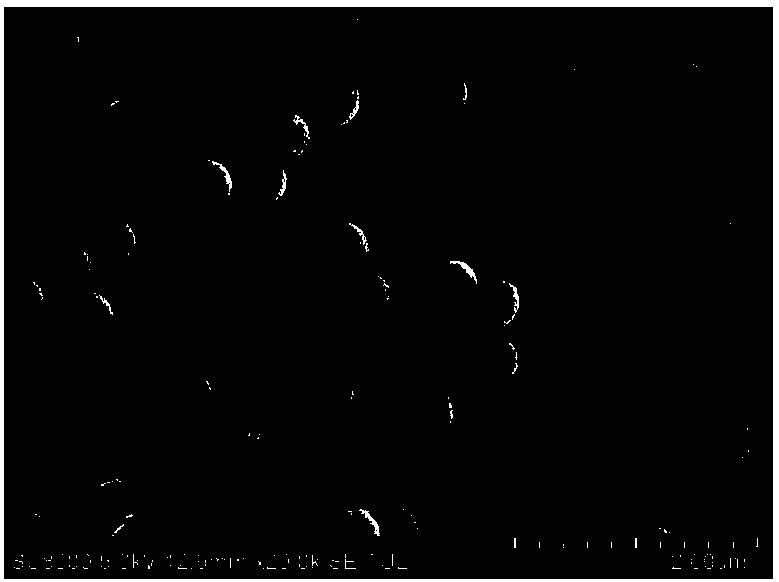

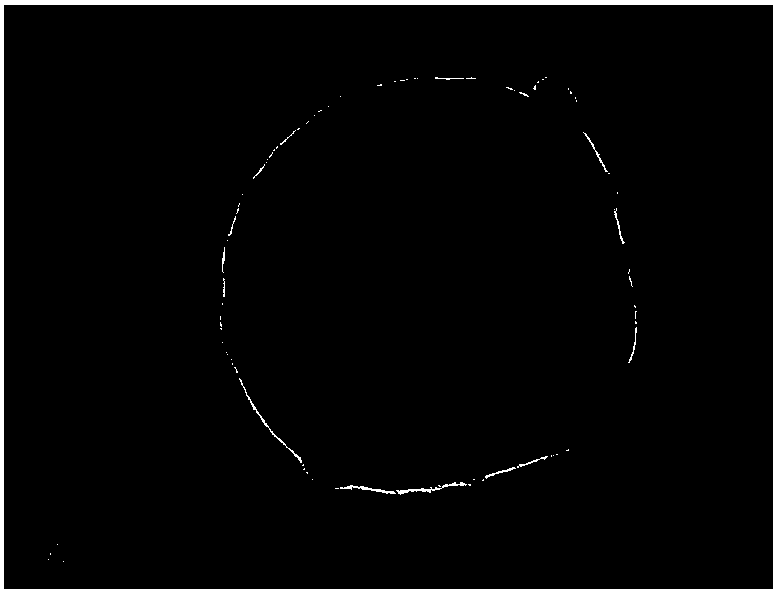

Image

Examples

Embodiment 1

[0034] The concrete steps of preparation are:

[0035] Step 1, first place colloidal spheres with a diameter of 50 nm on the substrate to form a single-layer close-packed colloidal crystal template; wherein, the colloidal spheres are polystyrene colloidal spheres, and the substrate is a silicon wafer in a semiconductor substrate. Then, the single-layer close-packed colloidal crystal template was placed at 70° C. for 12 minutes to obtain a single-layer close-packed colloidal crystal template in which the colloidal spheres were fixedly connected to the substrate.

[0036] In step 2, the single-layer close-packed colloidal crystal template in which the colloidal spheres are fixedly connected to the substrate is first subjected to plasma etching for 20 minutes to obtain a single-layer non-close-packed colloidal crystal template in which the colloidal spheres are fixedly connected to the substrate. Then vapor-deposit a 5nm-thick platinum layer and a 20nm-thick silver layer (or gold...

Embodiment 2

[0039] The concrete steps of preparation are:

[0040] Step 1, first place colloidal spheres with a diameter of 163nm on the substrate to form a single-layer close-packed colloidal crystal template; wherein, the colloidal spheres are polystyrene colloidal spheres, and the substrate is a silicon wafer in a semiconductor substrate. Then, the single-layer close-packed colloidal crystal template was placed at 75° C. for 11 minutes to obtain a single-layer close-packed colloidal crystal template in which the colloidal spheres were fixedly connected to the substrate.

[0041] In step 2, the single-layer close-packed colloidal crystal template in which the colloidal spheres are fixedly connected to the substrate is first subjected to plasma etching for 25 minutes to obtain a single-layer non-close-packed colloidal crystal template in which the colloidal spheres are fixedly connected to the substrate. Then vapor-deposit a 11nm thick platinum layer and a 16nm thick silver layer (or gol...

Embodiment 3

[0044] The concrete steps of preparation are:

[0045]Step 1, first place colloidal spheres with a diameter of 275nm on the substrate to form a single-layer close-packed colloidal crystal template; wherein, the colloidal spheres are polystyrene colloidal spheres, and the substrate is a silicon wafer in a semiconductor substrate. Then, the single-layer close-packed colloidal crystal template was placed at 80° C. for 10 minutes to obtain a single-layer close-packed colloidal crystal template in which the colloidal spheres were fixedly connected to the substrate.

[0046] In step 2, the single-layer close-packed colloidal crystal template in which the colloidal spheres are fixedly connected to the substrate is first subjected to plasma etching for 30 minutes to obtain a single-layer non-close-packed colloidal crystal template in which the colloidal spheres are fixedly connected to the substrate. Then vapor-deposit a 18nm thick platinum layer and a 12nm thick silver layer (or gold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com