Patents

Literature

34results about How to "Ease of widespread commercial application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microcapsule self-repairing anticorrosive coating and preparation method thereof

ActiveCN109536012ACost-effectiveImprove repair rateAnti-corrosive paintsSilicon dioxidePlatinum catalyst

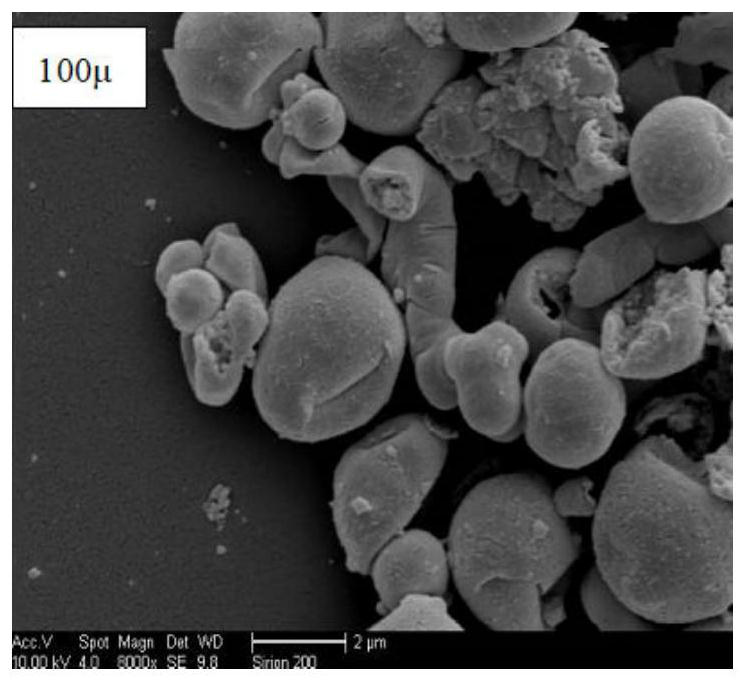

The invention discloses a microcapsule self-repairing anticorrosive coating and a preparation method thereof. The coating is composed of silicon dioxide microcapsules containing corrosion inhibitor inside in silicon-based emulsion. The method is as follows: firstly, a tetraethyl orthosilicate cyclohexane solution and the corrosion inhibitor are mixed, and the pH value is adjusted by acid, then themixture is stirred and allowed to react, and then the reaction solution is filtered; subsequently, a sodium dodecyl benzene sulfonate aqueous solution is added to the obtained organic-inorganic hybrid emulsion and stirred, the obtained water-in-oil core material emulsion is subjected to solid-liquid separation, washing and drying in turn to obtain silicon dioxide microcapsule encapsulated with corrosion inhibitor, the metal platinum catalyst is added in silicone oil and stirred to obtain silicon-based emulsion, the silicon dioxide microcapsule encapsulated with corrosion inhibitor and the a metal platinum catalyst are mixed and maleic anhydride monododecyl ester is added, the mixture is subjected to stirring and reacting to obtain the target product. It has good stability and fast repairing speed, so it is very easy to be widely used in the field of steel structure and concrete steel structure corrosion protection.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

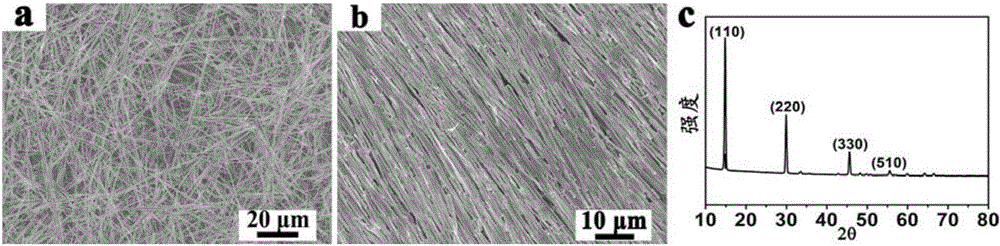

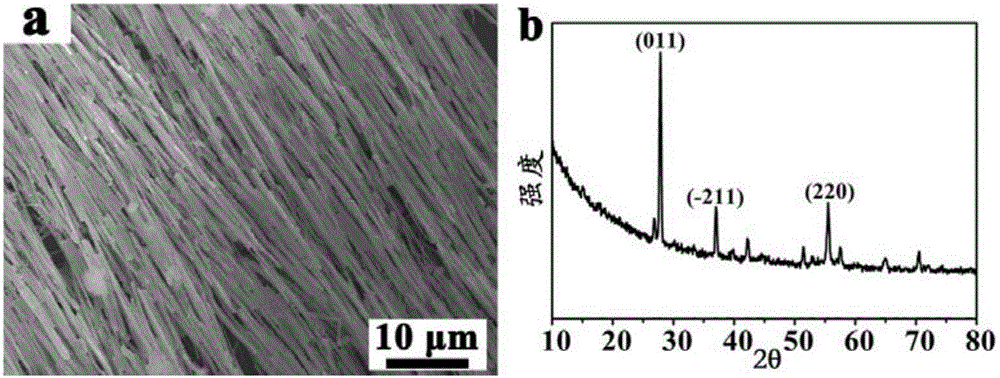

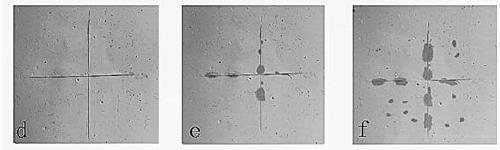

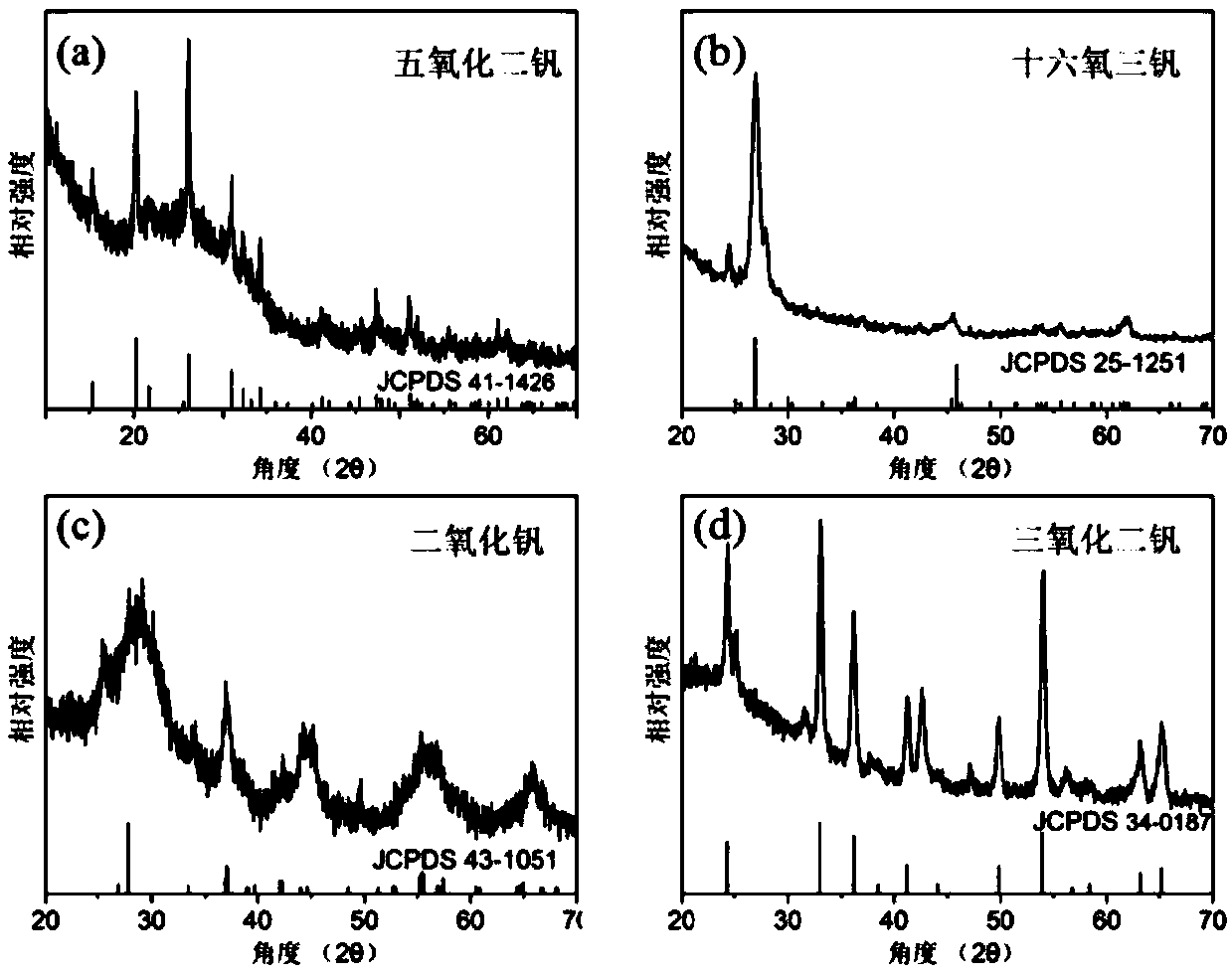

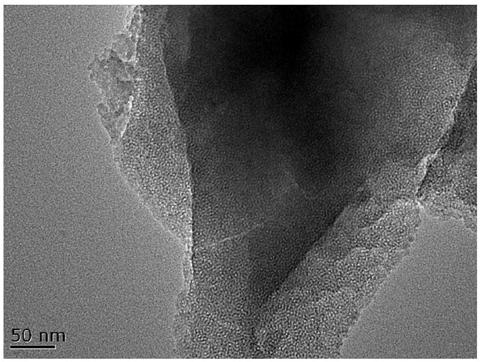

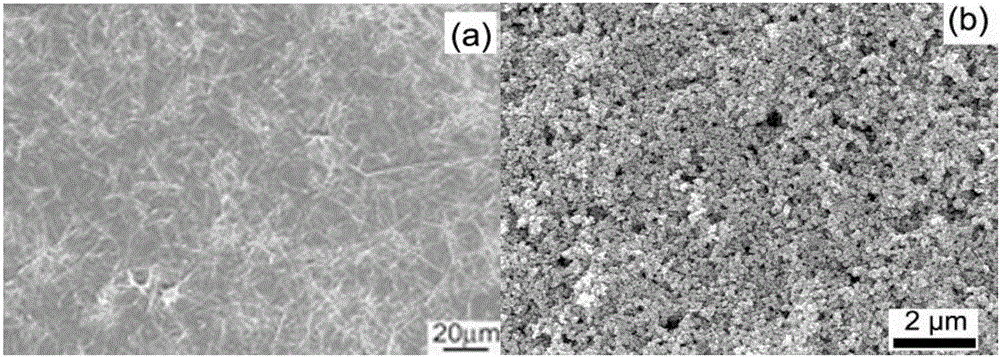

VO2(M) nanowire ordered array and preparation method thereof

InactiveCN106082337AEase of widespread commercial applicationExtensive commercial applicationVanadium oxidesMicrometerChloroform

The invention discloses a VO2(M) nanowire ordered array and a preparation method thereof. According to the ordered array, a VO2(M) nanowire is arranged orderly in the wire length direction to form an array, the diameter of the VO2(M) nano wire forming the VO2(M) nanowire ordered array ranges from 200 nm to 600 nm, and the wire length ranges from 10 micrometers to 50 micrometers. The method comprises the steps that firstly, a hydrothermal method is used for obtaining the VO2(M) nanowire, then the VO2(M) nanowire is mixed with water, then ultrasonic treatment is carried out, and a VO2(M) nanowire dispersion liquid is obtained; then, the VO2(M) nanowire dispersion liquid is firstly dropwise added into chloroform, after the VO2(M) nanowire is assembled into the ordered sequence by itself on the surface of chloroform, the VO2(M) nanowire is fished out through a substrate, and the substrate coated with the VO2(M) nanowire ordered array is obtained; then after the substrate coated with the VO2(M) nanowire ordered array is placed in a vacuum or protective atmosphere for annealing, the substrate is separated, and the target product is obtained. The VO2(M) nanowire ordered array can be widely and commercially applied to the fields of photoelectric detection, intelligent responses, electro-catalysis, sensors, magnetic devices and the like easily.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

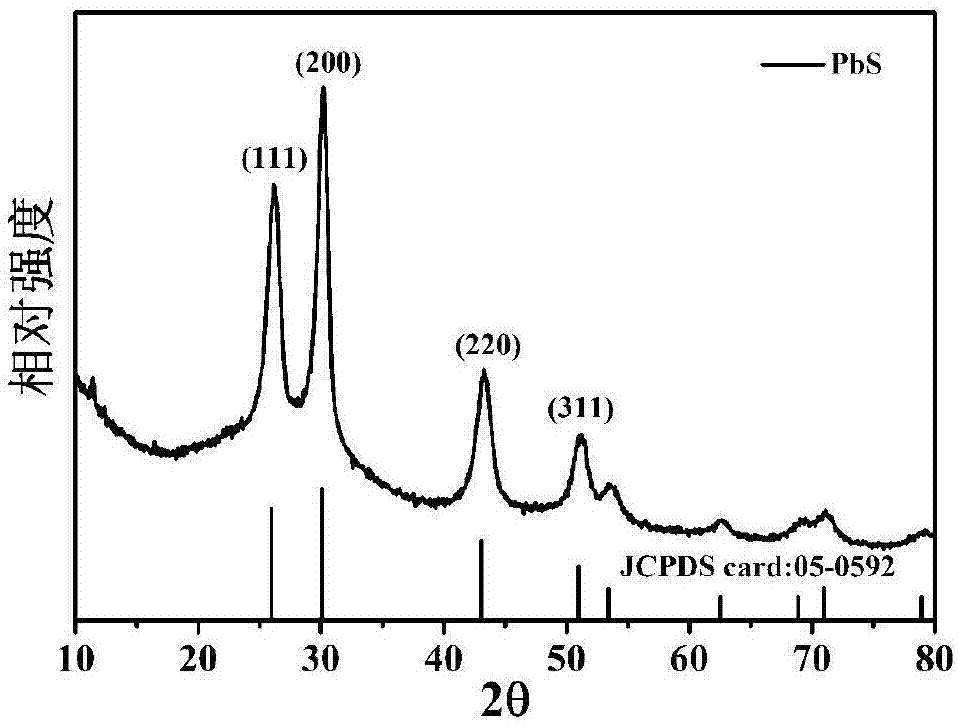

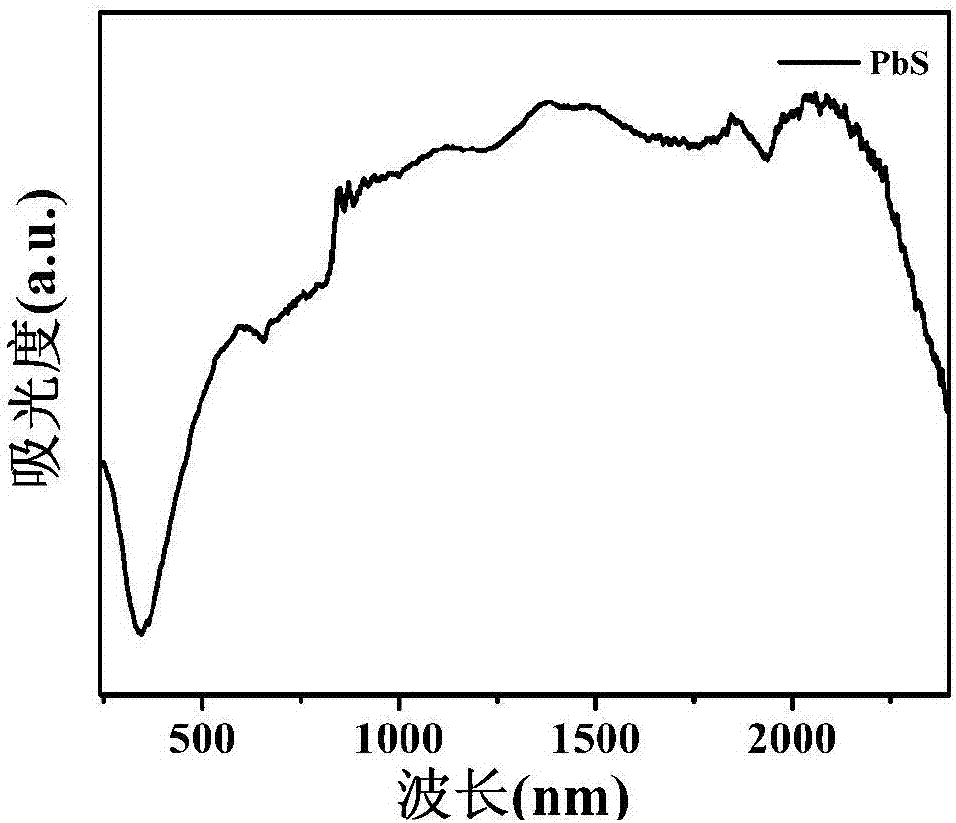

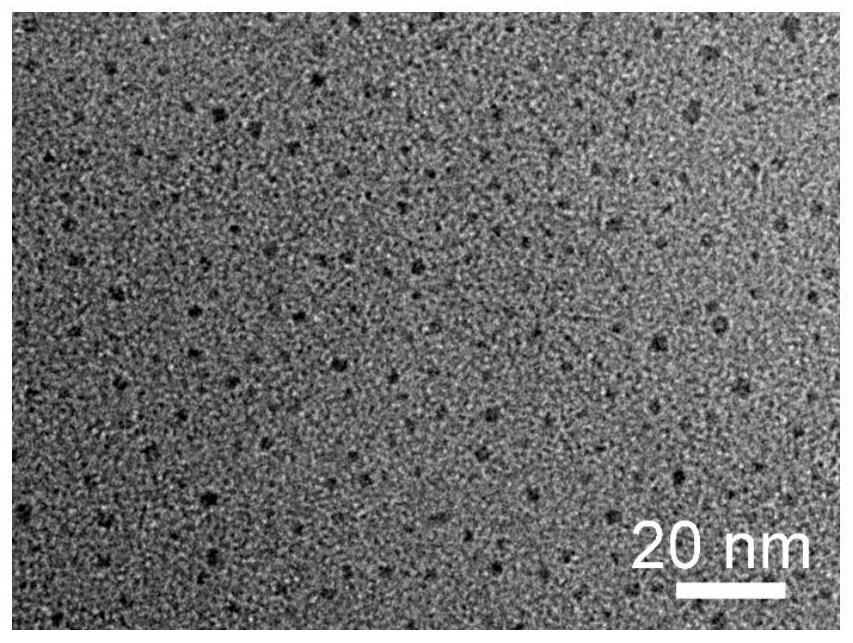

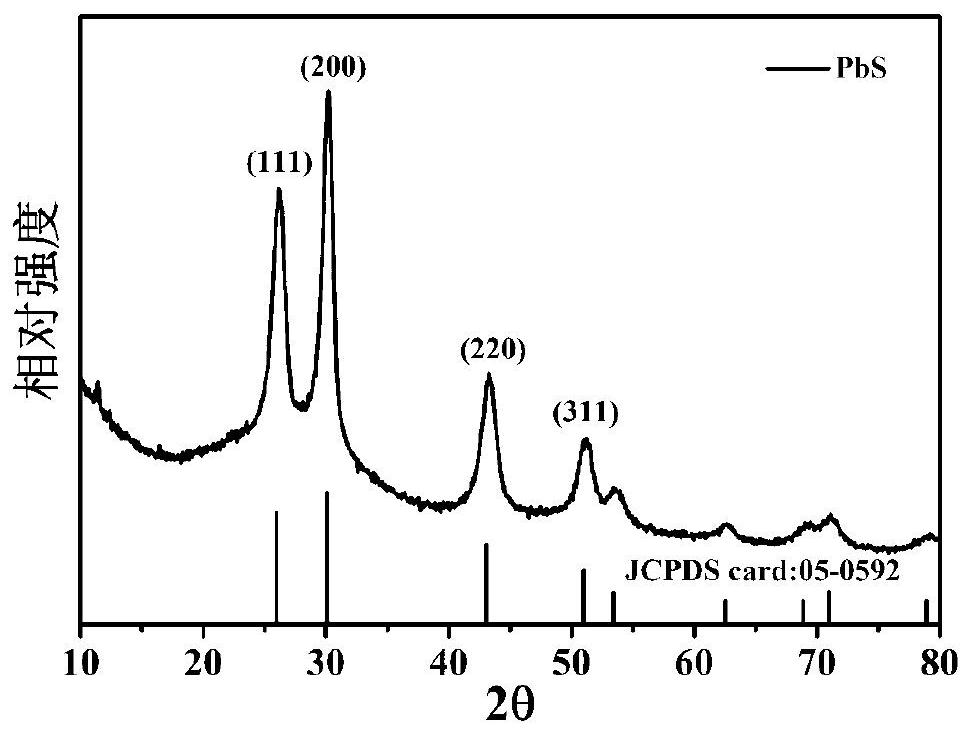

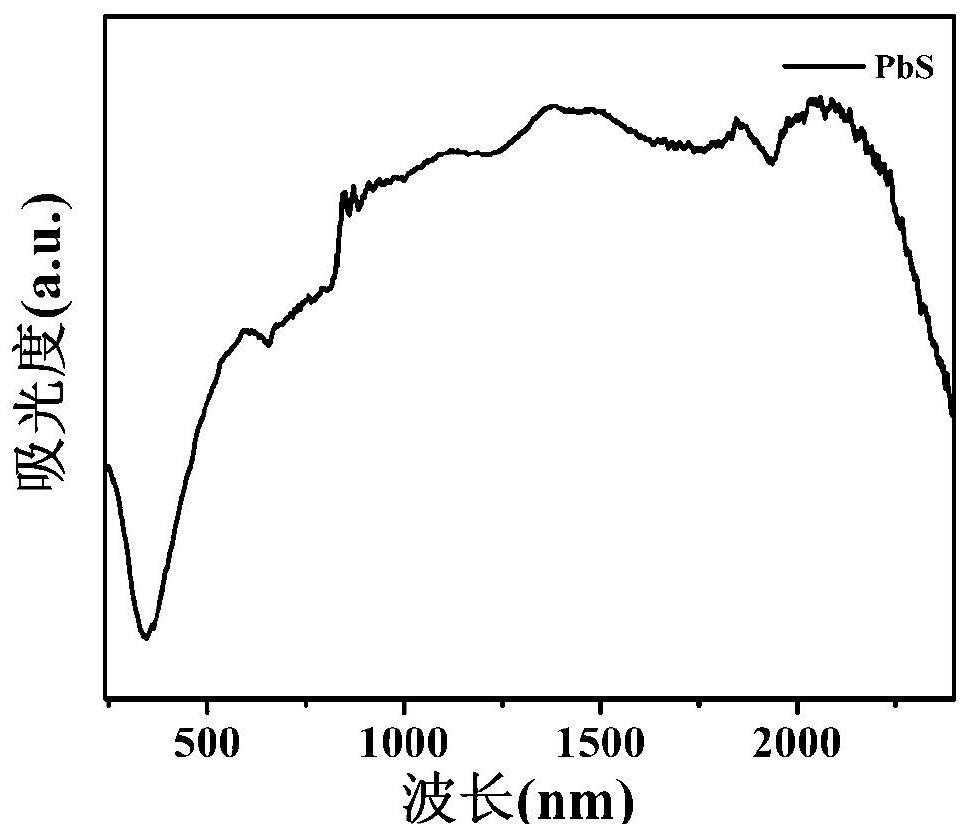

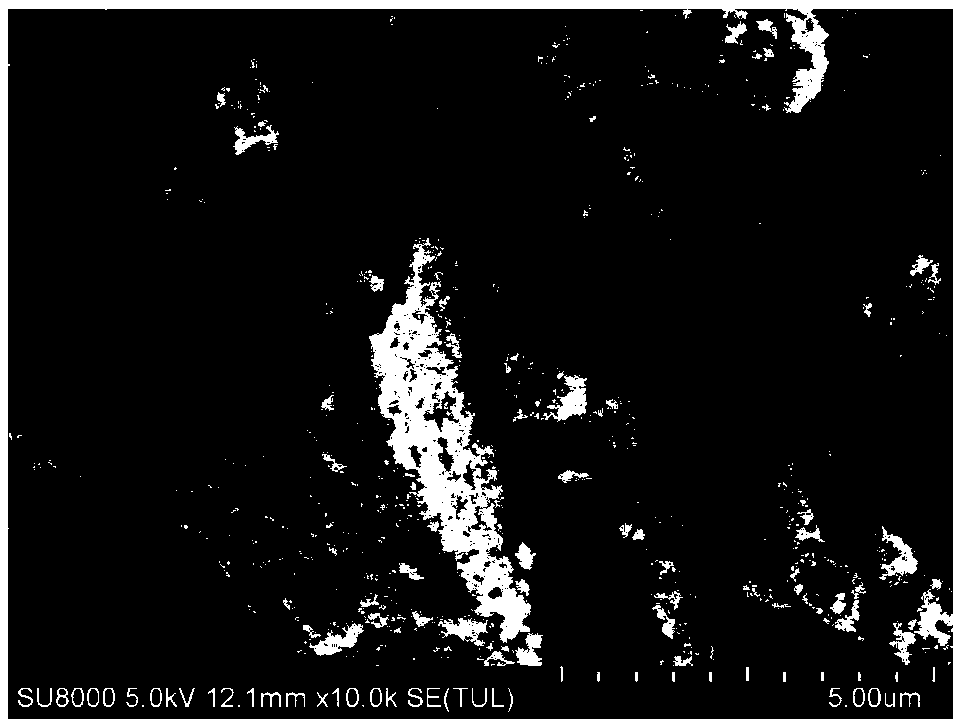

Lead sulfide thin film with wide absorption spectrum and preparation method of lead sulfide thin film

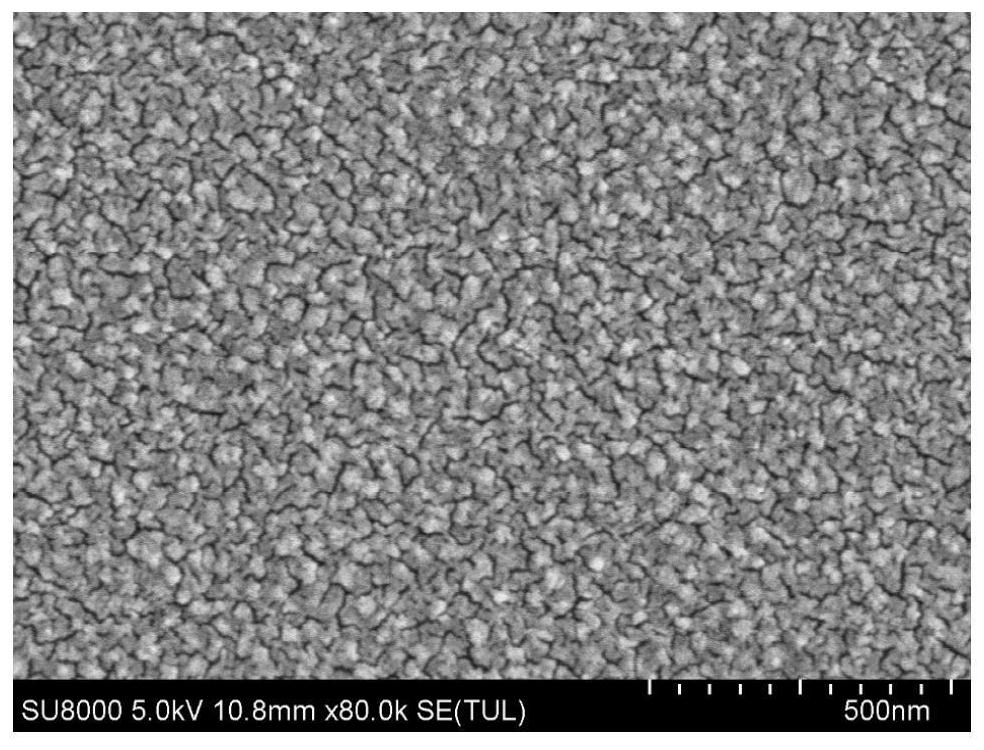

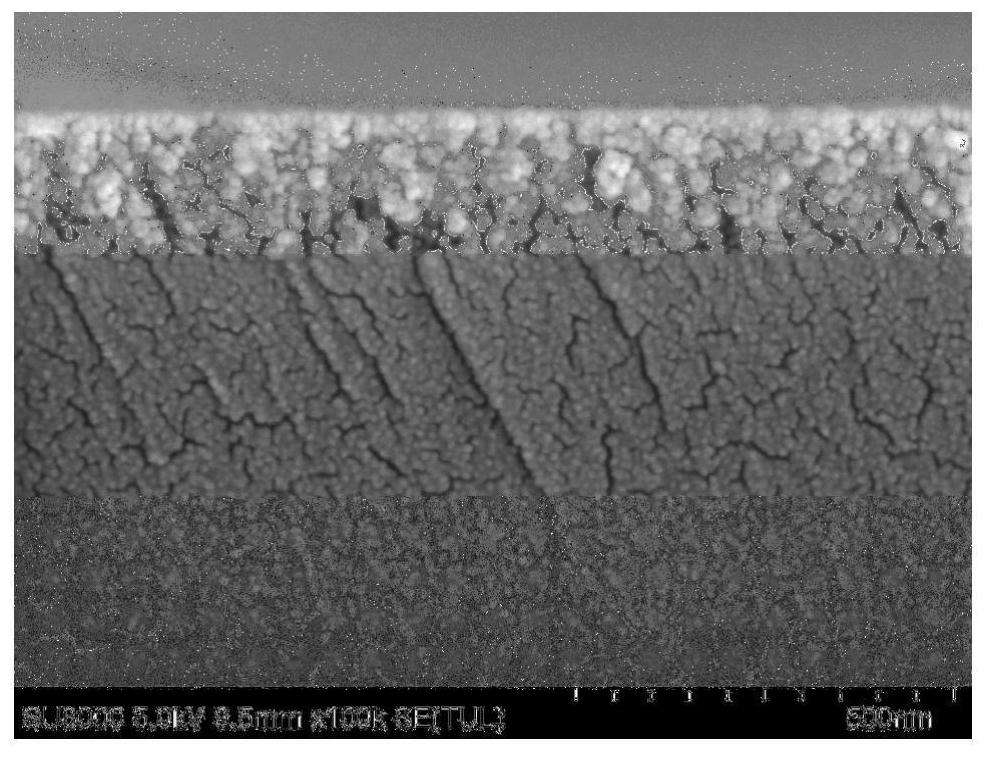

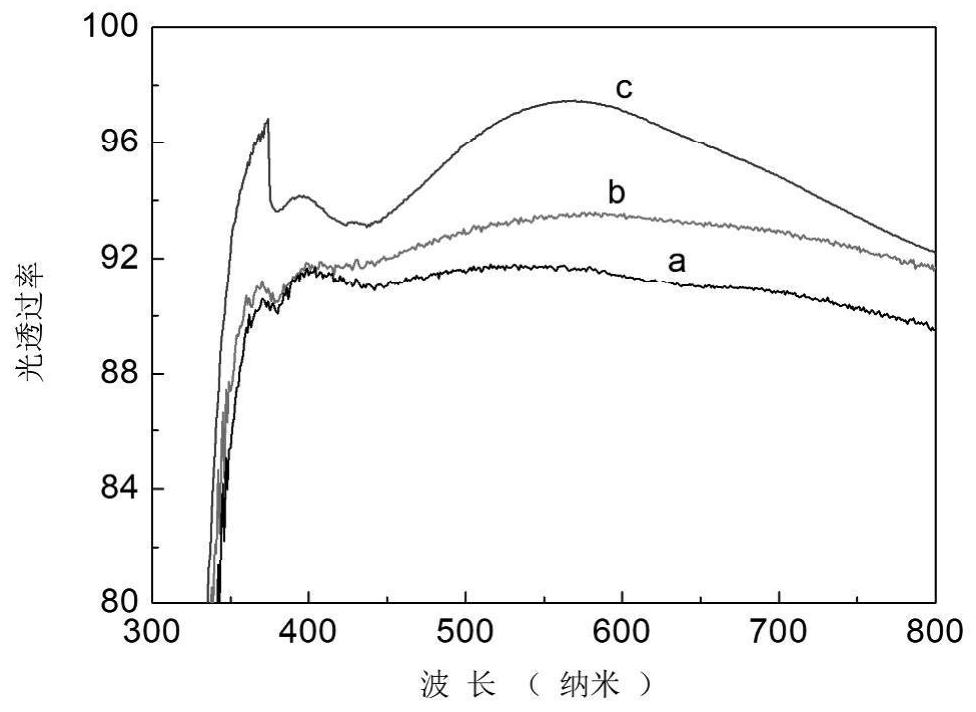

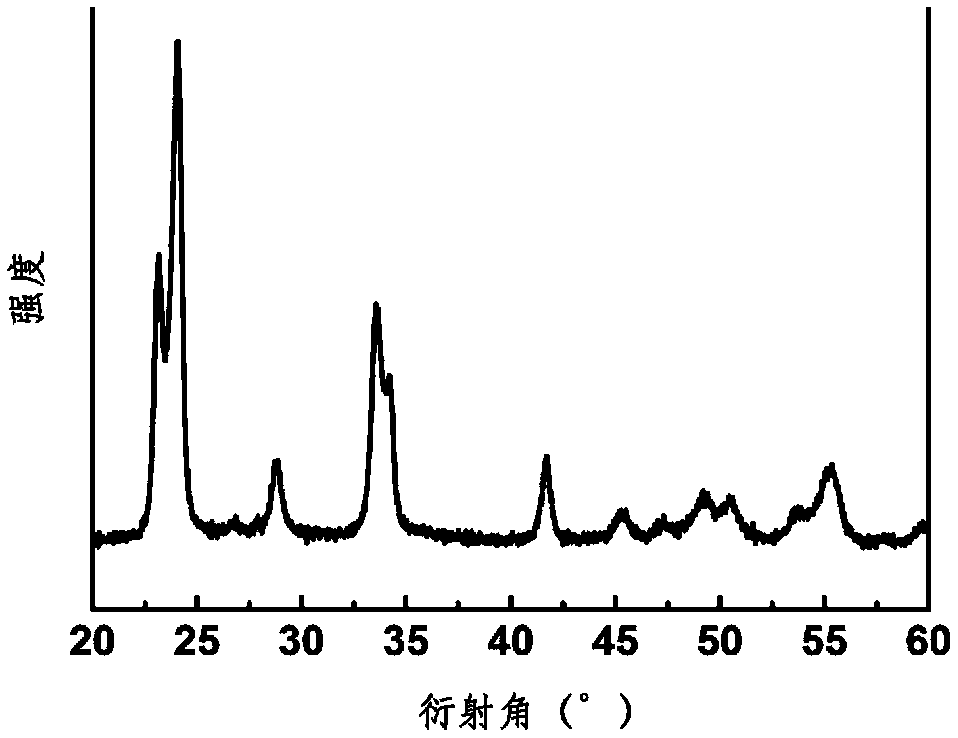

ActiveCN107315215ABroadband Absorption CharacteristicsEase of widespread commercial applicationLead sulfidesOptical elementsThioureaLead sulfide

The invention discloses a lead sulfide thin film with the wide absorption spectrum and a preparation method of the lead sulfide thin film. The thickness of the thin film is 500-540nm. The particle diameter of each lead sulfide crystal grain is 6-10nm. At the wave band of 450-220nm, the thin film consisting of the lead sulfide crystal grains the diameter of each of which 6-10nm displays an absorption peak. According to the invention, by use of the chemical vapour deposition method: firstly successively adding the sodium hydroxide solution, the thiourea solution and the triethanolamine solution into the lead acetate solution so as to obtain a mixed solution; then adding the deionized water into the mixed solution to obtain a reaction solution; arranging a substrate into the stirred reaction solution of the 70 DEG C-80 DEG C for at least 2h so as to obtain the substrate with the reagent on the surface; and cleaning and drying the substrate with the reagent on the surface to prepare the target product. According to the invention, the thin film has the quite wide wave band absorption characteristic, and is quite easily, widely and commercially applicable to field of photodetection, solar energy coating absorption layers and gas sensing detection.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

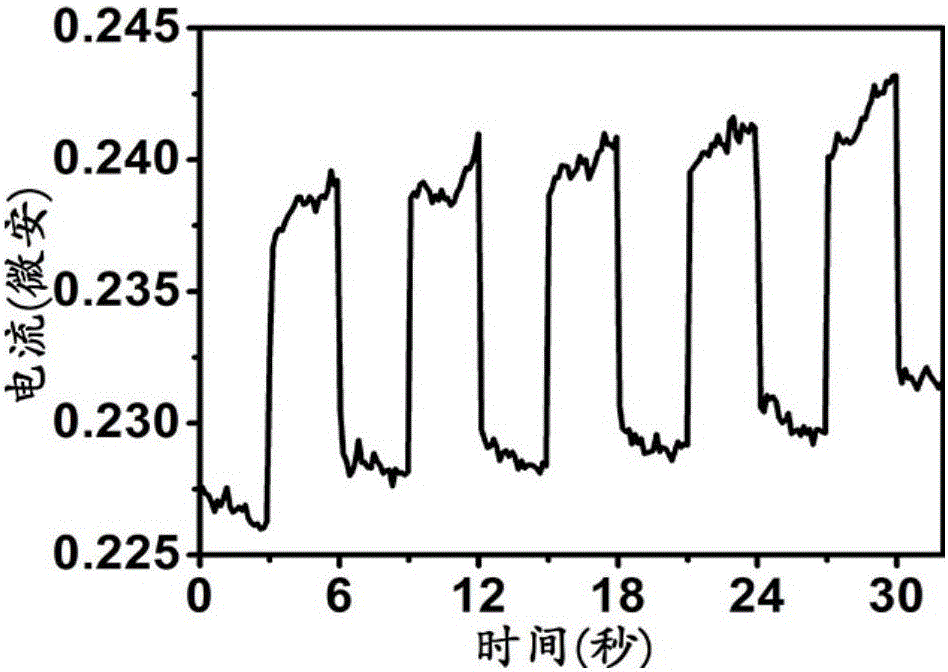

Gas sensor array and method for identifying three alcohol types and concentrations thereof

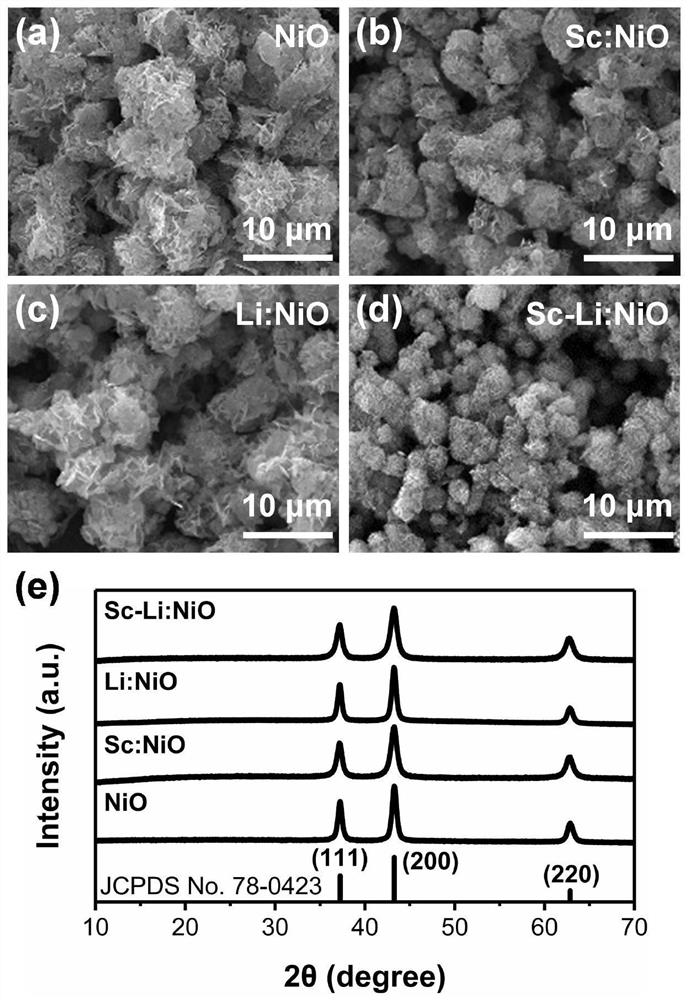

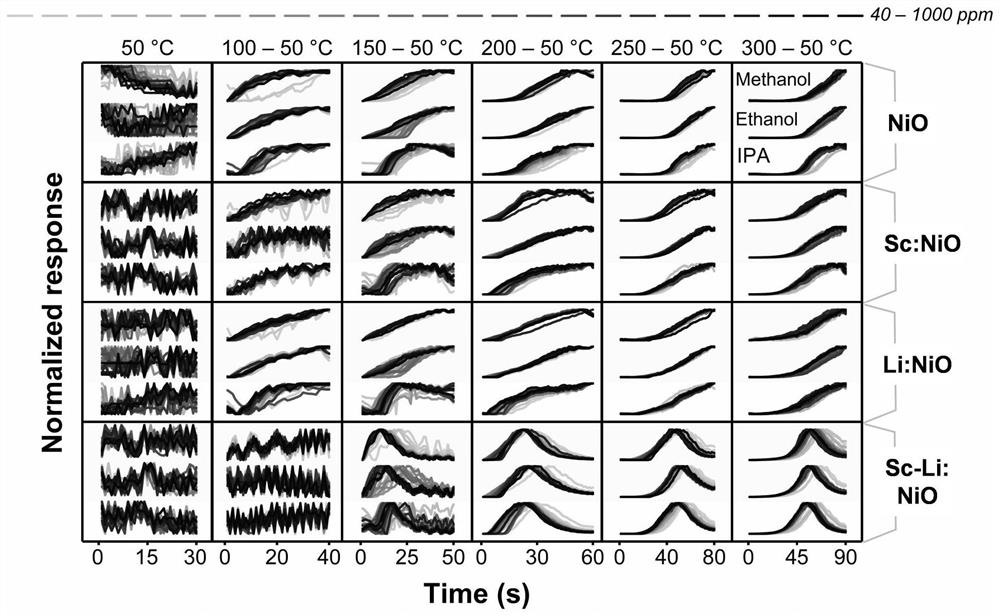

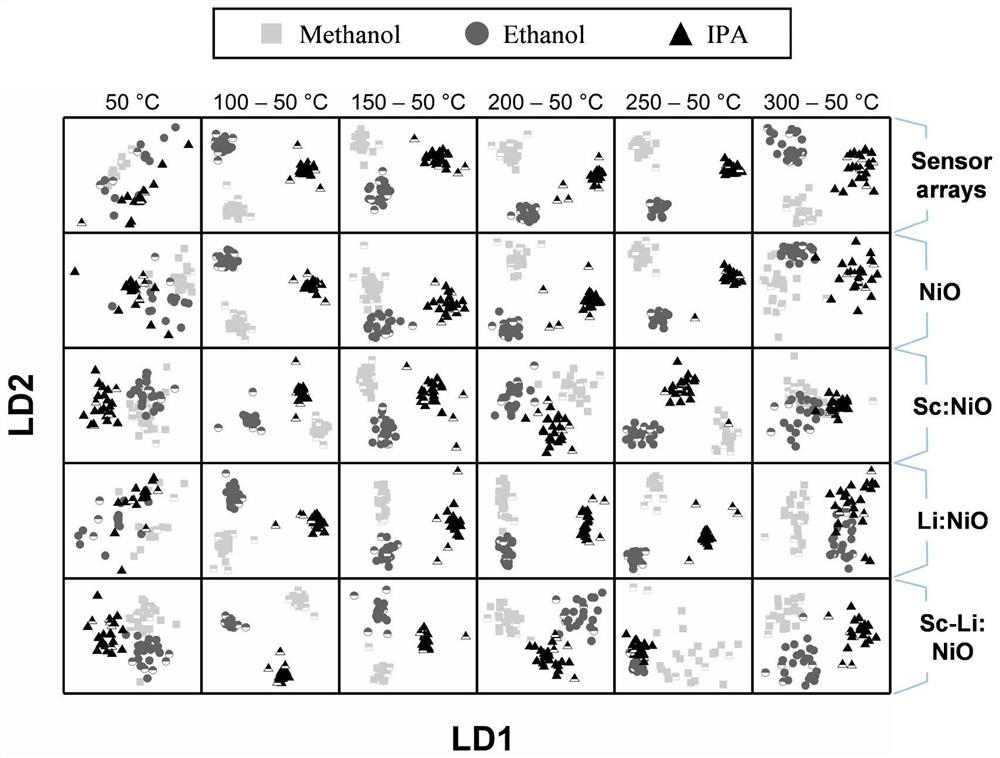

ActiveCN113030194ASurface properties varyEasy to identifyMaterial resistanceAir quality improvementSensor arraySupervised learning

The invention discloses a metal oxide gas sensor array and a method for identifying the type and concentration of methanol or ethanol or isopropanol by using the gas sensor array. The sensor array comprises sensors coated with n different nickel oxide sensitive films, the nickel oxide sensitive films are prepared through a solution method, and the types and recognition performance of the metal oxide sensitive films are expanded through doping of different metal ions; Furthermore, thermal modulation resistance response signals of the sensor array to methanol, ethanol or isopropanol with different concentrations and types are tested through variable-temperature thermal modulation, and then normalization processing of thermal modulation sensitivity response signals is carried out; mapping (calibration) between methanol or ethanol or isopropanol with different concentrations and a normalized sensitivity signal is established through a supervised learning algorithm, then types and concentrations of the three alcohols are identified, and the method can be widely applied to quantitative identification and detection of types and concentrations of other volatile organic compounds very easily.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

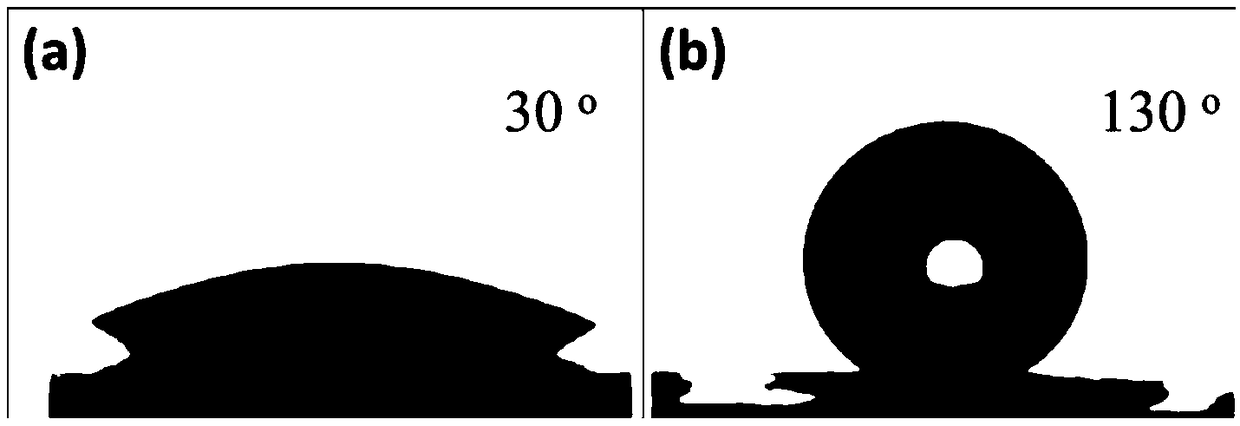

Silicon dioxide nano porous membrane with gradient porosity and preparation method of silicon dioxide nano porous membrane

ActiveCN107867874AMeet wear resistanceMeet superhydrophilicityCeramicwareSilicon dioxideMaterials science

The invention discloses a silicon dioxide nano porous membrane with gradient porosity and a preparation method of the silicon dioxide nano porous membrane. The nano porous membrane has the membrane thickness of 100-500 nm and consists of three or more layers of porous membranes with different spherical pore diameters, wherein the bottom pore diameter is 1-3 nm, the surface pore diameter is 5-8 nm,the pore edge space is 10-2 nm from bottom to top, and the porosity ranges from 30%-35% to 60%-70% from bottom to top. The method comprises the steps as follows: tetraethyl orthosilicate and ethanolare mixed, a mixed solution is obtained, a nitric acid aqueous solution is dropwise added to the mixed solution, silicon dioxide sol is obtained after stirring, cetyl trimethyl ammonium bromide is added, stirring is performed, mixed sol is obtained after aging, then, a substrate is sequentially placed in the mixed sol with gradually increased cetyl trimethyl ammonium bromide for pull coating 3 times or more, the obtained product is aired and annealed, and a target product is prepared. The silicon dioxide nano porous membrane has wear resistance and super-hydrophilic property and can be very easily and commercially applied to anti-fog, self-cleaning, wide spectrum anti-reflection fields and the like.

Owner:上海西源新能源技术有限公司

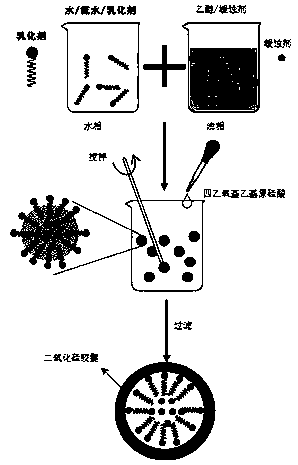

Silicon dioxide microcapsule self-repairing anticorrosive paint and preparation method thereof

InactiveCN111471389AGood effectImprove liquidityAnti-corrosive paintsPolyurea/polyurethane coatingsSilicic acidSilicon oxide

The invention provides silicon dioxide microcapsule self-repairing anticorrosive paint and a preparation method thereof. The self-repairing anticorrosive paint is prepared by the following steps: dispersing an oil phase formed by a corrosion inhibitor and diethyl ether into a water phase formed by ammonia water, an emulsifier and water; then dropwise adding tetrakis(2-ethoxyethyl) orthosilicate for reaction to obtain an emulsion, then ageing, washing with water and drying to obtain a self-repairing microcapsule material; and then uniformly stirring the microcapsule material, a polyurethane emulsion, an acrylic emulsion, a filler, a defoaming agent and a thixotropic agent. According to the self-repairing anticorrosive paint provided by the invention, the microcapsule material formed by coating the corrosion inhibitor with silicon dioxide is added, and the corrosion inhibitor is good in flowability, high in activity and good in stability, so that the self-repairing efficiency of the paint is improved, the service lifetime is effectively prolonged, the price of used materials is low, the process is simple, the preparation cost is low, and the application prospect is wide.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

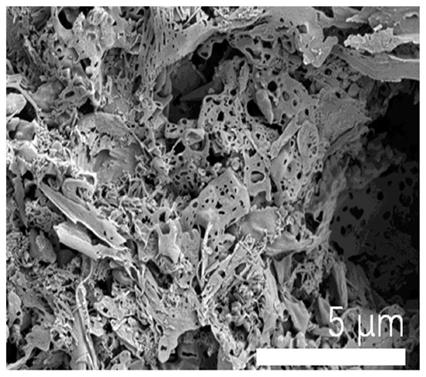

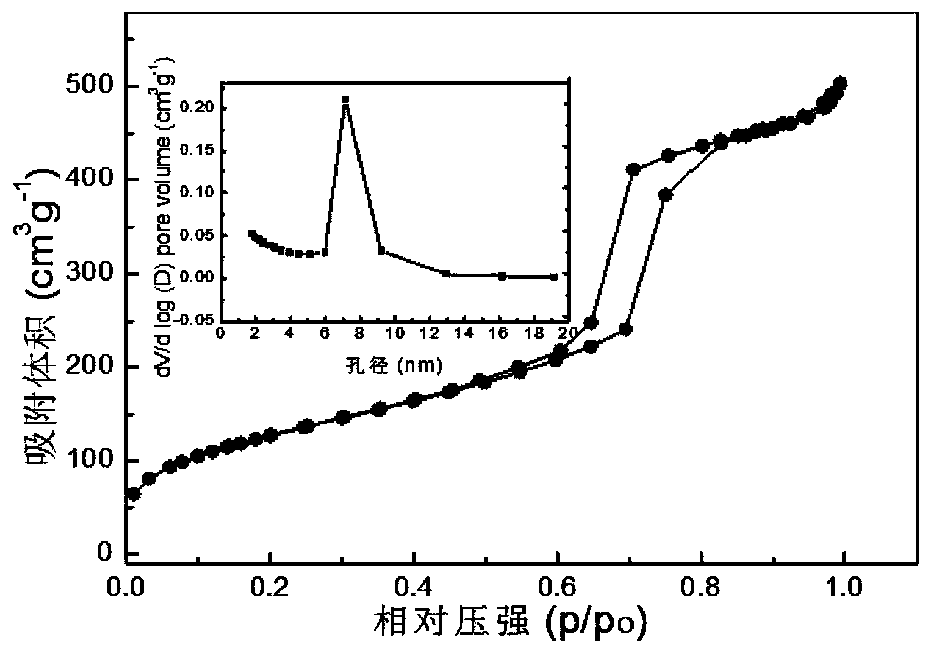

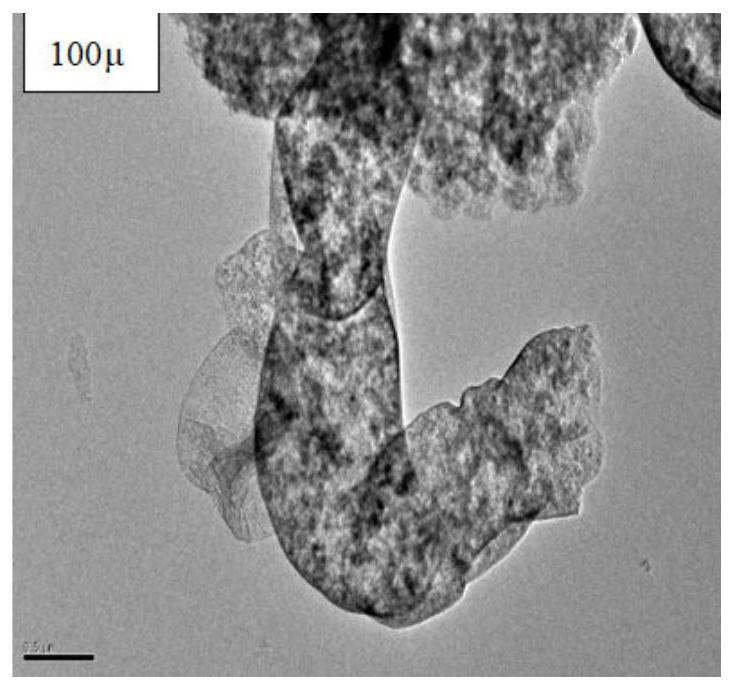

Mesoporous graphite-like phase carbon nitride material as well as preparation method and application thereof

ActiveCN111153390AHigh specific surface areaIncrease the rate of hydrogen productionPhysical/chemical process catalystsNanotechnologyMaterials scienceHydrogen production

The invention discloses a mesoporous graphite-like phase carbon nitride material as well as a preparation method and application thereof. The material is characterized in that graphite-like phase carbon nitride nanosheets with mesopores are in a cross-linking accumulation state, wherein the sheet thickness of the nanosheets is 8-12 nm, the pore diameter of the mesopores is 2-20 nm, and the specific surface area of the graphite-like phase carbon nitride nanosheets with mesopores in the cross-linking accumulation state is larger than or equal to 456.3 m<2> / g. The method adopts a high-temperaturesynthesis method and comprises the steps: mixing and stirring cyanuric acid, cyanuric chloride and an organic solvent to obtain a mixed solution, drying the mixed solution to obtain a precursor, andheating the precursor at the temperature of 580-630 DEG C to obtain the target product. The material has a large specific surface area and high performance of photocatalytic decomposition of water forhydrogen production, and can be easily and widely commercially applied to the field of photocatalytic hydrogen production.

Owner:ANHUI UNIVERSITY

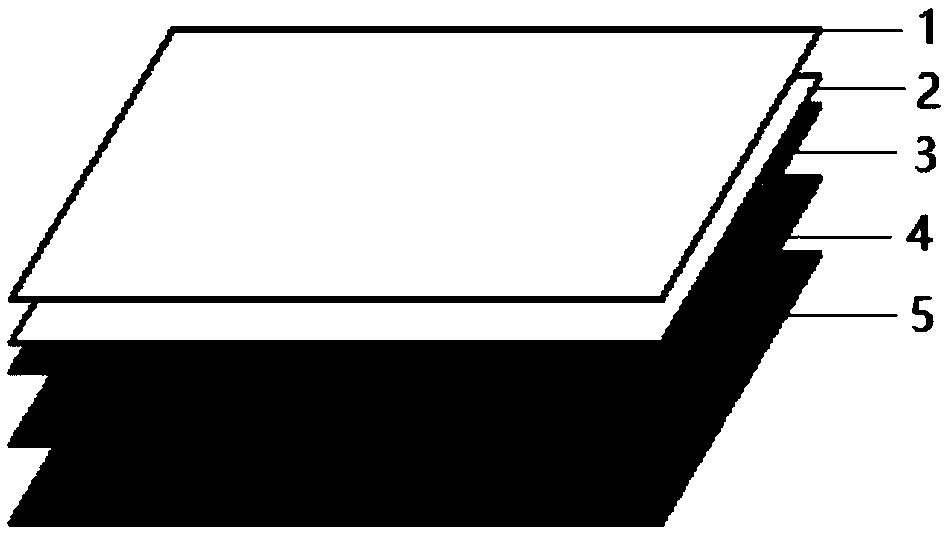

Composite blocky floor and preparation method thereof

PendingCN109403584AHigh strengthImprove applicabilityCovering/liningsFlooring insulationsCalcium silicateFoaming agent

The invention discloses a composite blocky floor and a preparation method thereof. The composite blocky floor is composed of a protective layer, a printing layer (3), a stabilizing layer (4) and a substrate layer (5) which are glued and pressed, wherein the protective layer is a PVC abrasion-resistant layer (2), the stabilizing layer (4) is a mixed extruded product of PVC, calcium carbonate stonepowder, a foaming agent, a lubricant, a modifier and a calcium and zinc composite stabilizer, and the substrate layer (5) is a fiber cement plate or a cement foaming plate or a fiber reinforced calcium silicate plate. The preparation method comprises the steps that firstly, the PVC, the calcium carbonate stone powder, the foaming agent, the lubricant, the modifier and the calcium and zinc composite stabilizer are mixed, and then the obtained mixture is blended and extruded to be formed; then through a hot pressing process, the PVC abrasion-resistant layer (2), the printing layer (3) and the obtained stabilizing layer (4) are composited and then subjected to still standing; and then the obtained mixed layer and the substrate layer (5) are glued and pressed into a whole, and the target product is prepared. The composite blocky floor is high in applicability, good in environmental friendliness and quick and convenient to pave, and is very easily and widely applied to the field of decoration in a commercialized mode.

Owner:ANHUI COORDINATED LIN PLASTIC TECH CO LTD

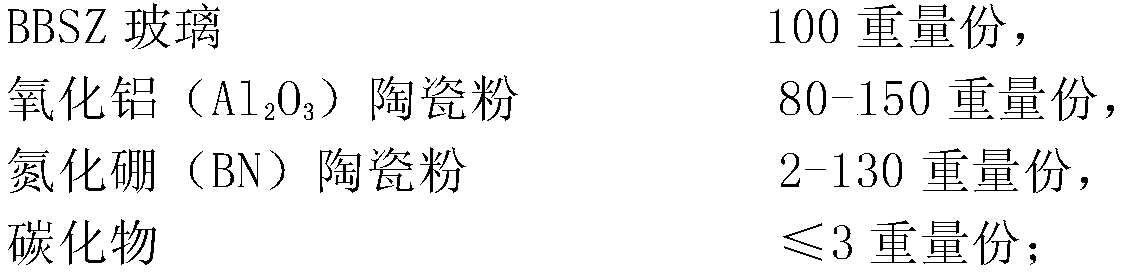

Low-temperature co-fired ceramic material of double-phase ceramic filler, and preparation method thereof

The invention discloses a low-temperature co-fired ceramic material of a double-phase ceramic filler, and a preparation method thereof. The material comprises, by weight, 100 parts of BBSZ glass, 80-150 parts of aluminum oxide ceramic powder, 2-130 parts of boron nitride ceramic powder and 3 parts or below of carbide, wherein the particle size of the aluminum oxide ceramic powder is 1-2 [mu]m, andthe particle size of the boron nitride ceramic powder is less than or equal to 400 nm. The method comprises the following steps: mixing bismuth trioxide, boron oxide, silicon oxide and zinc oxide, melting the obtained mixture, carrying out water-cooling quenching, ball-milling the obtained BBSZ glass slag into powder, and mixing the powder with the aluminum oxide ceramic powder and the boron nitride ceramic powder, and then sequentially carrying out joint ball milling on the obtained mixed powder, a solvent, a dispersing agent, a binding agent, a plasticizer and a homogenizing agent, carryingout tape casting on the obtained slurry in a mold, drying the cast slurry, sequentially placing obtained raw ceramic chips at different temperatures to remove organic additives, and carrying out sinter molding to obtain the target product. The material has excellent heat conduction and dielectric properties, and can be easily and widely commercially applied to the field of electronic packaging.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Microcapsule self-healing anticorrosion coating and preparation method thereof

The invention discloses a microcapsule self-repairing anticorrosive coating and a preparation method thereof. The coating is composed of silicon dioxide microcapsules containing corrosion inhibitor inside in silicon-based emulsion. The method is as follows: firstly, a tetraethyl orthosilicate cyclohexane solution and the corrosion inhibitor are mixed, and the pH value is adjusted by acid, then themixture is stirred and allowed to react, and then the reaction solution is filtered; subsequently, a sodium dodecyl benzene sulfonate aqueous solution is added to the obtained organic-inorganic hybrid emulsion and stirred, the obtained water-in-oil core material emulsion is subjected to solid-liquid separation, washing and drying in turn to obtain silicon dioxide microcapsule encapsulated with corrosion inhibitor, the metal platinum catalyst is added in silicone oil and stirred to obtain silicon-based emulsion, the silicon dioxide microcapsule encapsulated with corrosion inhibitor and the a metal platinum catalyst are mixed and maleic anhydride monododecyl ester is added, the mixture is subjected to stirring and reacting to obtain the target product. It has good stability and fast repairing speed, so it is very easy to be widely used in the field of steel structure and concrete steel structure corrosion protection.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

SiO2 acid-base composite nanometer coating with porous structure and preparation method thereof

The invention discloses a SiO2 acid-base composite nanometer coating with a porous structure and a preparation method thereof. The coating consists of a multi-slit film with the thickness of 150-200 nm, and a substrate is covered with the multi-slit film, wherein the multi-slit film is formed by placing SiO2 nanometer chains containing mesopores between SiO2 nanoparticles which are distributed in a three-dimensional net shape. The method includes the steps that separately prepared tetraethyl silicate ethanol solutions are dropwise added into a mixed aqueous solution and stirred for aging first, water and a mixed solution of ethanol and ethyl tetrasilicate are sequentially added into obtained SiO2 alkaline sol after an aqueous solution of nitric acid is added dropwise into the SiO2 alkaline sol, stirring is carried out to obtain acid-base composite sol, and then polyethylene glycol 300 is added into the acid-base composite sol and stirred for aging; the substrate is placed in the obtained sol for film coating and then subjected to immersing, pulling, film coating and air-drying, and then an obtained film-coated substrate is subjected to annealing to obtain a target product. The nanometer coating has good hydrophilicity and wear resistance and high light transmission performance and is extremely likely to be commercially used in the fields of fog resistance, automatic cleaning, wide-spectrum reflection enhancement and the like in a wide range.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

Preparation method of copper sulfide nano-sheet array

InactiveCN108383148AEase of widespread commercial applicationSave raw materialsCopper sulfidesSolar cellAqueous solution

The invention discloses a preparation method of a copper sulfide nano-sheet array. The preparation method comprises a solution method and especially comprises the following specific steps: evaporatinga copper film with the thickness of 20 to 500nm on the surface of a substrate, so as to obtain a substrate with the surface coated with the copper film; then putting the substrate with the surface coated with the copper film into a sodium sulfide water solution with the concentration of 0.001 to 0.1 weight percent and immersing for at least 4h; then taking out the substrate and washing to preparea target product with the sheet length of 100 to 2000nm and the sheet thickness of 10 to 50nm. According to the preparation method disclosed by the invention, the copper sulfide nano-sheet array cangrow on various substrates, and the preparation method has the characteristics of few raw materials, greenness and environment protection, energy saving and time saving and low cost, so that the target product is extremely easily widely and commercially applied to the fields of solar cells, photocatalysis and sensors.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

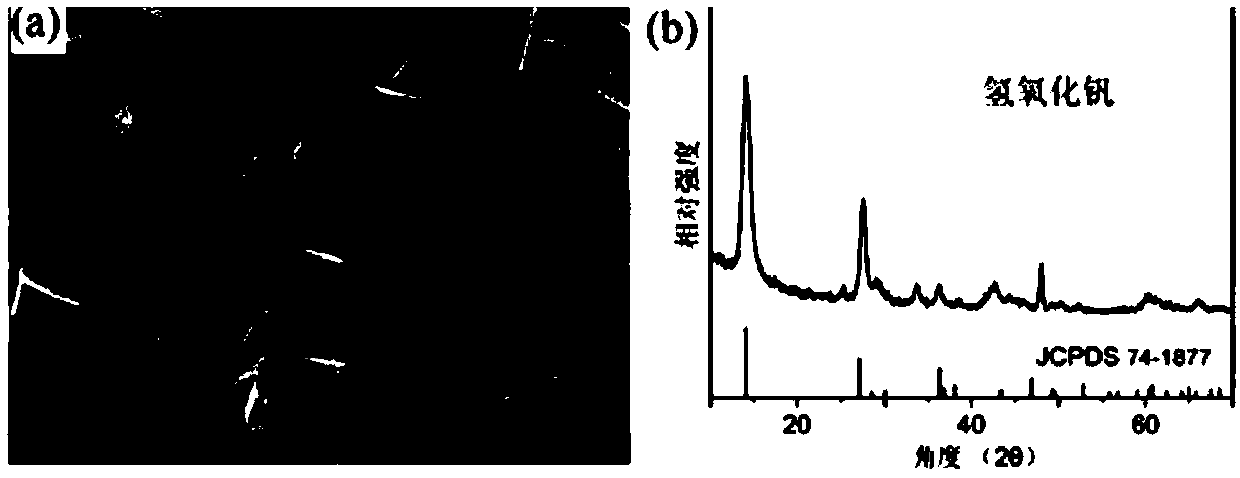

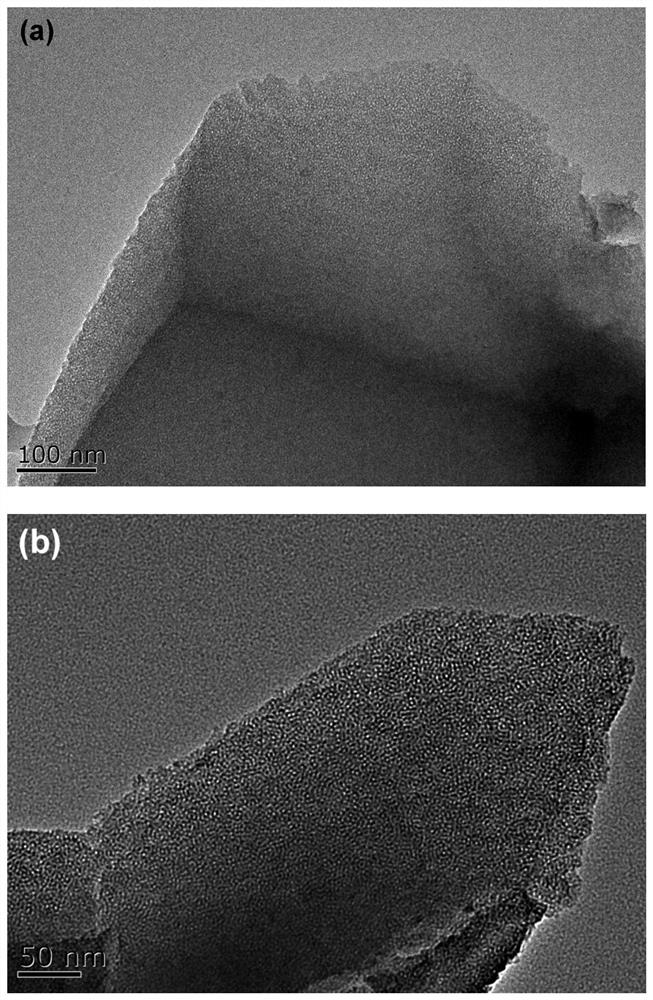

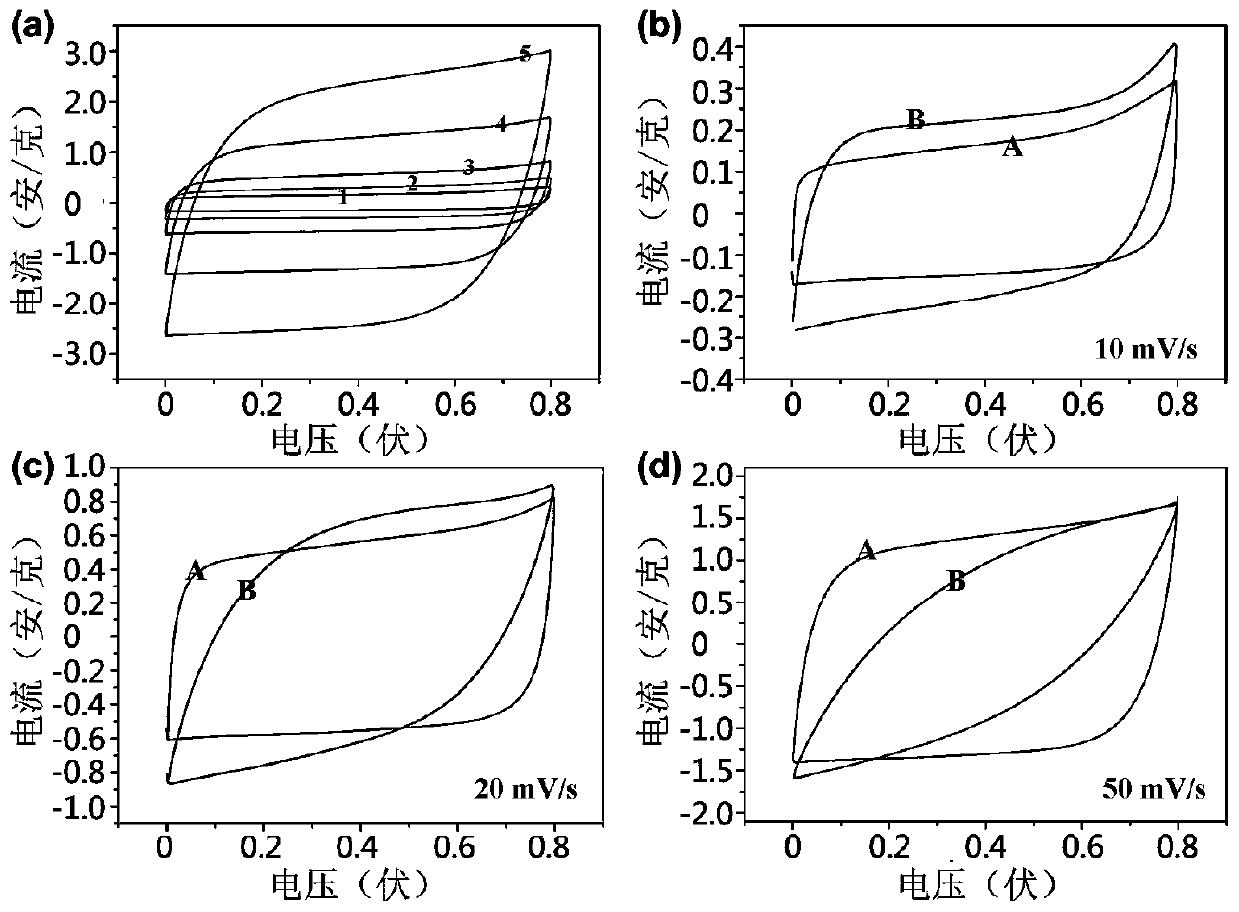

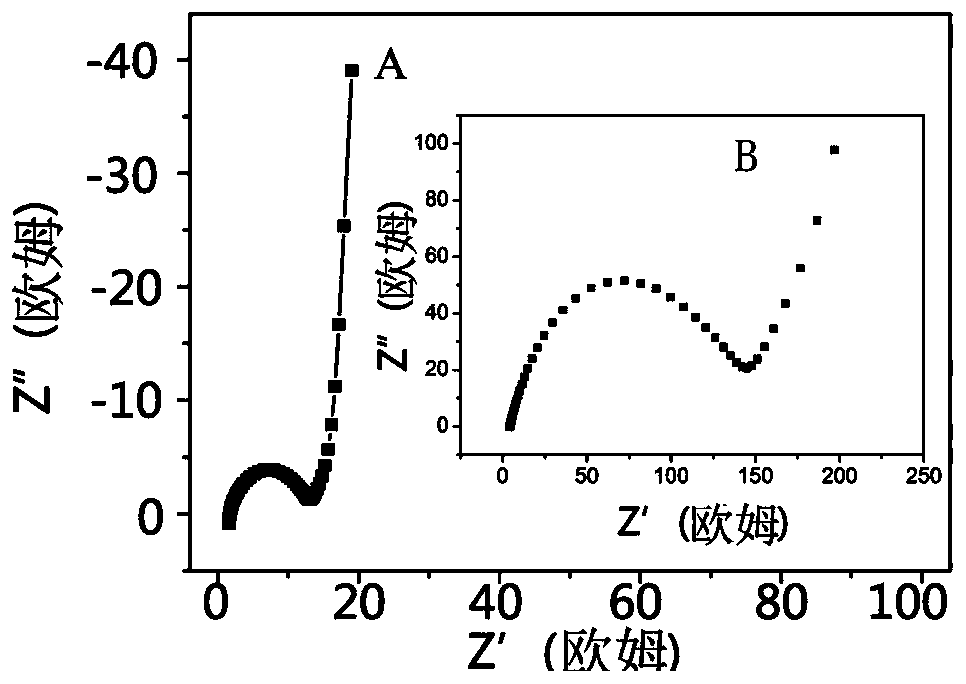

Vanadium hydroxide nanosheet and preparation method thereof

InactiveCN108675351AReasonable structureLarge specific surface areaNanotechnologyVanadium compoundsVanadateMagnesium ion

The invention discloses a vanadium hydroxide nanosheet and a preparation method thereof. The nanosheet is a vanadium hydroxide sheet having a thickness of 3 to 10 nm, a length of 200 to 500 nm and a width of 200 to 500 nm. The method comprises the steps: first mixing vanadium pentoxide or ammonium vanadate, ethylene glycol and deionized water, then stirring to obtain a mixed solution, reacting themixed solution in a closed state to obtain a turbid reaction liquid, then carrying out solid-liquid separation on the turbid reaction liquid, washing, and drying in turn to obtain the target product.The product has a reasonable structure and a high specific surface area, and is easy to widely use in the fields of sodium / lithium / magnesium ion batteries, supercapacitors and photocatalysis / electrocatalysis.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Durably-hydrophilic SiO2 nano mesoporous coating preparation method

The invention discloses durably-hydrophilic SiO2 nano mesoporous coating preparation method. The method includes: respectively preparing tetraethyl orthosilicate ethanol solution and nitric acid aqueous solution, and dropwise adding the nitric acid aqueous solution into the tetraethyl orthosilicate ethanol solution to obtain reaction precursor solution; then, stirring the reaction precursor solution, adding a pore forming agent into obtained SiO2 sol, stirring and aging to obtain sol for coating; finally, subjecting a glass substrate to dip coating in the sol for coating, airing, annealing thecoated glass substrate, cooling, and soaking in water to obtain a durably-hydrophilic SiO2 nano mesoporous coating on the glass substrate, wherein the durably-hydrophilic SiO2 nano mesoporous coatingin thickness of 100-200nm is formed by mesopores in diameter of 1-2nm. The durably-hydrophilic SiO2 nano mesoporous coating preparation method has advantages of energy saving, time saving and low manufacturing cost and can be easily, extensively and commercially applied to preparation of durably-hydrophilic SiO2 nano mesoporous coatings.

Owner:上海西源新能源技术有限公司

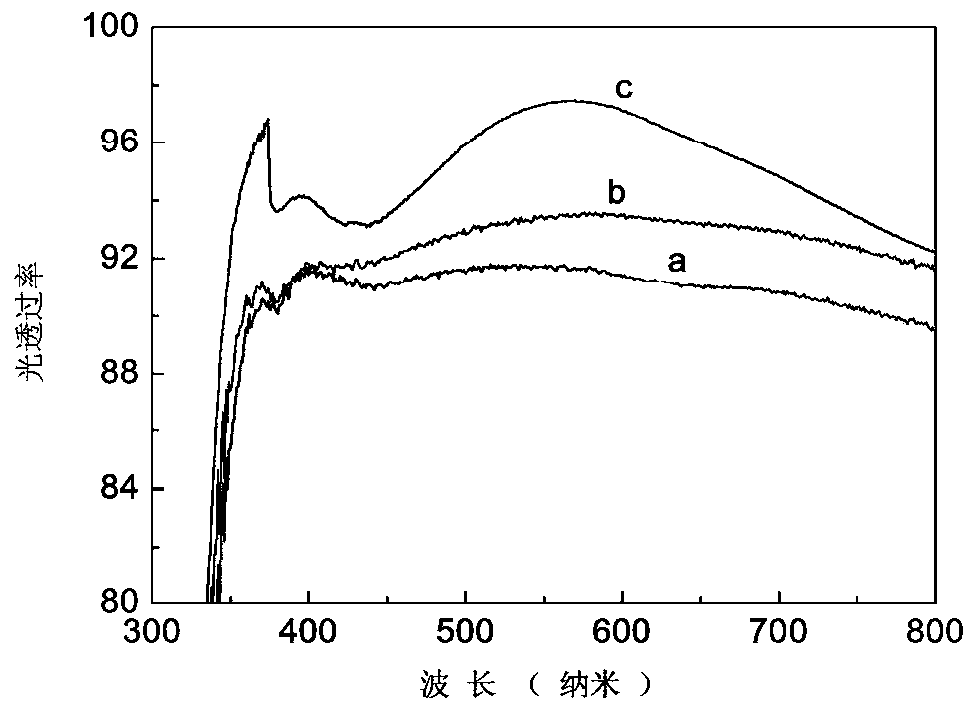

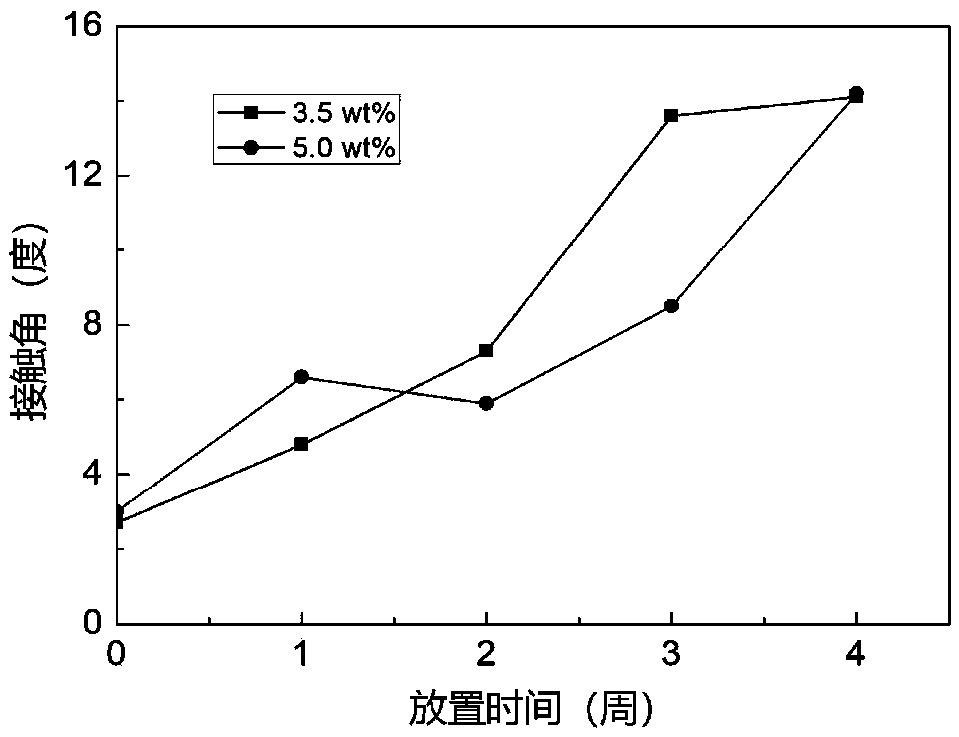

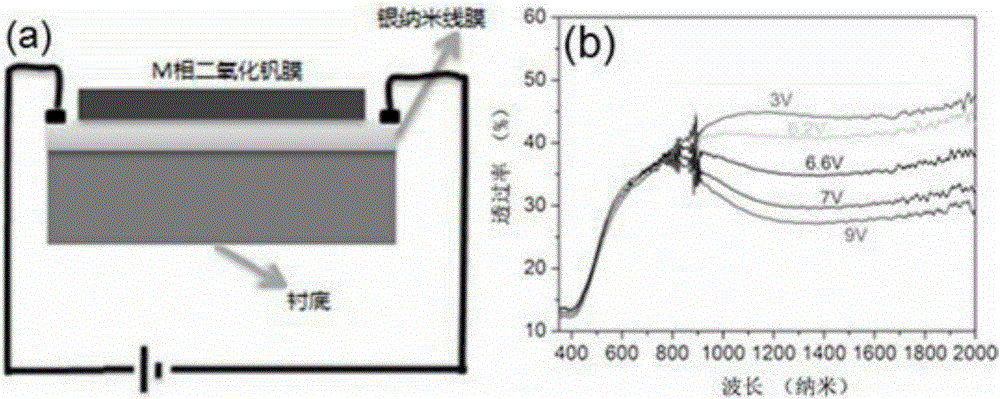

Silver nanowire-m-phase vanadium dioxide nanoparticle composite film and preparation method thereof

ActiveCN104228208BGood dispersionImprove transmittanceMaterial nanotechnologyLiquid surface applicatorsVanadium dioxideComposite film

The invention discloses a silver nanowire and M-phase vanadium dioxide nanoparticle composite film and a preparation method thereof. The film is prepared from silver nanowire film with the film thickness of 80-120 nm and an M-phase vanadium dioxide nanoparticle film with the film thickness of 100-1000 nm, which are sequentially coated on a substrate, wherein the linear diameter of the silver nanowire for forming the silver nanowire film is 40-100 nm, and the wire length is 50-100 microns; the particle size of the M-phase vanadium dioxide nanoparticle for forming the M-phase vanadium dioxide nanoparticle film is 20-100 nm. The preparation method comprises the following steps: spin coating or blade coating the substrate with silver nanowire isopropanol solution with the concentration of 0.3-1.5 wt%, drying the substrate, spin coating or blade coating the substrate coated with the silver nanowire film with M-phase vanadium dioxide nanoparticle aqueous solution with the concentration of 2-5 wt% or ethanol solution, and at last preparing the target product. The silver nanowire and M-phase vanadium dioxide nanoparticle composite film is low in phase transformation voltage; the preparation method is convenient and low in cost; the composite film can be widely applied to the fields such as energy-saving windows, gas sensors, optoelectronic switches, thermistors, infrared remote sensing receivers and uncooled focal plane radiation detectors.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

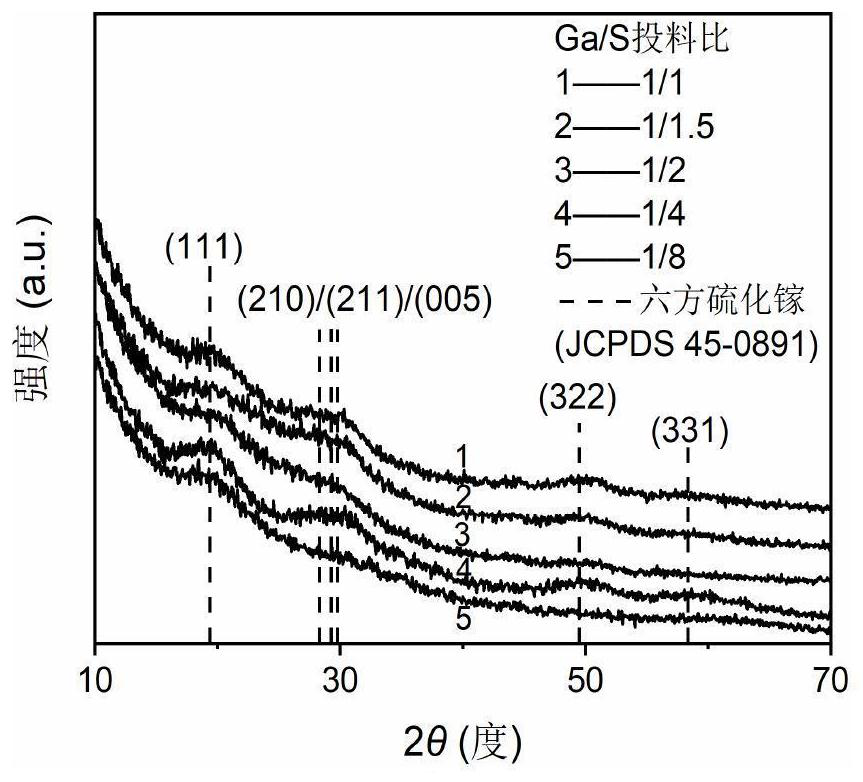

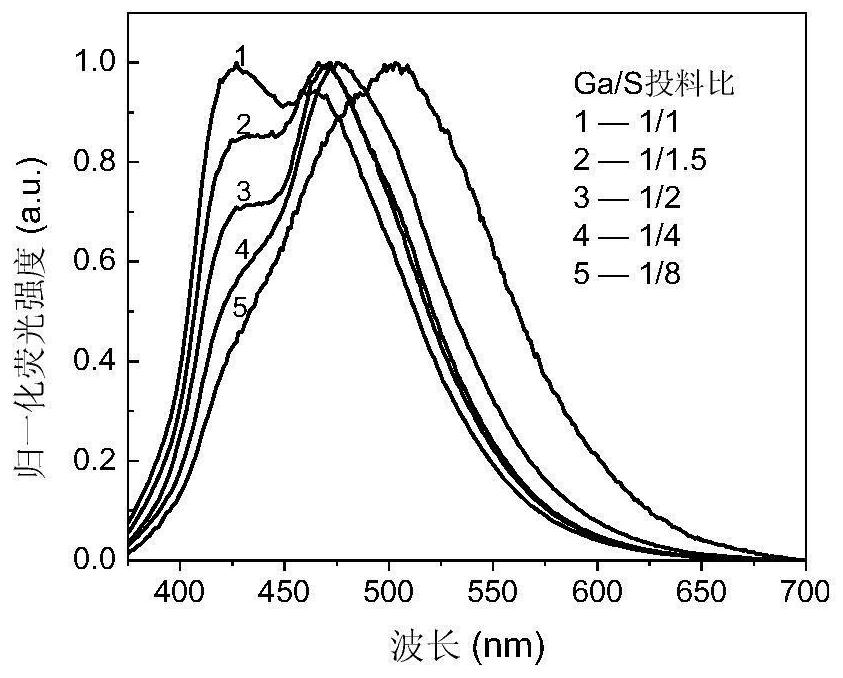

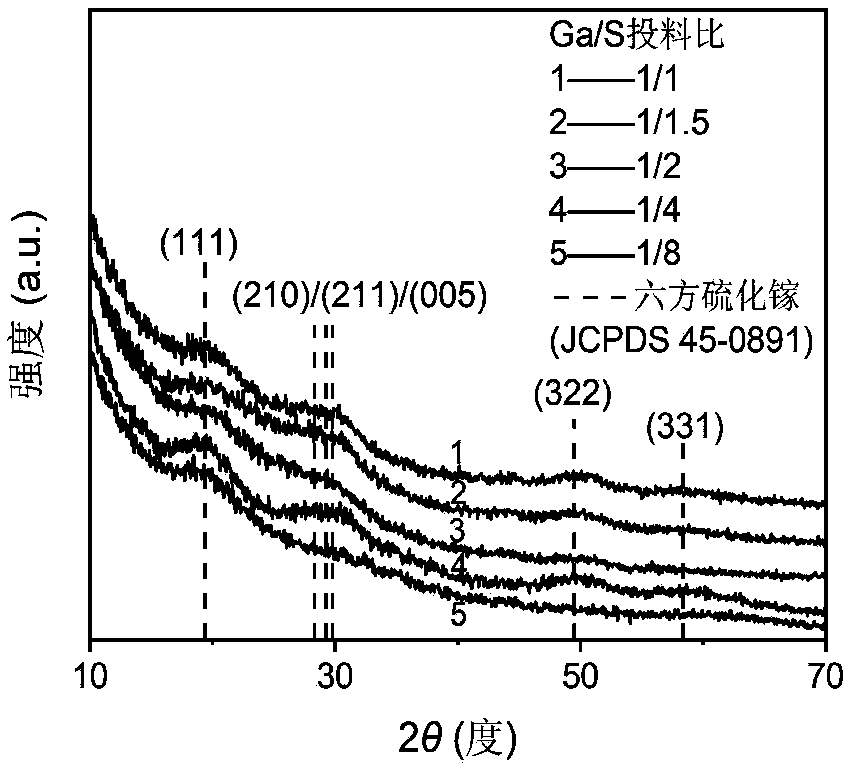

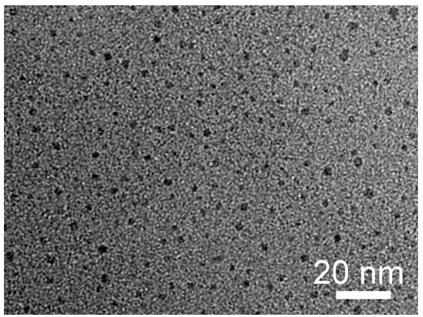

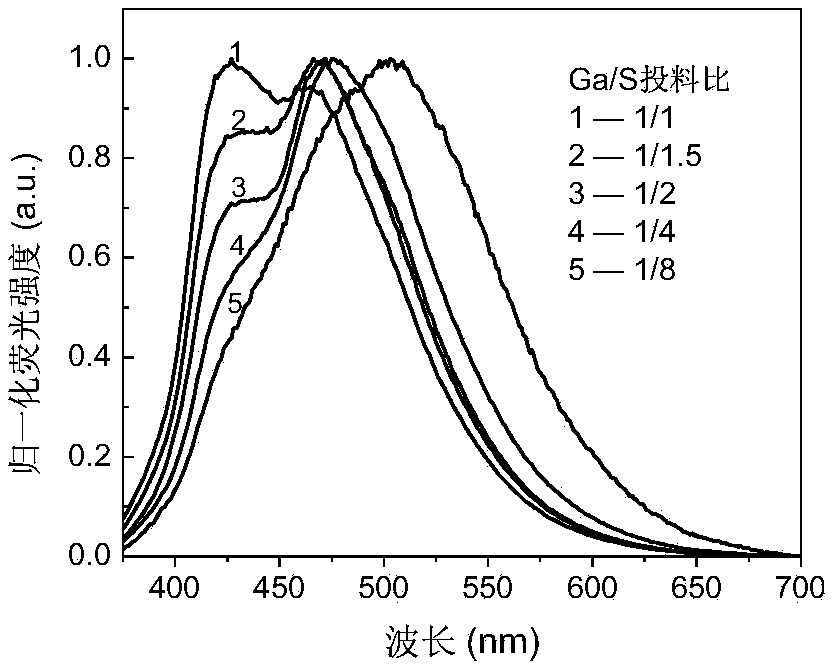

Gallium sulfide quantum dot material and preparation method thereof

ActiveCN109385272BEase of widespread commercial applicationSimple processLuminescent compositionsGallium sulfideUltraviolet lights

The invention discloses a gallium sulfide quantum dot material and a preparation method thereof. The material is gallium sulfide quantum dots, the chemical formula is Ga x S 3 , where 1≤x≤5, the chemical formula is Ga x S 3 The gallium sulfide quantum dots have a diameter of 1-8nm; the method is to mix four or mixed to obtain a mixed solution, and then the mixed solution is placed in an inert atmosphere and reacted at 220-300°C for 2-20min to obtain a reaction solution. After that, the molar ratio of the gallium source, solvent and precipitant in the reaction solution The ratio is 1:50-300:100-1400, adding solvent and precipitant successively to the reaction liquid cooled under an inert atmosphere to obtain a suspension, and then performing solid-liquid separation on the suspension to obtain a gallium sulfide quantum dot material . Its luminescence peak under the excitation of ultraviolet light is adjustable in the range of 420-505nm, and it is very easy to be widely commercialized and applied in the fields of light-emitting devices and ion detection.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Silica nanoporous membrane with graded porosity and preparation method thereof

The invention discloses a silicon dioxide nano porous membrane with gradient porosity and a preparation method of the silicon dioxide nano porous membrane. The nano porous membrane has the membrane thickness of 100-500 nm and consists of three or more layers of porous membranes with different spherical pore diameters, wherein the bottom pore diameter is 1-3 nm, the surface pore diameter is 5-8 nm,the pore edge space is 10-2 nm from bottom to top, and the porosity ranges from 30%-35% to 60%-70% from bottom to top. The method comprises the steps as follows: tetraethyl orthosilicate and ethanolare mixed, a mixed solution is obtained, a nitric acid aqueous solution is dropwise added to the mixed solution, silicon dioxide sol is obtained after stirring, cetyl trimethyl ammonium bromide is added, stirring is performed, mixed sol is obtained after aging, then, a substrate is sequentially placed in the mixed sol with gradually increased cetyl trimethyl ammonium bromide for pull coating 3 times or more, the obtained product is aired and annealed, and a target product is prepared. The silicon dioxide nano porous membrane has wear resistance and super-hydrophilic property and can be very easily and commercially applied to anti-fog, self-cleaning, wide spectrum anti-reflection fields and the like.

Owner:上海西源新能源技术有限公司

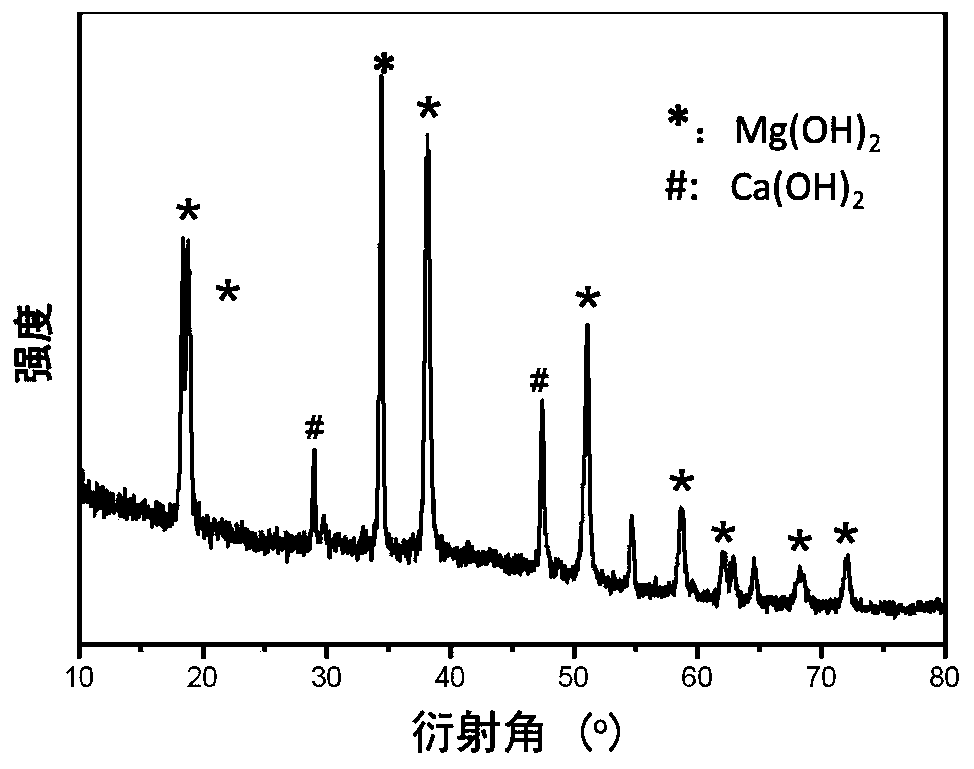

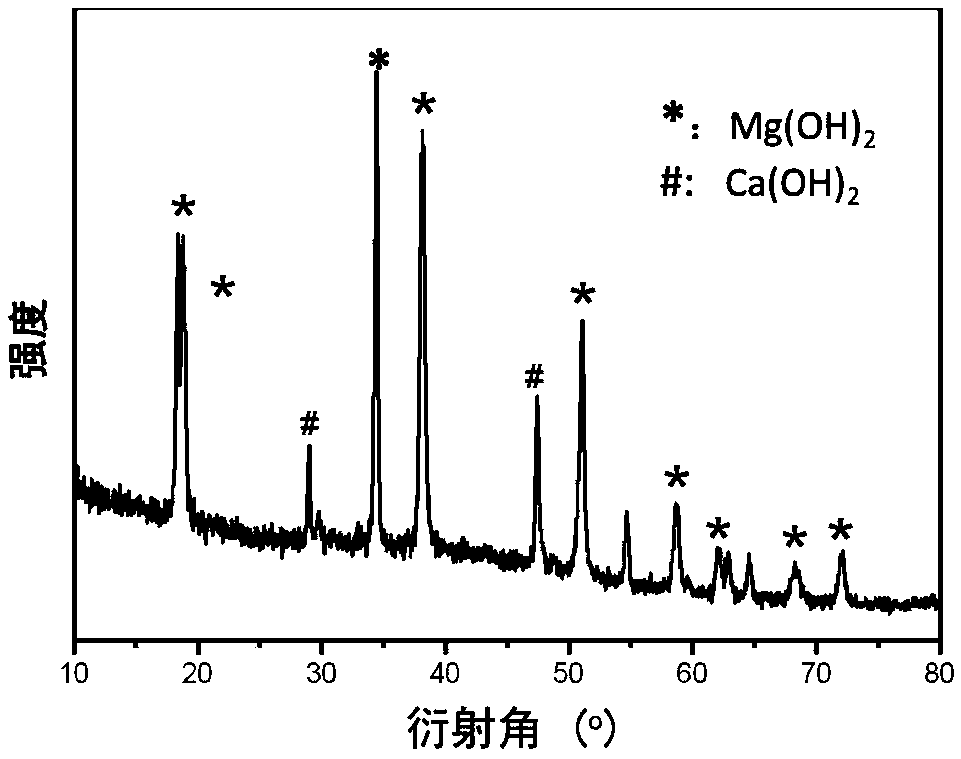

Magnesium hydroxide-calcium alginate composite flame retardant and preparation method thereof

ActiveCN108822874BImprove flame retardant performanceImprove thermal stabilityFireproof paintsSpinningLimiting oxygen index

The invention discloses a magnesium hydroxide-calcium alginate composite fire retardant and a preparation method thereof. The fire retardant is prepared from magnesium hydroxide and calcium alginate with the molar ratio being (1 to 3) to 1. The method comprises the following steps of calcining dolomite mineral powder to obtain dolomite ash powder, then adding the dolomite ash powder into water forstirring to obtain a digestive juice, then dropwise adding a sodium alginate aqueous solution into the digestive juice under stirring, performing stirring and foaming to obtain a foamed gel, then performing dryness finalization treatment on the foamed gel to prepare a target product, wherein dryness finalization treatment is spray drying finalization, spinning drying finalization, coating dryingfinalization or die formation drying finalization. The magnesium hydroxide-calcium alginate composite fire retardant has a limit oxygen index of 40 percent, is not decomposed with heat still at high temperature of 250 DEG C and is very easy to be widely and commercially applied to the fields of degradable fire-retardant fabrics, fire-retardant coating layers for decoration, non-combustible children toys and the like.

Owner:武宣宝丰矿业有限公司

sio with porous structure 2 Acid-base composite nano-coating and preparation method thereof

ActiveCN110272212BImprove wear resistanceExhibit superhydrophilic propertiesSilicic acidNanoparticle

The invention discloses a SiO with porous structure 2 Acid-base composite nano-coating and preparation method thereof. The coating is composed of a 150‑200nm thick multi-slit film on the substrate, in which the multi-slit film is composed of SiO2 distributed in a three-dimensional network 2 Nanoparticles interposed with SiO containing mesoporous 2 Nano chains are formed; the method is to drop the separately prepared ethyl tetrasilicate ethanol solution into the mixed aqueous solution drop by drop, then stir and age, and then add the obtained SiO 2 After adding nitric acid aqueous solution dropwise to the alkaline sol, add water, ethanol and ethyl tetrasilicate mixture to it in turn, after stirring to obtain an acid-base composite sol, then add polyethylene glycol 300 to it first and stir for aging Finally, the substrate is placed in the obtained sol for coating, dipped to pull the coating, and then dried, and then annealed the obtained substrate coated with a film to obtain the target product. It has good hydrophilicity, wear resistance and high light transmittance, and it is very easy to be widely commercialized and used in anti-fog, self-cleaning, wide-spectrum anti-reflection and other fields.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

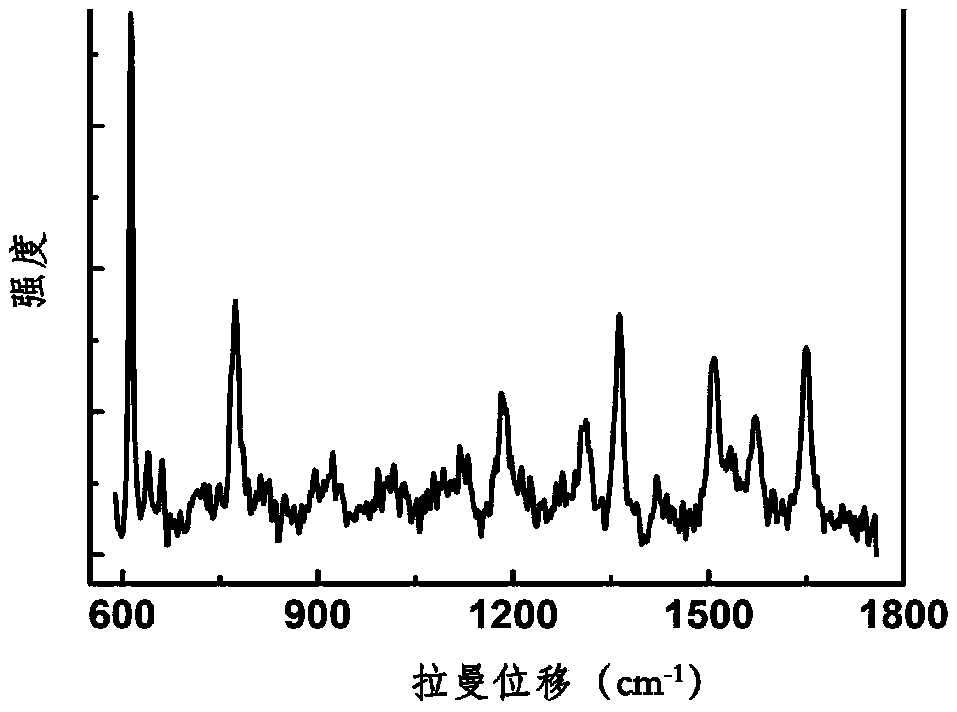

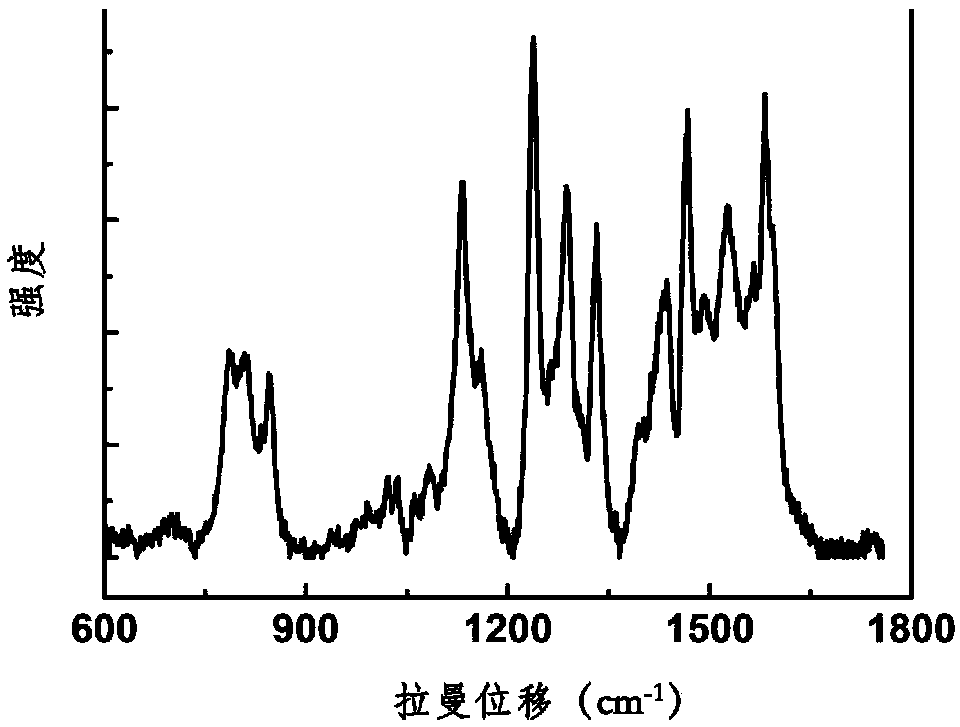

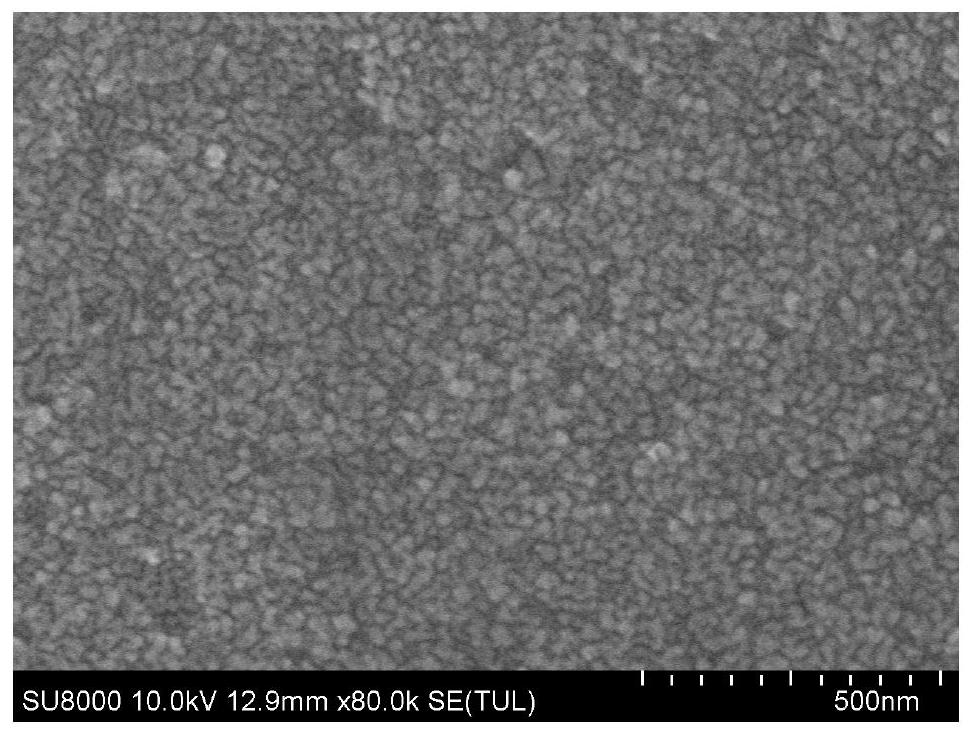

Preparation method of tungsten oxide film

The invention discloses a preparation method of a tungsten oxide film. The preparation method of the tungsten oxide film comprises the following steps: annealing an ammonium tungstate powder first toobtain a tungsten trioxide powder, and then mixing the tungsten trioxide powder and water to obtain an aqueous solution of tungsten trioxide; then, adding sodium borohydride to the aqueous solution oftungsten trioxide first and reacting for 0.5 to 5 hours to obtain a reaction liquid, and then performing solid-liquid separation, washing and drying on the reaction liquid successively to obtain a powdery intermediate product; and finally, dispersing the powdery intermediate product in ethanol first to obtain a dispersion liquid, and coating the dispersion liquid onto a substrate to obtain a target product. The preparation method of the tungsten oxide film has the characteristics of simple and secure process, and low cost of required equipment, and makes the target product very easy to be widely commercialized for rapid trace detection of the rhodamine 6G and 3,3'-diethylthiotricarbocyanine iodine.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

outdoor sio 2 Superhydrophilic nano coating and preparation method thereof

ActiveCN109081608BImprove hydrophilicityGood weather resistanceCoatingsWeather resistanceSilicic acid

The invention discloses an outdoor SiO 2 Superhydrophilic nano coating and its preparation method. The coating is composed of a mesoporous acid film connected to a granular alkali film on a glass substrate; the method is to first drop the prepared ethyl tetrasilicate ethanol solution into the aqueous ammonia solution, and then stir and age the obtained alkali-catalyzed reaction precursor solution After, to the obtained aged SiO 2 Add nitric acid aqueous solution dropwise to the alkaline sol, then add water and a mixture of ethanol and ethyl tetrasilicate to it in turn, then, first stir the obtained acid-catalyzed reaction precursor solution containing alkali particle sol, and then wait for the obtained acid After the alkali composite sol is allowed to cool to room temperature, add a pore-forming agent to it and then age after stirring. Finally, the glass substrate is dipped in the obtained sol for coating to pull the coating and then dried, and then the obtained coating is Annealing the glass substrate to obtain the target product. It has high outdoor weather resistance, and it is very easy to be widely commercialized and applied in anti-fog, self-cleaning, wide-spectrum anti-reflection and other fields.

Owner:上海西源新能源技术有限公司

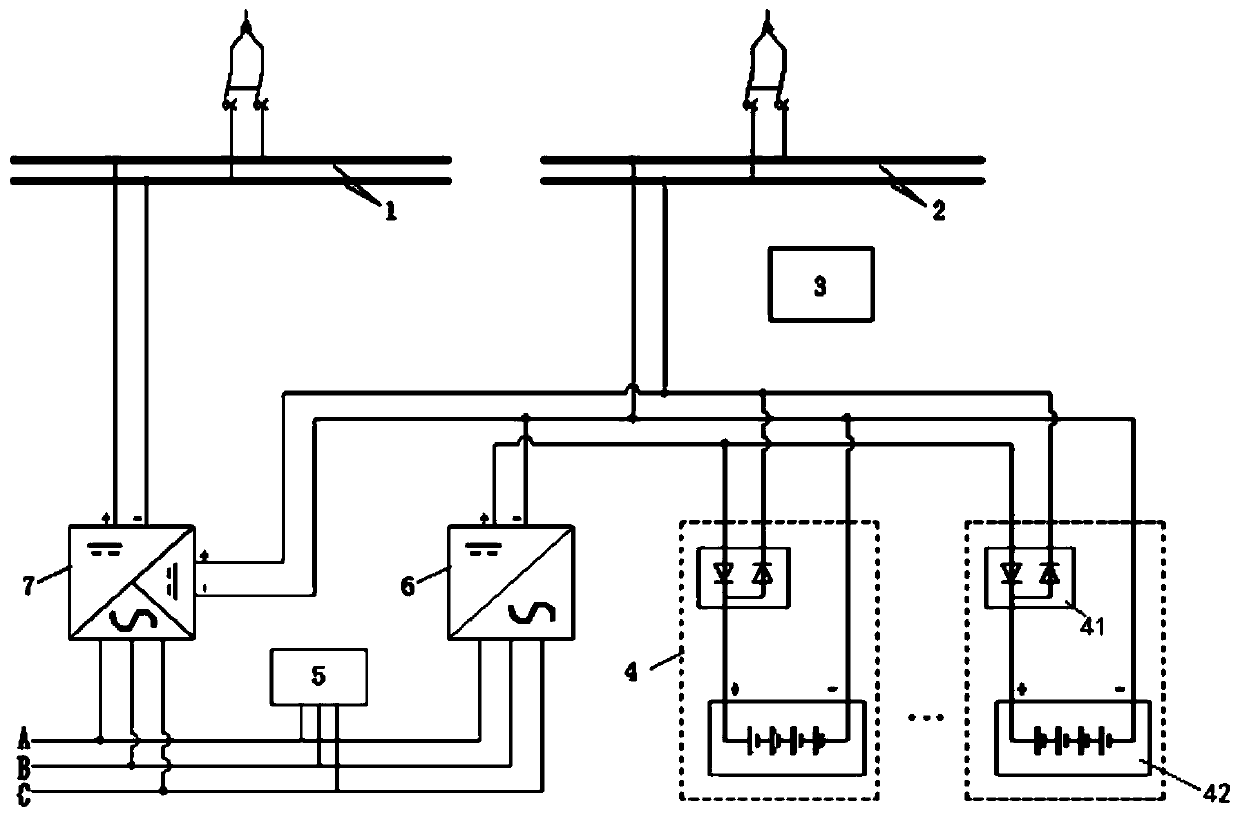

Hybrid direct-current power supply device for transformer substation

PendingCN110380507AEasy maintenanceEasy to replaceAc-dc conversion without reversalDc-dc conversionElectricityPower station

The invention discloses a hybrid direct-current power supply device for a transformer substation, which is characterized in that a storage battery pack of the hybrid direct-current power supply is a common battery pack (4) formed by connecting a counter current assembly (41) and a power storage assembly (42), the input end of the common battery pack (4) is electrically connected with the output end of a charging component (6), the output end of the common battery pack (4) is electrically connected with a communication power supply (2), the input end of the charging component (6) is electrically connected with an alternating-current power supply (ABC), the output end of the charging component (6) is electrically connected with the input end of the common battery pack (4), the output end ofa current transforming component (7) formed by a rectifying assembly and a direct current boosting assembly is electrically connected with an electric power operation power supply (1), the input end of the rectifying assembly is electrically connected with the alternating-current power supply (ABC), and the input end of the direct current boosting assembly is electrically connected with the outputend of the common battery pack (4). The hybrid direct-current power supply device is simple in structure, convenient to operate and maintain and extremely easy to be widely and commercially applied to various power plants and transformer substations in China to serve as a control power supply for popularization and application.

Owner:ANHUI XINLI ELECTRICAL EQUIP

Lead sulfide film with broad absorption spectrum and preparation method thereof

ActiveCN107315215BWide range of full coverage featuresBroadband Absorption CharacteristicsLead sulfidesOptical elementsThioureaEthylic acid

The invention discloses a lead sulfide thin film with the wide absorption spectrum and a preparation method of the lead sulfide thin film. The thickness of the thin film is 500-540nm. The particle diameter of each lead sulfide crystal grain is 6-10nm. At the wave band of 450-220nm, the thin film consisting of the lead sulfide crystal grains the diameter of each of which 6-10nm displays an absorption peak. According to the invention, by use of the chemical vapour deposition method: firstly successively adding the sodium hydroxide solution, the thiourea solution and the triethanolamine solution into the lead acetate solution so as to obtain a mixed solution; then adding the deionized water into the mixed solution to obtain a reaction solution; arranging a substrate into the stirred reaction solution of the 70 DEG C-80 DEG C for at least 2h so as to obtain the substrate with the reagent on the surface; and cleaning and drying the substrate with the reagent on the surface to prepare the target product. According to the invention, the thin film has the quite wide wave band absorption characteristic, and is quite easily, widely and commercially applicable to field of photodetection, solar energy coating absorption layers and gas sensing detection.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

Magnesium hydroxide-calcium alginate composite fire retardant and preparation method thereof

ActiveCN108822874AImprove flame retardant performanceImprove thermal stabilityFireproof paintsLimiting oxygen indexCalcium alginate

The invention discloses a magnesium hydroxide-calcium alginate composite fire retardant and a preparation method thereof. The fire retardant is prepared from magnesium hydroxide and calcium alginate with the molar ratio being (1 to 3) to 1. The method comprises the following steps of calcining dolomite mineral powder to obtain dolomite ash powder, then adding the dolomite ash powder into water forstirring to obtain a digestive juice, then dropwise adding a sodium alginate aqueous solution into the digestive juice under stirring, performing stirring and foaming to obtain a foamed gel, then performing dryness finalization treatment on the foamed gel to prepare a target product, wherein dryness finalization treatment is spray drying finalization, spinning drying finalization, coating dryingfinalization or die formation drying finalization. The magnesium hydroxide-calcium alginate composite fire retardant has a limit oxygen index of 40 percent, is not decomposed with heat still at high temperature of 250 DEG C and is very easy to be widely and commercially applied to the fields of degradable fire-retardant fabrics, fire-retardant coating layers for decoration, non-combustible children toys and the like.

Owner:武宣宝丰矿业有限公司

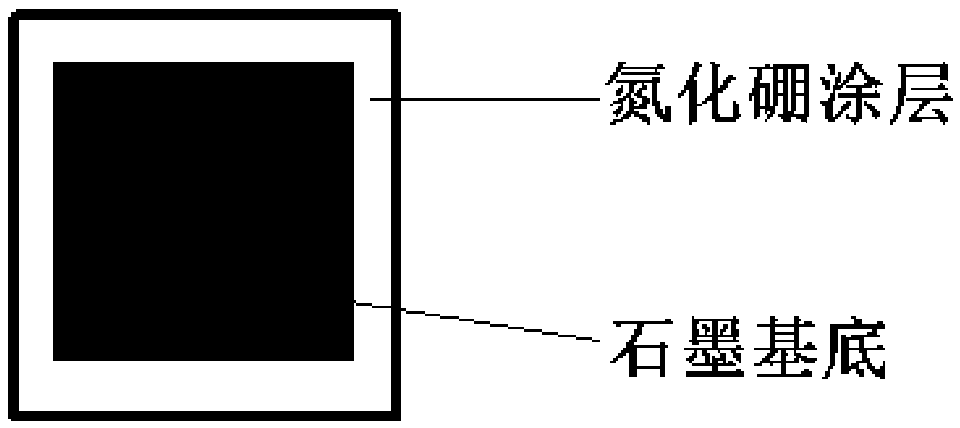

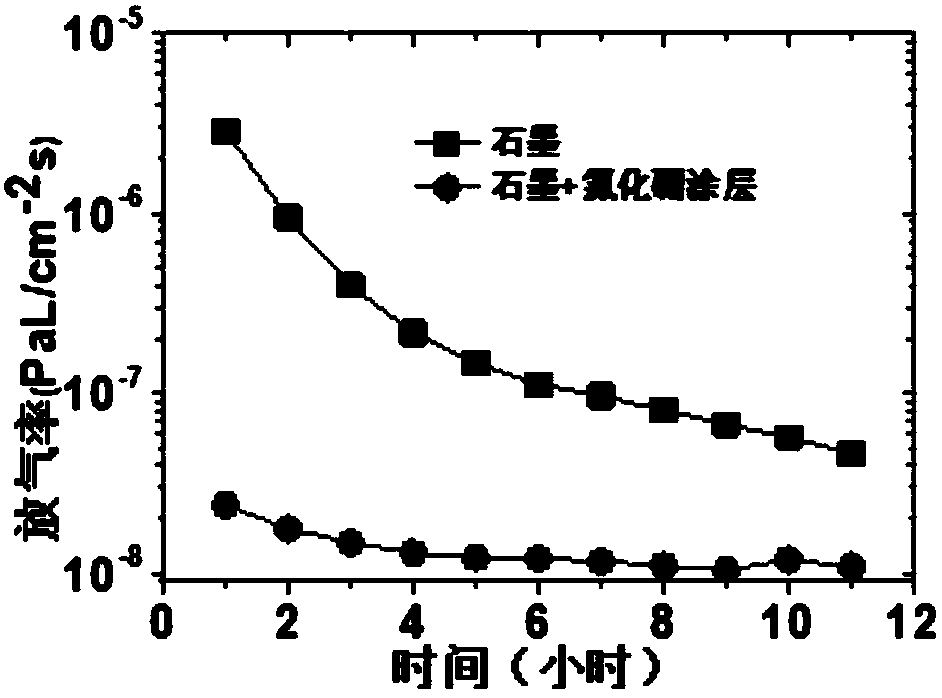

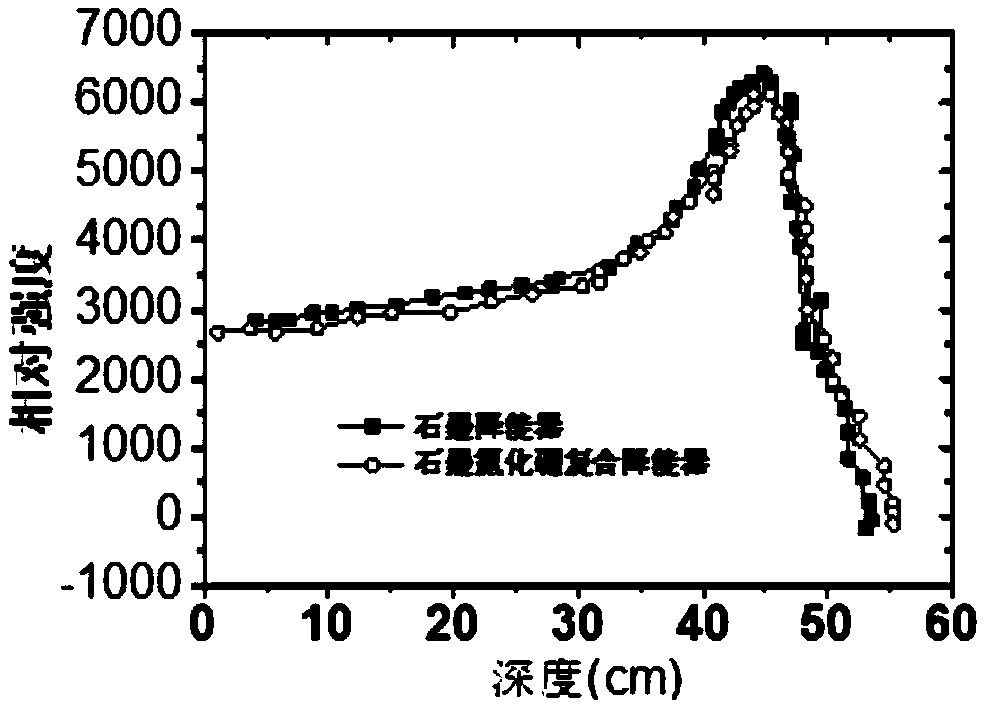

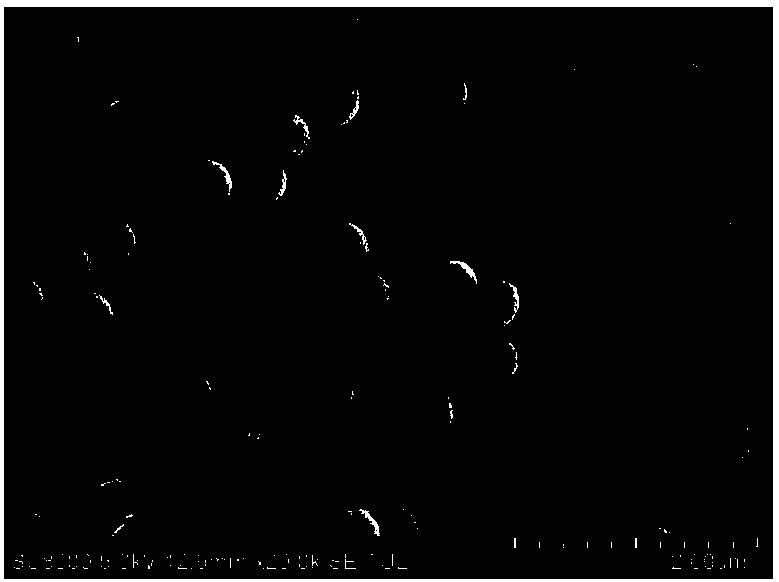

Energy-reducing device for high-energy particles and its preparation method

ActiveCN107863173BImprove adhesionPut an end to deflationRadiation/particle handlingVacuum evaporation coatingBeam energyBoron nitride

The invention discloses a high-energy particle energy-reducing device and a preparation method thereof. The energy-reducing device is a graphite substrate covered with a dense boron nitride coating, and the thickness of the dense boron nitride coating is 5-800[mu]m; the preparation method adopts a vapor deposition method, and comprises the following steps: firstly, placing a graphite substrate into a vacuum chamber, then mixing an ammonia gas, a boron chloride gas and a nitrogen gas according to the volume ratio of the ammonia gas to the boron chloride gas to the nitrogen gas of (0.8-1.2):(0.8-1.2):(40-60) to obtain a mixed gas, then firstly raising the temperature in the vacuum chamber to 500-2000 DEG C, and finally introducing the mixed gas with a flow quantity of 10-100sccm into the vacuum chamber for 12-36h to obtain the target product. According to the high-energy particle energy-reducing device provided by the invention, the degassing rate is much lower than that of a graphite energy-reducing device, a high-energy particle beam has good penetrating performance on the high-energy particle energy-reducing device and the graphite energy-reducing device, and the high-energy particle energy-reducing device can be easily, widely and commercially applied to the fields of high-precision and high-energy particle beam energy reduction of a cyclotron.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

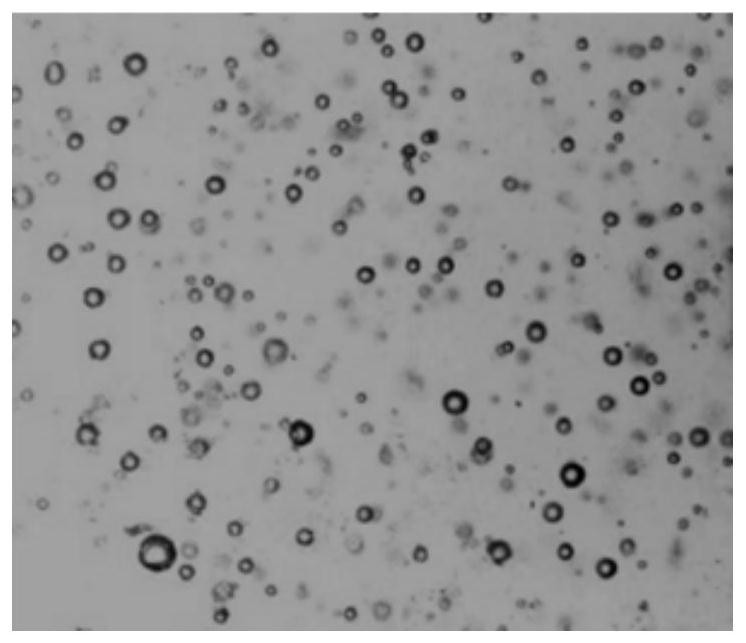

Nano colloidal motor and preparation method thereof

InactiveCN108483393AGood dispersionSuitable for targeted exerciseSpecific nanostructure formationIndividual molecule manipulationPlatinumSewage treatment

The invention discloses a nano colloidal motor and a preparation method thereof. The motor comprises an open spherical platinum shell, wherein the diameter of the shell is smaller than or equal to 500nm, the thickness of the shell is 5-30 nm, and the shell is coated with a silver shell or gold shell with thickness of 5-20 nm. The method comprises the following steps: firstly, placing a colloidalsphere on a substrate to form a single-layer close-packed colloidal crystal template, and heating the colloidal crystal template so as to obtain the single-layer close-packed colloidal crystal template, wherein the colloidal sphere is fixedly connected with the substrate; and then carrying out plasma etching on the single-layer close-packed colloidal crystal template so as to obtain a single-layernon-close-packed colloidal crystal template, wherein the colloidal sphere is fixedly connected with the substrate, then sequentially evaporating a platinum layer and a silver layer (or a gold layer)on the single-layer non-close-packed colloidal crystal template, then separating the colloidal sphere sequentially coated with the platinum layer and the silver layer (or the gold layer) on the surface on the single-layer non-close-packed colloidal crystal template from the substrate by using a physical method, putting the mixture into a solvent or subjecting the mixture to calcining to remove thecolloid ball to prepare a target product. The product is small in size, single in movement direction and hollow, and can be easily, widely and commercially applied to the technical fields of drug targeting motion, material transportation, ion detection, sewage treatment and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

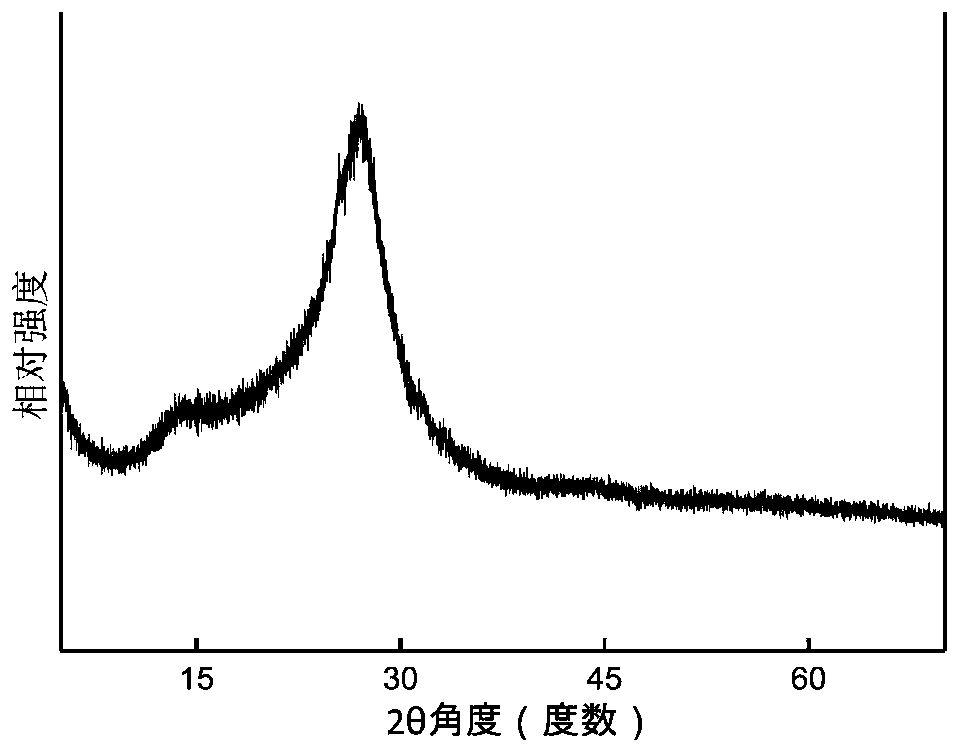

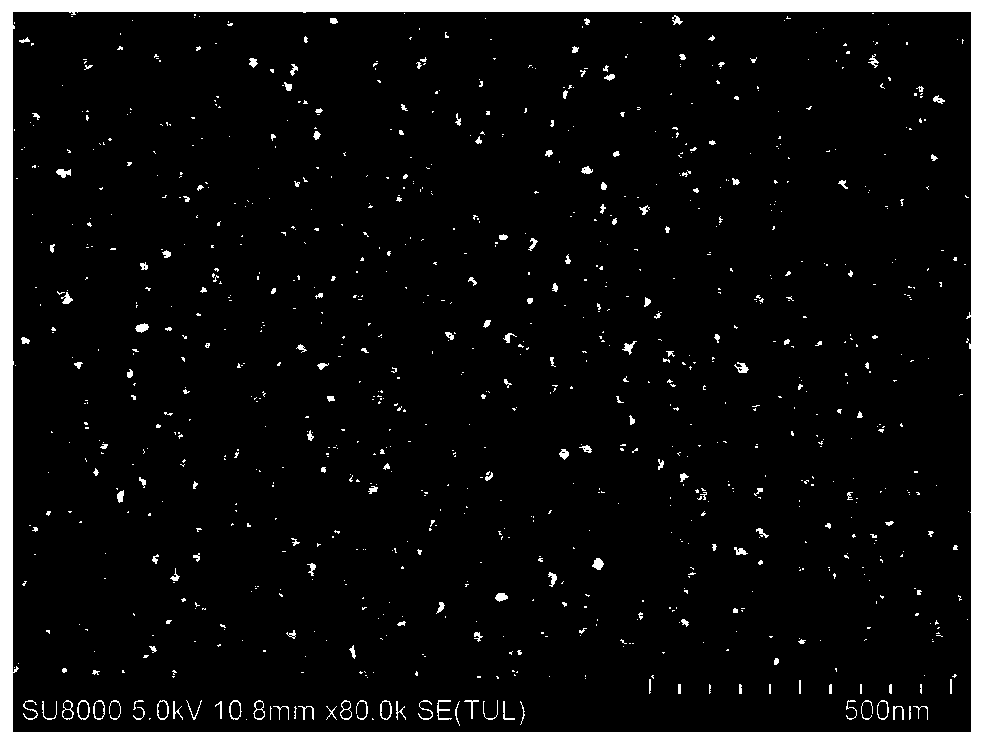

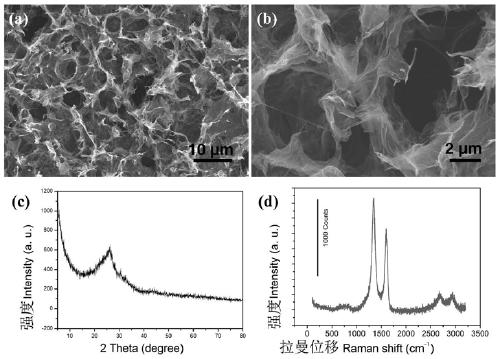

Preparation method of porous graphene

ActiveCN107311155BGood electrical conductivityEase of widespread commercial applicationGraphenePorous grapheneArgon atmosphere

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Gallium sulfide quantum dot material and preparation method thereof

ActiveCN109385272AEase of widespread commercial applicationSimple processLuminescent compositionsSolventGallium sulfide

The invention discloses a gallium sulfide quantum dot material and a preparation method thereof. The material contains gallium sulfide quantum dots, the chemical formula is GaxS3, wherein x is more than or equal to 1 and less than or equal to 5, and the diameter of the gallium sulfide quantum dots of the chemical formula GaxS3 is 1-8 nm. The method comprises the steps of mixing a gallium source, asulfur source, octadecene and a ligand in a molar ratio of 1: (0.5-10): (20-80): (20-100) to obtain a mixed solution, then placing the mixed solution in an inert atmosphere, reacting at 220 to 300 DEG C for 2 to 20 min to obtain a reaction solution, sequentially adding a solvent and a precipitant to the reaction solution cooled in the inert atmosphere according to the molar ratio of 1: (50-300):(100-1400) of the gallium source, the solvent and the precipitant in the reaction solution to obtain a suspension, and performing solid-liquid separation on the suspension to obtain the gallium sulfide quantum dot material. The luminescent peak of the material under ultraviolet excitation is adjustable in the range of 420 to 505 nm, and the material can be widely and commercially applied in the fields of light-emitting devices, ion detection and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

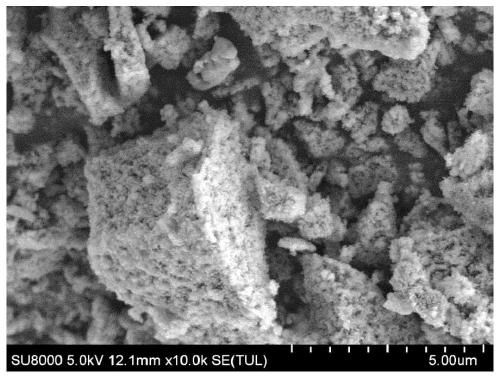

Active magnesium hydroxide flame retardant and preparation method thereof

The invention discloses an active magnesium hydroxide flame retardant and a preparation method thereof. The flame retardant is prepared by carrying out chemical bonding on powdery magnesium hydroxideand a diamino-silane coupling agent, wherein the molar ratio of the powdery magnesium hydroxide to the diamino-silane coupling agent is 200 to (1 to 2). The method comprises the following steps: drying the powdery magnesium hydroxide and preparing a mixed solution of ethanol, water and the diamino-silane coupling agent; then dispersing the dried powdery magnesium hydroxide into the mixed solutionand stirring to obtain reaction liquid; sequentially carrying out solid-liquid separation, washing and drying treatment on the reaction liquid to obtain a target product. The active magnesium hydroxide flame retardant has higher compatibility with high polymer materials and is prone to be widely commercially applied to the flame retardant field of polymer materials.

Owner:武宣宝丰矿业有限公司

Colorful solar cell and preparation method thereof

ActiveCN106876592BVariable colorReasonable structureFinal product manufactureSolid-state devicesEvaporation (deposition)Electrical battery

The invention discloses a colorful solar cell and a preparation method thereof. The battery is an ordered silicon nanowire array with a PN junction formed on the surface on a silicon substrate, wherein the diameter of the silicon nanowire is 50-120nm, the period is 500-1500nm, and the surface is covered with a dielectric layer with a thickness of 1-200nm; method In order to make an ordered mask on the surface of the silicon substrate using the nanosphere template method or electron beam exposure method or nanoimprint technology, the ordered nanometers are etched on it using a wet process or a Bosch process of reactive ion etching. line array, and then use the diffusion process to do the boron element on the surface of the silicon substrate with the ordered silicon nanowire array on it, and then, the obtained ordered silicon nanowire array with the PN junction formed on the surface After the dielectric layer is made by chemical vapor deposition method, electron beam evaporation method, atomic layer deposition technology or spin coating method on the silicon substrate, electrodes are made on it to obtain the target product. It can be easily and widely commercially applied to photovoltaic power generation systems in cities.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com