Mesoporous graphite-like phase carbon nitride material as well as preparation method and application thereof

A graphite-phase carbon nitride and mesoporous technology, applied in chemical instruments and methods, nitrogen compounds, nitrogen and non-metallic compounds, etc., can solve the problems of inability to obtain specific surface area products and limited increase in product specific surface area, and achieve low cost , The preparation method is simple, and the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The concrete steps of preparation are:

[0037] Step 1, according to the weight ratio of cyanuric acid, cyanuric chloride and organic solvent is 2:4:10, the three are mixed and stirred for 20 minutes; wherein, the organic solvent is acetonitrile to obtain a mixed solution.

[0038] Step 2, drying the mixed solution at 60°C to obtain a precursor.

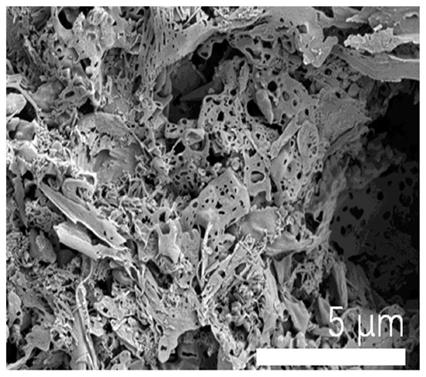

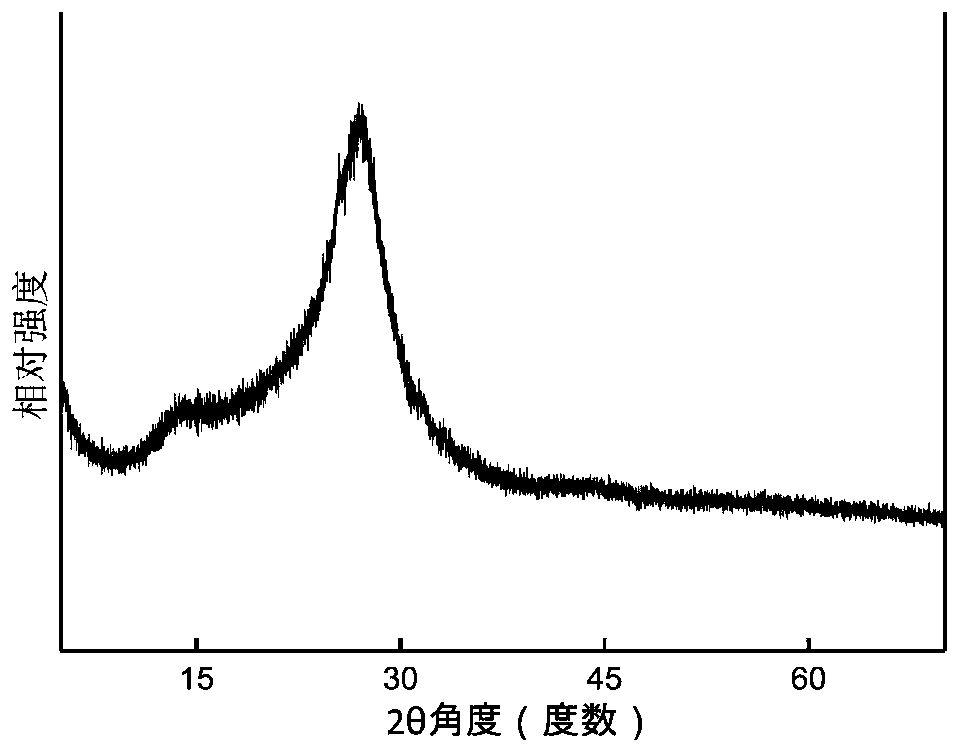

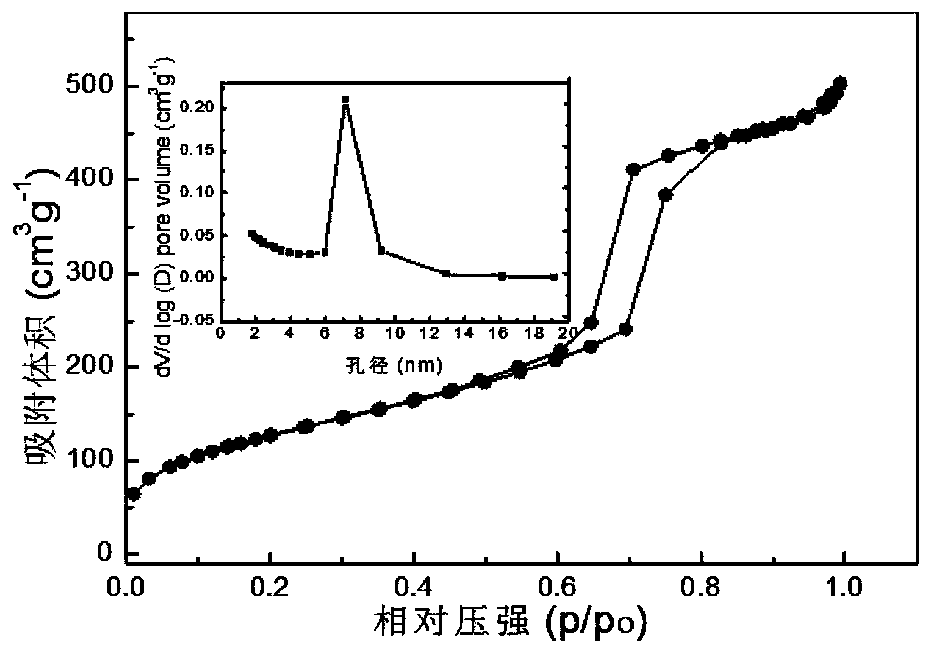

[0039] In step 3, heat the precursor at 580°C for 20 minutes; wherein, the temperature rise rate of the precursor from room temperature to the heating temperature is 8°C / min, and the approximate figure 1 shown, and as figure 2 with image 3 Mesoporous graphitic phase carbon nitride material shown in the curve.

Embodiment 2

[0041] The concrete steps of preparation are:

[0042] Step 1, according to the weight ratio of cyanuric acid, cyanuric chloride and organic solvent is 2.5:3.5:10, the three are mixed and stirred for 25 minutes; wherein, the organic solvent is acetonitrile to obtain a mixed solution.

[0043] Step 2, drying the mixed solution at 70°C to obtain a precursor.

[0044] Step 3, heat the precursor at 593°C for 17.5min; wherein, the temperature rise rate of the precursor from room temperature to the heating temperature is 9°C / min, and the obtained figure 1 shown, and as figure 2 with image 3 Mesoporous graphitic phase carbon nitride material shown in the curve.

Embodiment 3

[0046] The concrete steps of preparation are:

[0047] Step 1, according to the weight ratio of cyanuric acid, cyanuric chloride and organic solvent is 3:3:10, the three are mixed and stirred for 30 minutes; wherein, the organic solvent is acetonitrile to obtain a mixed solution.

[0048] Step 2, drying the mixed solution at 80°C to obtain a precursor.

[0049] Step 3, heat the precursor at 605°C for 15 minutes; wherein, the temperature rise rate of the precursor from room temperature to the heating temperature is 10°C / min, and the following figure 1 shown, and as figure 2 with image 3 Mesoporous graphitic phase carbon nitride material shown in the curve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com