Gallium sulfide quantum dot material and preparation method thereof

A technology of quantum dot materials and gallium sulfide, applied in the field of gallium sulfide quantum dot materials and its preparation, can solve the problems of non-adjustability, inability to obtain products, and narrow fluorescent emission range, and achieve low cost, simple preparation method, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The concrete steps of preparation are:

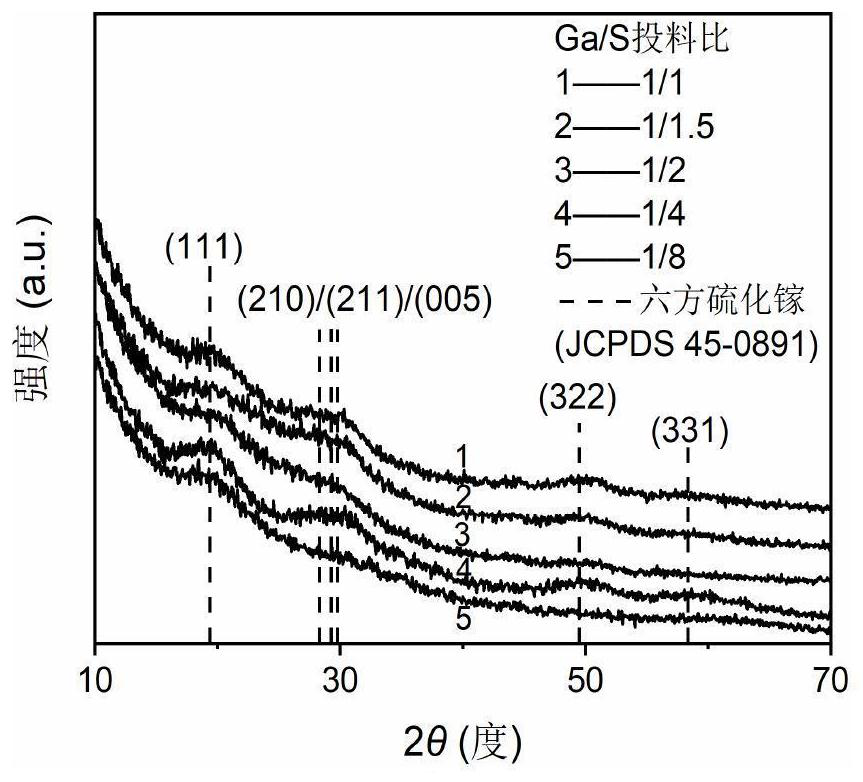

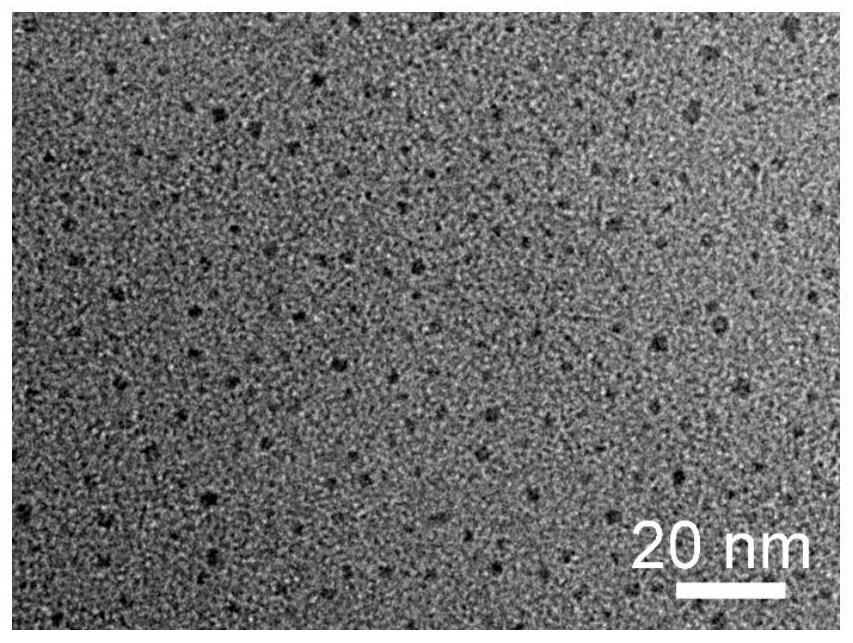

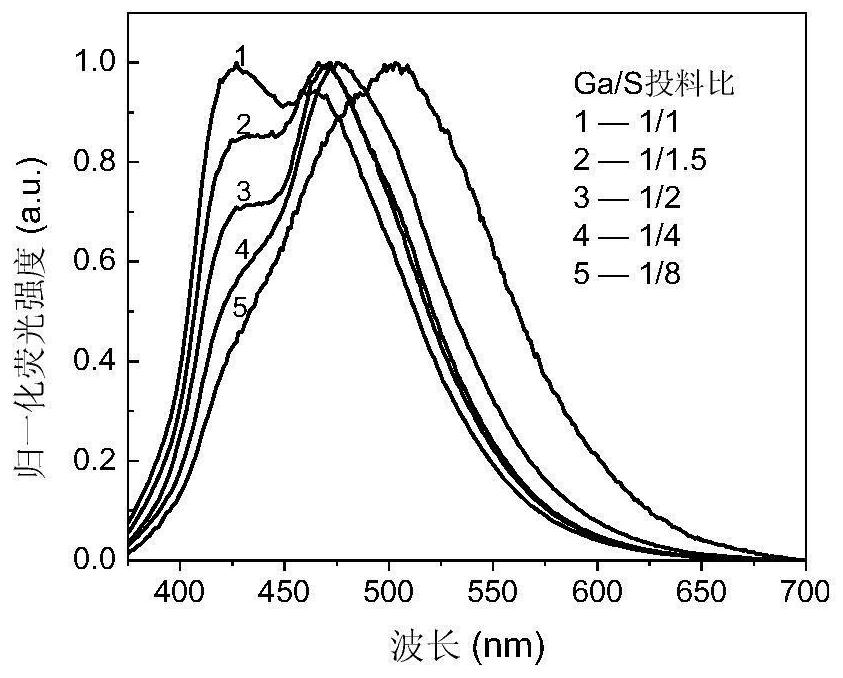

[0041] Step 1, first mix the gallium source, sulfur source, octadecene and ligand at a molar ratio of 1:0.5:80:20; where the gallium source is gallium acetylacetonate, and the sulfur source is sulfur powder , the ligand is a mixture of oleic acid, n-dodecanethiol and oleylamine to obtain a mixed solution. The mixed solution was placed in an inert atmosphere at 100°C for 10 minutes, and then reacted at 220°C for 20 minutes in an inert atmosphere; wherein the inert atmosphere was an argon atmosphere to obtain a reaction solution.

[0042] Step 2, first according to the molar ratio of the gallium source in the reaction solution, the solvent and the precipitant is the ratio of 1:50:1400, add the solvent and the precipitant successively to the reaction solution cooled under the inert atmosphere; wherein, the solvent is n-ethyl Alkanes, the precipitating agent is ethanol, and a suspension is obtained. Then, the suspension is subjecte...

Embodiment 2

[0044] Step 1, first mix the gallium source, sulfur source, octadecene and ligand at a molar ratio of 1:2.5:65:40; where the gallium source is gallium acetylacetonate, and the sulfur source is sulfur powder , the ligand is a mixture of oleic acid, n-dodecanethiol and oleylamine to obtain a mixed solution. The mixed solution was placed in an inert atmosphere at 105° C. for 8.8 minutes, and then reacted at 240° C. for 15.5 minutes in an inert atmosphere; wherein the inert atmosphere was an argon atmosphere to obtain a reaction solution.

[0045] Step 2, first according to the molar ratio of the gallium source in the reaction solution, the solvent and the precipitant is the ratio of 1:113:1075, add the solvent and the precipitant successively to the reaction solution cooled under the inert atmosphere; wherein, the solvent is n-ethyl Alkanes, the precipitating agent is ethanol, and a suspension is obtained. Then, the suspension is subjected to solid-liquid separation treatment; w...

Embodiment 3

[0047] Step 1, first mix the gallium source, sulfur source, octadecene and ligand at a molar ratio of 1:5:50:60; where the gallium source is gallium acetylacetonate, and the sulfur source is sulfur powder , the ligand is a mixture of oleic acid, n-dodecanethiol and oleylamine to obtain a mixed solution. The mixture was placed in an inert atmosphere at 110° C. for 7.5 minutes, and then reacted at 260° C. for 11 minutes in an inert atmosphere; wherein the inert atmosphere was an argon atmosphere to obtain a reaction solution.

[0048]Step 2, first according to the molar ratio of the gallium source in the reaction solution, the solvent and the precipitating agent is the ratio of 1:175:750, add the solvent and the precipitating agent successively in the reaction solution cooled under the inert atmosphere; wherein, the solvent is n-ethyl Alkanes, the precipitating agent is ethanol, and a suspension is obtained. Then the suspension is subjected to solid-liquid separation treatment;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com