Active magnesium hydroxide flame retardant and preparation method thereof

A technology of magnesium hydroxide and flame retardant, applied in the field of active magnesium hydroxide flame retardant and its preparation, can solve the problems of inability to obtain compatible products, unsatisfactory product compatibility, explosive metal magnesium, etc. Achieve the effect of improving compatibility, short cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

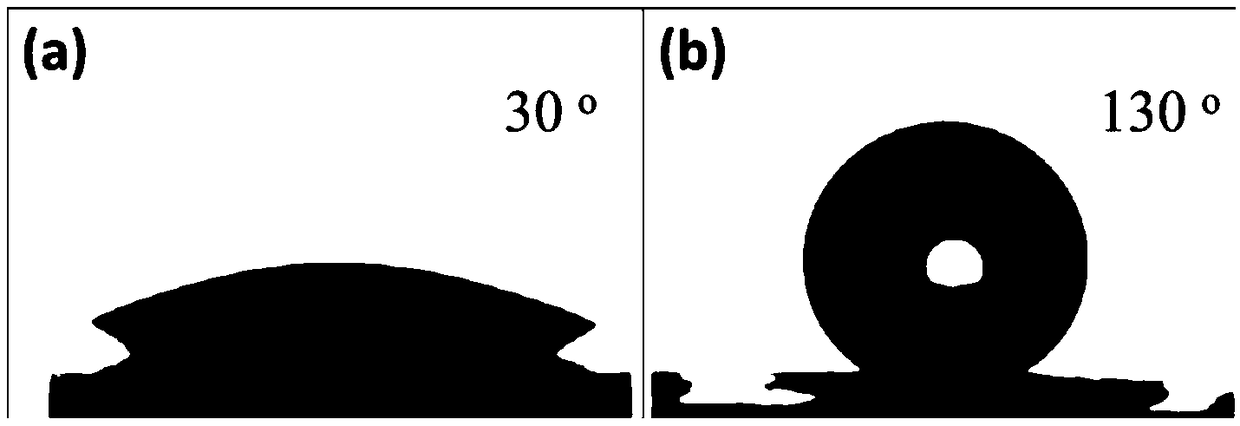

Method used

Image

Examples

Embodiment 1

[0034] The concrete steps of preparation are:

[0035] Step 1, dry powdered magnesium hydroxide at 80°C for 15 hours, prepare a mixed solution according to the volume ratio of ethanol, water and bisaminosilane coupling agent at a ratio of 76:3:18; wherein, powdered magnesium hydroxide The particle size is 0.5 μm, and the bisaminosilane coupling agent is N-(2-aminoethyl)-3-aminopropylmethyldimethoxysilane.

[0036] Step 2, first disperse the dried powdered magnesium hydroxide in the mixed solution at 70° C. and stir for 60 minutes; wherein, the stirring speed is 300 r / min to obtain a reaction solution. Then the reaction solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is centrifugation, the speed is 5000r / min, and the time is 6min, and the washing process is to use deionized water to separate the solid matter Washing was performed 3 times, the separation of solid matter during washing was centrifugat...

Embodiment 2

[0038] The concrete steps of preparation are:

[0039] Step 1, dry powdered magnesium hydroxide at 88°C for 14 hours, prepare a mixed solution according to the volume ratio of ethanol, water and bisaminosilane coupling agent at a ratio of 77:2.5:19; wherein, powdered magnesium hydroxide The particle size is 20 μm, and the bisaminosilane coupling agent is N-(2-aminoethyl)-3-aminopropylmethyldimethoxysilane.

[0040] Step 2, first disperse the dried powdered magnesium hydroxide in the mixed solution at 75° C. and stir for 48 minutes; wherein, the stirring speed is 350 r / min to obtain a reaction solution. Then the reaction solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is centrifugation, the speed is 5500r / min, and the time is 5.5min, and the washing process is to use deionized water to separate the solid The solid matter was washed three times, the solid matter was separated by centrifugation during...

Embodiment 3

[0042] The concrete steps of preparation are:

[0043] Step 1, dry powdered magnesium hydroxide at 95°C for 13 hours, prepare a mixed solution according to the volume ratio of ethanol, water and bisaminosilane coupling agent at a ratio of 78:2:20; wherein, powdered magnesium hydroxide The particle size is 50 μm, and the bisaminosilane coupling agent is N-(2-aminoethyl)-3-aminopropylmethyldimethoxysilane.

[0044] Step 2, first disperse the dried powdered magnesium hydroxide in the mixed solution at 80° C. and stir for 35 minutes; wherein, the stirring speed is 400 r / min to obtain a reaction solution. Then the reaction solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is centrifugation, the rotation speed is 6000r / min, and the time is 5min, and the washing process is to use deionized water to separate the solid matter Washing was carried out 4 times, the separation of solid matter during washing was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com