outdoor sio 2 Superhydrophilic nano coating and preparation method thereof

A nano-coating, super-hydrophilic technology, applied in the coating and other directions, can solve the problem of not being able to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

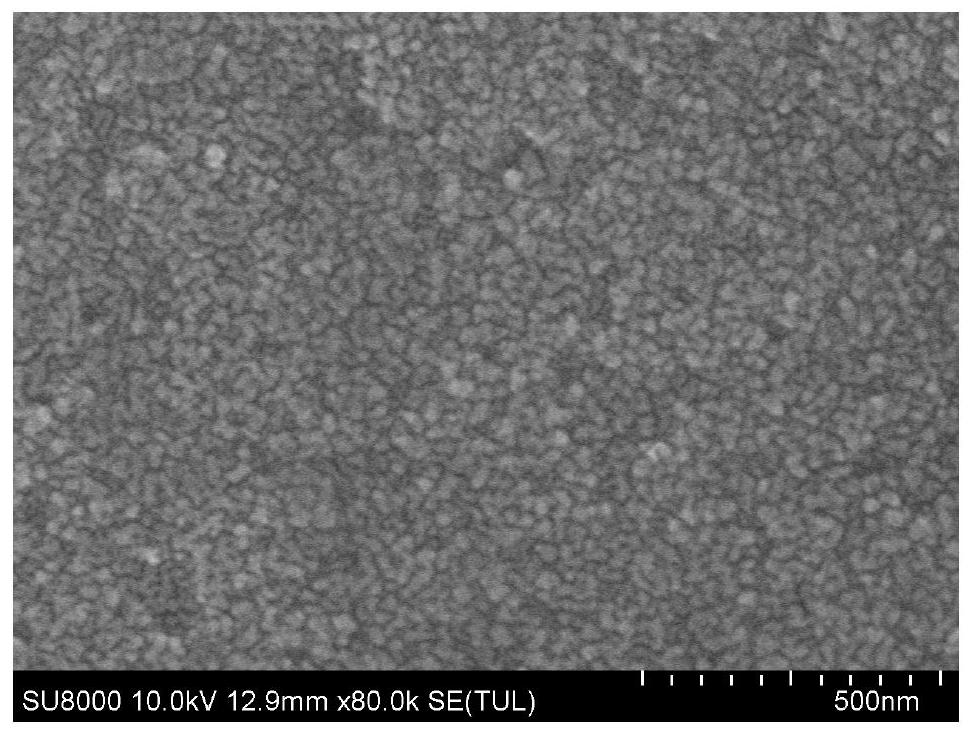

Image

Examples

Embodiment 1

[0035] The concrete steps of preparation are:

[0036] Step 1, first prepare ethyl tetrasilicate ethanol solution at a ratio of ethyl tetrasilicate and ethanol at a molar ratio of 1:18, and prepare an aqueous ammonia solution with a molar ratio of water and ammonia at a ratio of 5:0.5. Then according to the molar ratio of ethyl tetrasilicate in the ethyl tetrasilicate ethanol solution to the water in the aqueous ammonia solution of 1:5, the ethyl tetrasilicate ethanol solution was dropped into the aqueous ammonia solution drop by drop to obtain the alkali Catalytic reaction precursor solution.

[0037] Step 2, first put the alkali-catalyzed reaction precursor solution at 25°C and stir for 8 hours; wherein, the stirring rate is 500r / min to obtain SiO 2 Alkaline sol post aging 3d. After aging SiO 2 Add an aqueous solution of nitric acid with a concentration ≥ 66% to the alkaline sol to make the pH value 1, then add water, a mixture of ethanol and ethyl tetrasilicate to it in ...

Embodiment 2

[0041] The concrete steps of preparation are:

[0042] Step 1, first prepare ethyl tetrasilicate ethanol solution at a ratio of ethyl tetrasilicate and ethanol at a molar ratio of 1:19, and prepare an aqueous ammonia solution with a molar ratio of water and ammonia at a ratio of 5:0.45. Then according to the molar ratio of ethyl tetrasilicate in the ethyl tetrasilicate ethanol solution to the water in the aqueous ammonia solution of 1:5, the ethyl tetrasilicate ethanol solution was dropped into the aqueous ammonia solution drop by drop to obtain the alkali Catalytic reaction precursor solution.

[0043] Step 2, first put the base-catalyzed reaction precursor solution at 28°C and stir for 7.5h; wherein, the stirring rate is 500r / min to obtain SiO 2Alkaline sol post aging 4d. After aging SiO 2 Add an aqueous solution of nitric acid with a concentration ≥ 66% dropwise to the alkaline sol to make the pH value 1.3, then add water and a mixture of ethanol and ethyl tetrasilicate ...

Embodiment 3

[0047] The concrete steps of preparation are:

[0048] Step 1, first prepare ethyl tetrasilicate ethanol solution at a molar ratio of ethyl tetrasilicate and ethanol at a ratio of 1:20, and prepare an aqueous ammonia solution with a molar ratio of water and ammonia at a ratio of 5:0.4. Then according to the molar ratio of ethyl tetrasilicate in the ethyl tetrasilicate ethanol solution to the water in the aqueous ammonia solution of 1:5, the ethyl tetrasilicate ethanol solution was dropped into the aqueous ammonia solution drop by drop to obtain the alkali Catalytic reaction precursor solution.

[0049] Step 2, first place the base-catalyzed reaction precursor solution at 30°C and stir for 7 hours; wherein, the stirring rate is 500r / min to obtain SiO 2 Aging for 5 days after alkaline sol. After aging SiO 2 Add an aqueous solution of nitric acid with a concentration ≥ 66% dropwise to the alkaline sol to make the pH value 1.5, then add water, a mixture of ethanol and ethyl tet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com