Vanadium hydroxide nanosheet and preparation method thereof

A vanadium hydroxide nanometer, vanadium hydroxide technology, applied in chemical instruments and methods, nanotechnology, vanadium compounds, etc., can solve the problems of too small specific surface area, few active sites, and difficult to make film-like follow-up products. , to achieve the effect of scientific preparation method, high specific surface area and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The concrete steps of preparation are:

[0033] Step 1, first mix the three according to the molar ratio of vanadium pentoxide (or ammonium vanadate), ethylene glycol and deionized water in a ratio of 1:2:8 and then stir for 2 hours to obtain a mixed solution; The speed is 1200r / min. Then the mixed solution was placed at 180° C. for 120 h in a closed reaction to obtain a suspension-like reaction solution.

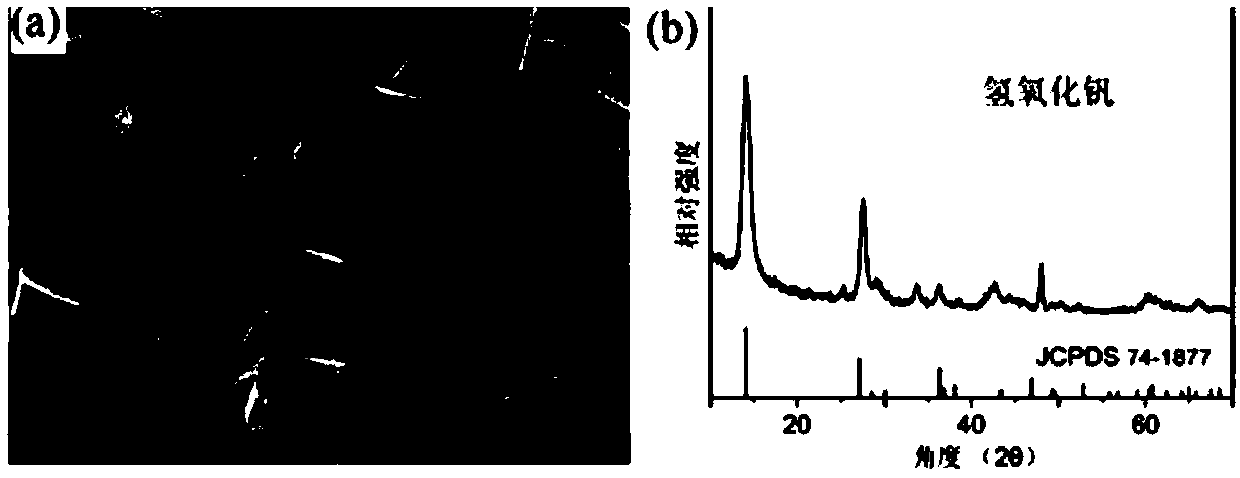

[0034] Step 2, the suspension reaction solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is centrifugation, the rotation speed is 8000r / min, and the time is 6min, and the washing process is to use acetone and ethanol The separated solid matter is cleaned, the separation of the solid matter during cleaning is centrifugation, and the drying process is drying the cleaned solid matter at 50°C. The resulting shape is similar to figure 1 a and figure 2 shown, and the physical appearance as f...

Embodiment 2

[0036] The concrete steps of preparation are:

[0037] Step 1, first mix the three according to the molar ratio of vanadium pentoxide (or ammonium vanadate), ethylene glycol and deionized water as 1:2.75:7.25 and stir for 2.5h to obtain a mixed solution; wherein, when stirring The rotating speed is 1100r / min. Then the mixed solution was placed at 190° C. for 92 h in a closed reaction to obtain a suspension-like reaction solution.

[0038] Step 2, sequentially carry out solid-liquid separation, washing and drying treatment on the suspended reaction solution; wherein, the solid-liquid separation treatment is centrifugation, the rotation speed is 8500r / min, and the time is 5min, and the washing treatment is using acetone and ethanol The separated solid matter is cleaned, the separation of the solid matter during cleaning is centrifugation, and the drying process is drying the cleaned solid matter at 55°C. The resulting shape is similar to figure 1 a and figure 2 shown, and t...

Embodiment 3

[0040] The concrete steps of preparation are:

[0041] Step 1, first mix the three according to the molar ratio of vanadium pentoxide (or ammonium vanadate), ethylene glycol and deionized water in a ratio of 1:3.5:6.5 and then stir for 3 hours to obtain a mixed solution; The speed is 1000r / min. Then the mixed solution was placed at 200° C. for 64 h in a closed reaction to obtain a suspension-like reaction solution.

[0042] Step 2, the suspension reaction solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is centrifugation, the rotation speed is 9000r / min, and the time is 4min, and the washing process is to use acetone and ethanol The separated solid matter is cleaned, the separation of the solid matter during cleaning is centrifugation, and the drying process is drying the cleaned solid matter at 60°C. made in the form of figure 1 a and figure 2 shown, and the physical appearance as figure 1 Van...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com