Silica nanoporous membrane with graded porosity and preparation method thereof

A silica and nanoporous technology, applied in ceramic products, household appliances, other household appliances, etc., can solve the problem of poor wear resistance, unsatisfactory hydrophilicity, and difficulty in taking into account wear resistance and hydrophilicity at the same time. problem, to achieve the effect of low preparation cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

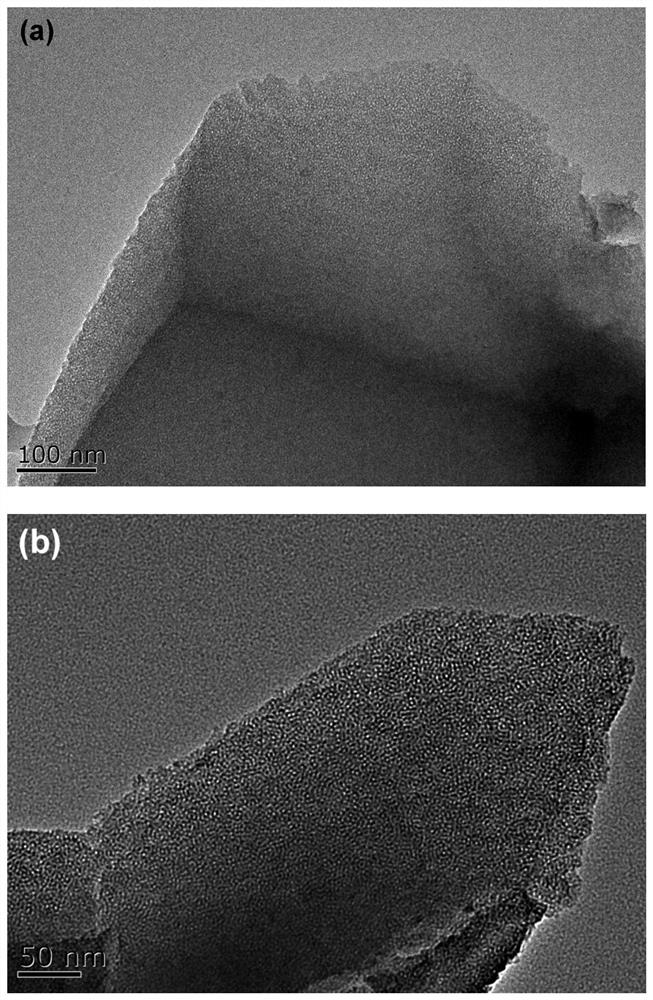

Image

Examples

Embodiment 1

[0033] The concrete steps of preparation are:

[0034] Step 1: According to the molar ratio of ethyl tetrasilicate, ethanol, nitric acid and water being 1:8:0.09:3, firstly mix and stir ethyl tetrasilicate and ethanol to obtain a mixed solution. Then nitric acid and water were mixed and stirred to obtain an aqueous solution of nitric acid.

[0035] In step 2, the nitric acid aqueous solution was first dropped into the mixed solution drop by drop, and stirred at 55° C. for 4 hours; wherein, the stirring speed was 750 r / min to obtain a silica sol. Then 1wt%, 3wt%, and 5wt% cetyltrimethylammonium bromide were added to 3 parts of silica sol respectively, stirred for 1 hour, aged for 4 days, and 3 parts of mixed sols were obtained.

[0036] Step 3, first place the substrate in the mixed sol containing cetyltrimethylammonium bromide gradually increasing for 3 times, and then dry it; wherein, the substrate is one of the insulators—— For glass slides, the descending speed of the sub...

Embodiment 2

[0038] The concrete steps of preparation are:

[0039] Step 1: According to the molar ratio of ethyl tetrasilicate, ethanol, nitric acid and water being 1:8.5:0.08:3.5, firstly mix and stir ethyl tetrasilicate and ethanol to obtain a mixed solution. Then nitric acid and water were mixed and stirred to obtain an aqueous solution of nitric acid.

[0040] In step 2, the nitric acid aqueous solution was first dropped into the mixed solution drop by drop, and stirred at 58° C. for 3.5 h; wherein, the stirring speed was 750 r / min to obtain a silica sol. Add cetyltrimethylammonium bromide with a mass fraction of 1wt%, 2wt%, 3wt%, and 5wt% to 4 parts of silica sol respectively, and after stirring for 1.3h, age for 4.5d to obtain 4 parts mixed sol.

[0041] Step 3, first place the substrate in the mixed sol containing cetyltrimethylammonium bromide gradually increasing, carry out 4 times of pulling coating, and then dry it; wherein, the substrate is one of the insulators—— For glass...

Embodiment 3

[0043] The concrete steps of preparation are:

[0044] Step 1: According to the molar ratio of ethyl tetrasilicate, ethanol, nitric acid and water being 1:9:0.07:4, firstly mix and stir ethyl tetrasilicate and ethanol to obtain a mixed solution. Then nitric acid and water were mixed and stirred to obtain an aqueous solution of nitric acid.

[0045] In step 2, the nitric acid aqueous solution was first dropped into the mixed solution drop by drop, and stirred at 60° C. for 3 hours; wherein, the stirring speed was 750 r / min to obtain a silica sol. Add cetyltrimethylammonium bromide with a mass fraction of 1wt%, 2wt%, 3wt%, 4wt% and 5wt% to 5 parts of silica sol respectively, and after stirring for 1.5h, age for 5d to obtain 5 parts mixed sol.

[0046]Step 3, first place the substrate in the mixed sol containing cetyltrimethylammonium bromide gradually increasing, carry out 5 times of pulling coating, and then dry it; wherein, the substrate is one of the insulators—— For glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com