A slow plugging type aeolian sand permeable brick loaded with nano titanium dioxide on the surface and its preparation method

A nano-titanium dioxide, surface-loaded technology, applied to ceramic products, other household appliances, household appliances, etc., can solve the problems of decreased permeability, short service life, easy blockage of permeable bricks, etc., to enhance water permeability, reduce tortuosity, Solve the effect of poor frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In one embodiment, the present invention provides a method for preparing a surface-loaded nano-titanium dioxide slow-clogging type aeolian sand permeable brick, comprising the following steps:

[0039] 1) Prepare a permeable brick matrix with aeolian sand as the main raw material;

[0040] 2) adding an appropriate amount of dispersant and nano-titanium dioxide into pure water, followed by ultrasonic treatment and magnetic stirring to obtain a nano-titanium dioxide dispersion;

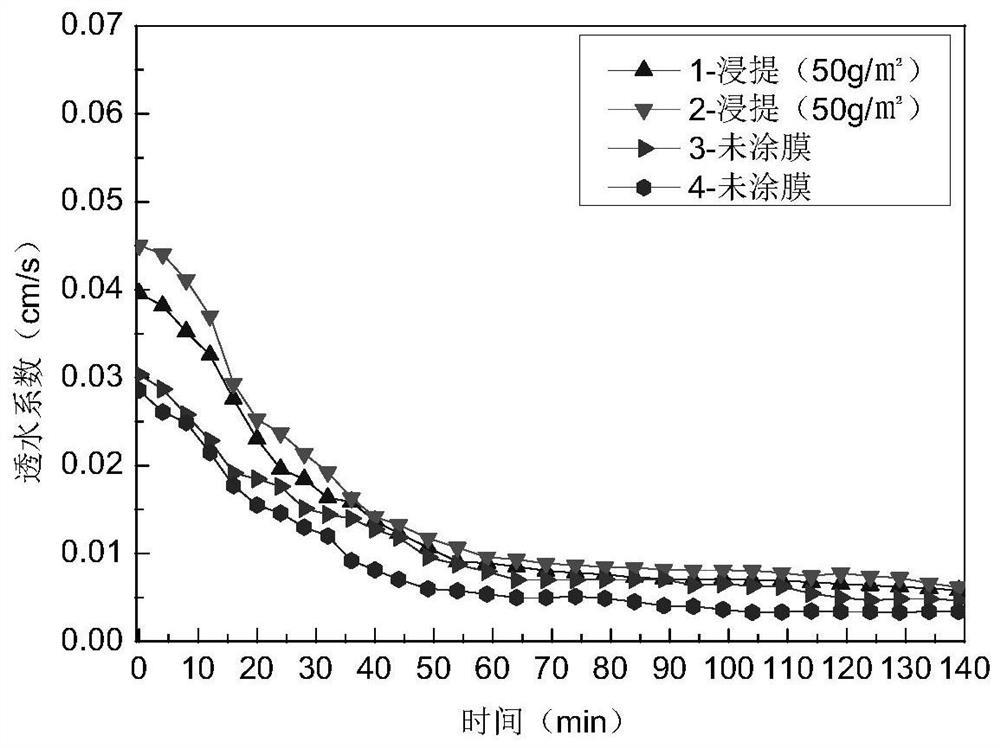

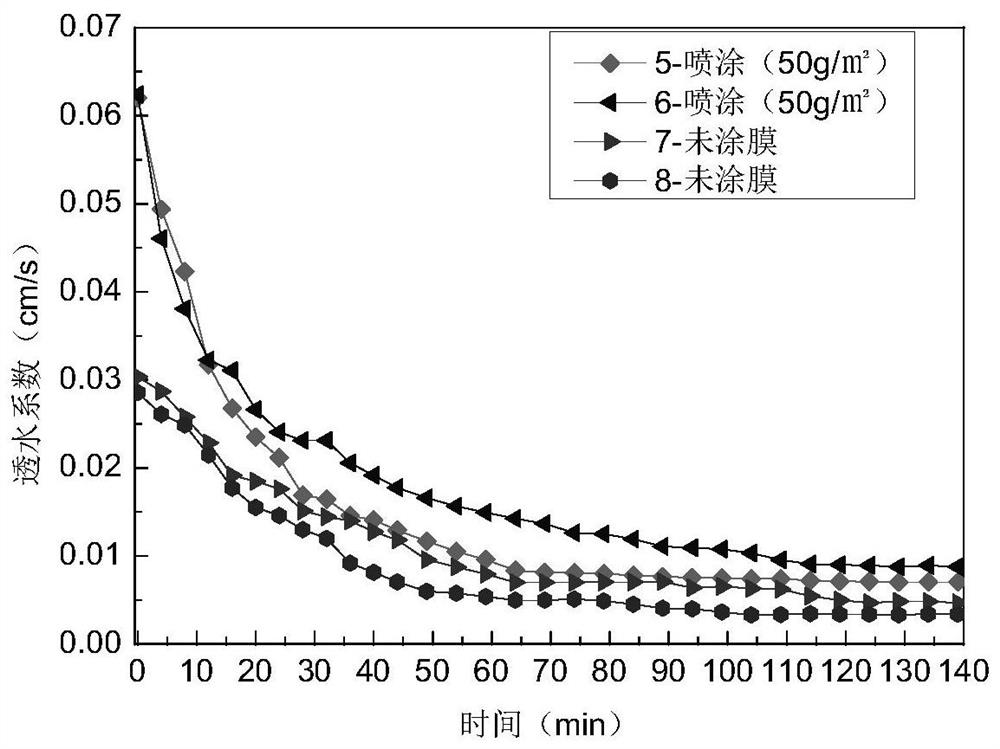

[0041] 3) The nano-titanium dioxide dispersion is evenly loaded onto the rough surface of the permeable brick substrate by leaching and spraying;

[0042] 4) drying the permeable brick substrate treated in step 3) to form a film, keeping it warm, and finally preparing a permeable brick loaded with a nano-titanium dioxide coating.

[0043] In the preferred embodiment, in step 1), the permeable brick base is made of aeolian sand as the main raw material, walnut sand as the pore-forming agent, lime...

Embodiment 1

[0060] 1. Preparation of aeolian sand permeable brick matrix:

[0061] The permeable brick matrix of the present invention uses aeolian sand as the main raw material, walnut sand as the pore-forming agent, limestone as the foaming agent, and feldspar powder, waste glass powder and CMC as the binder. The percentage by mass is: 81% accumulated sand, 0.5% walnut sand, 0.5% limestone, 12% feldspar powder, and 6% waste glass powder. Finally, the dry weight mass of the matrix is 4% CMC sol with a concentration of 10%. The preparation method specifically includes the following steps:

[0062] 101) After the aeolian sand is dried, sieve and classify, and take 40-60 mesh for subsequent use;

[0063] Sieve and classify the walnut sand, and take 40-60 mesh for subsequent use;

[0064] Sieve and classify the feldspar powder, and take 140-160 mesh for later use;

[0065] Pulverize limestone and waste glass respectively, grind them in a ball mill, sieve and classify, and take 140-160 m...

Embodiment 2

[0078] 1. Preparation of aeolian sand permeable brick matrix:

[0079] The permeable brick matrix of the present invention uses aeolian sand as the main raw material, walnut sand as the pore-forming agent, limestone as the foaming agent, and feldspar powder, waste glass powder and CMC as the binder. The percentage by mass is: 75% accumulated sand, 2% walnut sand, 2% limestone, 12% feldspar powder, and 9% waste glass powder. Finally, add 4% CMC sol with a concentration of 12% of the dry weight of the matrix. The preparation method specifically comprises the following steps:

[0080] 101) After the aeolian sand is dried, sieve and classify, and take 40-60 mesh for subsequent use;

[0081] Sieve and classify the walnut sand, and take 40-60 mesh for subsequent use;

[0082] Sieve and classify the feldspar powder, and take 140-160 mesh for later use;

[0083] Pulverize limestone and waste glass respectively, grind them in a ball mill, sieve and classify, and take 140-160 mesh f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com