Lead sulfide film with broad absorption spectrum and preparation method thereof

A technology of absorption spectrum and lead sulfide, which is applied in the field of lead sulfide film with wide absorption spectrum and its preparation, can solve the problems of not being able to obtain products with broad-band absorption characteristics and restricting applications, and achieve simple and easy-to-operate processes and scientific preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The concrete steps of preparation are:

[0038] Step 1, according to the volume ratio of 1.5mol / L sodium hydroxide solution, 2.1mol / L thiourea solution, 7mol / L triethanolamine, 0.6mol / L lead acetate solution and deionized water is 5:4:0.2 : 6:70 ratio, first add sodium hydroxide solution, thiourea solution and triethanolamine to lead acetate solution in sequence to obtain a mixed solution; then add deionized water to the mixed solution to obtain a reaction solution.

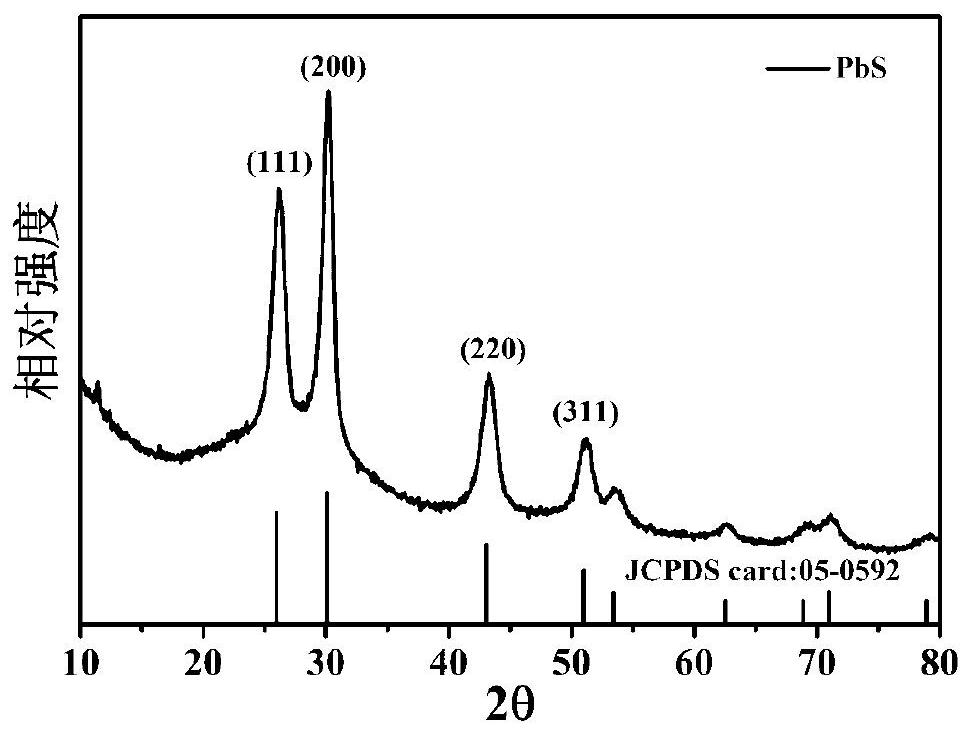

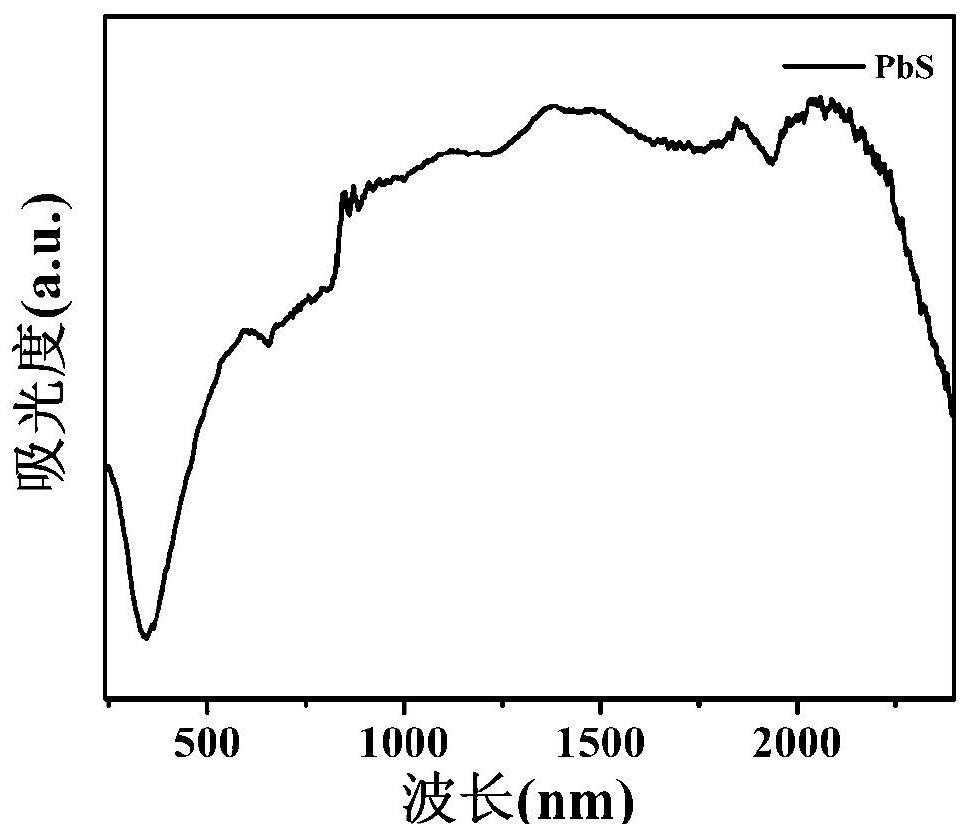

[0039] In step 2, first place the substrate in a stirred reaction solution at 70° C. for 4 hours to obtain a substrate with reactants placed on its surface; wherein, the substrate is a glass substrate, and the stirring rate is 200 r / min. Then, the substrate with the reactant placed on its surface is cleaned and dried; wherein, the cleaning is washed twice with deionized water, and the drying is natural drying. made as figure 1 and figure 2 The broad absorption spectrum of the lead sulfide thin film sho...

Embodiment 2

[0041] The concrete steps of preparation are:

[0042] Step 1, according to the volume ratio of 1.55mol / L sodium hydroxide solution, 2.05mol / L thiourea solution, 7.2mol / L triethanolamine, 0.55mol / L lead acetate solution and deionized water is 5.5:3.5: The ratio of 0.25:5.5:70, first add sodium hydroxide solution, thiourea solution and triethanolamine to the lead acetate solution in sequence to obtain a mixed solution; then add deionized water to the mixed solution to obtain a reaction solution.

[0043] In step 2, first place the substrate in a stirred reaction solution at 73° C. for 3.5 hours to obtain a substrate with reactants placed on its surface; wherein, the substrate is a glass substrate, and the stirring rate is 210 r / min. Then, the substrate with the reactant placed on its surface is cleaned and dried; wherein, the cleaning is washed twice with deionized water, and the drying is natural drying. made as figure 1 and figure 2 The broad absorption spectrum of the le...

Embodiment 3

[0045] The concrete steps of preparation are:

[0046] Step 1, according to the volume ratio of 1.6mol / L sodium hydroxide solution, 2mol / L thiourea solution, 7.3mol / L triethanolamine, 0.5mol / L lead acetate solution and deionized water is 6:3:0.3 : The ratio of 5:70, first add sodium hydroxide solution, thiourea solution and triethanolamine to the lead acetate solution in sequence to obtain a mixed solution; then add deionized water to the mixed solution to obtain a reaction solution.

[0047] In step 2, first place the substrate in a stirred reaction solution at 75° C. for 3 hours to obtain a substrate with reactants placed on its surface; wherein, the substrate is a glass substrate, and the stirring rate is 220 r / min. Then, the substrate with the reactant placed on its surface is cleaned and dried; wherein, the cleaning is cleaned three times with deionized water, and the drying is natural drying. made as figure 1 and figure 2 The broad absorption spectrum of the lead sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com