Durably-hydrophilic SiO2 nano mesoporous coating preparation method

A nano-mesoporous and hydrophilic technology, applied in the coating and other directions, can solve the problems of increased contact angle and low porosity of particle coating, and achieve the effects of improved durability, simple preparation method and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

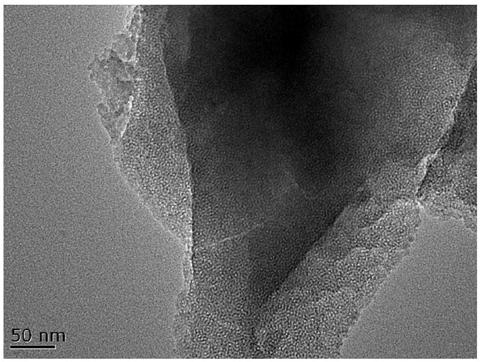

Image

Examples

Embodiment 1

[0028] The concrete steps of preparation are:

[0029] Step 1, first prepare ethyl tetrasilicate ethanol solution at a molar ratio of ethyl tetrasilicate and ethanol at a ratio of 1:8, and prepare an aqueous solution of nitric acid at a molar ratio of water and nitric acid at a ratio of 4:0.08. Then, according to the molar ratio of ethyl tetrasilicate in the ethyl tetrasilicate ethanol solution to the water in the nitric acid aqueous solution is 1:4, the nitric acid aqueous solution is dropped into the ethyl tetrasilicate ethanol solution drop by drop to obtain the reaction Precursor solution.

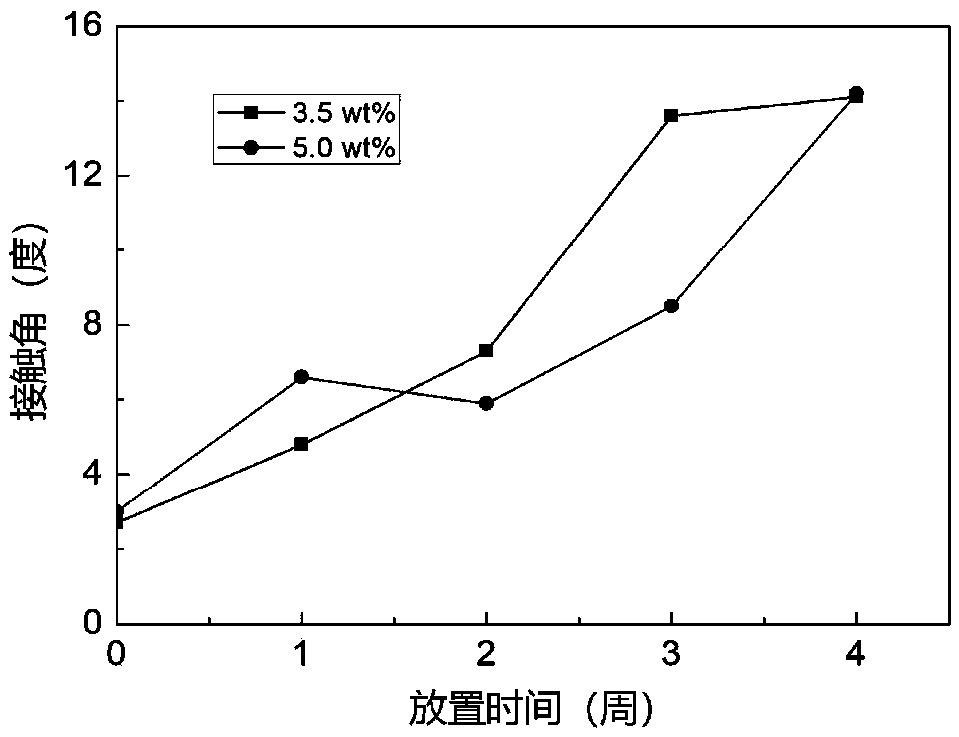

[0030] Step 2, first place the reaction precursor solution at 50°C and stir for 3 hours; wherein, the stirring rate is 750r / min to obtain SiO 2 Sol. to SiO 2 Add 3.5wt% pore-forming agent to the sol, stir for 1 hour, and then age for 3 days; wherein, the pore-forming agent is cetyltrimethylammonium bromide to obtain a sol for coating.

[0031] Step 3, first dip the cleaned and drie...

Embodiment 2

[0033] The concrete steps of preparation are:

[0034] Step 1, first prepare ethyl tetrasilicate ethanol solution according to the molar ratio of ethyl tetrasilicate and ethanol as 1:8.5, and prepare nitric acid aqueous solution at the molar ratio of water and nitric acid as 4:0.075. Then, according to the molar ratio of ethyl tetrasilicate in the ethyl tetrasilicate ethanol solution to the water in the nitric acid aqueous solution is 1:4, the nitric acid aqueous solution is dropped into the ethyl tetrasilicate ethanol solution drop by drop to obtain the reaction Precursor solution.

[0035] Step 2, first place the reaction precursor solution at 55°C and stir for 2.8h; wherein, the stirring rate is 750r / min to obtain SiO 2 Sol. to SiO 2 Add 3.9wt% pore-forming agent to the sol, stir for 1.3h, and then age for 2.5d; wherein, the pore-forming agent is cetyltrimethylammonium bromide to obtain a sol for coating.

[0036] Step 3, first dip the cleaned and dried glass substrate ...

Embodiment 3

[0038] The concrete steps of preparation are:

[0039] Step 1: first prepare ethyl tetrasilicate ethanol solution at a molar ratio of ethyl tetrasilicate and ethanol at a ratio of 1:9, and prepare an aqueous solution of nitric acid at a molar ratio of water and nitric acid at a ratio of 4:0.07. Then, according to the molar ratio of ethyl tetrasilicate in the ethyl tetrasilicate ethanol solution to the water in the nitric acid aqueous solution is 1:4, the nitric acid aqueous solution is dropped into the ethyl tetrasilicate ethanol solution drop by drop to obtain the reaction Precursor solution.

[0040] In step 2, first place the reaction precursor solution at 60° C. and stir for 2.5 hours; wherein, the stirring rate is 750 r / min to obtain SiO2 sol. to SiO2 Add 4.3wt% pore-forming agent to the sol and stir for 1.5 hours, then age for 2 days; wherein, the pore-forming agent is cetyltrimethylammonium bromide to obtain a coating sol.

[0041] Step 3, firstly dip the cleaned and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com