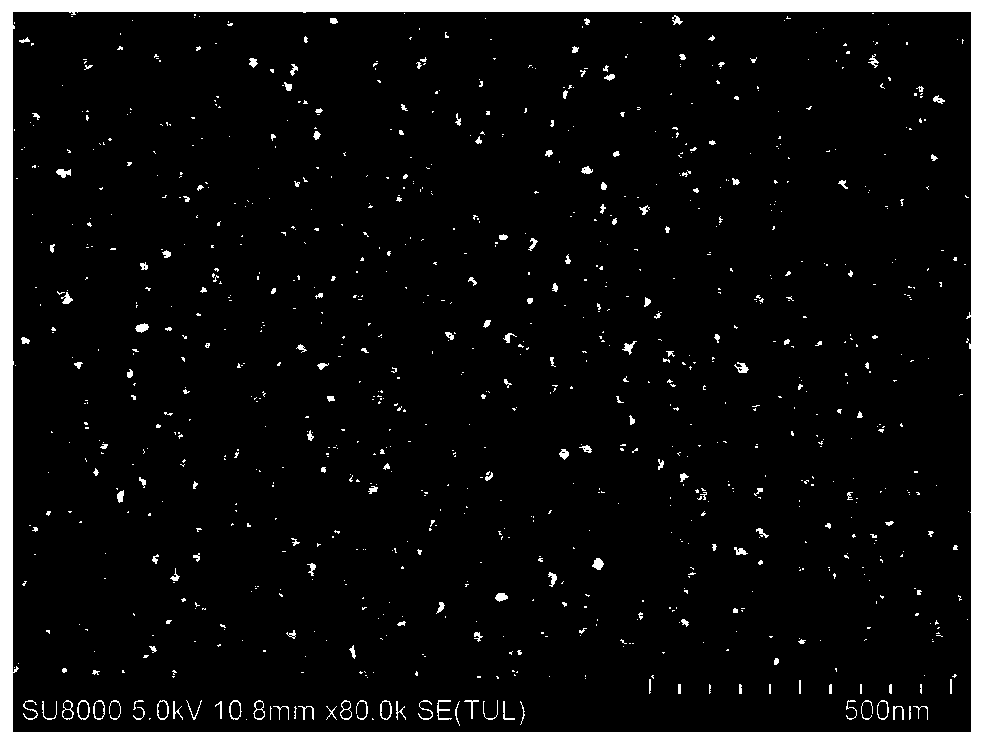

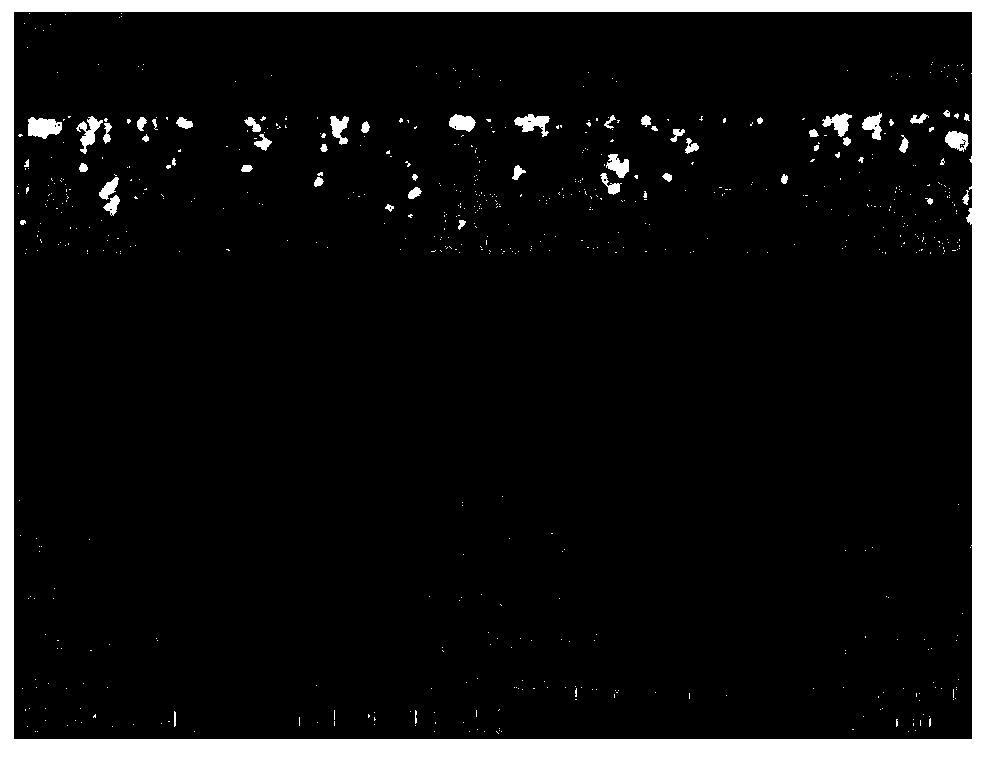

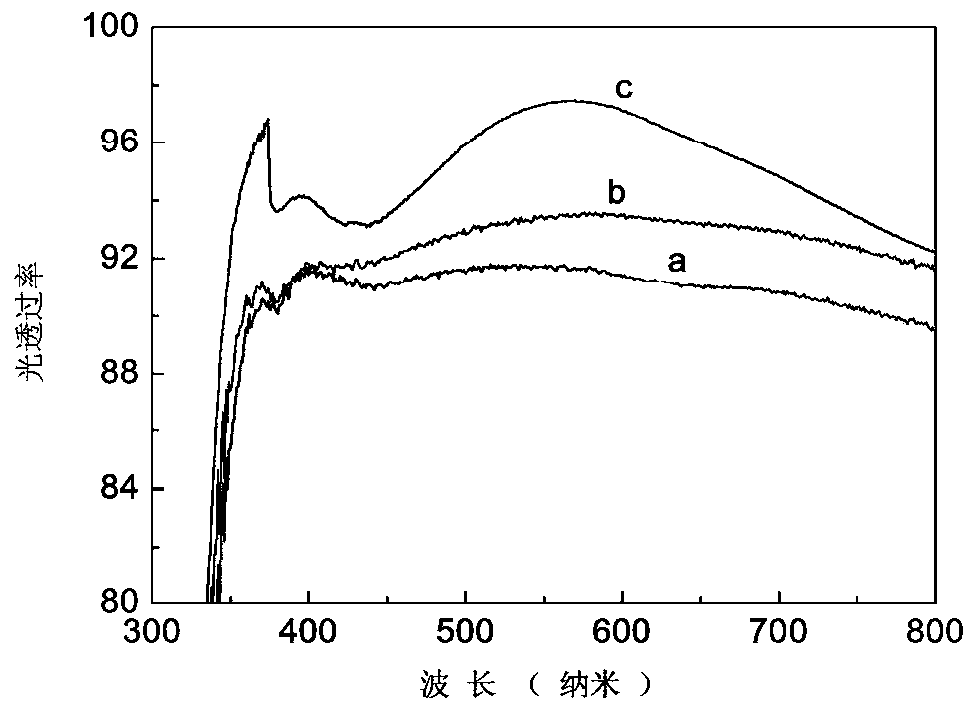

SiO2 acid-base composite nanometer coating with porous structure and preparation method thereof

A technology of porous structure and nano-coating, which is applied in the field of SiO2 acid-base composite nano-coating and its preparation, can solve the problems of low porosity, unsatisfactory hydrophilicity, poor anti-reflection effect, etc., and achieves a simple preparation method. , low cost and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The concrete steps of preparation are:

[0046] Step 1, first prepare ethyl tetrasilicate ethanol solution according to the molar ratio of ethyl tetrasilicate and ethanol as 1:8. Then prepare a mixed aqueous solution according to the molar ratio of ethanol, water and ammonia water at a ratio of 12:5:0.3.

[0047] Step 2: First, according to the ratio of ethyl tetrasilicate ethanol solution and ethanol in the mixed aqueous solution at a ratio of 1:1, the ethyl tetrasilicate ethanol solution is dropped into the mixed aqueous solution drop by drop to obtain an alkalization reaction precursor solution. Then the alkalization reaction precursor solution was placed at 25°C and stirred at a rate of 500r / min for 8h to obtain SiO 2 Aging for 5 days after alkaline sol.

[0048] Step 3, first to the aged SiO 2 Aqueous nitric acid solution with a concentration of 66% was added dropwise to the alkaline sol to make the pH value 2, and then water, a mixture of ethanol and ethyl tetr...

Embodiment 2

[0052] The concrete steps of preparation are:

[0053] Step 1, first prepare ethyl tetrasilicate ethanol solution according to the molar ratio of ethyl tetrasilicate and ethanol as 1:9. Then prepare a mixed aqueous solution according to the molar ratio of ethanol, water and ammonia water at a ratio of 11:5:0.3.

[0054] Step 2: First, according to the ratio of ethyl tetrasilicate ethanol solution and ethanol in the mixed aqueous solution at a ratio of 1:1, the ethyl tetrasilicate ethanol solution is dropped into the mixed aqueous solution drop by drop to obtain an alkalization reaction precursor solution. Then put the alkalization reaction precursor solution at 28°C and stir for 7.5h at a rate of 500r / min to obtain SiO 2 Alkaline sol post aging 5.5d.

[0055] Step 3, first to the aged SiO 2 Add a concentration of 66.5% nitric acid aqueous solution to the alkaline sol dropwise to make the pH value 1.8, then add water and a mixture of ethanol and ethyl tetrasilicate to it in ...

Embodiment 3

[0059] The concrete steps of preparation are:

[0060] Step 1, first prepare an ethyl tetrasilicate ethanol solution according to the molar ratio of ethyl tetrasilicate and ethanol of 1:10. Then prepare a mixed aqueous solution according to the molar ratio of ethanol, water and ammonia water at a ratio of 10:5:0.3.

[0061] Step 2: First, according to the ratio of ethyl tetrasilicate ethanol solution and ethanol in the mixed aqueous solution at a ratio of 1:1, the ethyl tetrasilicate ethanol solution is dropped into the mixed aqueous solution drop by drop to obtain an alkalization reaction precursor solution. Then put the alkalization reaction precursor solution at 30°C and stir for 7h at a rate of 500r / min to obtain SiO 2 Alkaline sol post aging 6d.

[0062] Step 3, first to the aged SiO 2 Add a 67% aqueous solution of nitric acid dropwise to the alkaline sol to make the pH value 1.5, then add water and a mixture of ethanol and ethyl tetrasilicate to it in turn, wherein th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com