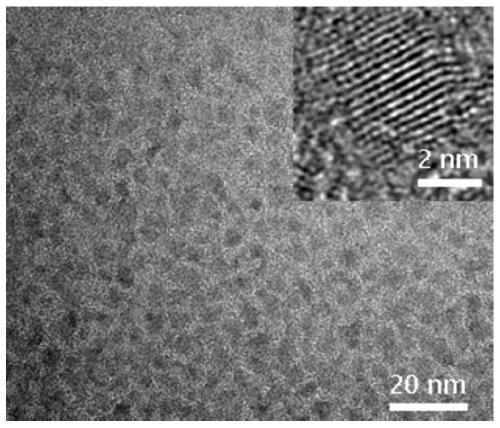

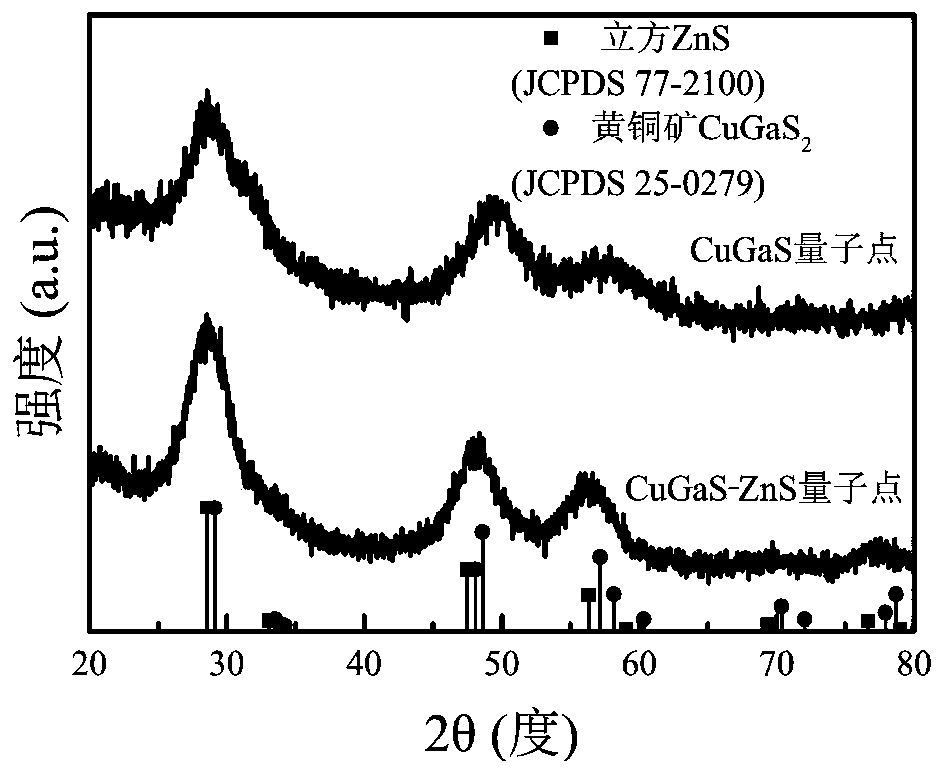

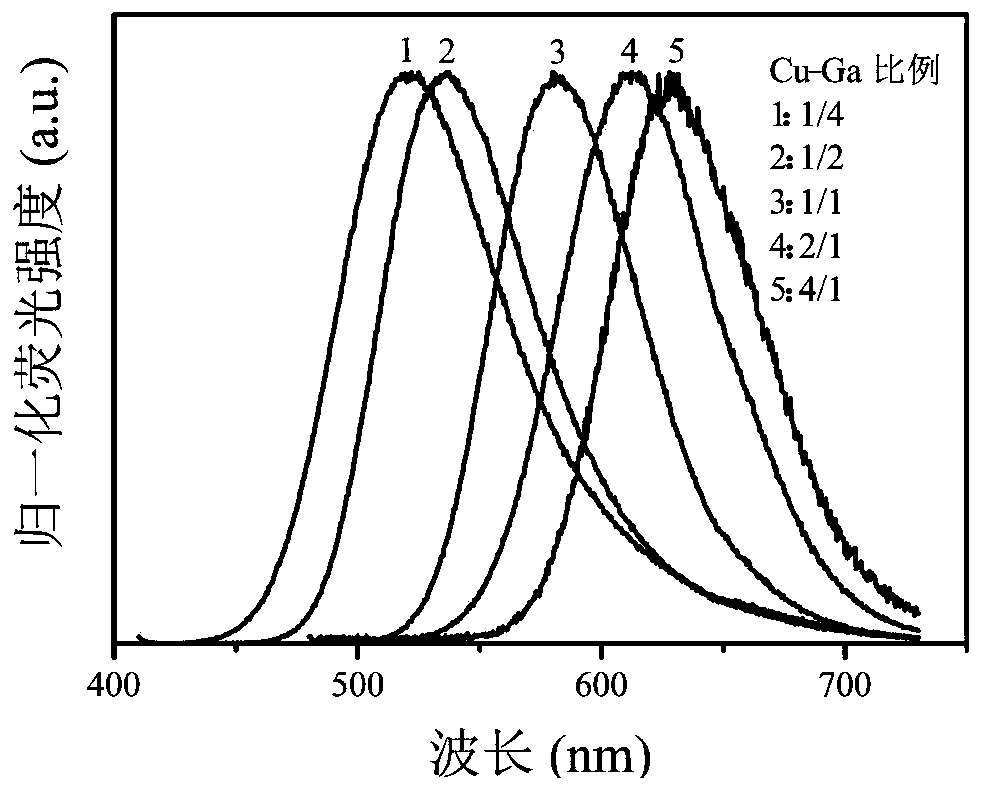

cugas-zns core-shell quantum dot material and preparation method thereof

A technology of quantum dot material and core-shell structure, which is applied in the field of CuGaS-ZnS core-shell structure quantum dot material and its preparation, can solve the problems of non-adjustable position and inability to obtain products, and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The concrete steps of preparation are:

[0041] Step 1. Firstly, according to the weight ratio of copper source, gallium source and sulfur source at a ratio of 0.05:1:30, the three are mixed, placed in an inert atmosphere, heated to 100°C and kept for 30 minutes; wherein, the copper source is iodine cuprous chloride, the gallium source is gallium acetylacetonate, the sulfur source is n-dodecanethiol, and the inert atmosphere is an argon atmosphere to obtain a mixture. Then, the temperature of the mixture was raised to 220° C. and reacted for 20 minutes to obtain a CuGaS quantum dot reaction liquid.

[0042] Step 2: First, according to the volume ratio of the CuGaS quantum dot reaction solution and the zinc precursor solution at a ratio of 1:0.8, the zinc precursor solution is injected into the CuGaS quantum dot reaction solution and kept at 210°C for 90 minutes; among them, the zinc precursor solution is 0.18 g / L zinc source oleic acid solution, the zinc source is zinc...

Embodiment 2

[0045] The concrete steps of preparation are:

[0046] Step 1, first mix the three sources according to the weight ratio of copper source, gallium source and sulfur source at a ratio of 0.5:1:28, heat to 105°C under an inert atmosphere and keep it warm for 24 minutes; among them, the copper source is iodine cuprous chloride, the gallium source is gallium acetylacetonate, the sulfur source is n-dodecanethiol, and the inert atmosphere is an argon atmosphere to obtain a mixture. Then, the temperature of the mixture was raised to 240° C. and reacted for 15.5 minutes to obtain a CuGaS quantum dot reaction liquid.

[0047] Step 2, first according to the volume ratio of CuGaS quantum dot reaction solution and zinc precursor solution is 1:1.85, inject the zinc precursor solution into the CuGaS quantum dot reaction solution and keep it warm at 228°C for 75min; among them, the zinc precursor solution is 0.3 g / L zinc source oleic acid solution, the zinc source is zinc acetate to obtain ...

Embodiment 3

[0050] The concrete steps of preparation are:

[0051] Step 1. Firstly, according to the weight ratio of copper source, gallium source and sulfur source as 1:1:25, mix the three, place in an inert atmosphere and heat to 110°C and keep it warm for 18 minutes; among them, the copper source is iodine cuprous chloride, the gallium source is gallium acetylacetonate, the sulfur source is n-dodecanethiol, and the inert atmosphere is an argon atmosphere to obtain a mixture. Then, the temperature of the mixture was raised to 260° C. and reacted for 11 minutes to obtain a CuGaS quantum dot reaction solution.

[0052] Step 2, first according to the volume ratio of the CuGaS quantum dot reaction solution and the zinc precursor solution is 1:2.9, the zinc precursor solution is injected into the CuGaS quantum dot reaction solution and kept at 245°C for 60 minutes; among them, the zinc precursor solution is 0.41 g / L zinc source oleic acid solution, the zinc source is zinc acetate to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com