Vertical graphene and growth method thereof

A growth method and graphene technology, applied in the field of graphene, can solve the problems of not being able to fully meet the practical needs and the slow rate of graphene, and achieve the effect of wide commercial application, simple method, and high-efficiency realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

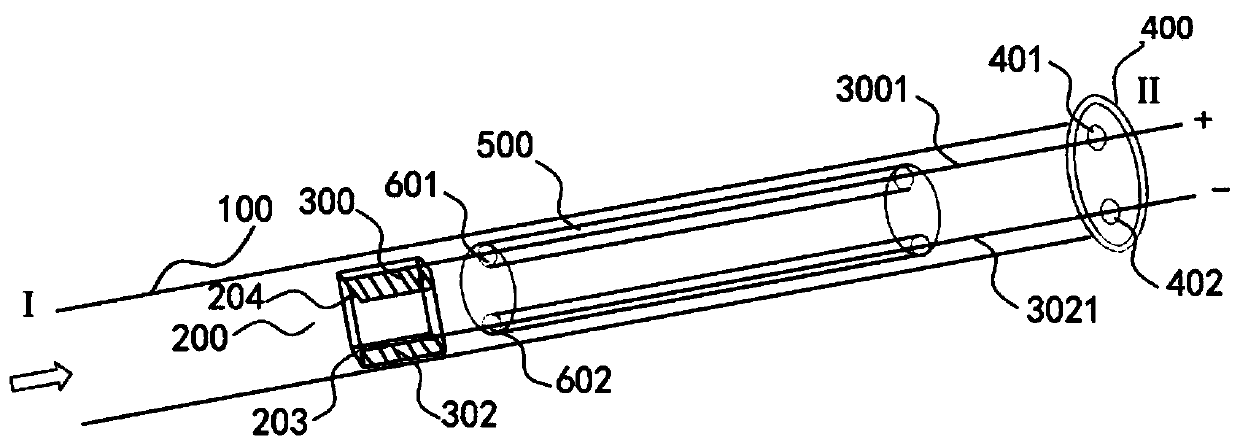

[0074] use figure 1 The shown setup performs vertical graphene growth. Among them, the reaction temperature is set to 650°C, the power of the plasma source is set to 250W, a voltage of 20V is introduced into the plasma-enhanced chemical vapor deposition system, the distance between the two plates is 1.5cm, 20sccm methanol is added as a carbon source, and the growth is 0.5h .

[0075] Figure 5A It is the SEM figure of the vertical graphene of embodiment 1, it can be seen that a neat vertical graphene array has been grown on the substrate, wherein the upper left corner is the vertical graphene array surface observed from a top view angle, and the center of the figure shows A topography image of vertical graphene arrays grown on a substrate viewed from the side is shown. Figure 5B Be the Raman test figure of the vertical graphene of embodiment 1, Figure 5C It is the transmission electron microscope figure of the vertical graphene of embodiment 1; Figure 5D It is the XPS ...

Embodiment 2

[0077] use figure 1 The shown setup performs vertical graphene growth. Among them, the reaction temperature is set to 650°C, the power of the plasma source is set to 250W, a voltage of 40V is introduced into the plasma-enhanced chemical vapor deposition system, the distance between the two plates is 1.5cm, 20sccm methanol is added as a carbon source, and the growth is 0.5h , Figure 6 It is the SEM figure of the vertical graphene of embodiment 2, wherein the upper left corner is the vertical graphene array surface observed from the top view angle, and the center of the figure shows the vertical graphene array grown on the substrate observed from the side Topography.

Embodiment 3

[0079] use figure 1 The shown setup performs vertical graphene growth. Among them, the reaction temperature is set to 650°C, the power of the plasma source is set to 250W, a voltage of 60V is introduced into the plasma-enhanced chemical vapor deposition system, the distance between the two plates is 1.5cm, 20sccm methanol is added as a carbon source, and the growth is 0.5h , Figure 7 It is the SEM figure of the vertical graphene of embodiment 3, wherein the upper left corner is the vertical graphene array surface observed from the top view angle, and the center of the figure shows the vertical graphene array grown on the substrate observed from the side Topography.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com