Sodium ion battery electrode material, electrode and battery

A technology for sodium ion batteries and positive electrode materials, which is applied in battery electrodes, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of difficulty in finding and deintercalating sodium ions, difficulty in selecting electrode materials, and low sodium storage capacity of graphite. Reversible capacity, environmental friendliness, simple preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Carbon molecular sieve one (effective pore diameter is 0.35nm, specific surface area is 5m 2 / g, pore volume 0.013cm 3 / g), and polyvinylidene fluoride after oven drying at 60°C, fully grind evenly according to the ratio of 8:1, mix evenly under the action of solvent 1-methyl-2-pyrrolidone to form a viscous paste, fully stir for 6h After coating the film, the current collector is carbon-coated copper foil. After the above electrode sheet was fully dried in an oven at 120° C. for 12 hours, a negative electrode sheet with a diameter of 14 mm was prepared. The negative electrode sheet and electrolyte (1mol / L NaClO 4 , 1:1 ethyl carbonate and diethyl carbonate), glass fibers, and sodium sheets are assembled into a sodium-ion battery.

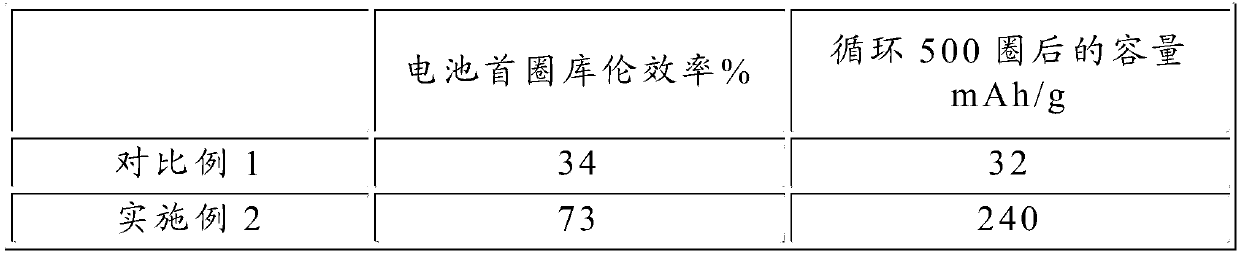

Embodiment 2

[0055] Carbon molecular sieve II (effective pore diameter is 0.40m, specific surface area is 16m 2 / g, pore volume 0.015cm 3 / g), with conductive carbon black and polyvinylidene fluoride at 60 ° C, after drying in an oven, fully grind evenly according to the ratio of 8:1:1, and mix evenly under the action of solvent 1-methyl-2-pyrrolidone to become viscous It is in the form of a paste, and after being fully stirred for 6 hours, it is coated on the current collector, which is a carbon-coated copper foil. After the above-mentioned electrode sheet was fully dried in an oven at 120° C. for 12 hours, it was punched into a negative electrode sheet with a diameter of 14 mm. The negative electrode sheet and electrolyte (1mol / L NaClO 4 , 1:1 ethyl carbonate and diethyl carbonate), glass fibers, and sodium sheets are assembled into a sodium-ion battery.

Embodiment 3

[0057] Carbon molecular sieve three (effective pore diameter is 0.6nm, specific surface area is 36m 2 / g, pore volume 0.15cm 3 / g), with conductive carbon black and polyvinylidene fluoride at 60 ° C, after drying in an oven, fully grind evenly according to the ratio of 8:1:1, and mix evenly under the action of solvent 1-methyl-2-pyrrolidone to become viscous It is in the form of a paste, and after being fully stirred for 6 hours, it is coated on the current collector, which is a carbon-coated copper foil. After the above-mentioned electrode sheet was fully dried in an oven at 120° C. for 12 hours, it was punched into a negative electrode sheet with a diameter of 14 mm. The negative electrode sheet and electrolyte (1mol / L NaClO 4 , 1:1 ethyl carbonate and diethyl carbonate), glass fibers, and sodium sheets are assembled into a sodium-ion battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com