Indium oxide thin-film material modified with aluminium oxide-coated palladium nanoparticles and preparation method and application thereof

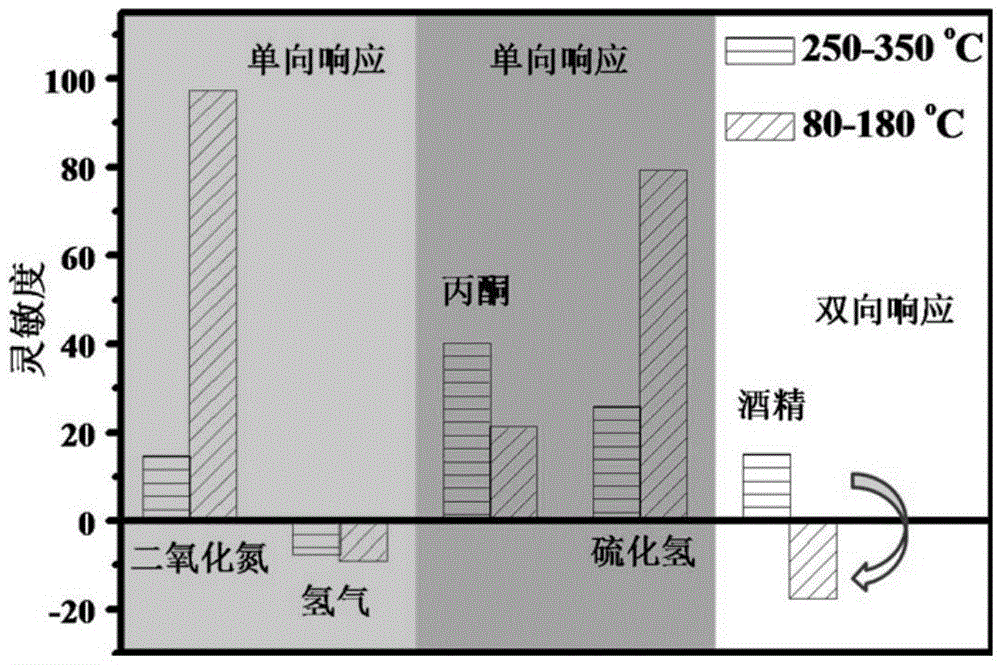

A technology of palladium nanoparticles and thin film materials, applied in the direction of material resistance, etc., can solve the problems of inability to achieve selective identification of ethanol gas, inability to obtain products, etc., and achieve the effects of improving gas sensing performance, reasonable structure, and scientific preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The concrete steps of preparation are:

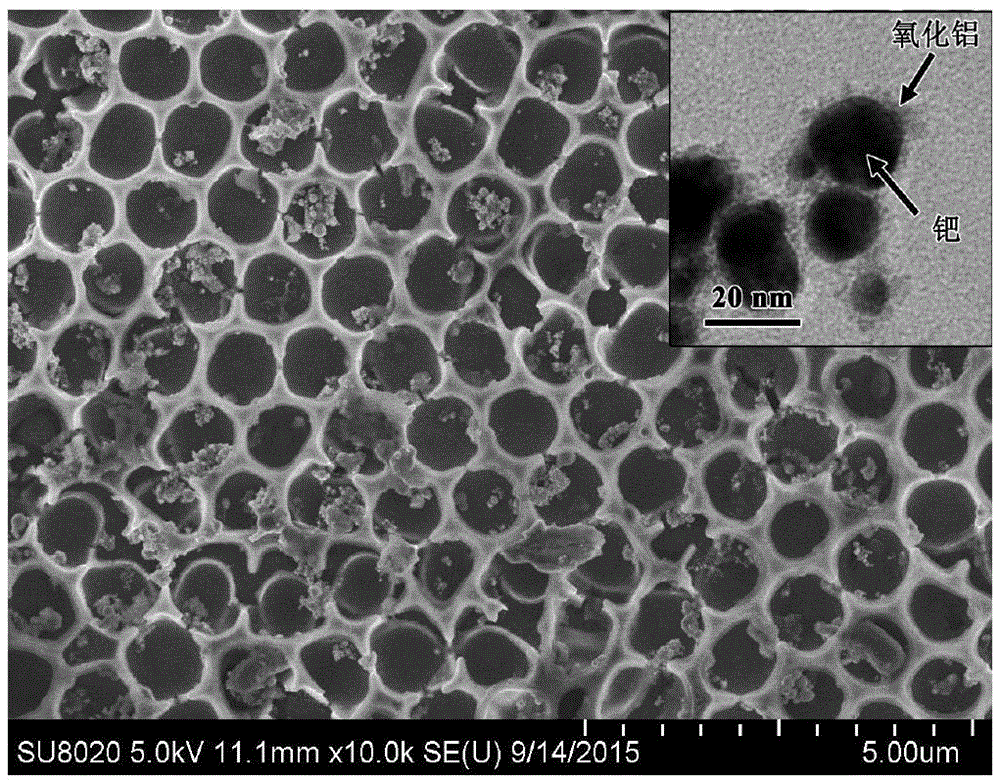

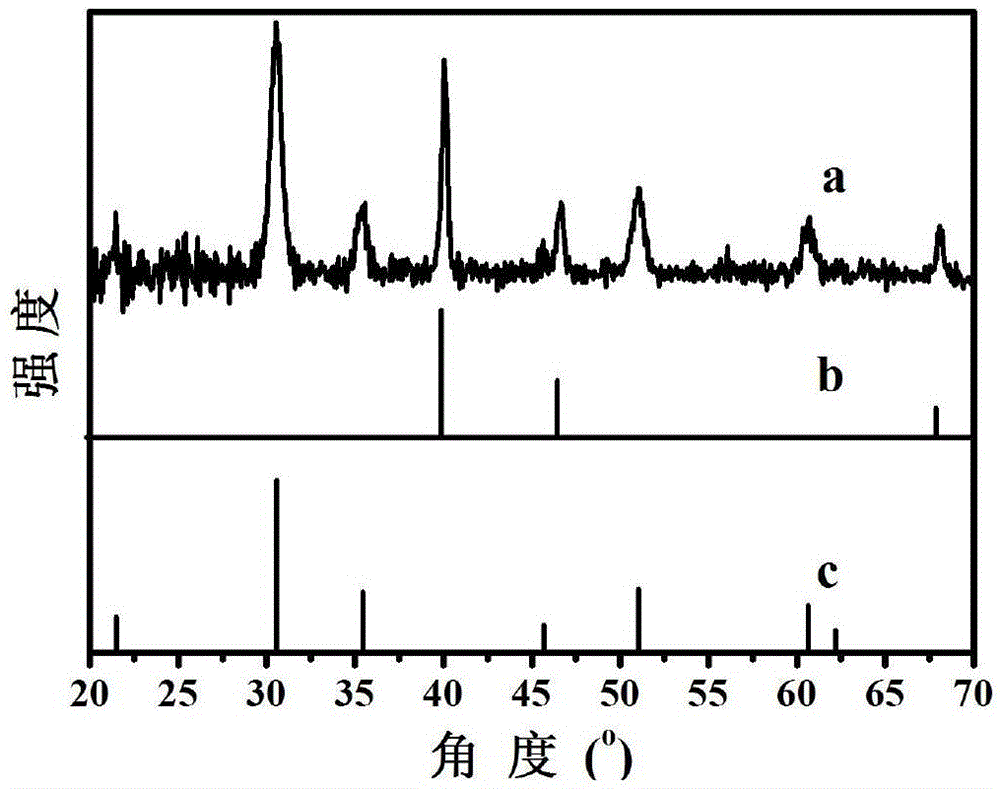

[0041] Step 1, first pick up the single-layer colloidal ball template floating in the indium nitrate solution and then heat it to obtain a single-layer colloidal ball template solidified with indium nitrate; wherein, the colloidal balls forming the single-layer colloidal ball template have a ball diameter of 1000nm polystyrene colloidal balls. Then place the single-layer colloidal ball template solidified with indium nitrate at 300° C. for annealing to obtain a single-layer porous indium oxide film.

[0042]Step 2, first place the palladium target in a stirred 0.01mol / L aluminum nitrate solution; wherein, the aluminum nitrate solution is an aqueous aluminum nitrate solution. Then use a laser with a wavelength of 532nm (or 1064nm), a repetition rate of 1Hz, a pulse width of 15ns, and a power of 40mJ / pulse to irradiate the palladium target for 18 minutes; wherein, the diameter of the laser spot is 0.5mm, and the emission wavelengt...

Embodiment 2

[0045] The concrete steps of preparation are:

[0046] Step 1, first pick up the single-layer colloidal ball template floating in the indium nitrate solution and then heat it to obtain a single-layer colloidal ball template solidified with indium nitrate; wherein, the colloidal balls forming the single-layer colloidal ball template have a ball diameter of 1000nm polystyrene colloidal balls. Then place the single-layer colloidal ball template solidified with indium nitrate at 325° C. for annealing to obtain a single-layer porous indium oxide film.

[0047] Step 2, first place the palladium target in a stirred 0.05 mol / L aluminum nitrate solution; wherein, the aluminum nitrate solution is an aqueous aluminum nitrate solution. Then use a laser with a wavelength of 532nm (or 1064nm), a repetition rate of 5Hz, a pulse width of 12.5ns, and a power of 60mJ / pulse to irradiate the palladium target for 14min; wherein, the laser spot diameter is 1mm, and the emission wavelength is 532nm...

Embodiment 3

[0050] The concrete steps of preparation are:

[0051] Step 1, first pick up the single-layer colloidal ball template floating in the indium nitrate solution and then heat it to obtain a single-layer colloidal ball template solidified with indium nitrate; wherein, the colloidal balls forming the single-layer colloidal ball template have a ball diameter of 1000nm polystyrene colloidal balls. Then place the single-layer colloidal ball template solidified with indium nitrate at 350° C. for annealing to obtain a single-layer porous indium oxide film.

[0052] Step 2, first place the palladium target in a 0.2 mol / L aluminum nitrate solution under stirring; wherein, the aluminum nitrate solution is an aqueous aluminum nitrate solution. Then use a laser with a wavelength of 532nm (or 1064nm), a repetition rate of 10Hz, a pulse width of 10ns, and a power of 80mJ / pulse to irradiate the palladium target for 9 minutes; wherein, the laser spot diameter is 1.5mm, and the emission waveleng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com