Preparation method of carbon nanofiber film without metal catalyst

A technology of carbon nanofibers and metal catalysts, which is applied in the direction of nanocarbons and graphene, can solve the problems of difficult removal, difficulty in realizing low-cost and large-scale production of carbon nanofiber films, and limiting the application range of carbon nanofiber films. Pollution reduction, easy industrial scale production, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The concrete steps of preparation are:

[0029] Step 1, immerse the aluminum sheet in 0.08 mol / L copper nitrate aqueous solution for 40 minutes, then take it out and dry to obtain the aluminum sheet with copper nitrate supported on the surface.

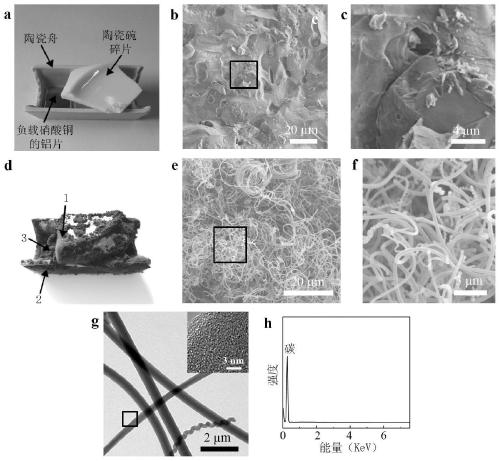

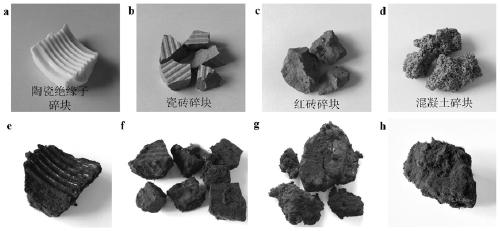

[0030] Step 2, placing the aluminum sheet loaded with copper nitrate on the surface in a ceramic container, and covering it with ceramic product fragments; wherein, the ceramic container is a ceramic boat, and the ceramic product fragments are ceramic bowl fragments, and the bottom is sequentially covered with Ceramic containers with aluminum flakes and ceramic fragments loaded with copper nitrate on the surface.

[0031] Step 3, first place the ceramic container whose bottom is successively covered with copper nitrate-loaded aluminum sheet and ceramic product fragments in an argon atmosphere to raise the temperature to 420°C, and then place it in a mixed atmosphere of acetylene and argon at the same temperature 40h; Among the...

Embodiment 2

[0033] The concrete steps of preparation are:

[0034] Step 1, after immersing the aluminum sheet in 0.09 mol / L copper nitrate aqueous solution for 35 minutes, taking it out and drying it to obtain the aluminum sheet with copper nitrate supported on the surface.

[0035] Step 2, placing the aluminum sheet loaded with copper nitrate on the surface in a ceramic container, and covering it with ceramic product fragments; wherein, the ceramic container is a ceramic boat, and the ceramic product fragments are ceramic bowl fragments, and the bottom is sequentially covered with Ceramic containers with aluminum flakes and ceramic fragments loaded with copper nitrate on the surface.

[0036] Step 3, first place the ceramic container whose bottom is successively covered with copper nitrate-loaded aluminum sheet and ceramic product fragments in an argon atmosphere to raise the temperature to 430°C, and then place it in a mixed atmosphere of acetylene and argon at the same temperature 35h...

Embodiment 3

[0038]The concrete steps of preparation are:

[0039] Step 1, after immersing the aluminum sheet in 0.1 mol / L copper nitrate aqueous solution for 30 minutes, take it out and dry it to obtain the aluminum sheet with copper nitrate supported on the surface.

[0040] Step 2, placing the aluminum sheet loaded with copper nitrate on the surface in a ceramic container, and covering it with ceramic product fragments; wherein, the ceramic container is a ceramic boat, and the ceramic product fragments are ceramic bowl fragments, and the bottom is sequentially covered with Ceramic containers with aluminum flakes and ceramic fragments loaded with copper nitrate on the surface.

[0041] Step 3, first place the ceramic container whose bottom is successively covered with copper nitrate-loaded aluminum sheet and ceramic product fragments in an argon atmosphere to raise the temperature to 440°C, and then place it in a mixed atmosphere of acetylene and argon at the same temperature 30h; Among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com