Praseodymium-doped lanthanum fluoride organic-inorganic hybrid nanometer powder and its preparation method and use

A nano-powder and lanthanum fluoride technology, which is applied in the field of organic-inorganic hybrid nano-powder and its preparation, can solve the problems of low energy, large energy loss, and high cost of red, green, and blue light, and achieve simple preparation methods and convenient use and maintenance. , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The concrete steps of preparation are:

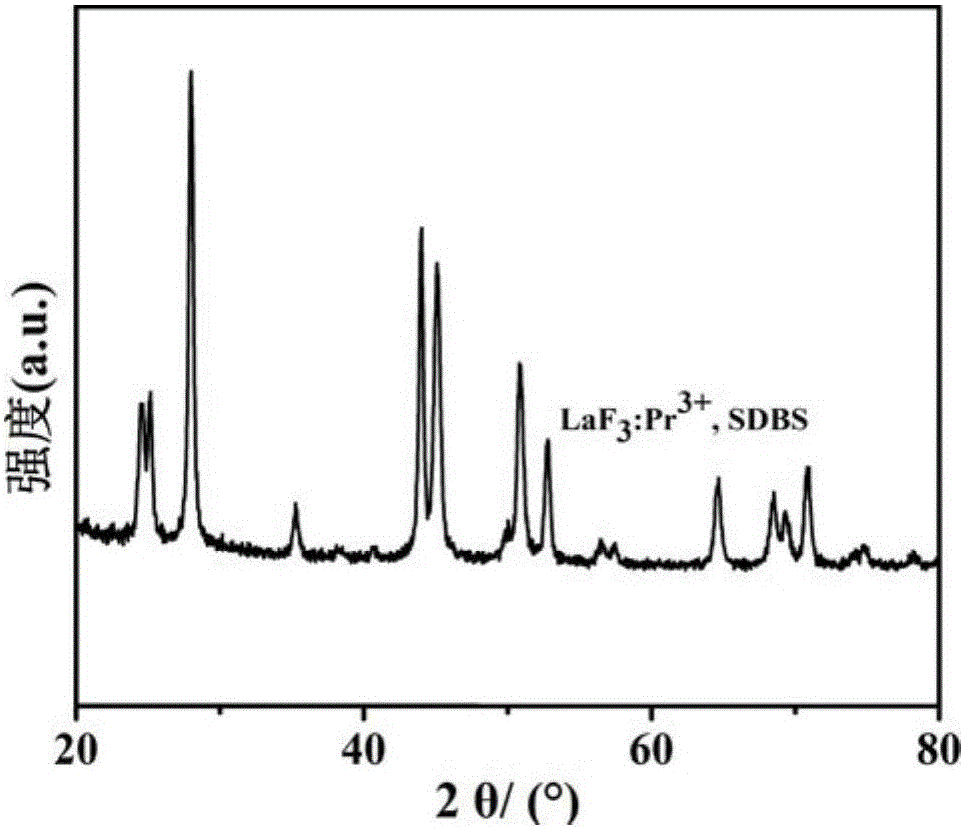

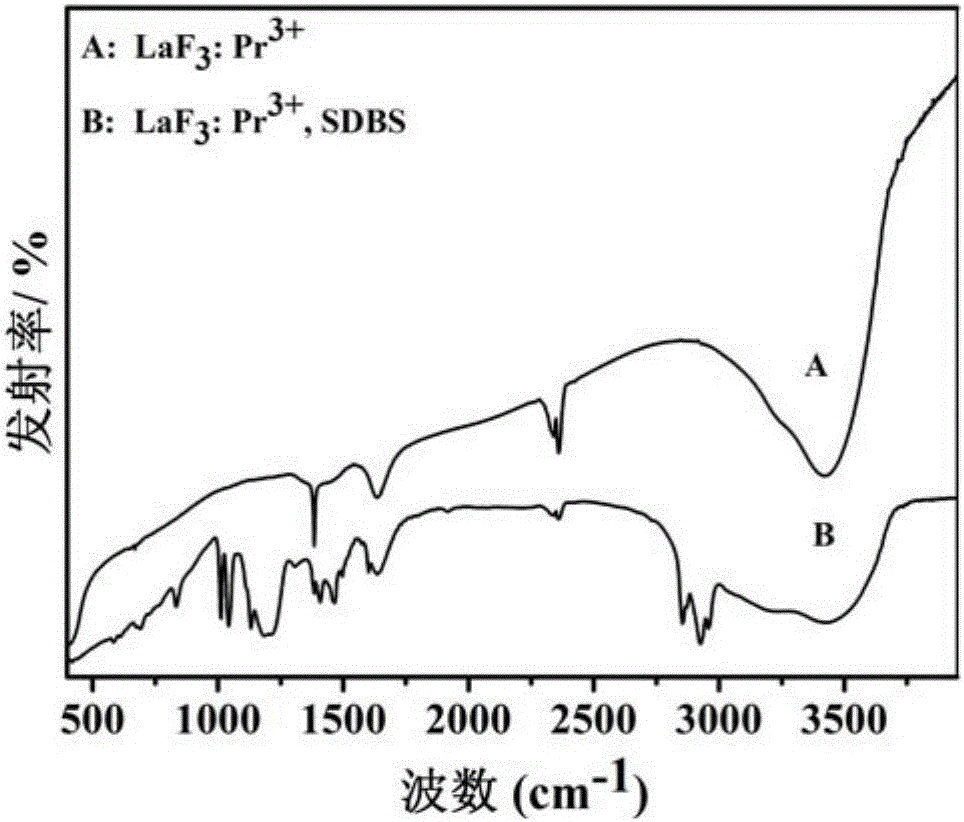

[0037] Step 1, first follow La 0.999 PR 0.001 f 3 After weighing the corresponding amount of lanthanum oxide and praseodymium oxide, the lanthanum oxide, praseodymium oxide and 6 mol / L nitric acid aqueous solution were mixed under stirring to prepare a rare earth nitrate aqueous solution with a total rare earth ion concentration of 0.1 mol / L. Then respectively add 0.5mol / L surfactant aqueous solution and ammonium fluoride into the rare earth nitrate aqueous solution, and stir until the reaction is complete to obtain the precursor solution; wherein, the total rare earth ions in the precursor solution, the surfactant aqueous solution The molar ratio of the surfactant and ammonium fluoride is 1:0.5:4, and the surfactant is sodium dodecylbenzenesulfonate.

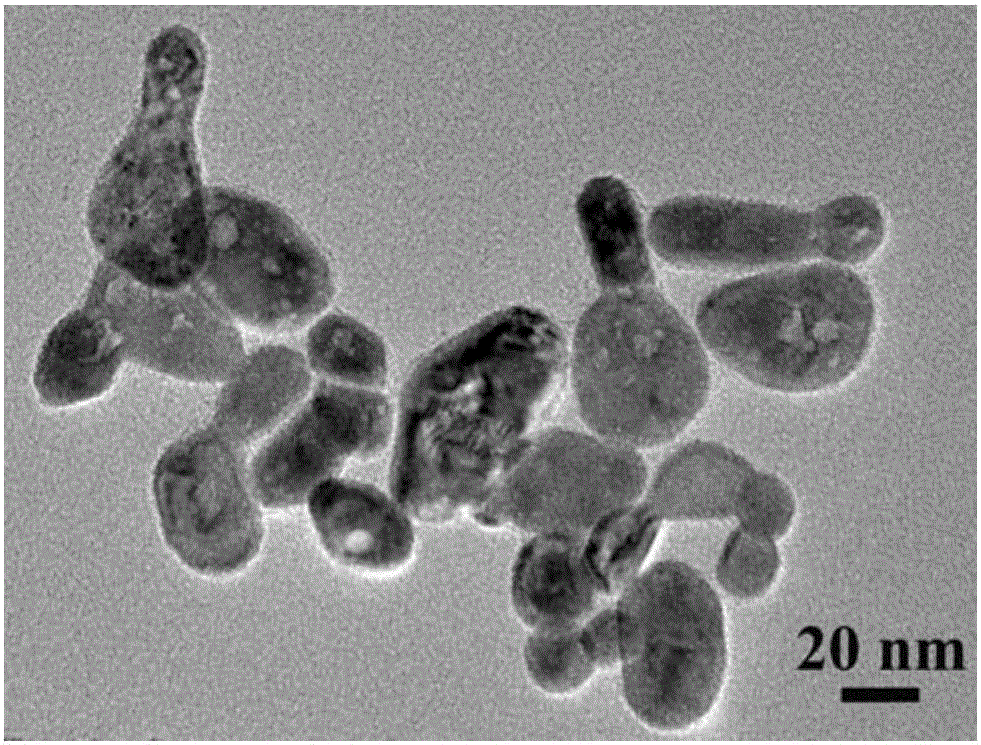

[0038]In step 2, first place the precursor solution in an airtight state, and react at 140° C. for 24 hours to obtain a reaction solution. Carry out the treatment of solid-liq...

Embodiment 2

[0040] The concrete steps of preparation are:

[0041] Step 1, first follow La 0.995 PR 0.005 f 3 After weighing the corresponding amount of lanthanum oxide and praseodymium oxide, the lanthanum oxide, praseodymium oxide and 9 mol / L nitric acid aqueous solution were mixed under stirring to prepare a rare earth nitrate aqueous solution with a total rare earth ion concentration of 0.2 mol / L. Then respectively add 0.4mol / L surfactant aqueous solution and ammonium fluoride into the rare earth nitrate aqueous solution, stir until the reaction is complete, and obtain the precursor solution; wherein, the total rare earth ions in the precursor solution, the surfactant aqueous solution The molar ratio of the surfactant and ammonium fluoride is 1:0.9:3.8, and the surfactant is sodium dodecylbenzenesulfonate.

[0042] In step 2, first place the precursor solution in an airtight state, and react at 160° C. for 20 hours to obtain a reaction solution. Carry out the processing of solid-l...

Embodiment 3

[0044] The concrete steps of preparation are:

[0045] Step 1, first follow La 0.99 PR 0.01 f 3 After weighing the corresponding amount of lanthanum oxide and praseodymium oxide, the lanthanum oxide, praseodymium oxide and 11mol / L nitric acid aqueous solution were mixed under stirring to prepare a rare earth nitrate aqueous solution with a total rare earth ion concentration of 0.3mol / L. Then respectively add 0.3mol / L surfactant aqueous solution and ammonium fluoride in the rare earth nitrate aqueous solution, and stir until the reaction is complete to obtain the precursor solution; wherein, the total rare earth ions in the precursor solution, the surfactant aqueous solution The molar ratio of the surfactant and ammonium fluoride is 1:1.3:3.5, and the surfactant is sodium dodecylbenzenesulfonate.

[0046] In step 2, first place the precursor solution in an airtight state, and react at 180° C. for 16 hours to obtain a reaction solution. Carry out the processing of solid-liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com