A porous monoionic conductive polymer electrolyte membrane and a preparation method and application thereof

A technology of electrolyte separator and conductive polymer, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as environmental pollution, high operational safety requirements, and increase of internal short-circuit areas, and achieve wide commercial application and easy preparation. Method, effect of improving ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An embodiment of the present invention provides a porous single-ion conductive polymer electrolyte membrane, and the film-forming material of the electrolyte membrane is a single-ion conductive polymer electrolyte and a polymer binder.

[0028] The mass fraction of the single ion conducting polymer electrolyte is 30-70%.

[0029] Single-ion-conducting polymer electrolytes use polymer materials as skeleton materials, and lithium salts are embedded in them.

[0030] The skeleton material includes one or more of polyamide, polyimide, polyarylether, benzimidazole, polyethylene, polyvinyl fluoride, polyurethane, polyester and polyphosphazene.

[0031] The lithium salt includes one or more of lithium bissulfonylimide, sp3 hybrid boron, lithium sulfonate and lithium phosphate.

[0032] The polymer binder includes one or more of polyvinylidene fluoride and its derivatives, polyacrylonitrile, polyamide, polyimide, polyarylether, polymethyl methacrylate and polybenzimidazole.

...

Embodiment 2

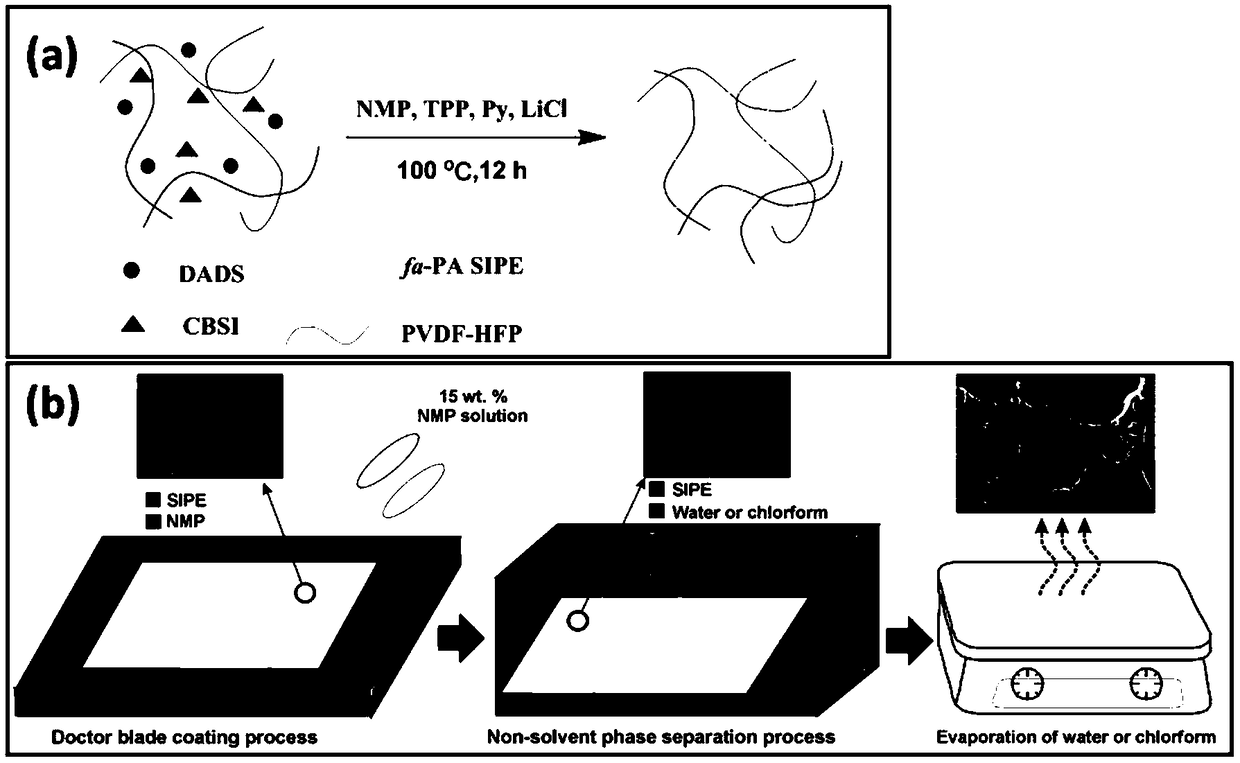

[0042] Embodiments of the present invention provide a porous single-ion-conducting polymer electrolyte membrane, the raw materials are all-aromatic polyamide single-ion-conducting polymer electrolyte (fa-PA-SIPE) and poly(vinylidene fluoride-cohexafluoropropylene) ) (PVDF-HFP) binder, the mass ratio of PVDF-HFP and fa-PA-SIPE is 1:1, and it is made into 15wt.% NMP casting solution. Chloroform was used as a non-solvent.

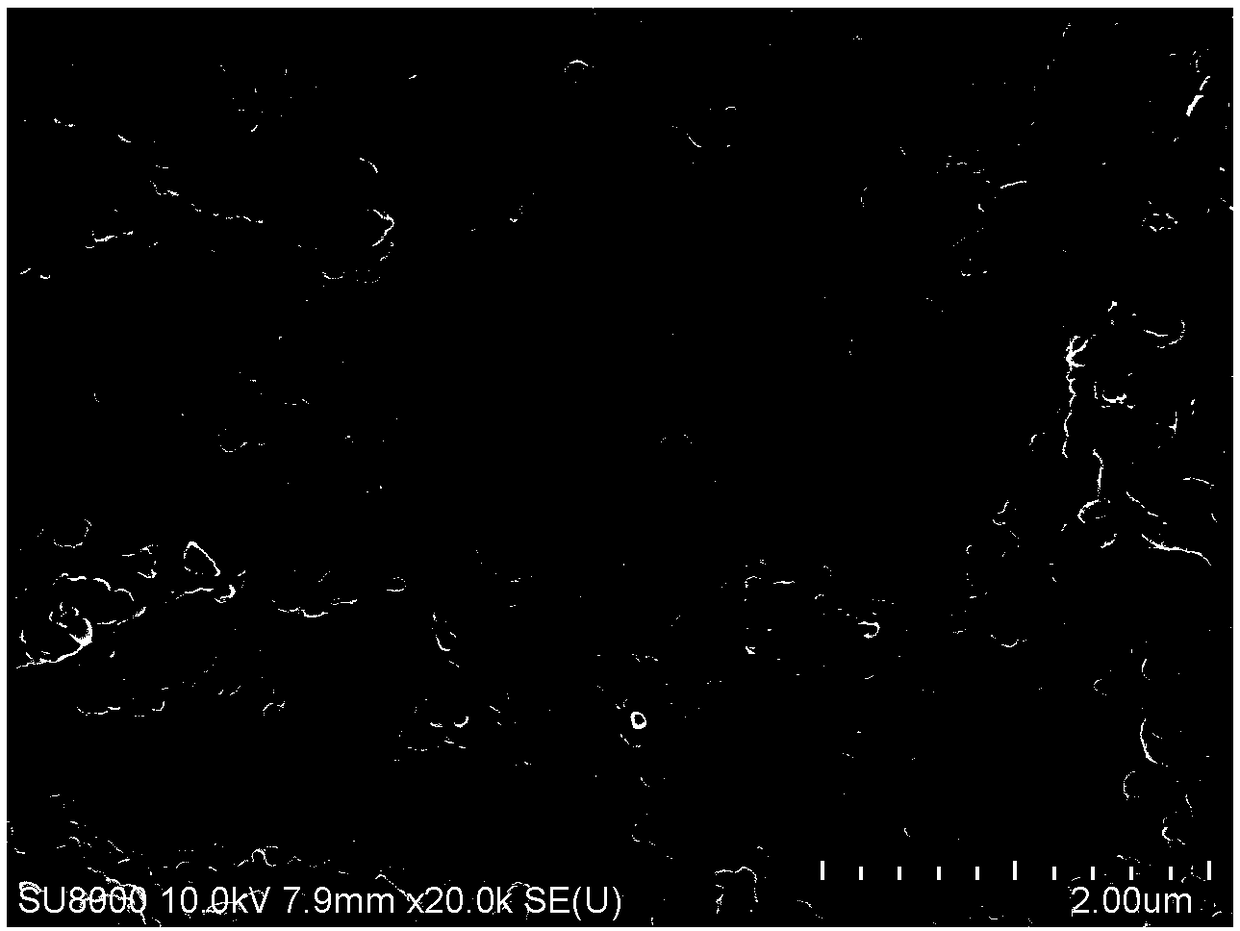

[0043] Please refer to figure 1 According to the method of Example 1, the prepared porous single-ion conductive polymer electrolyte membrane was prepared, and the microscopic morphology of the electrolyte membrane was obtained as figure 2 Shown, porosity, liquid absorption, tensile strength properties are shown in Table 1.

[0044] Porosity, liquid absorption, tensile strength of table 1 membrane

[0045]

Embodiment 3

[0047] Embodiments of the present invention provide a porous single-ion-conducting polymer electrolyte membrane, the raw materials are all-aromatic polyamide single-ion-conducting polymer electrolyte (fa-PA-SIPE) and poly(vinylidene fluoride-cohexafluoropropylene) ) (PVDF-HFP) binder, the mass ratio of PVDF-HFP and fa-PA-SIPE is 1:1, and it is made into 15wt.% NMP casting solution. Water was used as a non-solvent.

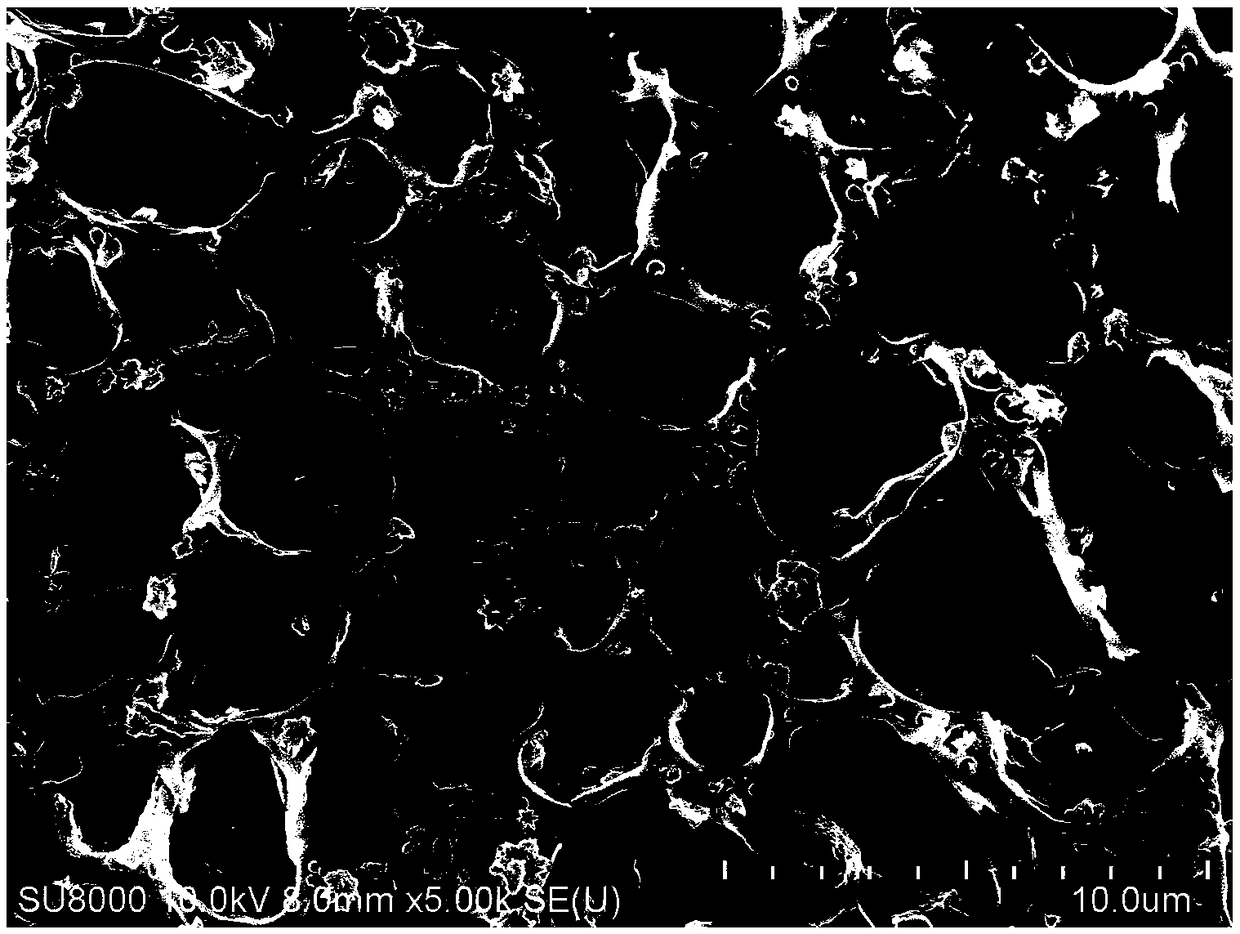

[0048] Please refer to figure 1 According to the method of Example 1, the prepared porous single-ion conductive polymer electrolyte membrane was prepared, and the microscopic morphology of the electrolyte membrane was obtained as image 3 Shown, porosity, liquid absorption, tensile strength properties are shown in Table 2.

[0049] Porosity, liquid absorption, tensile strength of table 2 membrane

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com