Graphene oxide modified orderly porous zinc oxide composite film and preparation method thereof

A technology of porous zinc oxide and composite film, applied in zinc oxide/zinc hydroxide, nanotechnology for materials and surface science, nanotechnology, etc. production and other problems, to achieve the effect of good gas sensing or catalytic performance, simple preparation method and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

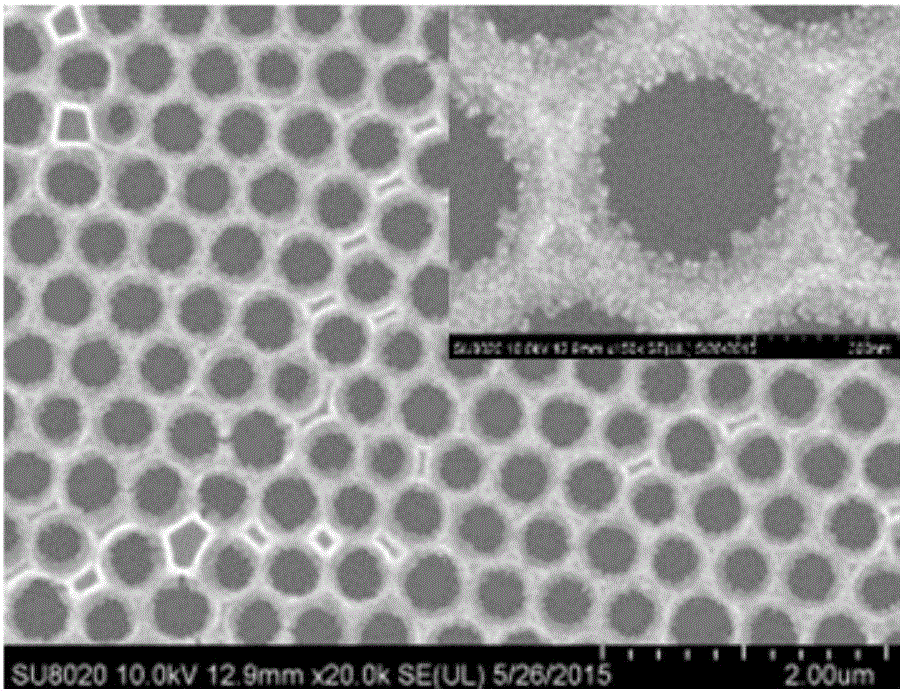

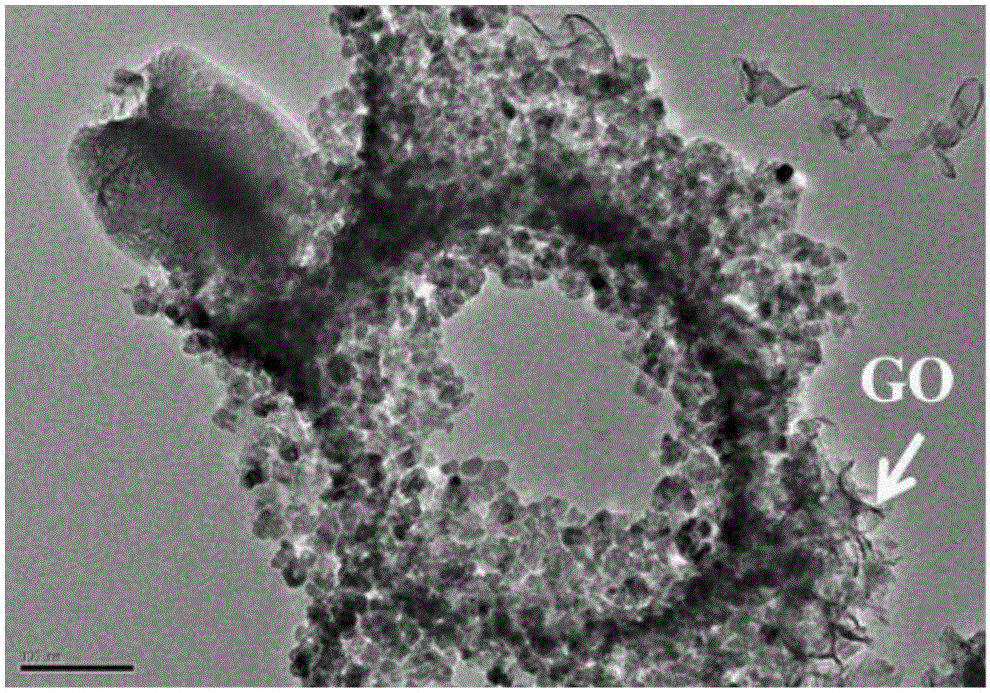

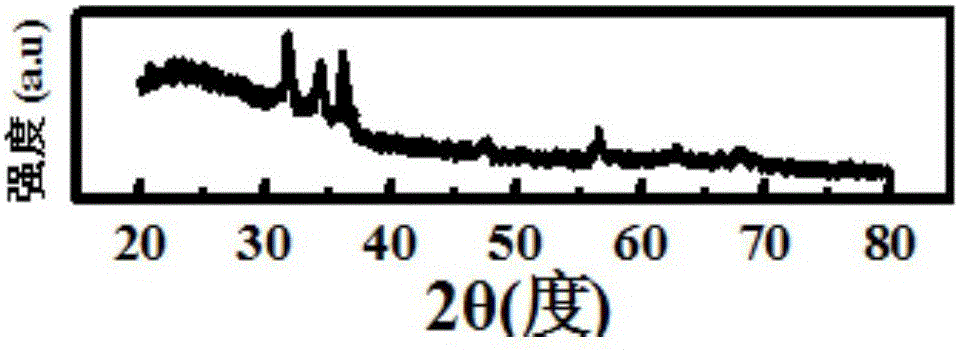

[0036] The concrete steps of preparation are:

[0037] Step 1, first mix the 0.1g / L graphene oxide aqueous solution and the 0.2mol / L zinc salt aqueous solution at a volume ratio of 1:23; wherein the zinc salt is zinc acetate to obtain a precursor solution . After placing the single-layer colloidal crystal template in the precursor solution, use the substrate to pick it up; wherein, the diameter of the colloidal spheres constituting the single-layer colloidal crystal template is 1000nm, and the substrate is a flat insulator. A substrate with a single-layer colloidal crystal template loaded with a precursor solution on its surface.

[0038] Step 2, first put the substrate covered with the single-layer colloidal crystal template with the precursor solution on the surface and bake it at 50 ° C for 12 hours to obtain the substrate covered with the single-layer colloidal crystal template with the precursor solution on the surface . Then place the substrate covered with the single...

Embodiment 2

[0040] The concrete steps of preparation are:

[0041] Step 1, first mix the 0.5g / L graphene oxide aqueous solution and the 0.2mol / L zinc salt aqueous solution at a volume ratio of 1:24; wherein the zinc salt is zinc acetate to obtain a precursor solution . After placing the single-layer colloidal crystal template in the precursor solution, use the substrate to pick it up; wherein, the diameter of the colloidal spheres constituting the single-layer colloidal crystal template is 1000nm, and the substrate is a flat insulator. A substrate with a single-layer colloidal crystal template loaded with a precursor solution on its surface.

[0042] Step 2, first place the substrate covered with the single-layer colloidal crystal template with the precursor solution on the surface and bake it at 55°C for 9 hours to obtain the substrate covered with the single-layer colloidal crystal template with the precursor solution on the surface . Then place the substrate covered with the single-...

Embodiment 3

[0044] The concrete steps of preparation are:

[0045] Step 1, first mix the 1g / L graphene oxide aqueous solution and the 0.2mol / L zinc salt aqueous solution at a volume ratio of 1:25; wherein the zinc salt is zinc acetate to obtain a precursor solution. After placing the single-layer colloidal crystal template in the precursor solution, use the substrate to pick it up; wherein, the diameter of the colloidal spheres constituting the single-layer colloidal crystal template is 1000nm, and the substrate is a flat insulator. A substrate with a single-layer colloidal crystal template loaded with a precursor solution on its surface.

[0046] Step 2, first place the substrate covered with the single-layer colloidal crystal template with the precursor solution on the surface and bake it at 60°C for 6 hours to obtain the substrate covered with the single-layer colloidal crystal template with the precursor solution on the surface . Then place the substrate covered with the single-layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com