A kind of biological source composite oil displacement system and its preparation method and oil displacement method

A compound oil displacement and biological source technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the low flooding efficiency of single biopolymer, the environmental hazards of chemically synthesized oil displacement agents, and poor temperature and salt resistance etc. to achieve superior rheological properties, a wide range of applicable oil reservoirs, and low molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

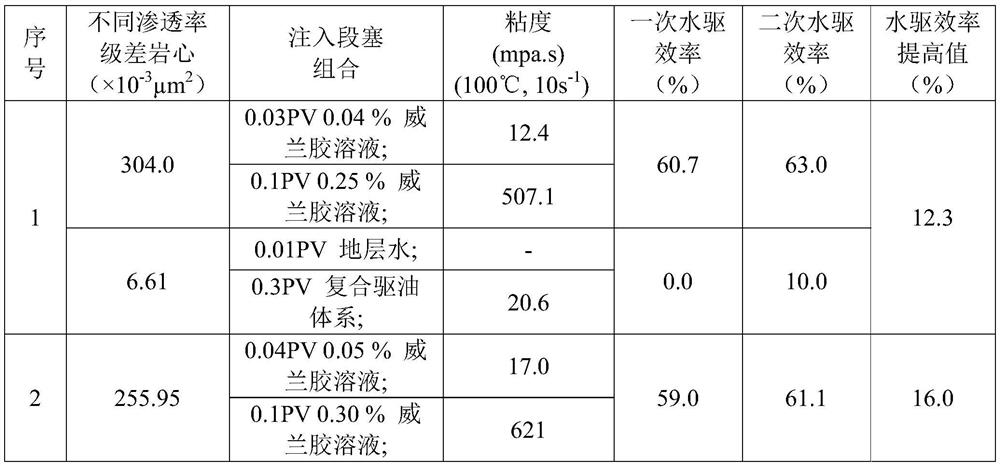

Examples

Embodiment 1

[0020] Example 1 Biological Safety Evaluation Experiment

[0021] (1) Proportion of the oil displacement system: by mass percentage, including 0.06% of welan gum, 0.60% of lipopeptide biosurfactant, 0.05% of SAS-60, and the rest is formation water.

[0022] (2) Preparation method of oil displacement system: add welan gum into formation water, prepare a welan gum solution with a mass concentration of 0.60%, stir and dissolve at room temperature for 3 hours, then add lipopeptide biosurfactant and SAS-60 Add to the above-mentioned welan gum solution in sequence, then add formation water until the mass percentage of welan gum is 0.06%, the mass percentage of lipopeptide biosurfactant is 0.60%, and the mass percentage of SAS-60 is 0.05%, stirring at room temperature Dissolved for 1 hour to obtain an oil displacement system.

[0023] (3) Skin irritation test: the back hair of the mouse was cut off, and the above-mentioned oil-displacing system was rubbed on the normal skin and the ...

Embodiment 2

[0025] Example 2 Compatibility experiment with high temperature and high salinity formation conditions

[0026] (1) The ratio and preparation method of the oil displacement agent are as described in Example 1.

[0027] (2) Seal the above-mentioned composite oil displacement agent system in an iodine bottle, place it in a constant temperature box at 100°C, and after 48 hours, no precipitation, flocculation or suspended matter occurs under the conditions of high-temperature and high-salinity reservoirs, It shows that it has good compatibility with reservoir conditions and will not block the formation.

Embodiment 3

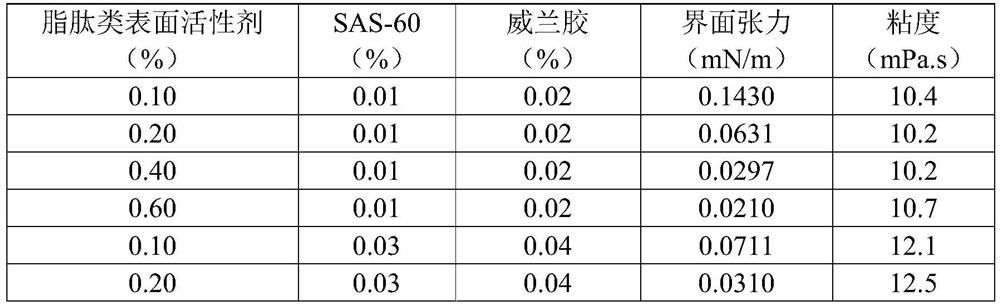

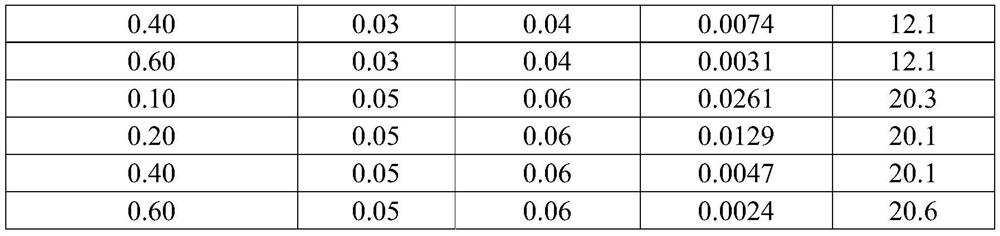

[0028] Example 3 Interfacial tension and viscosity of composite flooding system under different component concentration conditions

[0029] (1) Proportion of the oil displacement system: in terms of mass percentage, it includes 0.04-0.06% of welan gum, 0.40-0.60% of lipopeptide biosurfactant, 0.03-0.05% of SAS-60, and the rest is formation water. The specific mass percentages of each component are shown in Table 1.

[0030] (2) The preparation method of the oil displacement system is as described in Example 1.

[0031] (3) Seal the above composite oil displacement agent system in an iodine bottle, place it in a constant temperature box at 100°C, and measure the viscosity of the oil displacement system after 48 hours. g / cm 3 ) oil-water interfacial tension. The interfacial tension was measured by a TX-500 spinning drop interfacial tensiometer produced by the University of Texas. The apparent viscosity was measured by the Haake RS6000 rotational rheometer of Thermoelectric C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com