Reinforced-truss concrete precast panel, reinforced-truss concrete precast panel structure system and construction method thereof

A technology of reinforced trusses and prefabricated wall panels, which is applied to building components, building structures, processing of building materials, etc., can solve the problems of large amount of formwork works, long construction period, difficult demolition, etc., and achieves simple construction process and short construction period. , the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

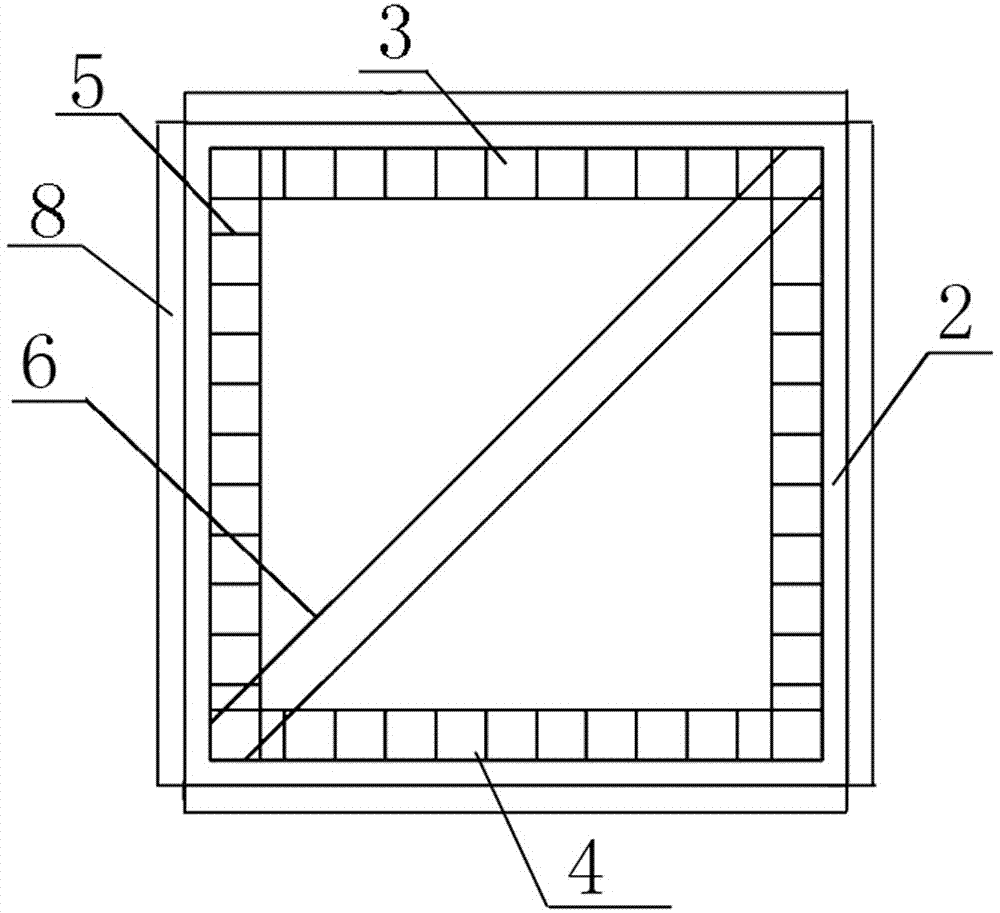

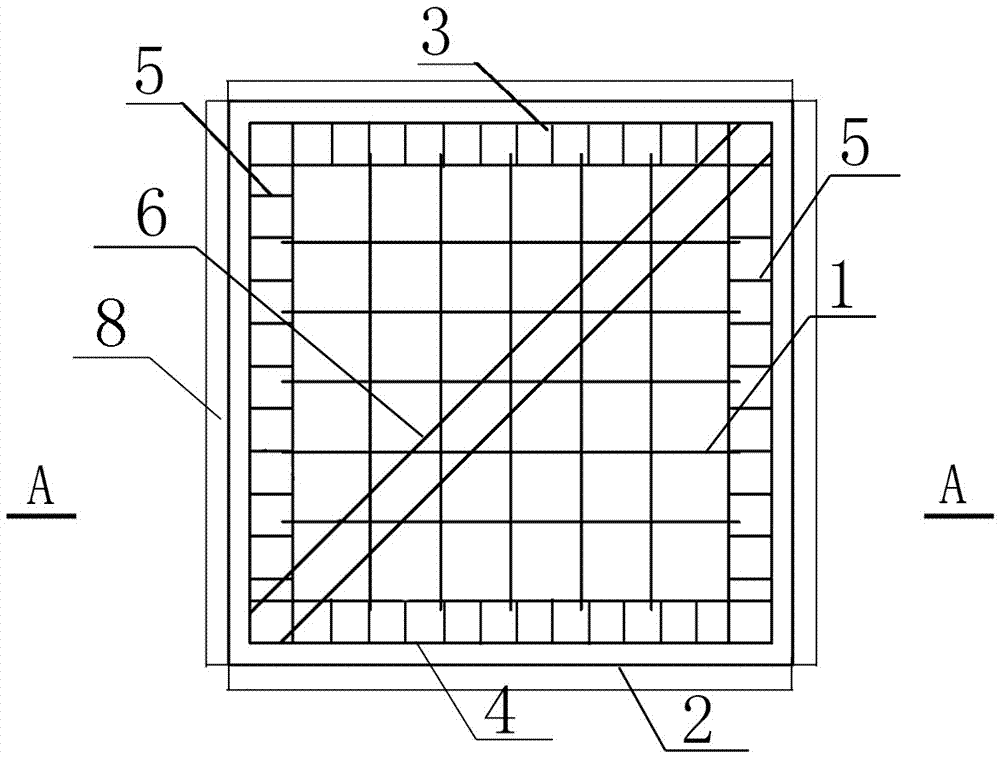

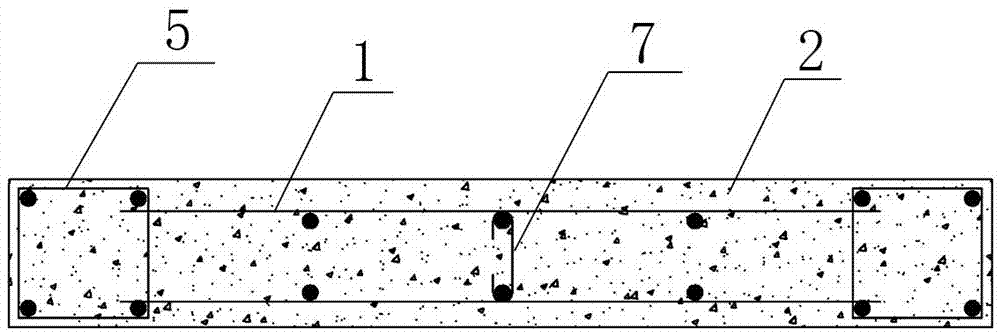

[0050] Such as Figure 1-8 As shown, this reinforced truss concrete prefabricated wall panel includes a reinforced truss frame and wall panel concrete 2 poured outside the reinforced truss frame; 3 and the vertical reinforcement cage 5 between the two ends of the lower chord reinforcement cage 4; in the frame surrounded by the upper chord reinforcement cage 3, the lower chord reinforcement cage 4 and the vertical reinforcement cage 5, an oblique reinforcement 6 is also provided; The oblique steel bars 6 are made of steel tendons or steel cages; the surrounding sides of the reinforced truss concrete prefabricated wall panels are also pre-embedded with a connecting plate-8; the connecting plates-8 are arranged along the axial direction of the side of the reinforced concrete prefabricated wall panels .

[0051] In this embodiment, the upper chord reinforcement cage 3 and the lower chord reinforcement cage 4 form a concealed beam together with the wallboard concrete 2 on the outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com