Liquid-jet hammer with fluid supplementation and energy storage function

A technology of jet type and hydraulic hammer, which is applied to the drilling drive device, earthwork drilling and drilling equipment in the wellbore, etc., can solve the problems of low impact power of the hydraulic hammer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

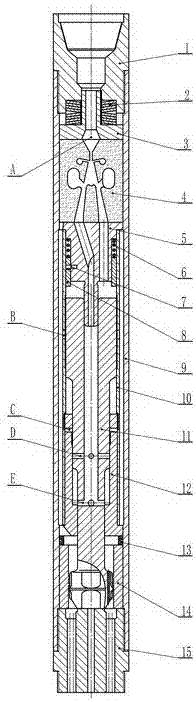

[0016] see figure 1 As shown, the present invention includes an upper joint 1, a combined disc spring 2, a deflector 3, a jet element 4, a flow distribution seat 5, an energy storage spring 6, a limit pin 7, an energy storage ring 8, an outer tube 9, and an inner cylinder 10 , hammer piston 11, cylinder head 12 and anvil 15; the upper joint 1 and the outer pipe 9 are threadedly connected, and the combined disc spring 2 is installed between the upper joint 1 and the deflector 3, and the deflector 3 is the combined disc spring 2 The fixed bracket is also the upper gland of the jet element 4; the combined disc spring 2 is used to absorb the counter-impact force borne by the jet element 4, and eliminate the machining error of the internal parts; the flow distribution seat 5 is installed above the inner cylinder 10 with a transition fit, An annular space is formed between the inner cylinder 10 and the outer pipe 9, the cylinder head 12 is installed at the lower end of the inner cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com