Self-locking aluminum-plate connecting device and self-locking aluminum-plate connecting method

A connecting device and self-locking technology, which is applied in the field of self-locking aluminum plate connecting devices, can solve problems such as loss of efficacy and looseness, and achieve the effects of easy processing, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

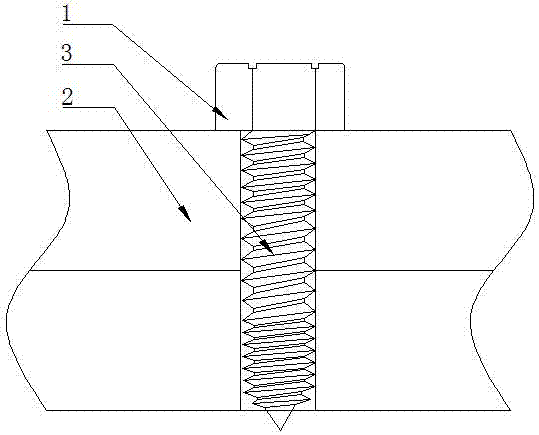

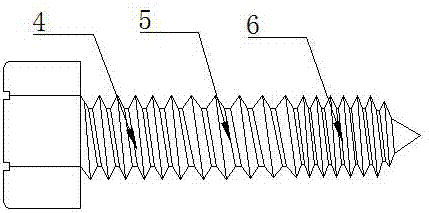

[0029] as attached figure 1 and 2 As shown, the self-locking aluminum plate connection device of the present invention includes a self-tapping screw 1 and two aluminum plates 2, the self-tapping screw 1 penetrates through the two aluminum plates 2 and the two aluminum plates 2 are fixedly connected; the self-tapping screw 1 includes a screw rod 3, The tip of the screw is extended to reduce the outer diameter and the tip of the screw is conical or conical; the middle screw is thread one 4, thread two 5 and thread three 6, and thread two 5 is located between thread one 4 and thread three 6 And the pitches of thread 1 4, thread 2 5 and thread 3 6 are all different to ensure that the self-tapping screw can self-lock and prevent the screw from rotating in reverse, loosening under the action of alternating shear loads and losing efficacy. The pitch of thread two 5 is greater than the pitch of thread one 4, and the pitch of thread one 4 is greater than the pitch of thread three 6. ...

Embodiment 2

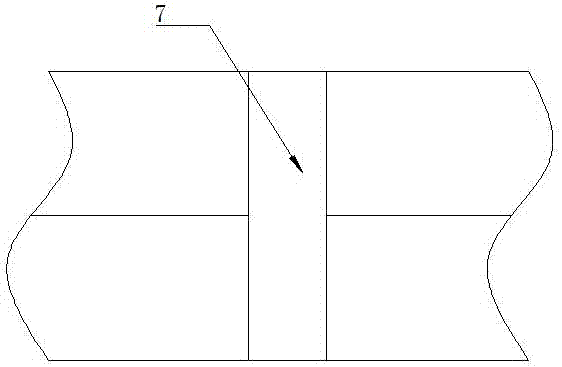

[0031] as attached image 3 As shown, the difference between the present embodiment and the first embodiment is that the aluminum plate 2 is provided with a through hole 7 . The diameter of the through hole 7 on the aluminum plate 2 is smaller than the diameter of the self-tapping screw 1 . Other structures and connections are the same as in Embodiment 1.

Embodiment 3

[0033] The self-locking aluminum plate connection method of the present invention is based on any one of the self-locking aluminum plate connection devices in embodiment 1, and the method comprises the following steps:

[0034] (1) Stack the two aluminum plates 2 that need to be connected together;

[0035] (2) Use the self-tapping screw tool to quickly rotate the self-tapping screw 1 and push it into the aluminum plate 2, use the heat generated by the high-speed rotation to soften the matrix of the aluminum plate 2, and form an aluminum plate based on the shape of the self-tapping screw 1 on the aluminum plate 2 The connection hole and the dense connection structure formed between the aluminum plate 2 and the self-tapping screw 1 can ensure that the screws with different pitches will not loosen;

[0036] (3) Take away the self-tapping screw tool to complete the fastening and self-locking connection of a self-tapping screw 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com