High-efficiency sewage source heat pump capable of being cleaned easily

A sewage source heat pump and easy-to-clean technology, applied in the field of heat pumps, can solve problems such as low heat transfer coefficient, difficult cleaning, deposition, etc., and achieve the effect of improving heat transfer coefficient, good directionality, and improved capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Sewage source heat pump, heat pump waste heat recovery.

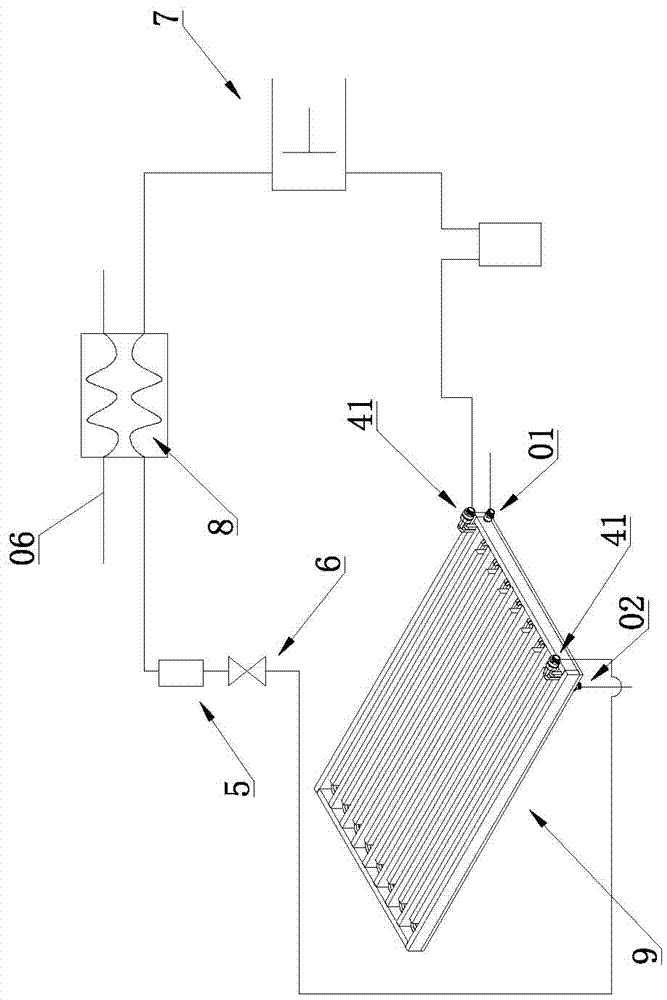

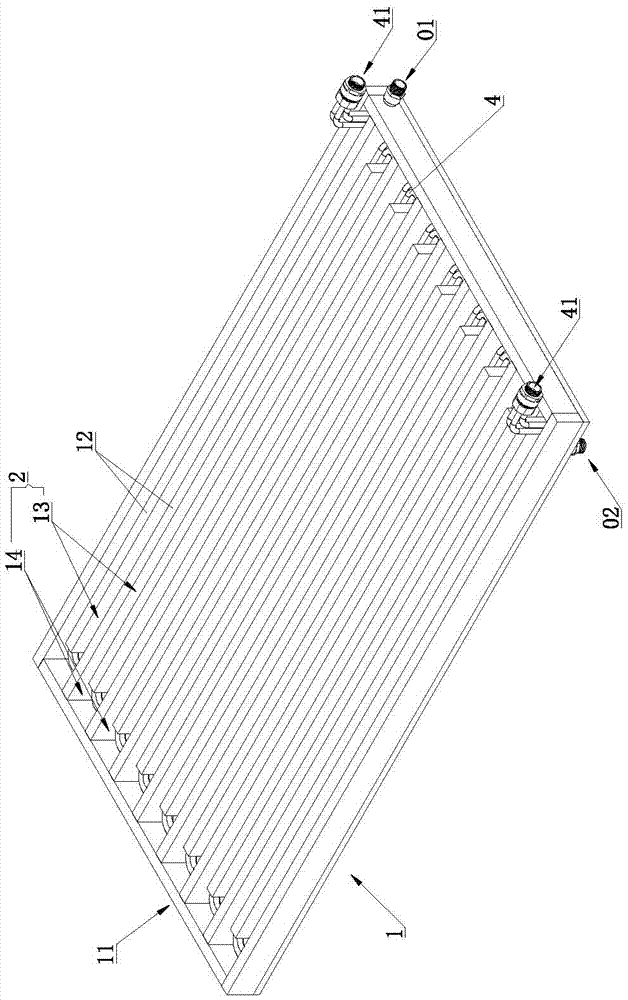

[0034] Such as Figure 1 to Figure 5 As shown, a high-efficiency and easy-to-clean sewage source heat pump includes an evaporator 9, a condenser 8, a compressor 7 connected to the evaporator 9 and the condenser 8, a refrigerant throttling device 6 connected to the evaporator 9, and a The refrigerator filter 5 connected to the refrigerant throttling device 6, the refrigerator filter 5 is connected to the condenser 8, the evaporator 9 includes a water tank 1 and a refrigerant pipeline 4, and the water tank 1 is provided with a guide for guiding The water flow channel 2 through which the sewage flows in a detour, the refrigerant pipeline 4 is laid on the water flow channel 2, and when the sewage with heat passes through the water flow channel 2, the refrigerant in the refrigerant pipeline 4 absorbs the heat of the sewage.

[0035] Sewage produced by shampoo beds, bathrooms, etc. flows into the water flow channel 2,...

Embodiment 2

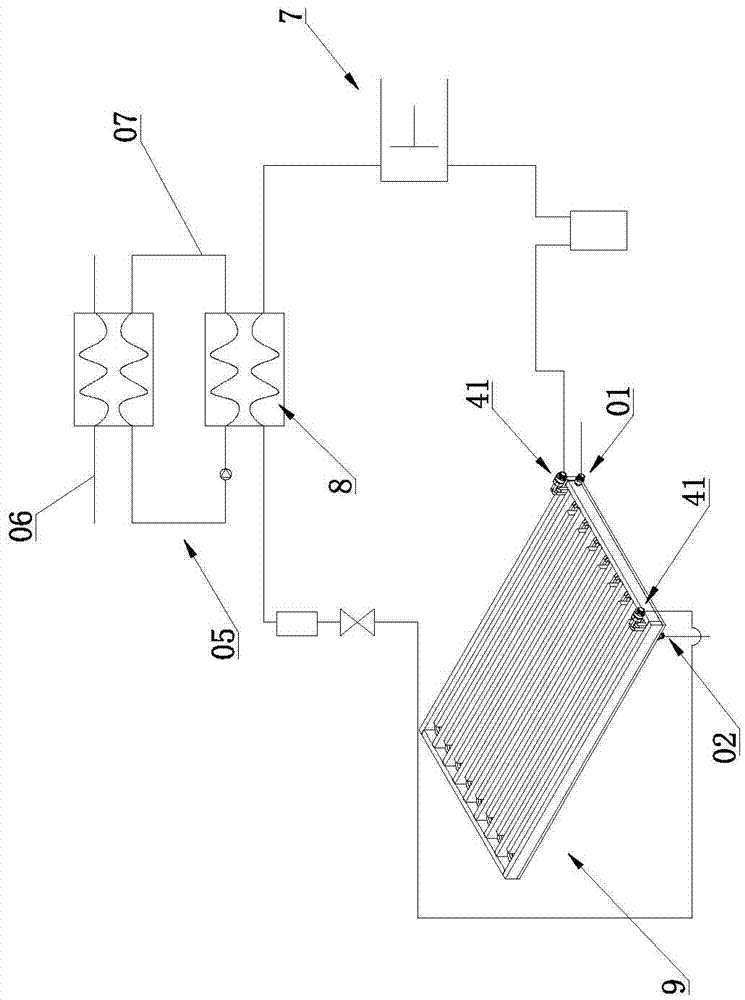

[0048] Compound waste heat recovery and multi-stage continuous heating.

[0049] Such as Figure 6 to Figure 9 As shown, the difference between the second embodiment and the first embodiment is that: the water flow channel 2 is also laid with a heat exchange pipe 3 for circulating tap water. When in use, the sewage with heat flows through the water flow channel 2 to exchange The tap water flowing in the hot pipe 3 absorbs the heat of the sewage. The heat exchange pipe 3 is provided with a waste heat recovery water inlet 31 and a waste heat recovery water outlet 32 . Tap water is passed to the heat exchange pipe 3, and when the tap water flows in the heat exchange pipe 3, it absorbs the heat of the sewage in the water flow channel 2, thereby recovering the heat of the sewage. In this embodiment, the refrigerant in the refrigerant pipe 4 and the tap water in the heat exchange pipe 3 are used to absorb the heat of the sewage to realize composite waste heat recovery.

[0050]...

Embodiment 3

[0053] Composite waste heat recovery, storage and reheating.

[0054] Such as Figure 10 to Figure 11 As shown, the difference between the third embodiment and the second embodiment is that a water storage tank 08 is also provided, and the delivery pipeline 38 is connected to the water storage tank 08 . The tap water absorbs the heat of the sewage in the water flow channel 2, enters the water storage tank 08 through the delivery pipe 38 for storage, and then is further heated to the set temperature by the condenser 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com