Silencer butt joint device for engine test bench

A technology of test bench and docking device, which is applied in the direction of engine test, measuring device, machine/structural component test, etc., can solve problems such as low efficiency, poor safety, cumbersome operation, etc., and achieve reduced sliding resistance, reliable driving, The effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

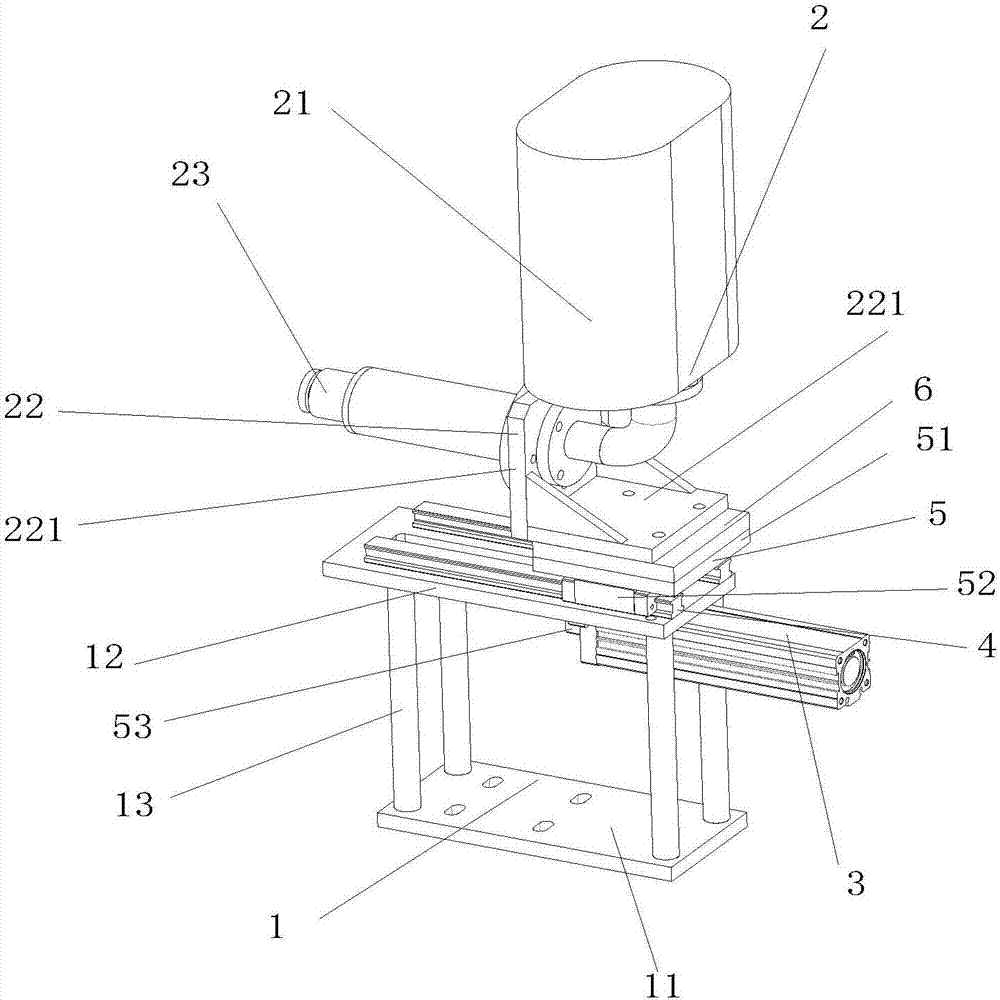

[0023] Such as figure 1 As shown, a muffler docking device of an engine test bench includes a fixed base 1, a muffler device 2 slidingly arranged on the fixed base 1 and a driving device 3 for driving the muffler device 2, and the fixed base 1 includes a base plate 11, The panel 12 and the column 13 for connecting the base plate 11 and the panel 12, the lower surface of the panel 12 is provided with a driving device 3, and the upper surface is provided with a left and right guide rail 4, and the noise reduction device 2 is driven by the sliding seat 5 and the guide rail 4. The device 3 is connected, and the panel 12 between the left and right guide rails 4 is provided with a bar-shaped hole to facilitate sliding of the sliding seat 5. The sliding seat 5 includes a sliding seat plate 51, a slide block 52 arranged on both sides of the sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com