Cyperus esculentus harvester and cyperus esculentus harvesting method

A technology of oily bean and harvester, applied in excavating harvester, harvester, excavator, etc., can solve the problems of restricting large-scale planting and inability to separate oily bean, and achieve the goal of accelerating excavation efficiency and reducing power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

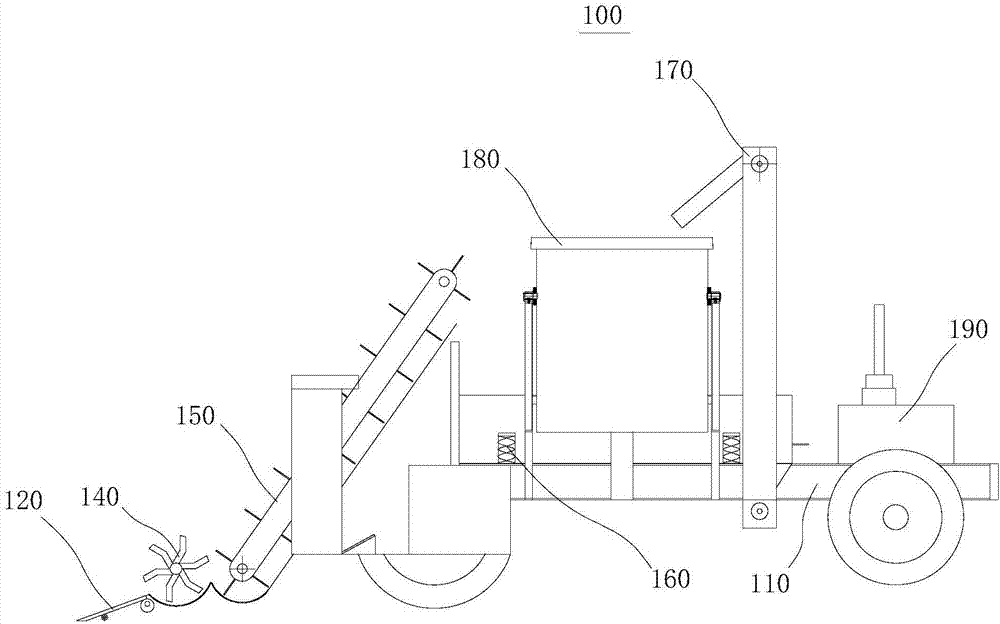

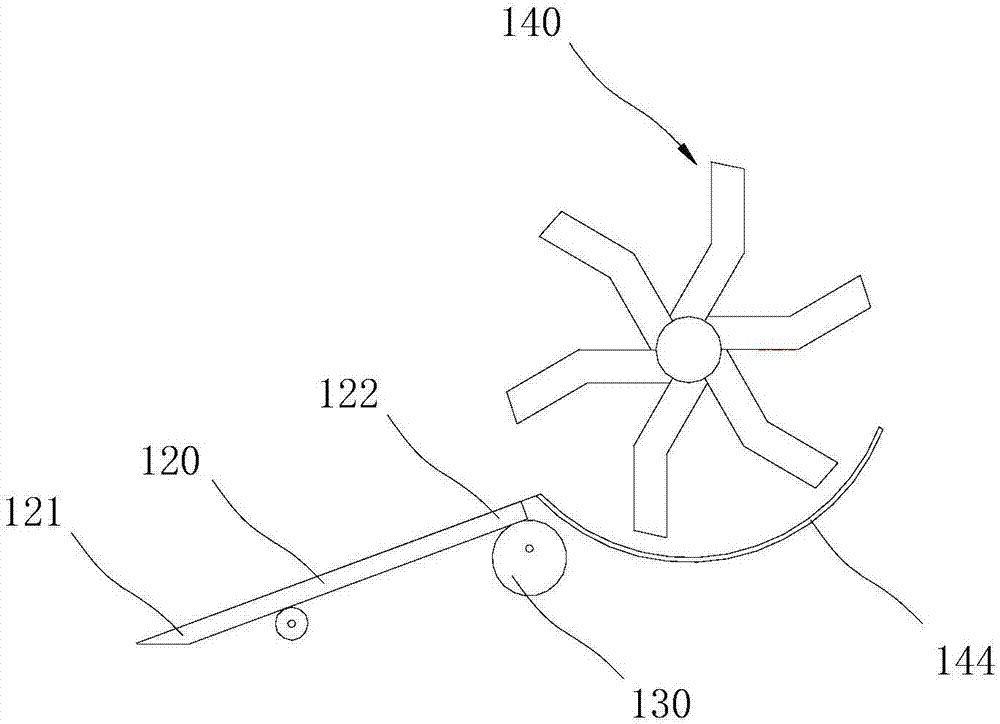

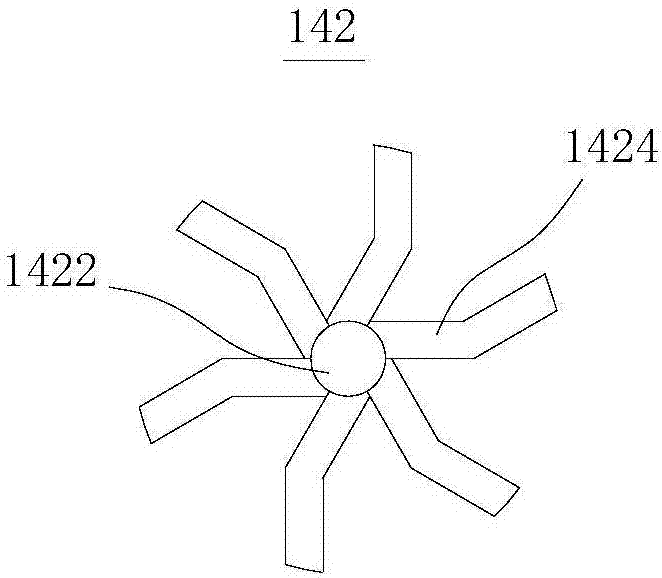

[0058] Such as figure 1 , the present embodiment provides an oily bean harvester 100, which mainly includes a frame 110, a vibrating blade 120, a sand separator 140, a scraper conveyor 150, a vibrating screen 160 and a power system 190. The frame 110 is used to fix other components on the oily bean harvester 100 , and the power system 190 provides power for the whole oily bean harvester 100 . The vibrating blade 120 is used to remove the oily bean in the soil, and then the oily bean plants and particles enter the sand separator 140 for preliminary separation, and then are sent to the vibrating screen 160 by the scraper conveyor 150 Perform vibratory sieving.

[0059] Such as figure 1 , The frame 110 includes a bottom beam, a support and wheels, the bottom beam adopts H-shaped steel beams to ensure the strength of the frame 110, the wheels are tubeless tires, and the frame 110 is used to install and fix the above components. The power system 190 includes a battery and a dies...

Embodiment 2

[0076] A method for harvesting oily bean, utilizing the oily bean harvester in embodiment 1, comprising the following steps:

[0077] a. Start the power system, so that the oily bean harvester moves forward, and the eccentric wheel is rotated, and the vibrating blade digs out the oily bean in the soil;

[0078] b. Preliminary separation of oily bean plants and particles using a sand separator;

[0079] c. Use the scraper conveyor to transport the preliminarily separated plants and granules to the vibrating screen for vibrating screening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com