Tea leaf frying device

A technology for roasting and tea leaves, which is applied in the field of tea roasting equipment, can solve problems such as pot wall adhesion, achieve the effects of preventing adhesion, improving stir-frying efficiency, and high stir-frying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

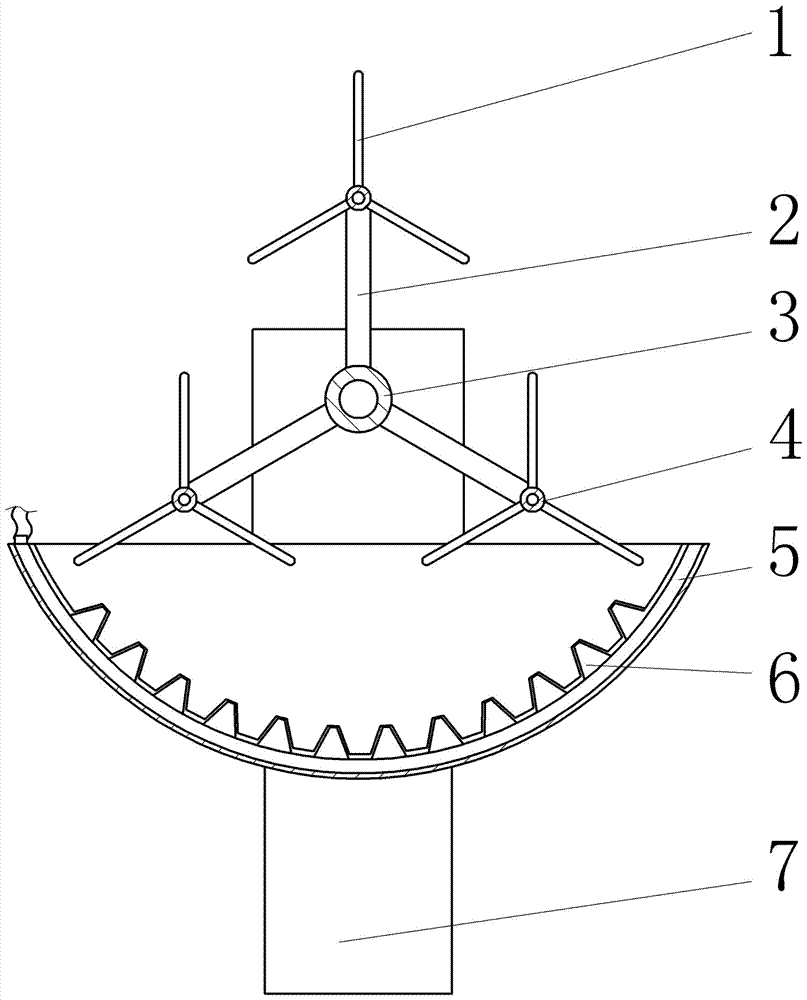

[0023] Embodiment: the tea leaf frying device in this scheme, as figure 1 As shown, it includes a support 7, a motor, a first rotating shaft 3, a plurality of connecting rods 2, a plurality of second rotating shafts 4 and a stir-frying piece 1.

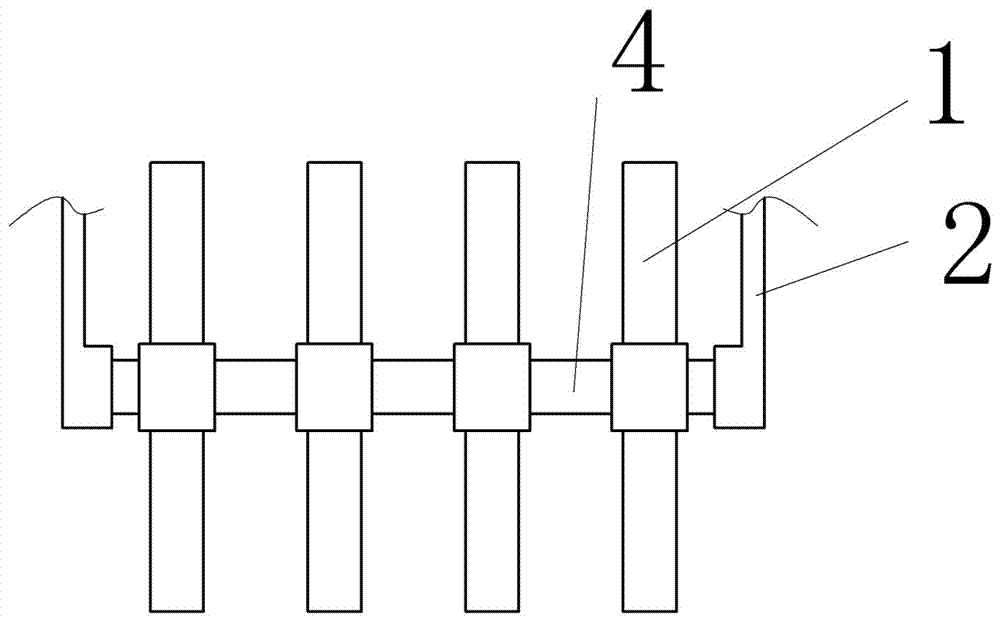

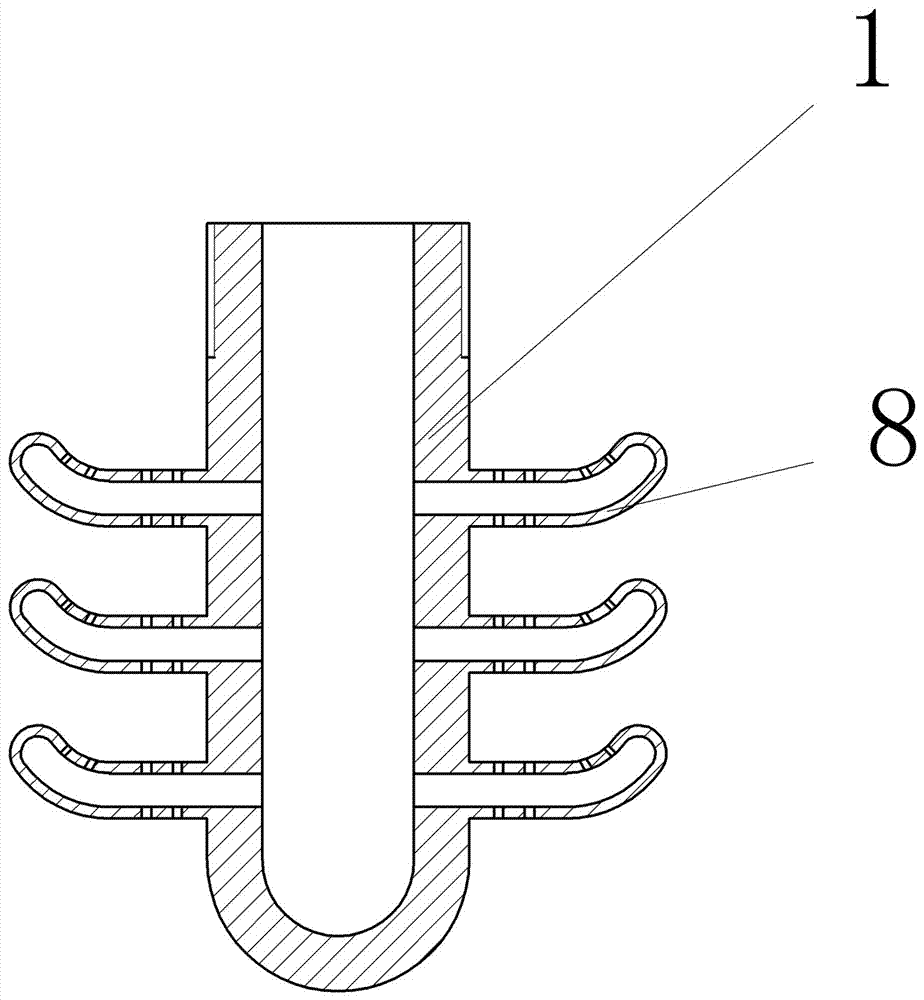

[0024] The motor is threadedly fixed on the support 7, and the first rotating shaft 3 is rotatably connected to the support 7 through a bearing. The first rotating shaft 3 is fixedly connected to the output end of the motor through a coupling, and one end of the connecting rod 2 is integrally formed on the side of the first rotating shaft 3 . Such as figure 2 As shown, the side of the other end of the connecting rod 2 is cup-shaped, and the cup-shaped part of the connecting rod 2 is sleeved on both ends of the second rotating shaft 4, so that the second rotating shaft 4 is rotatably connected to the connecting rod 2, and the connecting rod 2 The inner wall of the cup portion is provided with an O-ring seal. Three stir-fry parts 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com