Hot oil heating tea leaf drying machine

A technology of tea drying machine and hot oil, which is applied in the direction of drying machine, tea drying, drying, etc., can solve the problems of unsatisfactory industrial processing and production, waste of manpower, etc., and achieve improved frying and drying efficiency and high thermal efficiency , the effect of uniform heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

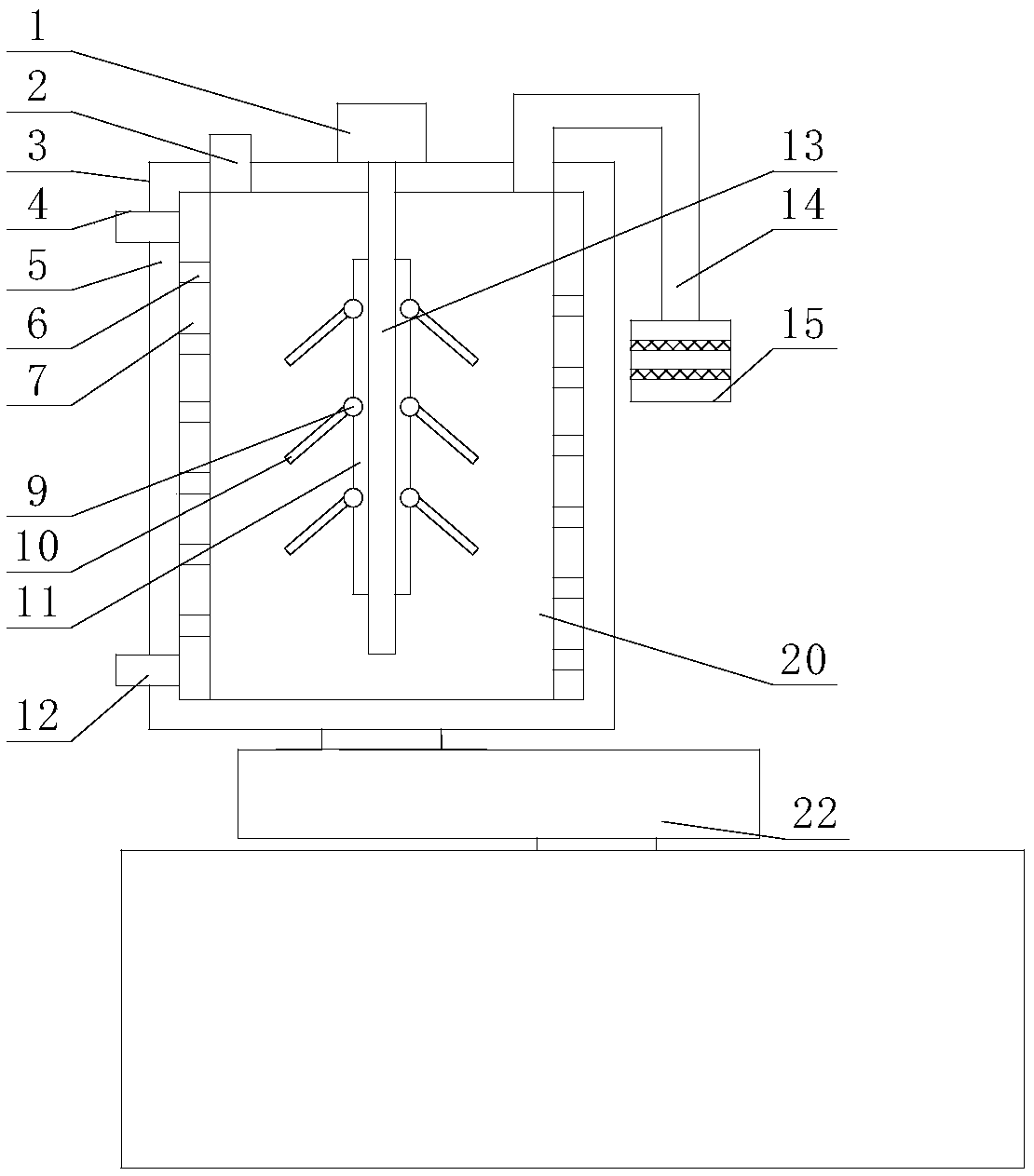

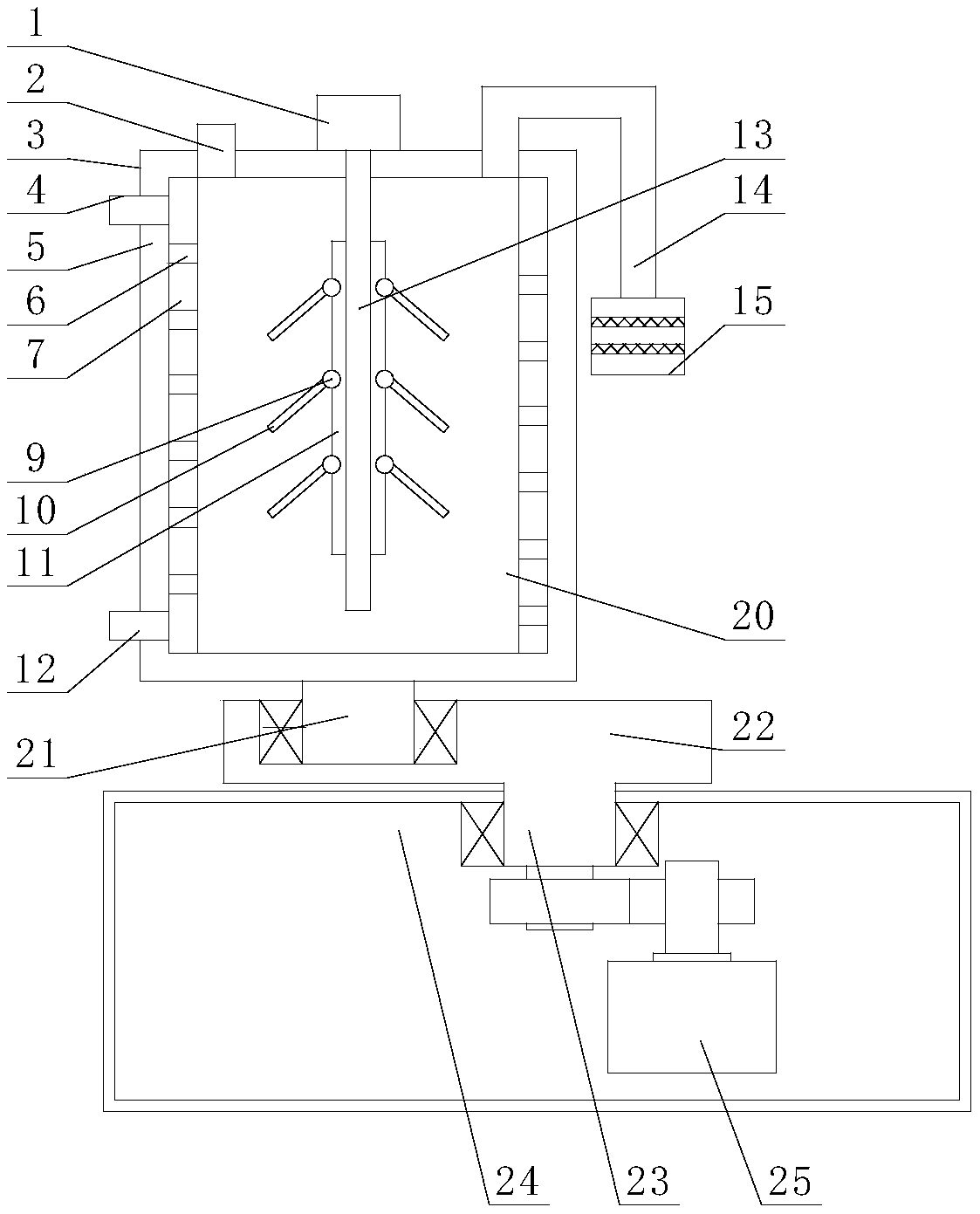

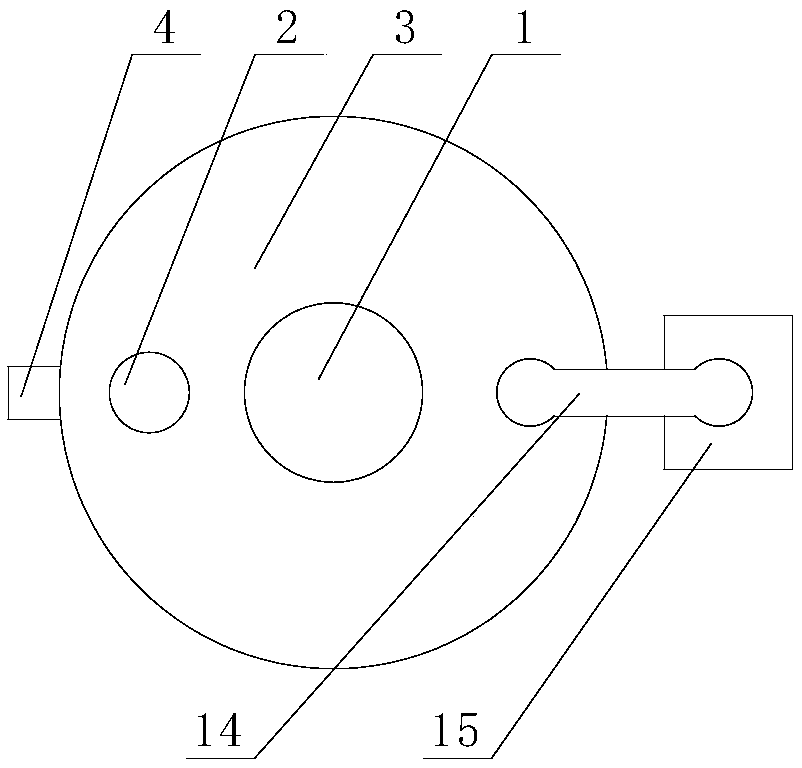

[0016] Attached below Figure 1-3 An embodiment of the present invention is described.

[0017] A tea drying machine heated by hot oil, comprising a housing 3, a stirring mechanism and a swing mechanism, the housing 3 is provided with a drying area 20, the upper part of the drying area 20 is provided with a feed pipe 2, and the drying area The bottom side of 20 is provided with a discharge pipe; the outside of the drying area 20 is wrapped with an oil tank 7, and a spiral partition 6 is arranged in the oil tank 7, and the spiral partition 6 separates the oil tank 7 into a connected spiral The outer side of the oil passage and the oil tank 7 is provided with an insulating layer 5; the upper end side of the housing 3 is provided with an oil inlet pipe 4, and the lower end side of the housing 3 is provided with an oil outlet pipe 12; the stirring mechanism includes a stirring motor 1 , the stirring motor 1 is fixedly installed in the top middle part of the housing 3, the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com