Screw series curing extrusion equipment and screw series curing extrusion method for rice noodle production

A screw and aging technology, which is applied in the field of screw aging extrusion equipment, can solve problems such as poor extrusion effect, low rice flour gel strength, and difficulty in design and manufacture, and achieve increased aging extrusion strength, rich rice flour gel, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

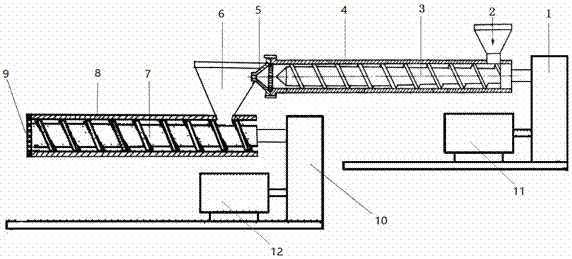

[0016] refer to figure 1 The screw tandem aging extrusion equipment for rice noodle production in this embodiment includes a first-stage screw self-cooking extruder and a second-stage screw extruder; the first-stage screw self-cooking extruder includes a first-stage screw self-cooking extruder Step barrel 4, one end of the first step barrel 4 is provided with a first step feed port 2, and the other end is provided with a first step discharge port 5, and the first step barrel 4 is provided with a self-cooking Screw 3, one end of the self-cooking screw 3 is connected with the motor I11 through the reduction box I1; the second-stage screw extruder includes a second-stage barrel 8, and one end of the second-stage barrel 8 is provided with a first The second-stage feed port 6, the other end is provided with a second-stage discharge port 9, the second-stage barrel 8 is provided with an extruding screw 7, and the extruding screw 7 is connected to the motor II12 through the reduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com