A kind of die forging forming method of gh4169 alloy disc forging

A GH4169, forming method technology, applied to vehicle parts, transportation and packaging, wheels, etc., can solve the problems that are not conducive to the improvement of forging strength, low material utilization rate, and increase the hole expansion process, so as to shorten the machining time and improve Productivity and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below:

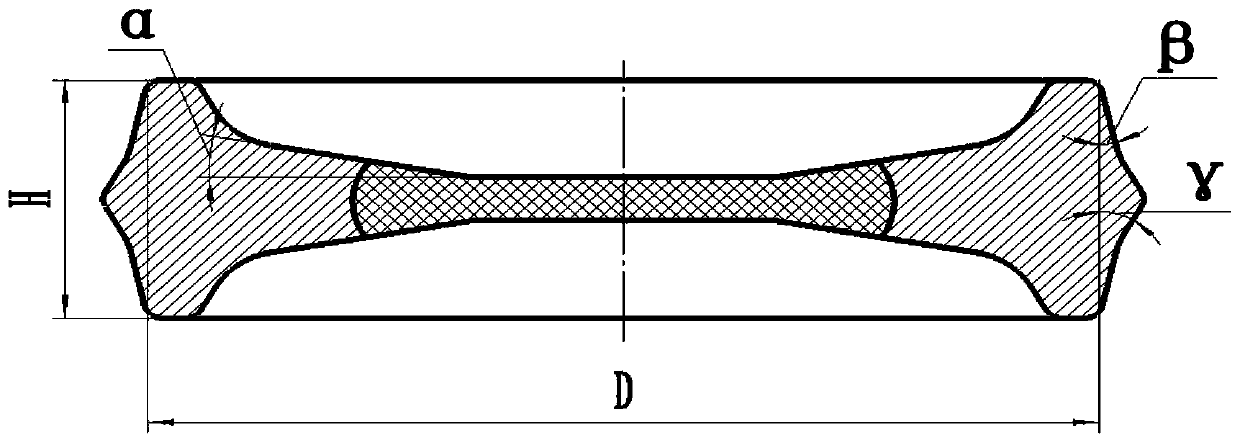

[0021] 1) First design the forging die, and after several computer simulation calculations, it is determined that the horizontal angle α at the center of the web is 10°, the draft angle β is 10°, and the draft angle γ at the parting surface is 20°~ 30°.

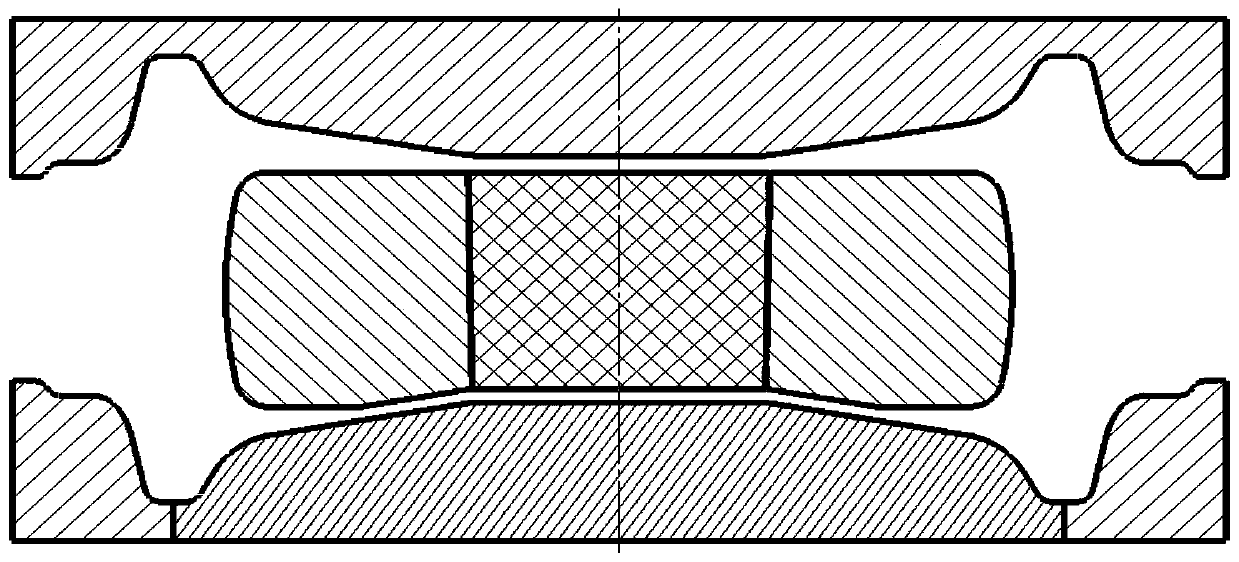

[0022] 2) Upsetting a bar of Φ300×392mm to Φ455×170mm and then punching the inner hole of Φ170mm, and then machining the inner hole of the ring billet from bottom to top with an inclined plane with an angle of ~2° to the axis; the center part and 20 #Low-carbon steel, low-carbon steel bar arc surface and the axis to maintain an angle of 2 °, height 170mm.

[0023] 3) After matching the 20# steel with the ring billet, preheat in the preheating furnace at 200°C to 250°C for ~20 minutes, and then spray the protective lubricant FRG35 with a thickness of ~1mm; at the same time, preheat the mold in the preheating furnace at 300°C Heat for 24h.

[0024] 4) Heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com