Method for automatically tracking quality of single continuous casting blank

An automatic tracking and continuous casting billet technology, which is applied in the field of converter steelmaking and automatic tracking of the quality of a single continuous casting billet, can solve the problem of inability to accurately track a single billet, and achieve the effect of quality control and accurate tracking throughout the whole process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below through embodiment.

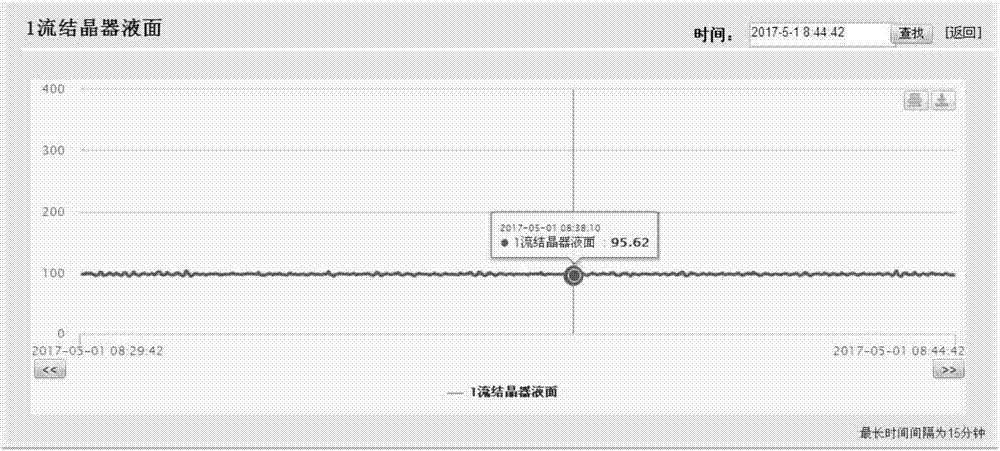

[0026] A method for automatically tracking the quality of a single continuous casting slab. Its special features are: converter process and refining process, data collection is realized in the unit of furnace number; continuous casting process, data collection is realized in the unit of each continuous casting slab, By collecting the spraying time of the billet automatic number spraying machine, based on the constant casting speed of the casting machine, combined with the sizing information and the running speed of the billet roller table, the liquid level fluctuation and casting speed of the cast billet in the crystallizer are realized. And the automatic tracking of the corresponding tundish temperature realizes the traceability of the production process of a single billet.

[0027] The concrete implementation process of this embodiment:

[0028] Using automatic PLC control technology, databas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com