Suturing device for bamboo winded product bamboo strip curtain

A suture device and technology of bamboo strip curtains, applied in the field of suture equipment for bamboo strip curtains of bamboo winding products, can solve problems affecting product quality, cracking and warping, easy warping of edges, etc., to achieve improved efficiency, less time consumption, and elimination of elasticity effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

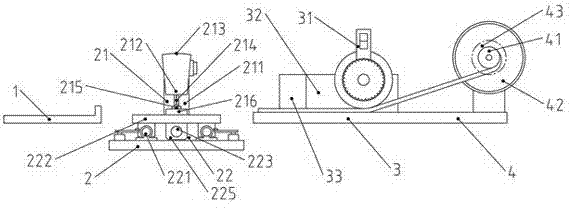

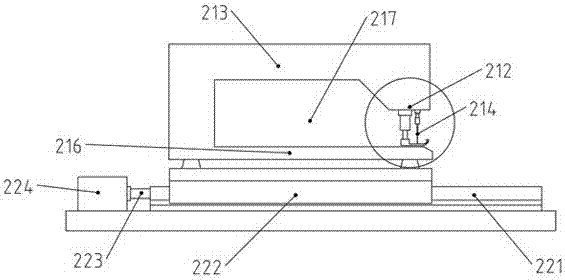

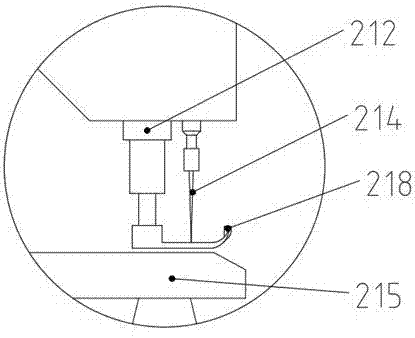

[0019] It specifically includes a stand on which a workbench is fixed. The workbench is divided into a stacking part 1, a sewing part 2, a counting part 3 and a winding part 4. On the workbench, the stacking part 1 constitutes a strip-shaped table top, and one of the short edges is adjacent to the sewing part 2. The sewing part 2 includes a sewing machine 21. The bottom of the sewing machine 21 is connected to the traverse part 22, and the stroke of the traverse part 22 The length is greater than the length of the bamboo strip curtain, and the counting part includes a length counter 31, and the length counter 31 is in contact with the sewn bamboo strip curtain, and the bamboo strip curtain is wound into the winding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com