Equipment foundation with elastic interlayer leveling piece and manufacturing method thereof

A technology of equipment foundation and interlayer, applied in basic structure engineering, construction, etc., can solve the problems of affecting the levelness of the anchor plate, heavy remedial work, deformation of the bolt rod body, etc., to improve welding quality and efficiency, structural connection firm, The effect of preventing solder leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

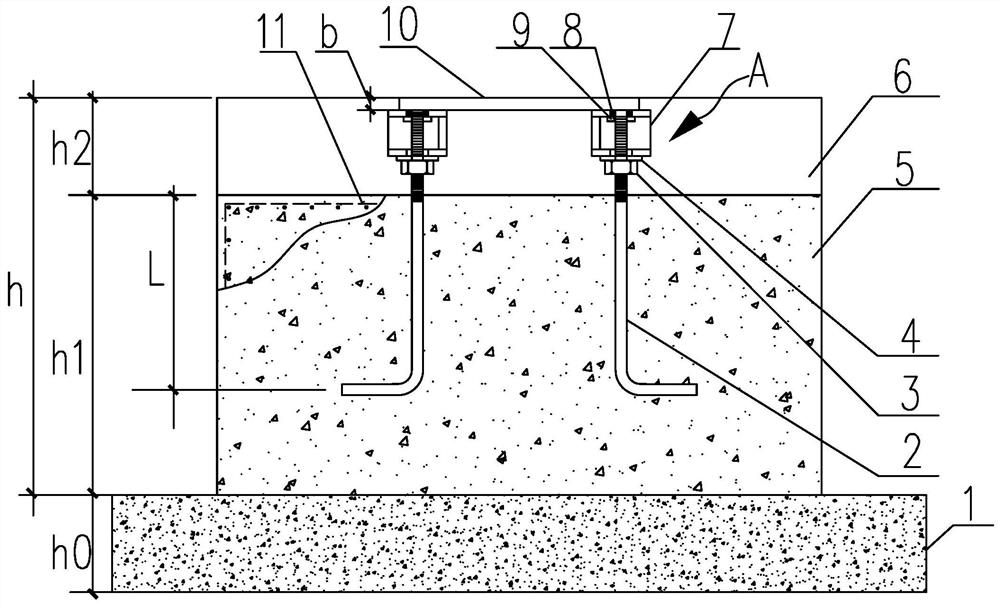

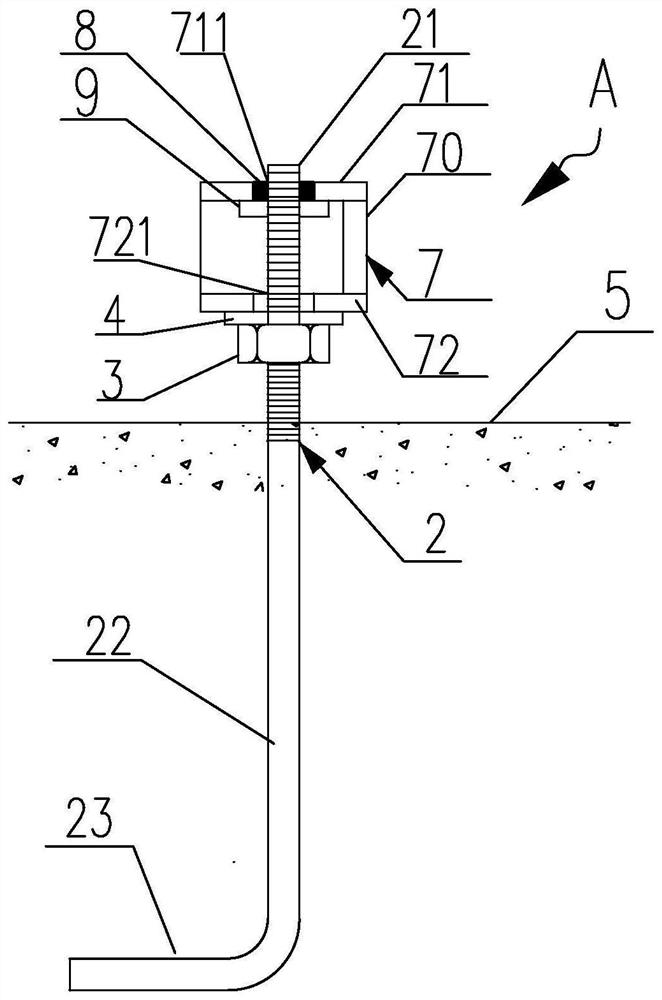

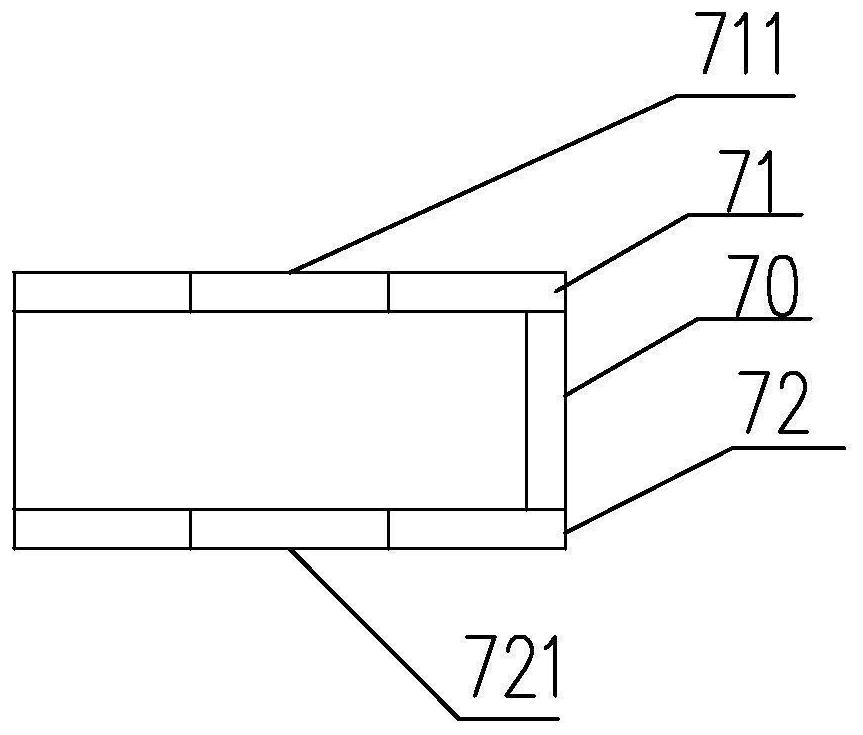

[0035] Figure 1~4 It shows an equipment foundation with elastic interlayer leveling parts for the leg of a milling machine, which is the same as the traditional equipment foundation. The equipment foundation includes a concrete cushion 1, a steel cage 11, multiple anchor bolts 2, anchor plates 10 and filling cladding concrete body. The reinforcement cage 11 is arranged on the concrete cushion 1, the plurality of anchor bolts 2 are placed vertically in the reinforcement cage 11, the anchor plate 10 is horizontally connected to the ends of the plurality of anchor bolts 2, and the concrete body is filled with Covering the bottom surface and peripheral edge of the reinforcement cage 11, the plurality of anchor bolts 2 and the anchor plate 10.

[0036] In the field of heating and mechanical processing technology, the number of anchor bolts used for the equipment foundation is more than 4, which is mainly set according to the requirements of the equipment structure. This embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com