Method for increasing fiber volume content of vacuum infusion composite product

A composite material and fiber volume technology, which is applied in the field of increasing the fiber volume content of vacuum-introduced composite products, can solve the problems of low fiber volume content and high porosity, reach the level of the pull-in process, reduce porosity, and increase fiber volume content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

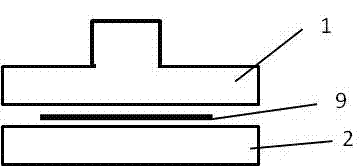

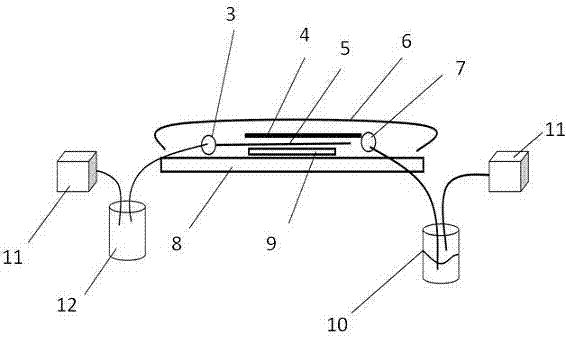

[0017] As shown in 1-2, the present invention is a method for increasing the fiber volume content of a vacuum-introduced composite product, the method comprising the following steps:

[0018] (1) Sprinkle a thermoplastic sizing agent on the surface of the carbon fiber fabric to make a prefabricated body;

[0019] (2) Lay the prefabricated body on the prefabricated body mold by heating and vacuum preloading. After the prefabricated body is paved and pasted, move it to the molding machine for pressurization, and then use a ziplock bag to vacuum seal; the pressurization method is repeated pressurization In order to obtain a thinner preform thickness; the calculation for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com